Composite tile: material specifications

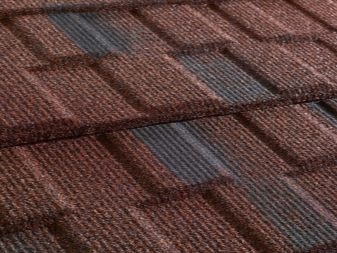

Composite tile - multi-layer roofing, characterized by high strength and durability. The material has excellent decorative qualities: depending on the modification, it can imitate products from clay, wood shingles, and ceramics. Due to good performance properties and favorable price, such coverage every year becomes more and more popular among consumers.

Description

Composite tile - what is it? Its basis is a steel sheet (thickness 0.5–0.9 mm), coated on both sides with an aluminum-zinc layer. Also products are processed by an acrylic layer and a decorative natural stone crumb.

For the manufacture of the latter are used:

- jasper;

- quartz sand;

- basalt or granite.

At the expense of a covering of the basis a stone crumb roofing sheets differ in the noble invoice. In addition to decorative qualities, the granulate allows the material to acquire a higher noise insulation and resistance to solar ultraviolet radiation.

The last layer of composite tile is acrylic glaze. It reliably protects the base from various adverse weather conditions. Due to this coating material acquires additional durability and reliability. Acrylic glaze also protects the roof from fading.

The multi-layered structure of the products allows the coating to last for more than a decade. According to manufacturers, composite tile is able to maintain its attractiveness for at least 30 years.

Features and sizes

Composite tile - a material with which it is possible to create a solid and reliable roof. The coating is designed to protect the structure from precipitation, winds and street noise. Such products have no restrictions on use. They are used both in private and in commercial construction. Composite sheets are lightweight materials.For example, compared with sand-cement or ceramic products, they are about 6 times lighter.

Important specifications and dimensions:

- the mass of the material is 6.4 kg / m2;

- length - up to 1.4 m;

- the average leaf area is 0.5 m2;

- the width of different manufacturers varies widely;

- Approximate weight of the sheet is 3.5 kg.

The tile is easy to install, since the sheet can be cut and bent at an optimal angle. Due to the modular structure, the material is suitable for the design of any type of roof, even non-standard.

Kinds

Before you buy the material, you need to familiarize yourself with the varieties of composite tiles proposed by the manufacturer.

Products are classified according to two factors:

- color spectrum;

- profile view.

Selecting a shade, you need to decide on the style of the structure. It is important that the color of the roof in harmony with the facade of a private house or building, as well as fit into the "overall picture." In order to accurately select the colors, it is recommended to preview photos of houses with a roof of composite tile.

Also pay attention to the profile view.

Manufacturers produce products that mimic:

- medieval pavement;

- shingles;

- wood chips.

However, most often consumers prefer products that visually resemble ceramic tile grooves. In appearance, this material is no different from natural, however, it is several times cheaper and easier.

Advantages and disadvantages

Composite tile has many advantages.

Consider the advantages of the material.

- A light weight. Due to the small weight, the savings in time and money for loading, transporting and unloading goods will be substantial.

- High quality material performance. The steel sheet is coated with an alumina zinc layer, which reliably protects the metal from the formation of corrosion.

- Reliability of products, due to the resistance of tiles to temperature extremes, high humidity and any weather conditions.

- Sound and heat insulation properties. The material perfectly retains the heat accumulated in the room, and prevents the penetration of noise from the outside.

- Fire resistance Composite tiles can withstand high temperatures. It can restrain the spread of flame for a long time.

- Convenient dimensions. Unlike a piece clay tile, composite is issued in sheets.This allows for quick installation of the coating.

- Easy installation material. Even an unprepared person will be able to lay the roof covering made of composite products. This fact is confirmed by numerous reviews on the Internet.

- Good flexibility. Due to this feature, the products can be installed on various roof profiles with a large number of bends.

- The rough surface of the sheet, preventing a sudden descent of snow masses from the roof.

- Extensive selection of colors. Thanks to a rich assortment of colors, it is possible to choose the optimal shades for any structure. On the market there are both standard typical colors, and original colors, allowing to realize the most daring and unusual design projects.

Despite numerous advantages, the material has certain disadvantages.

- One of the significant drawbacks include the poor vapor permeability of the roof, which leads to the impossibility of natural air circulation. To cope with the problem of lack of natural conductivity of air masses, it is necessary to equip the ventilation system under the roof.

- From the words of consumers with experience in the use of composite roofing materials, improperly laid tiles quickly rust. To avoid the premature occurrence of corrosion, many resort to the services of mercenary masters for the installation of the coating. And this is an additional financial cost.

- Another drawback that builders and consumers of composite tiles emit is the relatively high price. Of course, the material is more profitable at a cost than metal tile or other natural coatings, but it cannot be called cheap. The high cost of products due to their complex production technology.

Color solutions

Composite tile - a stylish and aesthetic material to create a bright and original roofing. One of the features of this material is an extensive color palette. Modern manufacturers offer shingles in more than fifty color variations. The material is made in monochromatic color modifications, and in two-color.

Shades of composite tiles are divided into standard and non-standard. The difference between them lies in the cost and delivery time.Products with non-standard shades are more expensive and longer "go" to the consumer.

The most popular colors of roofing materials include mocha, terracotta, red and black, wet asphalt, gray, green, coffee. Non-standard tones of the tiles include coral tones, slate, yellow, blue, terracotta yellow.

The color of roofing materials is one of the important components.that you need to pay attention to when buying tile coverings. Thanks to the well-chosen shade, it is possible to give elegance and sophistication to any structures.

Manufacturers Overview

The first composite roofing materials began to be produced in the 40s of the twentieth century. Already at that time such coatings were considered practical and durable, however, they did not possess outstanding decorative qualities. Today, dozens of well-known companies that sell products both within their countries and beyond are producing composite shingles.

- The first company to start developing and manufacturing composite roofing Metrotile. Products of the Belgian brand is in great demand. It is delivered to more than 80 countries of the world.The manufacturer presents 10 series of tiles in 24 color variations. Distinctive features of the proposed material - Magnelis double coating and matte protective glaze.

- In Russia, the company began to produce composite tile Luxardowned by concern TechnoNIKOL. The company produces more than 500 thousand m2 of roofing annually. Among the proposed range of consumers will find collections in various colors. The company's products "Luxard" is of high quality and low cost. The only manufacturer offering tile to the consumer in the same price segment is Roser (South Korea).

- The Belgian company also belongs to very famous companies. Decra. It began its work in 1979. This is one of the largest organizations that supplies to the world market more than 3 million m2 of tiles per year. A characteristic feature of Belgian-made products is 10 protective layers. Due to their durability and reliability, the use of such materials is especially important in countries with severe climatic conditions.

- The leaders in the production and sale of composite shingles also include the New Zealand company. Gerard. The company manufactures products in rich colors with various patterns. Gerard materials are distinguished not only by their excellent decorative qualities, but also by their strength. There are no microcracks on their surface, because of which the coatings are famous for their exceptional durability.

Whatever coating is chosen, it is important to mount it correctly. When making mistakes and omissions, even the most reliable and durable tiles may soon become unusable.

How to choose?

Most building stores offer a wide selection of composite shingles. Many buyers first of all pay attention to the price, aesthetic qualities of the material and its dimensions, since the appearance of the house will directly depend on the color and texture of the products. When choosing the shade of the coating, preference should be given to colors that allow to create a harmonious style of construction. If necessary, you can use the services of a designer.

It is also important to choose not only beautiful tiles, but also quality ones.

To choose a durable and reliable material, you need to be guided by professional advice.

- Perform a thorough inspection of products.About the durability of the coating says uniformly deposited on both sides of the material layer of aluminka. To assess its quality, pay attention to the seamy side of products: if the coating is uneven, you should abandon the purchase of tiles. Such defects often cause corrosion and the fragility of the roof.

- Check the product documentation. Quality materials contain natural stone chips. Unscrupulous manufacturers can use sand instead of natural granulate. This coating quickly loses brightness and color saturation.

- Pay attention to the "age" of the manufacturer. Often, young companies that have recently appeared on the market in the manufacture of tiles buy low-quality and cheap raw materials. This is done in order to reduce the cost of finished products. As a rule, such materials quickly lose their visual attractiveness and become useless.

- A quality tile should have all the necessary documents and certificates confirming its reliability and durability. If there are no such papers, it is better to refuse to purchase doubtful building materials.

In an effort to save on the acquisition of composite shingles should not be given preference to cheap coatings from unknown manufacturers. It is better to buy expensive, but quality products. Strong and durable roofing materials will justify their value in the process of long-term operation.

Recommendations for work

Installation of composite tiles can be made by hand. To familiarize themselves with the rules of laying manufacturers attached to the construction material detailed instructions. It provides information about the installation of a particular product. There are also general requirements that are mandatory for all types and varieties of composite roofing.

Installation of the coating includes several basic steps:

- preparation of the framework;

- mounting crates;

- laying cover.

Installation of composite coating is possible only on roofs that have a slope of more than 13 °. If this condition is not observed, it will be impossible to create a good waterproofing. To the preparatory work include reliable mounting rafters to the walls. Such power structures should be located at a distance of 60-90 cm from each other.It is important to determine the optimal thickness of the rafters, since it is on them that the whole load of snow and ice will fall in winter.

Before mounting the batten, it is necessary to install the counter lattice. It is designed to create ventilation ducts, due to which the risks of condensate will be negated. The intermediate construction should be installed with the necessary clearances.

Above the counterbribeta need to fill the crate. It is made of square-shaped bars with a cross-section of 3-5 cm. The pitch of the batten is usually indicated in the instructions attached to the building material.

After the work done, you must proceed to the installation of the coating. The technology of laying consists in fastening composite sheets from top to bottom. First, the first row fits completely, after which the bottom is raised and a subsequent sheet is put under it. To protect the structure from leakage, composite products should be fixed in a staggered manner. Fix the sheets should be with the help of hardware with a wide cap.

Pro tips

To prevent missteps when installing the roof, you should listen to recommendations from professional installers.

- In order to extend the service life of the wooden components of the roof (rafters, lathing), they must be treated with antiseptic compounds. If the design provides waterproofing shell, the use of chemically aggressive agents is not allowed.

- In order to facilitate the construction of the batten, it is recommended to create a template by which the distance between the bars will be determined in the future. Bars should be smooth and not thin. Otherwise, after laying the composite tile, the risks of roof deformation are high.

- Sheets must be overlapped. This is done in order to protect the attic from winds and precipitation.

- For cutting sheets can not use the grinder. When using this tool, the steel layer of the coating will heat up, which will lead to the destruction of the aluminum-zinc layer. If such a shell is damaged - the coating will begin to rust after the first precipitation. If you need to cut the material, use special construction scissors, a hacksaw or a circulating saw with a low speed.

- For fixing one sheet you need to use at least 8 nails. Hardware clogged at an angle of 45 degrees.

- It is not recommended to save on fasteners and use self-tapping screws instead of nails. This often leads to a violation of the tightness of the coating.

- Nail caps should be treated with weather-resistant paint, then covered with mineral stone crumbs (included in the complete set of tiles).

- Installation of additional elements should be made only after laying the roofing material.

- When mounting works on the roof, it is important to move in shoes with soft soles. This reduces the risk of damage to the surface of products.

- Do not forget about the need for regular inspections of the established coverage. If traces of dirt are found on the roof, they should be removed using soapy water.

In the absence of experience in construction and installation works or in case of uncertainty in their abilities, it is not recommended to install composite shingles yourself. It is better to seek help from hired craftsmen who are able to lay tile in accordance with all requirements in a short time.

Technology installation of composite shingles, see the following video.