Electrostatic smokehouse: what are and how to do it yourself

The process of home-smoked seafood and meat has always been associated with great hassle due to the fact that this procedure is rather long and requires expensive equipment. In addition, it was necessary to constantly be close to the smoked products in order to correct the process and check the readiness, because fish and meat are easy to overdry. To date, there are devices for sale for home use, but their price is quite high.

Features and benefits

Many people believe that electrostatic smokehouse can not also qualitatively process products, like classic smokehouses.In fact, the difference between these structures is only that the first one has a special block that increases the speed and depth of smoke penetration into the fibers of the product. The process of smoking by technology resembles the preparation of meat and fish for a couple, but with moist smoke instead of hot steam. Electrostatics only increases the rate of diffusion of smoke particles, which reduces the cooking time to just a few hours, when it can take several days with a conventional smokehouse.

Advantages and disadvantages

The advantage of electrostatic smokehouse is the ease of use and the possibility of making fragrant delicacies right on your balcony or in the garage. This unit does not take up much space and weighs up to 10 kg due to the fact that it is made of stainless steel. The use of this anti-corrosion material is not only safe, but also carries a decorative function - such a smokehouse will fit perfectly into any modern kitchen. In an electrostatic unit, it is possible to cook fragrant meat and tasty fish without standing around it constantly, and eating foods prepared without using fat is very useful for the body.

You can often hear the opinion that the taste of a product after a classical smokehouse is much richer.but such a judgment is highly subjective. In most cases, there are no significant differences in the taste of meat or fish cooked in conventional and electrostatic smokehouses. The only drawback that can be noted is the high price, as well as the lack of versatility of compact models.

Principle of operation

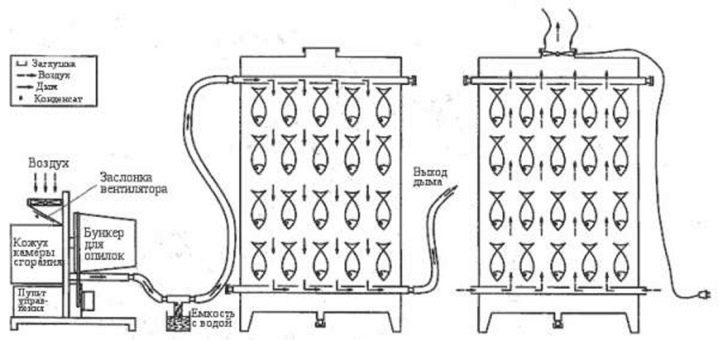

The device electrostatic installation is quite simple. As in other types of smoke, in the electrostatic version, the products are placed in a special section. Most often, meat, lard or fish is hung on special hooks in an upright position so that excess fat and moisture can flow freely.

The principle of operation of such a device is also quite simple. In the smoke regulator, using an electric heater of sawdust and chips of different types of wood, smoke is obtained, which is charged by passing through a charged grating with a high voltage pole. Ions rapidly penetrate into workpieces placed on a negatively charged pole, due to which the product smokes much faster and to a greater layer thickness.At that time, while the smokehouse is working, the excess smoke freely comes out with the help of a chimney.

Kinds

Depending on whether you can move the smokehouse from place to place, there are:

- portable devices;

- stationary;

- folding smokehouses.

The smokehouse can be large and small, with or without additional accessories. Electrostatic installations are almost always made of stainless steel, however, common metal versions are also found. In addition to conventional smokehouse, there is also a multifunctional, which are additionally used as an oven oven.

Depending on the purpose of the smokehouse can be divided into two types:

- household units used for home;

- industrial options for use in large-scale production.

By temperature effects, electrostatic installations can be divided into cold, hot or semi-smoked smokehouses. A more common method of cooking is hot-smoking. The temperature varies between 45-150 degrees, and the process takes only two hours.At the end of the event, a bright golden hue appears on the surface of the products. This method does not require drying and drying of meat and fish after smoking itself.

Before cold smoking products should be carefully salted.that can take from one to fourteen days. Smoking itself is carried out at a temperature not higher than 30 degrees for quite a long time: the process can take from five days to a whole month. Cold smoking does not significantly change the color of the finished product - meat and fish are similar in color to dried ones.

Independent production

There are two types of smokehouses with an electrostatic circuit that you can make at home with your own hands:

- on an old television transformer;

- on the old two-stroke engine or the ignition coil.

They differ from each other only by those blocks through which the smokehouse generates a field, and the building itself and the exterior may be the same.

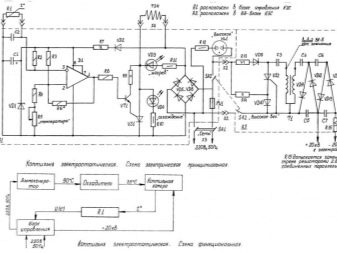

Schemes and drawings

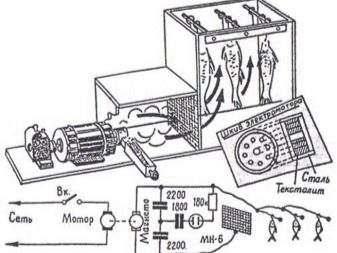

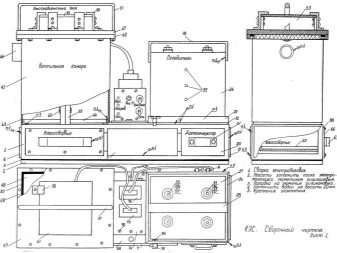

To make a smokehouse, it is necessary to clearly understand how exactly the final result of the work should look and what it consists of.On the general scheme of the electrostatic smokehouse you can find all the necessary elements, in particular, the oven itself, the body of which can be made of metal, or of wood or even dense plastic. A voltage generator should be attached next to it.

In wood chips heated by a shade or gas burner, smoke of the required density and aroma is formed. With the help of a fan, such a quantity of air is injected so that the sawdust does not catch fire. Saturated smoke should be cooled with water and through the fitting to get into the oven.

Selection of materials and components

The voltage in the smoke plant should vary between 20-30 kW, for which a high-voltage generator is used. It can also be made by yourself.

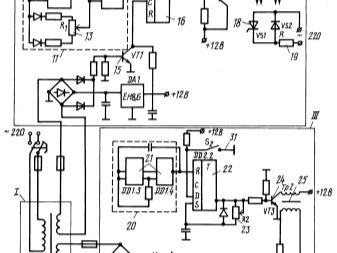

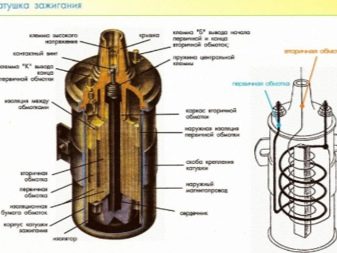

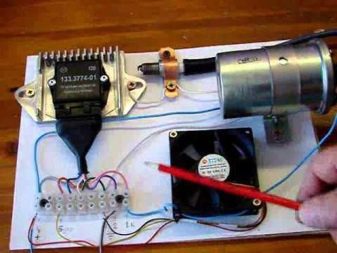

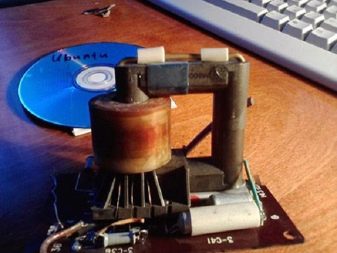

- From the ignition coil and engine switch. A high voltage unit assembled with a coil and a battery is a simple circuit with a power source and a key. The oscillating oscillator must be at a frequency of 1-2 kHz, and the voltage of the entire circuit is 12 V, which will require about 1-2 A.

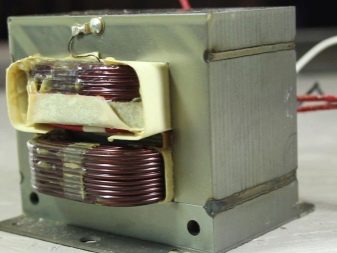

- From line transformer. As in the first scheme, here the pulses coming from the generator control the transistor. The result is 20-25 kW of constant voltage.Both the first and the second version of the scheme assume the presence of generators operating at certain frequencies. In the first case, the frequency of 1000-2000 Hz is needed, and in the second - 14000-16000 Hz. It is better to use the generator from the sweep of the TV, as it accelerates the movement of smoke particles more and the process ends earlier.

After selecting the voltage source, it is necessary to proceed to the manufacture of a steam generator. The best body for it will be a cast-iron brazier or stainless pan with thick walls and bottom. At the bottom of the container is poured a layer of granite granite or limestone in 2-3 cm and fit the heater.

The ideal heater is a spiral from a fireplace or an iron with ceramic insulating rings. A sheet with holes that is similar to a sieve is placed on top. On such a sheet is placed up to 5 cm of chips.

The hole drilled in the lid that covers the generator is equipped with a fitting and a flexible plastic or metal corrugated hose. The second end of the hose is attached to a smoke cooler. This cooler is made of a small water tank of a copper tube with a length of at least 150 cm.Copper is coiled up so that it fits into a container, and hoses from a smoke generator and a fan are connected to its terminals.

Assembly instructions

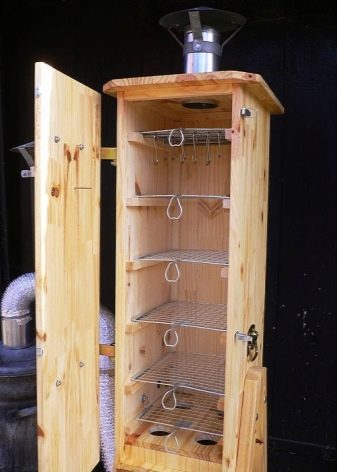

Homemade smoke cabinet is best made of wood or metal, but in the latter case it is more difficult to equip the insulation, and this option is more expensive.

It is going to the size of 70x50x100 cm with a door on hinges, which should be very close and do not leave gaps. The anode (positively charged electrode) is made of galvanized sheet. This tin is provided with spikes that are directed towards the product - this will create greater field strength. The edges are made using a notch corner and limb. Instead of tin, it is also possible to adjust the metal mesh.

The anode panel is made in the same way and is located on both sides of the cathode. Both parts of the anode must be wired and grounded - this will create a static voltage so powerful that smoke particles will literally “drill” the workpiece.

To prepare the finished smokehouse for work, it is necessary to place the chips in a pressure cooker or broiler and turn on the heater. In the smoke closet load fat or fish and turn on the fan. As soon as smoke begins to flow in trouble free mode, the cabinet door can be closed and the generator switched on. After the smoking process is completed, the generator must be turned off and wait two minutes so that it remains without voltage. Before touching the cabinet, turn off the steam generator and the fan, the device is unloaded, and only after that the wet cleaning of all soiled surfaces is performed.

Manufacturers Overview

Smokehouse can not only be collected, but also purchased ready-made, based on reviews on the Internet or rating of companies-sellers. For private use, small household electrostatic installations, represented in electric smokehouse ranges from American firm Greentechs or Finnish manufacturer Muurikka. Installations have a compact size with unfolded functionality and a democratic price in the range of 4-6 thousand rubles. Such smokehouses are perfect for work even in the smallest rooms.

If you need to purchase a multi-functional smoke plant, you should opt for devices. brands Anuka from New Zealand. Models with smoke generators are in the range of 10-12 thousand rubles.

With a great daily cooking products will do great. Korean electrostatic smokehouse brand Kocateq or German Landmann. With their help, you can procure meat, sausages and fish in large quantities in streaming mode. Such electrostatic installations more closely resemble large industrial apparatuses, but, apart from their large size, they have no limitations for home use.

Recommendations for use

Since when smoking such fatty foods as fat or fatty fish, stains and smudges remain in the smoking closet, it is necessary to carry out a wet cleaning of the installation in a timely manner. It is better to clean the collapsible structure immediately after cooling with the help of Blesk, Sorti or similar detergents. The generator must remain dry and clean. It should always be touched with caution, since the electric charge in it can remain for some time even after disconnection.

If you need to quickly gain access to the cathode or any other parts of the plant that are under voltage, you need to short the elements with a 5-10 kΩ wire and a handle for which you can safely move this wire.Introduction to the system of various toggle switches and buttons is meaningless, since they will immediately be blocked by a spark when starting the generator.

The humidity of the room in which the smoke plant is located should not exceed 80%. All electrical parts should be well insulated, and the smokehouse should stand on a dielectric base. You can not touch the included smokehouse, and the products inside also should not come into contact with anything other than the hooks on which they hang.

For the installation of the smokehouse body, it is possible to use both blanks from metal or wood, as well as ready-made spaces resulting from the refrigerator body or an old kitchen cabinet. Finished products should be stored in a dry cold room cellar, pantry or in the refrigerator.

Smokehouse owners, who assembled them themselves, talk about the different periods of cooking products. Therefore, the time required to complete the process in one or another assembled model can only be established experimentally.

If you first understand the device and assemble the mechanism yourself, then in case of a breakdown it will be easy to replace any part,and homemade delicacies made from poultry, meat and fish will delight your loved ones at joint meals and celebrations.

How to make a folding electrostatic smokehouse with your own hands, see the video below.