Metal tile canopies: types of structures and manufacturing features

Protection from the sun and wind, from rain and snow precipitation - this is an important function of ordinary homes and garages. But both people and cars must sometimes stand on the street. And in this case, invaluable assistance provides a quality canopy of metal.

Special features

For many decades, it was possible to block canopies only with the use of slate or asbestos cement slabs. The strength of both materials is good, but they are rather heavy and require the installation of special steel beams. As a result, the work becomes more complicated and expensive, far from all private developers can do it properly. The use of metal tiles has become a real breakthrough, and now strong, light, aesthetically looking canopies are accessible to almost everyone.

In addition, similar designs:

do not need special care, even in the courtyards of private houses;

built quickly and easily;

can be installed on the base of both steel profiles and wooden beams.

If the supports are made of wood, the aesthetic characteristics of the canopy increase markedly, it becomes more original and more natural. But there is another nuance: wood, especially the part that will go deep into the ground, should be impregnated with antiseptic compounds. Due to its increased strength, the metal tile itself is processed using only high-quality tools: a screwdriver, a grinder, and an electric drill. Manual shears for metal can also cut it, but it will take a lot of time and take a lot of strength.

And even if the workers will try, they will not be able to achieve such an even cut of the material, as when using mechanisms.

Sequence of work

It is quite clear that having familiarized with the advantages of metal roof sheds adjacent to houses, many homeowners want to acquire the same building themselves. The first step in the work is the removal of dimensions, and measure the house and the doors along with the porch, and when calculating the canopy, take into account the space left in this part of the building.It is most practical to take steel pipes (profile) as supports: for most of these sheds, only four of these elements are needed.

The calculated cross section increases if:

strong gusts of wind are possible;

significant icing in winter can be assumed;

Thick clods of snow and ice may fall from the roof.

It is advisable to use a garden drill for digging holes for supports, and its diameter should be larger than that of the used piles. The gap is plentifully filled with concrete, when working you need to make sure that no air bubbles or voids appear. It is very important to check whether there are racks on the same height.

Correct the violation of proportions, if it is revealed after the concrete has set, it is almost impossible. Therefore, the result should be monitored before pouring the mixture into the pits as soon as the supports are exposed.

To attach the canopy to be strong, a pipe is attached to the wall of the house with anchor boltswhich will become the main profile (it goes at an angle of 20-25 degrees). The height of the supports is selected individually, they should not prevent the opening of the doors of the house. Then comes the turn of installation of the rafters from the treated wood, the gap between them is maintained at about 1 m.Rafters approximately 25-30 cm out of the mauerlat (the so-called bar or log, laid on top of the perimeter of the outer wall and serves as a support), thereby forming the overhang. The crate is made of shaped pipes, the diameter of which is determined by the step of the trusses and the size of the whole structure.

For vehicles and not only

Those who have a car can not always put it in the garage (even if there is one), sometimes there is not enough time or just need to quickly go somewhere. Again metal sheds show their best.

Perhaps even several different solutions:

single-slope version joins the walls with anchors, the opposite section is mounted on specially prepared racks;

the support type implies the use of racks to hold the entire structure as a whole;

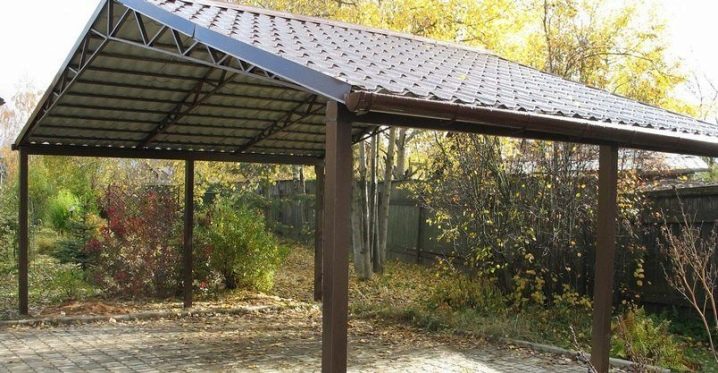

gable format is a kind of "house".

The foundation is made under the line of soil freezing (what it is, you can accurately find out in the building codes for a particular region). The fastening of the metal tile to the pine crate is carried out with the help of screws, according to the color of the corresponding main roof.In the gable option, the ridge profile is equipped at the highest place. The fastening of the plank at the edges of the shed depends on the wishes of the developers. But it is better not to skimp on this element, because it allows you to make the look of the canopy complete and clear.

If the house itself, to which the carport is attached, is tiled, you just need to find out what is the classification of its color on the RAL scale - qualified manufacturers will immediately pick up an identical solution. Sometimes the frame is welded with the intention to further sheathe the structure of the bottom panels. For professionals, such a nuance is not a problem, but you need to immediately mention such a wish. In addition to cars, under the sheds, you can store various agricultural equipment and tools that do not require temperature and humidity. Under the open sheds and canopies, sometimes people gather who want to chat outside or just stand outdoors, regardless of cloudy weather.

The closed type of metal roof canopy almost does not differ from the previous version, except that it is almost never used to protect against bad weather cars.But such buildings are equipped with walls that allow people not to be afraid of even slanting rain, and increase protection from the wind.

Important: to avoid excessive darkening, especially if an unheated hallway is formed at the house, the sidewalls made of polycarbonate sheets will help. It transmits almost as much light as window glass, while far ahead of it in strength and anti-vandal properties.

Additional details and recommendations

For the manufacture of rafters attached canopy mainly used boards with a cross section of 10x5 cm, one side of them based on the support beam, and the other end is held by a power plate. To attach the metal to the base is recommended to use screws with an external zinc layer. They maximize the stability of fasteners to the ordeals presented in winter, spring and autumn. An arched canopy is built a little differently than a regular one; in its execution it can also be open and closed.

Structures in the form of an arch are rarely made suspended, but usually professionals do this, because it is not easy to create a reliable mount (but no ground supports are needed).

For the manufacture of basic elements of the structure, pipes with a cross section of 6x4 cm are used, and for minor ones, it is possible to confine already to 4x4 cm. But the larger the canopy, the more solid the details should be. If it is known that in some terrain strong winds often blow, it is better to be safe and put the supports of the largest section. With increasing sizes, the depth to which the supports should be placed in the ground also increases.

To evaluate the necessary cross-sections of all elements of the canopy truss (diagonals, struts, upper belt, lower belt), you need to consider:

span length;

step between racks;

the amount of wind and snow load in a particular place.

How to make a canopy with your own hands from metal, see the next video.