Installation of shingles: laying technology

Currently, many owners of private homes choose a flexible roof for the roof. This material is popular because of its flexibility and ease of installation. It is possible to cope with its installation without involvement of professional masters. Today we will look at the technology of laying shingles in detail, as well as find out what characteristics and properties it possesses.

Features, Pros and Cons

The flexible tile by right is recognized as one of the most popular and demanded materials for facing of roofs. Such solutions are not only distinguished by durability and ease of installation, but also a spectacular appearance. By itself, this material is a flat sheet of small size.

Such details have one figured edge.

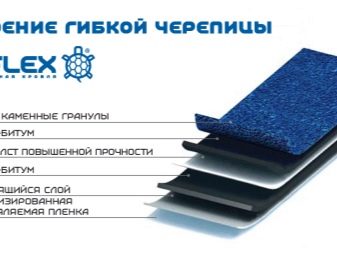

Often, shingles are produced using cellulose of organic origin. However, in most cases, the basis of such material is fiberglass impregnated with bitumen-polymer composition. The front side of shingles is covered with stone granules, performing a protective and decorative function.

Flexible roof is available in different colors, so you can choose the right products for construction, made in any palette. In a single ensemble correctly selected materials look very beautiful and harmonious.

The popularity of shingles is due to the many advantages that are characteristic of it.

Let's get acquainted with them.

- This roofing material has an attractive appearance.

- The flexible tile belongs to prestigious materials. Only composite or natural coatings of impeccable quality can compare with it.

- This material is economical, despite the high price. When using it, very few scraps remain.

- The flexible tile is not subject to corrosion.

- Such materials seamlessly tolerate temperature fluctuationstherefore, they can be installed in almost any climatic conditions.

- The flexible tile is a durable material. Its service life is on average 40-60 years.

- Such roofing material is noiseless.

- High-quality soft roof is not afraid of aggressive sunlight. Under their influence, such material does not lose the saturation of colors and is not deformed.

- With this material there are no problems in matters of transportation. It can be transported in any form of transport.

- As mentioned above, to establish this material is not difficult, you just need to follow simple instructions. Even an inexperienced novice can easily cope with such work.

Unfortunately, shingles are not perfect material.

This roof has several disadvantages.

- If you decide to trim the roof with such material, then you should know that it can not be laid on the base with a slope of less than 12 degrees.

- To put shingles, you must prepare a solid base. To do this, stock up with moisture-resistant materials, for example, OSB sheets or plywood. Such nuances certainly lead to a significant increase in the cost of the roofing pie.

In addition, you will need to build a roof-covering carpet if you roof with a slope of 12-18 degrees.

- Repair shingles is quite complicated. Such work is hard to do with your own hands.

- Despite the ease of laying such a roof, it is necessary to take into account that the deformation of the shingles is unacceptable, and it is very easy to face such a problem when it comes to soft tiles.

- Such material has a high price.

Types and characteristics

Shingles are available in the form of shingles. These elements are made with various parameters.

In addition, they have a different pattern, namely:

- rhombus;

- brick;

- shingles;

- rectangle (can be different formats);

- honeycomb;

- hexagon;

- beaver tail;

- dragon tooth;

- scales.

And also shingles can be:

- two-layer;

- three-layer.

These types of roofing material differ from each other by the presence of an additional layer of shingles. It has a slight displacement, due to which the coating acquires volume and relief surface.

Two-layer coverings belong to an average price category. Such roofing materials are in great demand. They can serve at least 30 years.Three-layer options are more expensive than double-layer ones, but they also last longer. Some manufacturers claim that their three-layer roof can last more than 60 years without any repair.

In addition, the popular flexible roof is also different in its color. Modern firms - manufacturers offer not only simple monochromatic copies, but also more original versions, the color of which changes from one shade to another. This interesting effect is achieved through the use of stone chips. The most common are blue, green and red-brown coatings.

At the heart of shingles is fiberglass or bitumen. Such components differ from steel in that they do not undergo destructive corrosion, which is why such a roof serves for much longer. In some cases, manufacturers provide a lifetime warranty on such materials.

High-quality flexible tile retains its original shape and performance in any climate. This practical material seamlessly withstands temperatures from -50 to +100 degrees Celsius.Neither precipitation nor ultraviolet rays are terrible for such a soft roof.

The characteristics of the bituminous roofing material include its excellent thermal insulation.

Thanks to this finish, a comfortable temperature will be maintained in the interior of the room, despite the weather conditions.

The flexible tile, as a rule, is packed into packs. In one package, it usually fits 22 shingle, that is, 33 square meters. m of finished roofing. As for the weight of such a roof, it directly depends on the type of tile itself. One square meter of a single-layer material usually has a weight of 5-8 kg, and multilayer - up to 20 kg.

Manufacturers Overview

If you want to cover the roof with high-quality and durable material, then you should refer to branded products from well-known brands. Let's get acquainted with some of them.

Ruflex

The large company Ruflex has been successfully operating since 1991. She is a member of the trade and production association “Association Diana”. The flexible bituminous tile of this producer differs in durability, a practicality and fine external registration. High-quality products of the company Ruflex are made on modern equipment of US enterprises.Previously, the manufacturer offered a warranty on its products at 35 years old, however, at present, Ruflex representatives are ready to provide a lifetime warranty.

Ruflex offers consumers a choice of shingles, represented by the following collections:

- "Red Gooseberry";

- "Taiga";

- Baltika;

- "Dark chocolate";

- "Terracotta";

- "Copper ebb";

- "Dune";

- "Norwegian Fjord".

Many consumers opt for Ruflex brand tile, as it is presented in a wide range, and also has reasonable prices.

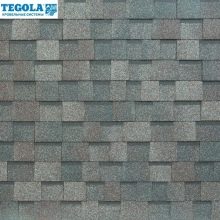

Tegola group

A large Italian manufacturer Tegola is a world leader in the production of roofing, waterproofing, and geosynthetic systems. The products of this company can be used both in private construction and in the construction of various industrial facilities.

The Tegola brand has a range of flexible tiles in a variety of colors and patterns. Consumers can choose for themselves coatings with bricks, scales or honeycombs.

The main advantages of these branded products are:

- frost resistance;

- heat resistance;

- no fear of strong and sudden gusts of wind;

- no fear of any precipitation;

- non-susceptibility of deformation under the action of temperature fluctuations;

- non-corrosive.

At the heart of branded soft tiles from Tegola is high-strength fiberglass, which is further enhanced by about 30%.

Due to its content, this material is characterized by durability and stable form.

JSC "Soft roof"

It is a Samara manufacturer, producing and supplying high-quality roofing, as well as waterproofing and heat-insulating materials. This brand has existed since 1932, and during its existence has managed to win the trust of consumers. Products from JSC "Soft roof" is constantly being improved and updated with new models.

Branded products of the Samara manufacturer attracts the attention of customers with their positive qualities, which include:

- the use of high-quality raw materials in the process of manufacturing the roof;

- the highest degree of product quality and reliability;

- long service life;

- ease of installation.

Currently, the products of CJSC "Soft Roof" are in great demand, and its quality and long service life are noted by many buyers.

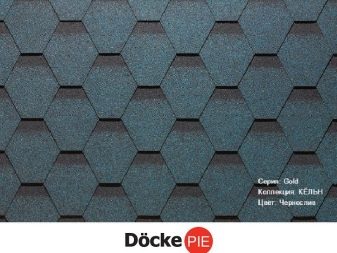

Docke

Docke is another well-known company that is one of the leaders in the domestic market of facade materials. In the possession of this brand there are two own factories where not only flexible tiles are manufactured, but also vinyl siding, PVC drainage systems and polymeric facade panels.

Docke high-quality soft roofing is made with the participation of leading German engineers and experienced designers. This famous brand is famous for its rich assortment of products of unsurpassed quality. Separately, it is necessary to highlight the line of shingles called "Tetris". It is represented by coatings with a neat and popular pattern. These materials are available in red and brown shades.

How to choose?

Many homeowners are wondering how to choose a suitable soft tile.

Let's look at what parameters you need to rely on, selecting such materials.

- Experts recommend to decide in advance on what kind of product and with what properties you need. It is advisable to select a number of suitable options and choose the best product from them.

- You need to calculate the material consumption per 1 m2 to determine the amount of coverage required.

- Pay attention not to price, but to quality. You should not look for too cheap roofing - they can last for a very short time.

- Low-quality materials will quickly manifest themselves in conditions of low temperatures, as well as their differences.

Consider that on a low-grade coating, tiny cracks appear first, but under the influence of dampness and moisture they grow.

- Choose elastic materials. The similar products are let out by the majority of modern large manufacturers.

- Decide in advance with the appropriate color tiles. Fortunately, today in the shops you can find coverings that easily fit to a variety of facades.

- Ensure the integrity of the packaging with tiles. It should not be damaged.

- Unpleasant chemical smell should not come from the material.

- The shingle thickness is also important. It is recommended to choose materials in which this parameter exceeds the mark of 4 mm. Of course, multilayer coatings have a more impressive weight, but are notable for reliability and longer service life.

- Pay attention to the date of manufacture of shingles.The level of strength of the self-adhesive surface primarily depends on it. Such coatings lose their adhesion one and a half years after their release.

- Choose products of famous brands. The roof from underground companies is unlikely to please you with good quality.

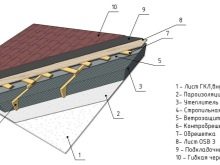

Roofing device

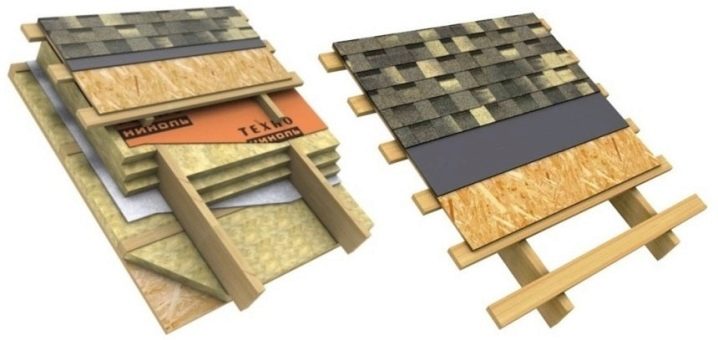

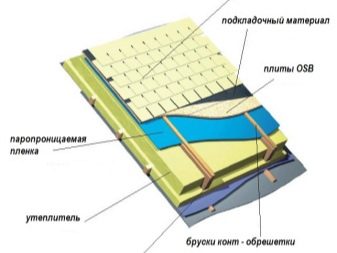

Attic space under the roof can be not only warmed, but also cold, depending on the device of the roofing pie itself.

Its structure from rafters and above in all cases is unchanged and consists of:

- waterproofing, which is stuffed on the rafters;

- crates constructed from bars having a thickness of 30 mm or more;

- solid flooring.

As for the waterproofing layer - it can be multi-layered (1-, 2- and three-layer). So, the simplest and cheapest are single-layer coatings, however, they perform only 2 main tasks - they do not allow moisture and moisture to enter the room, and also let the steam out. Such materials are protected such bases as the attic or attic. Single-layer membranes are less common than other options.

More durable are multilayer coatings. In addition to the waterproofing layer, they have an additional layer, which is responsible for the strength characteristics of the gap. The third layer of these materials is absorbent.Even if a droplet of condensate appeared on the surface of such a coating, this layer will easily absorb it. Three-layer membranes are recommended to be installed if the attic in the building is insulated with mineral wool. This material is seriously affected when wet.

If there is a cold attic under the roof, then it is recommended to refer to two-layer waterproofing materials.

Such specimens are more reliable than single-layer ones, but cost a little more.

No less important in the structure of the roof is lathing. It is installed above the waterproofing membrane parallel to the overhang. These structures are needed to form the required clearance for ventilation. Thanks to this component materials for the roof will always maintain a comfortable level of humidity.

As a rule, crates collected from coniferous wood. The thickness of the boards should be more than 30 mm. This gap is the smallest. It will ensure the normal circulation of air in the building. Before carrying out such work, it is very important to process wood with special antiseptics so that it does not dry out and rot.

As for the minimum length of battens, it should take at least 2 spans of rafters. These parts should be mounted above the truss feet. In other areas they can not be connected.

The final layer of a typical roofing pie is the flooring itself. Under the roll of flexible coating it is made without gaps (continuous coating).

Suitable materials are selected based on the fact that nails will be hammered into them, so in most cases they apply:

- OSP-3;

- plywood sheets not afraid of water;

- rabbit or edged boards of the same thickness (about 25 mm).

When creating a solid flooring between different components, you need to allocate a ventilation gap. So, installing plywood or OSB, it is necessary to allocate 3 mm, and between boards - from 1 to 5 mm. Sheet cover attached with the gap of seams, so that they have found solid joints. OSB sheets are fixed with screws and worn nails.

Related materials and components

If you are going to self-lay the shingles, then you should stock up on such components and materials:

- you will need a hammer;

- special scissors for cutting metal;

- roofing knife;

- glue;

- trowel to apply mastic;

- assembly dryer (it will come in handy if you install the roofing material in a sub-zero temperature environment);

- you will need a ridge-eaves cover;

- lining layer;

- sealant or bituminous mastic;

- details through passage;

- parts for fastening the eaves and the end part of the roof;

- parts for ventilation;

- special roofing nails with a wide bonnet.

How to lay?

It is possible to carry out the installation of a soft roof with your own hands, the main thing is to adhere to technology. This work should be carried out from the overhang to the ridge, leaving small ledges.

This is necessary so that the top level overlaps the bottom.

Endowy, pass-through units related to chimneys and ventilation pipes, need to be processed first. After that, eaves and front strips are installed, as well as gutter brackets. After completing these actions, you should close the surface of the slopes with shingles, cutting them in width and length, if necessary.

How to lay?

Lay shingles should be as follows.

- First you need to carve out the eaves row of ordinary shingles or ridge stripes.These parts need to be put and fixed on the eaves bar of steel (2 cm back from the bend point).

- If the ramp is rather long, the first row needs to begin to lay from the middle. At the same time, the indent of the eaves row should be approximately 1-2 cm, depending on the modification of the roofing material.

- The remaining rows should also be placed starting from the central section. In this case, the petals of the drawings should be shifted by half or in accordance with the intricate patterns of the front side. The edge of the bottom of the shingle should be placed in a level with the upper edge of the section of the part below.

- Nails need to be fixed perpendicular to the slope of the slope. In this case, the cap should press the roof without bevels. The heads of hardware do not need to be deepened. As a rule, a detailed punching map is available on the original packaging and depends on the material itself, as well as the angle of inclination of the roof.

If the shingles do not have a self-adhesive base, they are treated on the reverse side with mastic.

Sequence of work

The sequence of installation of a flexible roof can be divided into several main stages.

- First, the overhang is enhanced with a drip plate (L-shaped metal element).This detail will protect the crate, rafters and flooring from the penetration of moisture and water. Drip strip joins nails, clogging in a checkerboard pattern. In this case, the step in mounting fasteners should be 20-25 cm.

- Then the waterproofing layer spreads in the valley and along the ramp. This material must be rolled out, distributing 50 cm from both sides of the bend. Avoid stitches. It is better to lay waterproofing with an overlap of 15 cm. But also the material should be missed with bitumen. Next, waterproofing is fixed along the eaves light. If necessary, the carpet is trimmed.

- Then set the lining carpet. It should be laid on the entire plane of the roof, if its slope is 12-18 degrees. Carpet should be laid out from the bottom.

Joints should be lubricated with bitumen mastic.

- If the slope of the roof is more than 18 degrees, the carpet is laid only in the areas of kinks.

- To fix the lining carpet, it is often necessary to make an incision in separate places with a special knife.

- This is followed by the installation of metal end plates. It will cover the previously laid materials, as well as protect from wind loads and moisture.Lay the front part must be on top of the lining layer or waterproofing layer, while fixing nails.

- Then you need to make the layout of the slope grid. To do this, use a special paint cord. Marks along the overhang of the eaves are applied in 5 rows of tiles and after 1 m in a vertical position. With such marking it will be easier to lay the roof.

- Now you need to make an end carpet, installing it on a waterproofing material. It should be cut off in the overhang area and mark the boundaries. From the marked points it is necessary to retreat about 4-5 cm and apply mastic - on it and you will need to lay the end carpet. The folds will need to be smoothed and the edges pressed.

- Next, you need to handle the areas adjacent to the pipe. To do this, you need to prepare patterns of end carpet or metal. It is important to coat the surface of the pipe with plaster and primer.

- If you used an end carpet, then the pattern needs to be made so that the material lies on the pipe for more than 30 cm. The pattern needs to be processed with mastic and put in place. At first the frontal part is fixed, and then the right and left. Details on the side will need to wrap on the front side.

- If you have decorated the area around the pipe correctly, then you will have a kind of platform, closed completely with an end layer. Before laying the tile in this place, the base should be missed with bitumen mastic. Then the roofing material should be put on three sides, retreating from the walls of the pipe about 8 cm. It is important to seal the area at the top of the junction with a metal strip.

- Now you need to make a conclusion round pipes. To do this, take special devices. They are placed so that the edge from the bottom of the part falls on the roof more than 2 centimeters.

- Passing detail must be pressed to the roof and delineated inside.

A hole is cut along the contour - a pipe will be output into it.

- This is followed by the installation of the first strip of tile, and after it is installed ordinary tile, depending on the angle of inclination of the roof.

- After this, the valley and gables are drawn up.

- Only then can you proceed to install the skate. A hole is made along it that does not reach the edge of a rib of 30 cm. The ridge is installed using roofing nails. If this item has a greater length, then you can use several elements and connect them end-to-end.

- At the end of the work you need to close the ridge tile ribs, moving from the bottom up. Each piece needs to be glued and attached with nails.

Useful tips from the pros

Many people dream of building the perfect home of their dreams and complete such a beautiful and reliable roof. However, it should be borne in mind that the construction of the latter should be carried out without any errors. Wrong start can turn into a pitiful ending. It is very difficult to fix many problems associated with roll roofing.

We will get acquainted with useful tips and recommendations from professionals, so as not to face serious drawbacks when installing a roll roof.

- Installation of plastic roof is best done in the warm season. However, some craftsmen carry out such work in colder seasons, for example, in winter. At the same time, finishing materials must first be held at room temperature, and during installation they warm up their adhesive layer with a building dryer.

- When selecting a material, consider the coefficient of its overlap. For example, three-layer coatings often have a factor of more than 5. This means that they will cover the roof in 5 layers.

- It is not recommended to lay a plastic roof on a solid structure of unedged board, since in such conditions there is no flatness of the ramps. At the same time having installed a soft tile, you will underline absolutely all defects of the basis.

- If you made the markup in the process of laying a flexible roof, it is boring to remember that you cannot nail shingles on it. You only need it as a guide to facilitate further work.

- If you decide to lay such a roof on the roof, experts recommend providing it with good thermal insulation.

- Included with many branded roofing materials is a flow chart.

It is recommended to get acquainted with it before proceeding to self-laying of the roll roofing.

- A common mistake of masters is the weak consolidation of the base. In such a situation, roofing nails over time can get out of the wood, damaging it.

- Do not forget to leave the vents between the boards or sheet basics. In a different situation in wet weather, these structures can swell and damage waterproofing, as well as the appearance of the roof.

- Attach roofing plates as tightly and accurately as possible.This is necessary so that no water flows under them.

- Laying shingles, you should be careful. Try to avoid kinking or crushing. In addition, without special need not walk on this material.

- Do not forget to pre-calculate the required materials. Their average consumption: shingles in packs of 1.5-3 cubic meters. depending on the size, taking into account the overlap, as a rule, a margin of 5% is required, 200 g / m of mastic for endova carpet, 100 g / m for the ends, 750 g / m for abutment, nails - 80 g / kV m.

- Do not be afraid to install soft coatings on a complex roof. This facing material is suitable for the bases of absolutely any design.

- If you are afraid to independently carry out work on the installation of a flexible roof, it is better to contact the experts. Otherwise, you can build an unreliable structure and only in vain translate the roofing material, which is not so cheap.

For information on errors in the installation of shingles, see the following video.