Metal tile: advantages and disadvantages

The tile roof is a highlight in architectural appearance of the house. It looks expensive and sound, which is typical of the classical European style. However, the technology of finishing the roof with clay tiles is gradually becoming obsolete. Its drawbacks exceed the advantages, therefore, more modern materials have replaced the clay tile. And the leader of sales for a long time remains metal.

Special features

The metal tile is a sheet roofing material, profiled by the method of cold pressure. The basis is cold rolled steel sheet with the addition of copper and aluminum. From above the sheet is covered with a protective polymeric layer. Cold-rolled steel is more durable than hot-rolled. In addition to roofing materials, safes and security doors are made from it. The polymer layer protects the sheet from corrosion and helps to preserve color.

The first sheets of metal tiles, produced in the 80s of the XX century by the Finnish company Rannila, did not yet have all the characteristics of modern metal tiles. Nevertheless, even then they competed with clay tiles due to appearance, simple installation, aesthetics and low price. In Russia, metal appeared less than 30 years ago. Since then, the technology has been repeatedly improved, appeared its own production. But some limitations in the application have not yet been overcome.

The material can only be used for roofs with a slope of at least 14–15 °. Otherwise, snow will linger on it and leaks will quickly form. The recommended temperature range is from -50 to + 50ºС. At higher and lower temperatures, the material loses some of its unique properties. The same thing happens when using the coating in a moderately aggressive and aggressive environment: constant rainfall, winds, severe frosts,Critically high fever.

When using metal tiles in regions with difficult weather conditions, it is necessary to observe special installation technologies and take additional measures to protect the roof.

Application

Sheet metal is used mainly in private construction. The use of profiled sheets as building material is varied: finishing the roof of residential and non-residential premises, local use on individual architectural elements, the use of sheets for other than the intended purpose.

The most common option is to use metal tiles for roofing a country or private house. The room is usually sheathed in which the attic is not used as living space. This is due to the low sound insulation of metal.

As well as the limitation can be broken and domed roof. The metal tile does not have sufficient flexibility, in contrast to soft tile, therefore, it is not easy to finish the roofs of an intricate shape. Up to 50% of material can turn into surplus. The reason to abandon the use of metal - it is a flat roof.Due to the fact that precipitations will linger on it, it will begin to flow already in 2–3 seasons.

Roofs of other types are suitable for successful installation:

- single slope;

- two-sided;

- chetyrehskatnaya;

- hip;

- mansard;

- multi-tongs.

Another roof of metal - this is a good solution for a bath, terrace, gazebos in the country, outbuildings. An alternative option is to use sheet material for a bay window, balcony and other elements protruding from the facade of the house. The last way is to use a metal tile not to finish the roof.

They make country fences, canopies in the recreation area, trimming go for decorating children's “fungi”, pet houses, flower beds.

Advantages and disadvantages

The advantages of metal tiles made the material in demand among professional builders, architects and consumers. These include the following:

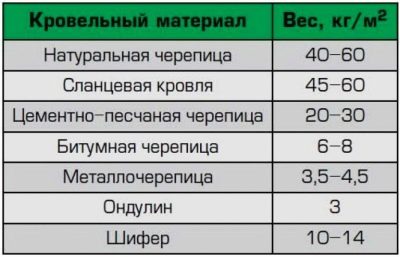

- low sheet weight. Clay tile gives a tremendous load on the rafter system, and the metal tile practically does not load it. A layer of snow of any thickness does not create the risk of a roof collapsing;

- convenient size. With an external resemblance to a tiled roof, the profiled sheet has a convenient width and length, rather than individual tiles of material. This speeds up installation;

- affordable price;

- wide range of. Sheets imitate ceramic tiles of different styles, vary in color and coloring technology;

- unpretentiousness. The sheeting makes a metal tile suitable for use in the majority of regions of our country. And for finishing the roof in an aggressive environment provides additional protection for sheets and improved equipment;

- complete with sheets you can buy all the necessary elements for finishing the roof: structural elements, drains, ebb, skates, valley and others;

- the minimum number of seams at the joints of the sheet material gives the roof strength;

- can be used on top of some types of old roofing;

- attractive appearance;

- the ability to combine material with many types of facade finishing and use for buildings in different styles;

- service life - up to 50 years.

Disadvantages of metal does not detract from its advantages, but they are, and in some cases are critical.

- Can not be used to cover the roof with a slope angle less than 15 degrees. Since the surface of the metal tile has a complex relief, snow masses linger on it. A large tilt angle helps solve this problem.

- Despite the assurances of manufacturers and consultants, it is difficult to cover the roof with a metal tile. The process is time consuming, requires roofing skills and often comes with errors. And the dismantling of the material incurs costs for the new material.

- Not all types of coating are resistant to mechanical damage. If scratches occur during installation, the material will lose corrosion protection. This reduces its service life by almost half.

- Bad soundproofing. To protect yourself from noise, you will have to put more effort into installation, spend more time and money on additional materials.

- Not suitable for complex roofs. Theoretically, the material can be used, it is quite elastic, however, you need to customize the pattern as wallpaper.

- Requires installation of crates. Sheets are strong, but not hard enough to be mounted without crates. These are additional costs and time.

- Metal, like all hard materials with a corrugated surface, can leak. Installation of a waterproofing layer under the roof is required. If you add up all the related work and the necessary materials, the final price of the metal roofing can be unpleasantly surprising.

Kinds

Roofing metal is of several types. The basis for dividing into species is the material of which the profile sheet is made, and the geometry of the profile. The term "metal tile" is usually understood as one of the three common types of products.

- Aluminum profile the most lightweight. It is not subject to corrosion, therefore does not need protection against moisture. However, the material is too thin and soft, it needs to be reinforced with other materials. Its cost is higher than that of other species, so it is not widespread.

- Copper profile looks noble, but from contact with the environment is covered with a touch of different shades. Its regular cleaning and maintenance costs too much for budget material.

- Galvanized steel profile it is used more often than others, as the most reliable.To protect against corrosion, it is coated with aluzinc and polymers, which makes it heavier, thickens, and increases the cost of construction at the same time.

The range of steel profiles in color and design is the most diverse. The following profile types are encountered:

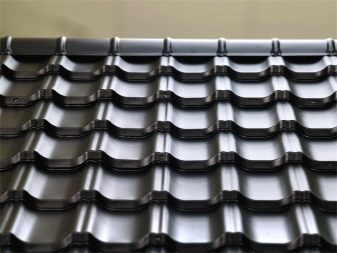

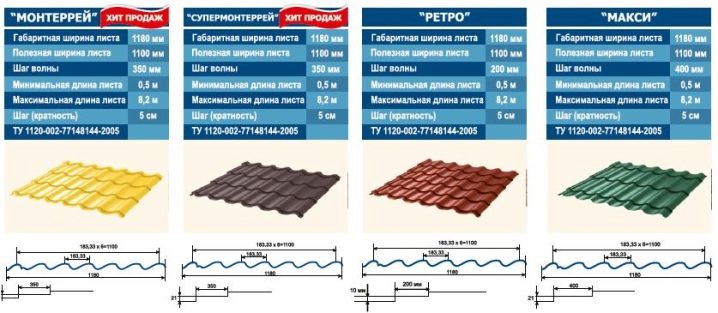

- "Monterrey" - is synonymous with the word "classic" in relation to metal tiles. The wave is smooth, glossy, in the color of natural clay tiles. The style is recognizable at first sight;

- "Kron" - this is a profile with a wave of different size and a sole. The corrugated surface is narrow, low, and the flat sole between the waves is wide;

- "Opal" - these are profiled sheets in which the width of a flat sole is equal to the width of a smooth semicircular wave;

- "Banga" - This is a design novelty among sheet tiles. It is made according to the technology of 3D-image - it has the highest wave and pronounced transitions;

- "Venice" - this is a beautiful large figure very similar to the profile of "Bang";

- "Shanghai". The pattern of this tile resembles a slender algorithm: a wide and high wave, two small and narrow waves on the sole, again a wide wave. Relief and unusual, although it does not look like a classic tile roof;

- "Spanish dune". The shape of the profile resembles a large tile;

- "Joker" - This is a profile with a concave rounded wave and high sharp edges at the junction of the waves. The roof resembles a wave of water, schematically conveyed in the figure. It looks like a classic: a small sole and soft waves imitating the cherished ceramic finish;

- Bavaria created using a special dyeing technology, which makes a flat metal-tiled roof look volumetric and natural, as if it is covered with small piece fragments;

- "Agneta" - it is a profiled material that consists of a narrow wave and a sole, but the sole is not just straight, but inclined to the right or left;

- "Country" - this is a tile with a minimum wave height;

- "Modern". A distinctive feature of the profile is a narrow wave with clear edges of the foam shape and a wide sole, concave inside the sheet.

Comparison with other materials

The metal tile differs from other types of roofing materials by different criteria. So, it is better than soft tile in terms of stiffness, but inferior to the same material in terms of sound insulation. It is cheaper than ceramic tiles, but more expensive than euroslate.

Comparing metal roofing with other types of roofing materials, they should be divided into two groups: soft and hard coatings.

Soft roofing

Soft coatings include: shingles (also known as bituminous), euroslate, onduvilla. Shingles in many ways inferior to metal. It is less durable and requires the installation of a continuous batten over the roof system. This is a time consuming process and an extra load on the structure. It leaves much to be desired resistance of shingles to environmental conditions. It deteriorates from humidity, ultraviolet rays, and severe frosts. When freezing the material becomes brittle, the upper layer cracks. Water gets into the cracks, and in a humid environment, mold and fungus develop, since the material is not biostable.

Bitumen refers to flammable substances. Soft tiles keep burning and release harmful substances in the process. Soft tile trim on 1 square. m is several times more expensive than steel. If we compare the positive characteristics, then there are aspects for which the metal tile is already losing: high-quality sound insulation and heat insulation, simple installation, elasticity, the minimum percentage of waste during installation of a complex roof. Low weight and wide assortment are the advantages inherent in both types of tiles.

Euroslate, better known on the market as Ondulin - is the main competitor of metal among soft coatings. According to some specifications, they are similar. So, both materials are sheet, have approximately the same weight and size. The service life of metal tiles is on average 10 years longer than that of ondulin. Both types of sheets support combustion and cannot be recovered after a fire.

Profiled steel sheets are superior to Ondulin in that the polymer coating retains the brightness of the color longer. The color scale of a metal tile is more various, than an ondulin.

According to some characteristics, metal tile differs from ondulin in an unprofitable way. So, the euroslate has 100% tightness, under it you can not mount waterproofing. Metal does not leak only the first few years, so without a waterproofing membrane is indispensable. Ondulin contributes to thermal insulation, steel sheets - no. Sound insulation of an ondulin is 15 dB higher, than at a metal tile. Differences between metal tile and ondulin are almost identical to the comparative characteristic with euroslate.

Hard coatings

Hard coatings:

- ceramic tiles;

- cement and sand tiles;

- professional flooring;

- slate;

- seam metal profile.

Ceramic tiles - This is a prototype of metal tiles. It has a small number of advantages. It is beautiful, resistant to freezing and fire, serves for decades. The rest of the modern material exceeds it.

Ceramic tile is assembled by hand from small clay plates. This is a long process requiring professional participation. The relief surface of the roof does not provide complete tightness, therefore it is necessary to install waterproofing and heat insulation. Tile heavy, gives a huge load on 1 square. m roof system. Ceramic plates are not resistant to mechanical damage. During installation, some of the material becomes unusable due to chipping and cracking. The total cost of material and work is many times higher than the cost of plating metal.

Cement-sand tile - This is a budget analogue of ceramic from natural materials. Like metal, it is presented in a wide color palette. They have the same long service life, biostability, extensive temperature range of use, virtually zero water absorption.

Natural tile does not rust, unlike metal, provides better noise insulation, is mounted with a minimum amount of waste (no more than 5%).

The disadvantages of natural and absent in metal tiles are the following:

- piece material;

- Mounted long, neatly and only by professionals;

- big weight;

- high price for materials and installation;

- low mechanical strength and associated transportation difficulties;

- limited variety of shapes and colors.

Slate is similar in characteristics to natural tile. With metal, this material is related to the size of sheets and good sound insulation. Otherwise, it is inferior to modern material due to the large weight, lack of aesthetic qualities, fragility and permeability. As for burning, slate uneasy supports it, but also explodes in the process.

Faltsevy roof, professional sheet, metalprofile - This is a group of materials that differs in the method of fixing and profiling sheets. In this regard, they have some external differences. And also varies the thickness of the sheets and the composition of the coating.The metal tile in comparison with all sheet materials from steel looks more interesting. In the rest of the professional sheets and metal tiles are interchangeable.

Specifications

The advantages of metal provide its technical characteristics.

Weight

The specific gravity of the sheet affects the way of transportation and the degree of complexity of installation. And also it shows what load the total weight of all sheets of plating gives. The norm for sheets of different thickness is regulated by GOST. According to the standard, weight is measured in kilograms per square meter. For thin sheet metal, it is 4 kg, taking into account the tolerances of the up or down. For thicker sheets (0.4-0.5 mm) per 1 square. m accounts for a load of 5 kg / m².

Sheet, custom-made for non-standard parameters, weighs more than the material according to GOST.

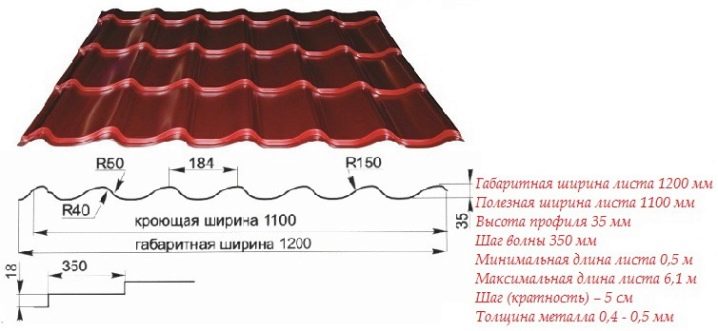

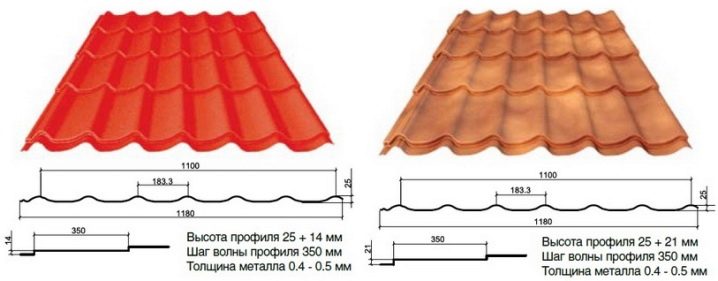

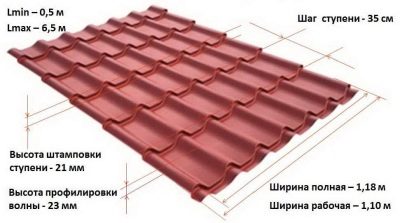

Dimensions

With regard to the size of the sheet, important overall parameters before installation and the usable area after laying on the roof. Since the sheets overlap each other and fit the pattern, the effective area decreases on all sides by the total amount of overlap. Standard sheet width can not exceed 120 cm.Before the compression procedure (wave formation), all sheets are 125 cm wide. They are compressed proportionally to the height - the greater the height (length) of the sheet, the smaller the width. The minimum value for a typical sheet is 110 mm.

Sheet heights are often cut to order for a specific roof size to minimize the amount of material waste.

Standard length too. It is determined by the size of the wave and is in the range of 50–365 cm. The width of the wave can be different, from 10 to 35 cm. The typical wavelength (distance between rows) is 35 cm. The width of the overlap is 10–15 cm. Accordingly, the useful area of the sheet It is reduced by 10–30 cm, and the average is 1.1 m².

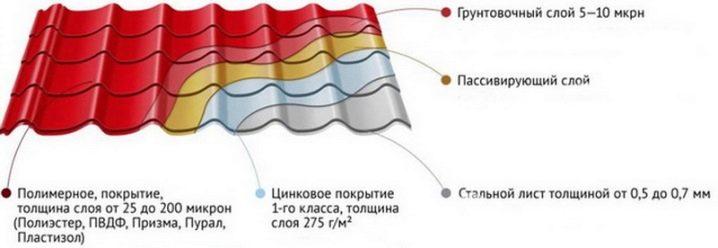

An important parameter is the thickness. It depends on the strength, resistance to mechanical stress and the ability to withstand a lot of weight (for example, snow masses), while maintaining its shape and tightness. The thickness of emit sheets economy, standard, premium. Economy have a minimum thickness of 0.33 to 0.4 mm. A standard or general purpose metal tile is 0.4–0.5 mm thick. The premium is distinguished by the highest indicators in this parameter - 0.5–0.9 mm.

Forms

Under the form of metal tiles imply a profiling pattern. Wave metal is square, rectangular, round.

- The square is distinguished by low waves, beautiful, sharp, clearly defined edges of the profile.

- The rectangular has a brighter shape and elongated upward shape. It can be both low and large, with a pronounced relief.

- Round is of two types: convex and concave. When the convex profile alternates high waves with a smooth, rounded ridge line. With a concave sheet of metal, it resembles a wave with a ridge pointed at its highest point.

Life time

Duration of operation of metal depends on the finishing coating of profiled sheets and environmental factors. The longest service life of sheets with plastisol coating. 50 years is a non-random number that should impress customers, and the real warranty period from the manufacturer.

The second place in terms of resistance is occupied by a polyurethane coating and PVDF (a substance based on vinyl). Their persistence is measured in 30–40 years. Other types of coatings can serve up to 30 years. In this case, the manufacturer gives a guarantee only for 10.

Lifetime can be significantly reduced if you buy a tile in advance and store it in inappropriate conditions. The metal tile will become useless if:

- to store material in the winter and in the summer outside, but not indoors;

- keep it under direct sunlight;

- contact with aggressive chemicals;

- do not protect from rain, snow and freezing;

- to store material in packs, not on logs, but on the ground.

Noise insulation

Thermal insulation and sound insulation are the weak points of the metal tile. The material has good thermal conductivity and does not drown out, but, on the contrary, enhances the sounds. Silent roofing with the use of metal tiles will not work, even if you mount the acoustic membrane between the steel sheets and the batten.

Other features

- Permeability Due to the polymer coating, the material simply repels water. It does not protect against leakage. The leakage is formed at the attachment points of the nails (self-tapping screws), when the rubber gasket wears out and ceases to create a sealed seam.

- Strength. The metal tile can withstand loads of up to 400 kg / m². In winter, two adults of average size can throw snow from the roof. The metal tile on the correct crate will withstand this load.

- Fireproof. The metal does not burn to +600 degrees, but the polymer coating supports combustion and melts.

- Electrostaticity. The roof of the metal can accumulate charge. This represents a danger during a thunderstorm, so the presence of a lightning conductor is mandatory.

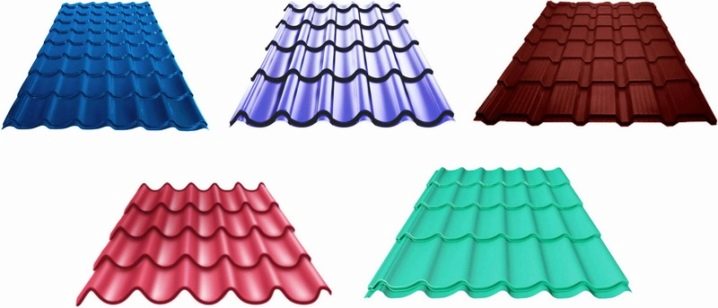

Colors

The color of the coating of metal depends on what color the coloring pigment is added to the composition of the protective coating, and on what technology the surface is painted. The choice of colors is influenced by several factors: individual preferences, the design of the facade and the color of finishing materials, the location of the house relative to other objects on the street. The last factor may seem dubious, however, how the house fits into the surrounding landscape is very important.

Manufacturers offer a wide range of colors to choose from. The colors correspond to the selection of the Ral catalog.

Ral is a German color standard that provides uniformity of shades of finishing materials. Thanks to the universal palette, you can use materials from different manufacturers for decoration and repair, and they will match as much as possible in color.

- Brown. It is a metal tile of a noble deep shade.Light brown color is usually not released. A dark brown tile is presented in the color of "bitter chocolate", which harmoniously combines with shades of dark and light spectrum for the decoration of the facade.

- Green Dark and rich, almost emerald roof is a sample of the classic use of greenery in the decoration of the house. It looks harmonious due to the fact that the color is natural, well combined with the natural landscape. It is combined with different shades and textures: brown wood, white plaster, red siding and others.

- Green moss Unlike the green metal tile, the material in this color is lighter and calmer, closer to pistachio and light green.

- Blue Difficult in terms of design, but very beautiful color. Often it is also called the color of the Berlin blue. It is in harmony with the natural landscape and light colors in the decoration of the facade.

- Terracotta. In the perception of the Russian consumer - it is orange. Very optimistic and eye-catching color. For the combination of suitable green, blue, gray color in the decoration of the facade.

- Red One more kind of color traditional for roofing material.It is universal for combination with different textures and materials, be it siding, plaster, wood, paint or glass.

- Black The color in the catalog is saturated blue-black, completely unusual for the Russian regions. The black metal tile looks good on wooden houses and in combination with the modern style: a lot of metal, glass, reflective surfaces and stone.

- Gray. The hue is less aggressive than black with respect to design stereotypes for exterior trim. Light graphite is a fairly saturated color. Often gray metal tile is dull, so it looks like a soft roofing. Almost any color range is suitable for the combination: yellow, green, blue and others.

- Cherry. This is a more modern and playful version of red tile. It can be used both in classic combinations and in more daring. For example, tiles in cherry color and light pink house facade.

- Beige. This is a rarely used type of metal tile. It is difficult to combine it with the finishing of the facade so that the roof is not “lost” against the background of the surrounding colors. Happens more and less saturated colors, from ivory to ocher.Light color and warm shade contribute to the improvement of thermal insulation, because it absorbs the sun's rays. At the same time, the light color burns out more slowly.

- Copper. Another decorative option is copper staining. And also there are roofing sheets of silver and steel shades.

- Multicolor. These are options in bicolor or painted by 3D technology. They mimic the presence of shadows and highlights on the surface of the waves, which makes them look more like ceramic tiles.

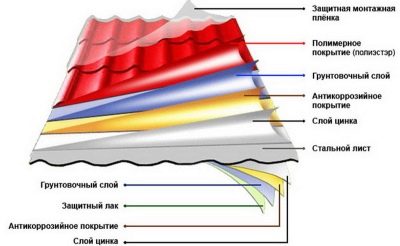

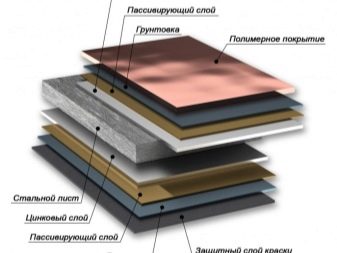

Composition

Thin-looking sheet metal in fact consists of at least six layers. The layers are “built up” not only on the front surface, but also on the “inside”, which lies on the batten. This ensures durability of the material. So, It is worth selecting a few layers.

- Metal base. It can be aluminum, copper galvanized steel or composite materials. If you need the most durable roof, galvanized steel is used. For moisture-resistant metal tile choose aluminum. For beauty - copper.

- Zinc shell. Sometimes used aluzinc. This layer is applied on top and bottom of the sheet in order to reduce the likelihood of rust when the polymer layer is damaged.

- Passivating. It is not present in all types of metal, but only in dense and expensive. This is an additional protection against corrosion. It forms a thin film that reduces the intensity of chemical reactions and the formation of rust.

- Primer. It improves the adhesion of the polymer layer to the base.

- Finishing sheeting. From the bottom side - it is paint. It is evenly distributed over the surface of the sheet by spraying. On the front side - this is a polymer coating.

Some decorative coatings have a name. It, like the color in the Ral catalog, means a specific type of surface: smooth, textured, matte or glossy.

There are several types of coverage.

- Polyester. Cost-effectiveness is the predominant quality. It retains color well, is characterized by flexibility and biostability. With a small thickness of the layer, it is scratch-resistant. There are two varieties: matte and glossy. Teflon is added to matte to create a velvety effect. This increases resistance to UV light, mechanical damage and difficult weather conditions. Consequently, the service life increases.The matte surface is covered by Cloudy, Matt, Safari. The glossy surface of the metal with polymer coating - Unikma, Satin, Still Silk, Finnera.

- Polyurethane. It is applied in a thick layer, therefore, has high rates of color fastness, mechanical resistance and anti-corrosion properties. Polyurethane is coated with Agneta, Prisma, Pural, Purman, Quarzit.

- Polyfluoride. It is made with the addition of acrylic and high quality pigments. Its main feature is color fastness. As well as pigments give shine, and lacquer coating makes the surface glossy. It can be produced with decorative chips in the composition. Often polyfluoride tiles are made, imitating copper or steel sheets of silver color. The surface of the sheet is smooth, for example, Norman, Atlas, Velur.

- Plastizol. This is high quality material. It is resistant to difficult weather conditions, often has a relief and texture, and due to this it retains its color longer. To textured and structural coatings belong Viking, Drap, Velvet, Safari, Purex.

- Pural This is a solid, hydrophobic, durable plastic sheath with the addition of polyamide. It is characterized by a wide range of temperatures, resistance to mechanical damage, color fastness and a long service life.The surface of the material is beautiful, matte and velvety in appearance.

Production

Metal roofing is done on fully automated production. The technology is phased. Each stage is accompanied by a control, so the output is a high quality product. Cold-rolled sheet steel is used as a raw material. The thickness of the sheet before the application of protective layers on it varies from 0.35 to 0.7 mm. The thicker the sheet, the higher the quality.

The technological chain of metal tile production includes the following steps:

- rolled steel sheets;

- application of protective anti-corrosion coating. Used iron, zinc, aluminum, silicon. Aluminum is applied in pure form or combined with one of the auxiliary elements;

- polymer protection coating;

- sheet profiling. Due to the fact that the sheet takes its final shape after applying all the protective coatings, the thickness of the coating on the whole sheet is the same. This provides reliable protection from exposure to the external environment;

- cutting. In fact, it is carried out by the same rolling mill that forms waves on the sheet.It is carried out according to the standard and by the individual order;

- after the final stage, metal-plastic tile falls on the packaging and is completely ready for use.

Manufacturers

Metal tiles first appeared in Finland. Today, after almost 40 years, factories for the production of this roofing material are located in Europe and Asia. There are in the list of bona fide manufacturers and domestic factories.

The rating is headed by imported brand products. Ruukki. This Finnish manufacturer actually stood at the origins of the production of metal tiles. Product quality has consistently increased with experience, so products receive well-deserved positive feedback. The price per square meter is higher than that of Russian manufacturers, but it pays off with quality. In no way inferior to other Finnish brands: Weckman, Takotta, Rannila.

Popular metal tile Arcelor Belgium produces, purchasing high quality steel from European manufacturers. The material is fully consistent with the standards adopted in Russia. It is characterized by a high zinc content in a protective anti-corrosion layer and different versions of the polymer topcoat.

It is the Arcelor tile of the Belgian production that the popular Cloudy tile with a matte and glossy surface is represented on the domestic market.

Another type of material supplied by Europe is the Swedish metal tile. Mera system. The manufacturer successfully combines the classic form with new technologies when applying a protective coating. Sweden and Germany also have branches of Arcelor shingles production. Pleasantly surprised by the price and quality of the Polish metal Blachotrapez. In addition to all the advantages of roofing material, it also has protection against the accumulation of static energy. This is convenient since it is not necessary to install a lightning rod.

Russia leads the construction materials market in terms of the percentage of domestic and imported goods on sale.

Many consumers choose metal roofing of Russian brands, since the metallurgical production in Russia is at a high level, and this ensures a supply of high-quality raw materials at factories. A plus is considered a lower price, which does not include customs tax and overpayment for the brand. Popular brands are VikingMP, TechnoNICOL, Unicma, Severstal, Quarzit. Lead, of course, Grand line. It is this manufacturer that supplies metal roofing to the market. Kvinta with a unique wave form and materials with different coatings - smooth “Steel silk” and textural “Steel velvet”.

Owner reviews

The effectiveness of the use of metal tiles and the status of manufacturers confirm the reviews of those who checked the properties of the material in practice. Mostly positive reviews. Professional roofers unanimously note the practicality of the material and its high quality at a relatively inexpensive price.

Homeowners who have not worked with the material with their own hands, mostly praise a beautiful result. The roof looks neat and aesthetic. The material is universal for combination with any kind of finish, the main thing is to choose the appropriate color. Persistence of color is also counted among the merits. Among the reviews there are data on the service life without complaints from 2 to 20 years.

Negative comments are often associated with difficulties in working with the material. Without minimal experience in roofing, it cannot be properly laid the first time.Difficult elements are especially problematic: endy, skates, gable. As a result of the sheathing of a complex roof, there are still a lot of scraps that have nowhere to apply. Not justified in practice and the statement that the metal can be painted. Its top layer repels not only water and dirt, but also paint. Opinions about the noise generated in the rain, diverge. Owners of houses without additional insulation under the rafters feel discomfort. In the presence of soundproof material, noise in the house is not audible.

How to choose?

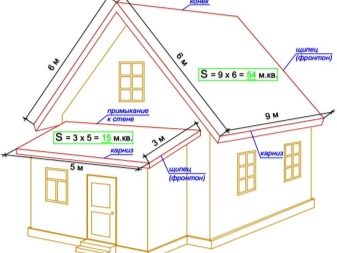

Before the start of roofing work, two more important tasks need to be solved. The first is to calculate the amount of material, and the second is to choose metal roofing. Correctly calculate the materials will help online resources, which need to enter data on the area of the roof. The alternative is manual calculation. But the most reliable solution is to entrust measurements and calculations to a professional roofer.

But the choice may be more difficult. Manufacturers produce more than 300 types of metal tiles! In order not to get confused, experts recommend answering a few questions.

- What color tiles do you need? This question will help flip away more options at once. There are only 4 primary colors, and they are universal. Green, chocolate, brown and the color of wet asphalt (graphite) are combined with most of the colors in the facade. The rest of the palette for lovers of bold design.

- Smooth or matte finish? This is not only a matter of aesthetics, but also a certain quality. Due to the top coating, matte tiles are of higher quality, durable and resistant to corrosion.

- What type of profile is needed? The profile does not actually affect performance. It is important to take into account only the fact that the simpler the drawing, the easier the installation and the less trimming. In order to save, it is recommended to choose the most concise profile. If this goal is not worth it, the choice is based only on taste preferences.

- What is the service life of a metal tile? For outbuildings suitable material with a service life of two years, for a residential building - from 30 years. Of all the types of material that have been selected by color, texture and type of profile, it is worth choosing the material with the longest service life. This factor should by default include the maximum thickness of the steel sheet, the optimal type and thickness of the anti-corrosion coating, and the most durable polymer coating.

Installation instructions

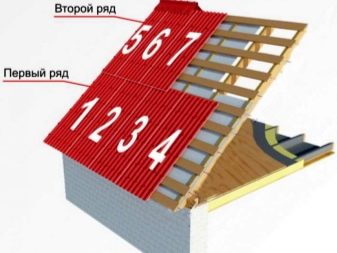

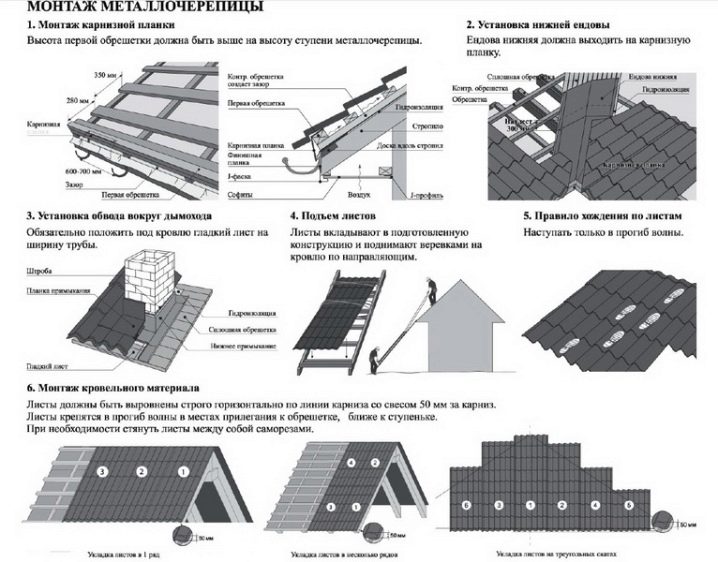

The metal roof covering passes only a few stages, such as.

- preparatory work is the choice of tools and weather conditions, surface treatment of the old roof or roof system;

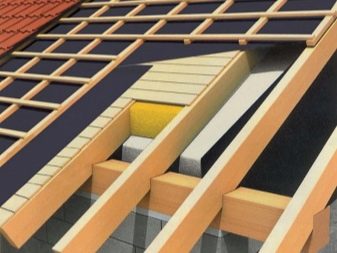

- installation of the batten;

- waterproofing and sound insulation of the space under the roof;

- preparation for installation of complex elements: chimney, ventilation system, protruding elements of the roof;

- installation of sheets and accessories.

In practice, it is very difficult to perform these steps yourself. You need to know the features of working with metal. They include the rules for handling the material, the rules for mounting, cutting, bypassing various obstacles and fixing components.

Experts recommend sticking with the following features when installing tiles:

- Basis in the form of crates is not universal for all types of material. For strong sheets, you can use a sparse frame, and for thin sheets a solid crate is better suited;

- waterproofing and insulation of waterproof materials are required for any type of metal;

- Better than conventional waterproofing can only be a special wind and moisture-proof basis.Roofers often use izospan and membranes;

- A vapor barrier is needed only if there is a living space under the roof, since the metal is very hot in hot weather;

- A film is used as a waterproofing, between it and the material there should be a small gap for air circulation. It is impossible to lay on roofing felt or lay on the metal tile only, since the materials absorb moisture and heat up, releasing harmful substances;

- for the same reason, when heated, bitumen or other substances are released, therefore it is impossible to lay metal tile on a cathepal (soft tile) or mount it on Ondulin without wooden lathing;

- putting steel sheets on the old roof with a similar finish would also be a mistake - the house will turn into a drum droning with wind and rain;

- atypical roof assemblies are only connected with custom-made elements. Standard ones are not suitable for them;

- connections in difficult areas, for example, between apron parts around the chimney, must be additionally treated with a sealant to avoid leakage;

- when laying metal tiles need lightning protection (lightning conductor).

These are just some of the nuances of working with a metal tile. If there is no idea what the correct step of crate is, what is needed for filing curtain eaves and how to mount the gutters so that the water flows into them, you should entrust the work to professional roofers.

Beautiful examples of houses

The roof of the metal should be beautiful, not only by itself, but also in combination with the decoration of the facade. Exterior design specialists know several win-win combinations based on color and texture.

- The first technique is to use two shades of the same color or similar colors in the decoration. This principle combines, for example, a light blue tint and Prussian blue, purple and cherry.

- The opposite technique involves a combination of contrasting colors. The signal blue color of the tile perfectly harmonizes with the yellow facade of the sandwich panels or orange plaster. The black metal tile will make more daring and stylish facade in red, white, lemon and brown color.

- Looks beautiful difference in textures. The combination of glossy tiles in the classic Monterrey profile will revive the half-timbered prefab house.A copper-red metal tile with a soft and wide wave will support the rustic style of a log house. The brick facade is perfectly combined with the profile, whose wave width coincides with the width of the brick. Smooth-walled facade looks beautiful in combination with absolutely any type of profile. The main thing is that the substrate above the smooth facade should have a protrusion and demonstrate an unusual finish, then the house does not look dull and modern.

How to install a metal tile, see the following video.