Ceramic tiles: properties and applications

Ceramic tile is considered one of the best and respectable options for the design of the roof. Due to this not only natural origin, but also the excellent technical characteristics of the material. According to a number of parameters (strength, resistance to environmental factors, durability), ceramic tile surpasses many other roofing materials.

What it is?

Natural ceramic tile - one of the oldest roofing materials, actively used in construction in our time.

The basis of the composition of the material - fatty clay varieties. GOST involves a multi-stage process of preparing raw materials and manufacturing tiles:

- preparation of raw materials based on pottery clay with the addition of plasticizers;

- tile molding by stamping, semi-dry pressing or tape plastic formation;

- roasting billets in a furnace, the temperature in which more than 1000C.

Special features

Pros and cons of the material due to the peculiarities of production and its composition. So, the environmental friendliness of ceramic tiles is one of its main advantages. Made on the basis of clay, it is not only safe for human health and ecology, but also allows you to create a favorable microclimate indoors. This is due to the “breathing” ability of shingles.

Among the operational and technical characteristics worth highlighting the most significant.

- The moisture resistance of the material, despite the porosity of its structure. Ceramic tiles do not absorb moisture, therefore, even with prolonged precipitation, they retain an attractive appearance and other indicators.

- The long period of operation - the service life of the material is 100 years.

- Frost - withstands up to 300 freezing cycles.

- Resistance to ultraviolet rays, which allows it to be used for building houses in the southern regions. The material does not fade in the sun, and therefore retains its shade, aesthetic properties.

- Lack of corrosion, deformations of a tile.

- Thanks to the small tiles it is possible to provide ventilation of the building, to avoid the greenhouse effect.

- High strength indicators (comparable to the strength of granite).

- High heat and sound insulation properties due to the special structure and density. In the house with a ceramic roof in the winter is not cold, and in the summer is not hot, even if it comes to mansard rooms. Strong winds and precipitation also do not become a source of noise in the house.

- Ease of installation - the individual elements of the tiles, like particles of a puzzle, are fastened together. This, by the way, causes ease and low maintenance of repair. If one item is damaged, only it is replaced. To remove a large section of the roof is not required.

- Unlike metal tiles, ceramic does not accumulate static electricity, and therefore a grounding device is not required.

Speaking about the advantages of the material, it is worth noting its aesthetic appeal. - at home with a roof look elegant and respectable.

The choice of owners of several types of forms of tiles and a diverse color palette, including both brick-red and yellow-brown natural shades.

The disadvantage of the ceramic roof is its considerable weight - 50-70 kg / m kV.In this regard, an additional load is placed on the supporting structures, and therefore their strengthening is required. The fragility of shingles on the basis of baked clay turns into the inconvenience of storage, transportation and special requirements for the installation process. Finally, ceramic tile has a high cost. But this is leveled by the high technical properties of the material and its continued operation.

Kinds

Despite the variety of shapes and shades of ceramic roofing tiles, there are 3 main types of it.

- Flat tiles (including the “beaver tail”) - has a rounded "blade" appearance. Suitable for buildings of complex shapes with many broken lines, mounted with a small overlap in the form of scales, which guarantees a reliable waterproof effect. The exception is “bobrovka”, which is put in a single layer and mounted on a special solution.

- Grooved ("munch-nunn") - also a variant more suitable for roofs of complex configuration. This roof tile has 2 layers: the bottom (“nunn”) is formed by concave shards, the top (“kun”) - convex. They are joined in pairs, which provides aesthetic expressiveness and the best waterproof performance. However, the material consumption grows almost 2 times.

- Undulating - aesthetically attractive tile, most often used to organize the roof of a country or a country house. Happens one-wave (Dutch tile) and two-wave.

Undulating and flat tile is equipped with grooves on one or two sides, which provides better material resistance and fastening reliability.

There is also a groove tile, which often takes the roof of simple forms. Externally, the groove resembles Dutch tile and forms a kind of "frill" on the roof. Each tile has a flat surface, on the edge becoming convex.

Cover tile can be represented by one of several common options.

- Natural - this tile has no coating, its surface and texture - natural burnt clay. The material looks good on the "old" buildings, buildings in retro style. Its shade is the natural color of clay after firing. These are reddish, brick tones. During operation, such plates are covered with patina, darken.

Different manufacturers of natural tile color may vary, which is associated with the use of different grades of clay.

- Glazed - reminiscent of a glassy coating, aesthetically attractive, regardless of the shade of the tile. The composition of the glaze - a glassy substance containing ions of various metals. The latter provide one or another shade of the product. The finished tile is elegant, glossy (when choosing the appropriate shade it has the same appearance as the metal tile), it has enhanced moisture-proof properties. The downside is low frost resistance, glazed tiles are more susceptible to cracking. It is worth noting its high cost, it is the most expensive kind of ceramic tiles.

- Ancobed - colored tile, shade, which is obtained by applying a thin layer of colored clay on the tile and its subsequent high-temperature firing. The color of clay is obtained by mixing it with mineral additives, the latter and determine the palette of finished products. Thanks to this technology, the color is persistent, and due to the fact that engobe and ceramic tiles have the same structure, the material does not crack in the cold. The surface of the roof tile is matte.

A variation of this method is the edelangobirovanny method. It involves the addition of frites (the smallest glass particles) to the coloring composition. Being exposed to high temperatures, they are sintered, forming a glossy surface. Edelangobirovannaya tile looks more attractive, but also costs more.

Material

Classic ceramic tile - clay, also called sand-ceramic tiles. It is based on raw materials of fat varieties and modifiers that provide technical and operational properties of the material. However, there are similar in composition.

- Cement sandy. Its basis is cement, water and sand. It is not baked, but steamed for 8 hours, after which it is dried. In terms of its operational parameters, it is not inferior to the clinker analogue: long service life, good heat and sound insulation, properties, resistance to moisture, frost, UV rays, naturalness. Much cheaper clinker plates. The downside is a very large weight - one tile (medium format) weighs 4 kg, which significantly narrows the area of its application.In addition, it has a more scarce color palette and is also fragile.

- Soft clay tiles. The front and inner parts of such tiles differ in composition. At the base of the outer side is basalt or mineral veil, which have the form of expanded clay granulate. The inner part is a self-adhesive bitumen layer having a protective polyethylene film. A multilayer construction based on non-woven polyester or fiberglass and bitumen is laid between these layers. Such tiles can fit on roofs, the slope of which is not more than 12 degrees. Installation can be made in dry weather at a temperature of 5-10C. Laying such a roof requires reinforcement of beams and walls.

If all the conditions are met, the user gets an attractive, resistant to environmental influences, durable material.

- Polymer-sandy. It is based on a thermoplast composite obtained by mixing hard and soft polymers, drying them in ovens and heating and mixing in an extruder. Thermoplast composite can be given any shape and shade, which provides a variety of design of finished products.

Outwardly, this tile is almost indistinguishable from ceramic, but has less weight. This, in turn, allows you to make frequent crate, to abandon the additional strengthening of the foundation. Due to the fact that the dye pigment penetrates the entire thickness of the material, the color is more stable, saturated. When ignited, the material self-extinguishes. Such tile is stronger than ceramic, does not absorb moisture, resists environmental factors.

The downside is the instability of the tiles, even from one party and the high cost.

Despite the fact that the material is lighter than ceramics, it is not recommended to be used for the restoration of old buildings. The latter have a dilapidated roof system, which risks collapsing under the weight of tiles.

Dimensions

Uniform standards for the dimensions of tile does not exist. In general, there are three main dimensional species.

- Large format. Convenient for use on the roof of a large area of simple construction. Due to the large dimensions of the tile, it is possible to speed up the installation process, to save the consumption of sawn timber due to the use of more rare lathing. Material consumption is about 10 tiles / m kV. Approximate dimensions - 310x477 mm.

- Medium format. The average option between large and small-format tiles, characterized by versatility of application. Consumption is in the range of 13-15 pieces / m kV, approximate size - 225x444 mm.

- Small format. It is preferable to choose it for small areas, roofs of complex configurations. Using a small-format tile, it is possible to lay out interesting patterns and drawings, using different shades of plates. Average consumption - 20 / m kV with an approximate size of the plates 315x160 mm.

Colors

The color of ceramic tiles depends on the method of its manufacture. Natural plates are characterized by the natural colors of baked clay - red, brick, brown. Differences in shades are due to the different composition of the clay used. Thus, with a high content of iron hydroxide after calcination, the material has a more red tint, and with a manganese content it is dark brown. When lime is added to raw materials, tile of yellow shades is obtained, magnesite is light red.

Engobed and glazed tiles have more shades, including black, green, dark blue, purple. The palette of glazed material is richer.Both options include a collection of artificially aged tiles.

Necessary tools and mixes

Installation of tiles requires the preparation of tools such as a cutter, screwdriver, tape measure, hammer. Of course, you need to purchase the tile itself and additional elements. Take care of the availability of materials for hydro- and vapor barrier, building materials to create crates.

The tiles have grooves, making installation quick and easy. In some cases, use fixative compositions.

Choosing and laying your own hands

When buying a tile do not forget to purchase a certain amount of stock - in case of marriage or for repairs. Otherwise, the product belonging to a different series of release will differ in color. Such "heterogeneity" looks sloppy on the roof, especially when it comes to flat plates.

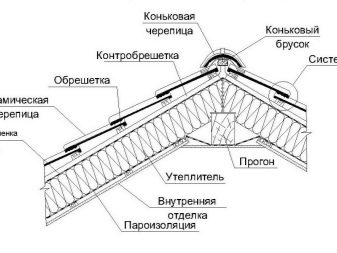

Installation of ceramic tiles involves the sequential implementation of several operations:

- The organization of the waterproofing system, the material is placed on the rafters.

- Creating a vapor barrier layer.

- Installation on the vapor barrier layer of the counter grille.

- Laying bars obreshetki on which the tile is mounted.The pitch of the batten depends on the length of the tile. When it is overlapped, the overlap width is subtracted from this size.

Tile tiles are laid from top to bottom, from left to right. After all the rows are laid, it is necessary to cut off the protruding parts of the material - those that go beyond the slope.

To prevent accumulation of steam under the tile, you should take care of its withdrawal. To do this, even at the stage of waterproofing need to make ventilation holes.

If necessary, cut the tile, it is recommended to pre-soak it in warm water for a day.

How to carry out installation of a tile, look in the following video.

Famous manufacturers and reviews

If you want the roof to serve you for more than one century, it is important not only to mount it correctly, but also to choose a reliable tile. The leading manufacturer of the latter is a German company. Roben. The success of products is due to the high quality of raw materials and compliance with the finest technological requirements of production. Tiles are of impeccable quality, durability, have a warranty of 30 years. The collection includes about 50 types of tiles.The colors are mostly natural, however, a unique collection has been developed for exacting customers, striking with its exquisite color palette.

Deserves attention and brand from Austria Koramic. Products meet European standards of quality and safety, has a guarantee of 30 years. The main advantage is the wealth of tile patterns and color variety.

Spain can also be proud of its brand-name ceramic tiles. La escandella. The basis of the tiles - clay of the smallest grinding, which allows to improve its technical characteristics. The choice of the buyer - 5 forms of tiles (including the popular "beaver tail") and about 20 colors. A special love of customers enjoys a series "Antique"imitating the aged surface of the roof. Warranty period from the manufacturer - 35 years.

An impressive warranty period (50 years) has a tile from a German manufacturer Meyer-holsen. Technologists of this company for the first time developed a method of applying glaze on tiles, so today a huge amount of tiles of the most fantastic colors are produced here.

The company also provides a half-century guarantee for its products. Sereni from Italy. Its products were used in the construction of the Olympic Village in Turin, the La Fenice Theater in Venice, the Venetian Marco Polo Airport and many other world-famous facilities. Quality, durability and freedom of choice - this is what guides the manufacturer in the production of ceramic tiles.

Canadian company MurolMore known as a leading manufacturer of drainage systems, it also produces clay tiles. Their distinctive feature from many similar tiles is impeccable size, rich colors. Polymer-ceramic tiles have high strength, due to the characteristics of the raw material composition.

Serbian manufacturer Mladost mIt can boast a harmonious combination of high quality products and an affordable price. The basis of the collection is natural and engobed tiles.

The brand also has positive feedback. Ludowici, the production of which has a minimum coefficient of water absorption (1%). The collection contains materials intended for use in extremely harsh environments.The choice of the buyer - many types of tiles, different materials of manufacture, shapes, colors.

Worthy marks of a tile of the Russian production to select extremely difficult. This is due to the formation of the production of material in the country. However, some large manufacturers are included in European concerns, for example, Braas. If we talk about sand-cement tiles, then, perhaps, the best products are Russian-Swedish production Sea wave. It successfully replaces ceramic tiles, but at the same time has a much more affordable cost.

Connoisseurs of fine appreciated the original palette of products, including burgundy, dark gray, blue, red and other shades, tiles with the effect of patina.

Successful examples and options

Ceramic tile is a good material for country buildings, if you wish to add respectability and sophistication to their appearance. The material is well combined with most of the facades - stone, siding, wood. Traditional clay shades accentuate the depth of the masonry palette, advantageously highlighting the light colors of the facade.

However, the tiled roof can merge with the facade, which looks eclectic and stylish. The main thing - to choose the appropriate elements that will bring animation to the exterior.

When using small-format tiles, it is recommended to combine 2-3 shades. This allows you to get the volume, make the roof decoration of the house.