What are the sizes of metal tiles?

Metal tile is a modern material that is suitable for roofing. These sheets of metal are prepared by cold stamping. Galvanized steel or copper is used as a base in enterprises. The base is covered with polymers that protect the sheets from the harmful effects of precipitation.

Special features

More and more users are interested in the quality of shingles. Sheets of a metal tile are suitable both for private, and for individual construction. However, some people do not take into account this material because of the mass differences between similar products. For example, besides technical characteristics, the length and width of not only the sheets themselves, but also the waves, differ. Wishing to improve the coating attracts the durability of the material, its light weight, high strength.The structure with a metal tile, becomes elegant and presentable.

You should consider the technical features of the material in more detail. If we take the initial stage of development of the workpiece, then in production it is represented by a steel sheet with a thickness of 0.4–0.5 mm. Several layers of spraying are applied on the sheet on both sides of the product. The first layer is galvanized. The service life of the metal tile depends on the thickness of the zinc coating. The second layer is an anti-corrosion coating, including durable phosphates. The third layer is the primer and then the finish paint is applied. Sheet metal acquires the shape of a tile due to rolling under special machines.

Thanks to multi-stage processing, the coating acquires characteristics that are superior to other roofing materials. For example, the stiffness of metal tiles is higher than that of slate, and even ordinary tiles. This is achieved thanks to the existing stiffeners. Correctly installed sheets can withstand a load of more than 200 kg / m². The thickness of high-quality fabrics should not be less than 0.5 mm. The advantage of metal sheets of tile is the possibility of laying the material yourself.In the absence of skills, you can inexpensively hire a special team. The material is durable and resistant to temperature changes.

The material is relevant due to the following technological advantages:

- the life of the product reaches fifty years;

- there is a possibility of using at temperature drops from -50 to +120 degrees;

- there is a possibility of use on all types of roofs;

- lightweight material is also an advantage;

- attractive appearance;

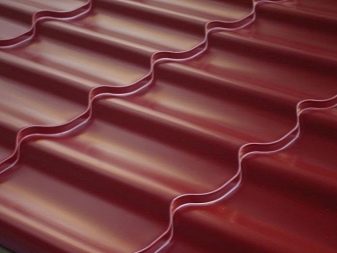

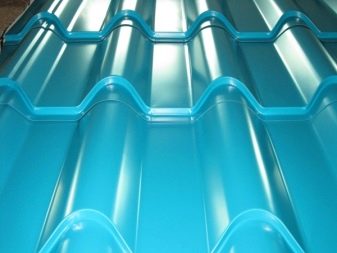

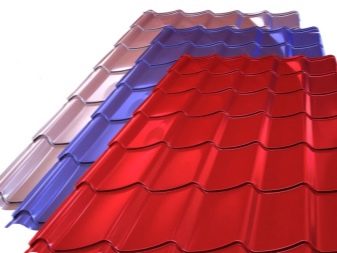

- a wealth of color;

- availability of price.

The last aspect is directly related to the used coatings on the production. One of the features of the material is a wide variation in prices for products. When choosing products, experts recommend not to save. A quality product will significantly increase the life of the roof. When buying cheap analogues it is worth bearing in mind that the service life of such products is usually less. Another disadvantage of inexpensive products is the increased noise level during mechanical impacts on surfaces (for example, in the house you will hear rain drops falling on the roof). The problem is solved by installing an additional protective layer between the crate and the sheets.But this ultimately increases the cost of installation and materials.

Types of material

Types of metal can be divided by the materials used in the production.

Steel sheet often serves as the basis for the finished product. Sheet thickness is from 0.45 to 0.55 mm. Zinc or aluzinc may be applied over the steel sheets. Zinc coating is good protection against corrosion. Alyutsink are considered more durable, but the price of products is usually higher.

Aluminum sheets used in the production of metal, do not need protection from corrosion. The additional primer affects the durability, and therefore the life of the products. One of the positive characteristics of products is lightness. However, aluminum tile is not characterized by a very wide range of colors.

Copper products are notable for their noble appearance. Sheets of copper tiles look especially elegant over time, when a patina of greenish patina appears on them. It, by the way, is additional protection against bad weather. So, the copper metal tile is not covered with additional polymers. However, the extremely high price of copper products leads users to look for other alternatives.

In addition to the material of manufacture, the types of metal can be divided by geometry and depth profile. For example, the so-called profile "Monterey" came from Finland and in appearance is very similar to the clay equivalent. The tile "Monterey" most fans, usually it is more expensive in terms of cost. The popularity of the material is associated with the ease of its installation, excellent protection from natural disasters. In appearance, this metal tile is easily recognizable, despite the fact that the products of different brands are similar.

Profile "Cascade" resembles the outer shapes of a chocolate bar. This tile is attractive severity of rectangular shapes. Its advantages are appreciated by the owners of houses with complex roofs. The roof with a tile "Cascade" turns out accurate and proportional. "Cascade" is suitable for buildings of the classical style, which is always in fashion.

Joker profile - This is the embodiment of the illusion of ceramic tiles. Sheets are distinguished by a traditional rounded ridge part, as well as a flat plantar part. Sheets of the classic size can be used on both complex and simple roofs.

Profile "Banga" - this is a new, modern, characterized by the originality of forms. The profile structure is distinguished by an increased height, due to which the illusion of a three-dimensional image appears. The small width of the metal of this type only adds advantages. The most spectacular of all this option looks on the roofs of tall houses.

The entire species series of sheets is widely represented on the Russian market. Popular is the Swedish tile Mera System. Modular positions provide ample choice. There are also many products from other companies on the market.

Purpose

The metal tile, first of all is a roofing material. It can be used under different climatic conditions. Manufacturers retain warranty obligations when using the material at temperatures from -50 to +50 degrees. At the same time, environmental conditions are desirable non-aggressive or slightly aggressive. Other conditions can be applied material, but treated with special coatings.

Manufacturers also recommend that you strictly follow the installation rules when covering the roof. For example, if the roof is hip, installation is recommended from the eaves.If the roof is gable, work should be started from the end. In this case, sheets can fit both from right to left and from left to right. Endows, end and ridges are mounted last. It is recommended to protect the places of cuts and holes by additional staining. For laying metal it is important to use special tools.

According to the principle of installation material is divided into two types.

- Sheet. It is mounted in the same sheets, the length of which is usually equal to the length of the roof slope.

- Modular. Sheets are mounted with the same modules. The equal area of such modules allows avoiding waste on the roofs of complex configurations. The scope of this material is diverse: both private and industrial construction. The material is used for both public and residential buildings. It is characterized by versatility, since it can be used on the roofs of buildings with any number of floors.

The only limitation in use is unwanted cutting of sheets. In this case, the integrity of the layers is violated. On the ground cut often forms corrosion. To avoid cutting, experts recommend combining different dimensions.

Standard sheet sizes

At the moment, a sufficient number of manufacturers of metal. Large and small companies produce material with several excellent dimensional characteristics. Therefore, the product of different brands can not be combined on the same roof. The accuracy of technical standards is ensured by industrial scale production.

Small companies do not always offer material of appropriate dimensions. This data is very important, as the useful and actual dimensions of the sheets differ. Typically, manufacturers offer to study the overall parameters in the form of a table, which includes the entire existing range.

Despite the huge number of manufacturers, most of the metal is made on similar equipment. For works, standard sheets with a width of 1115–1190 mm are used. Technological maximum width is 1180 mm. Especially large variation in overall parameters is observed in foreign manufacturers. For example, the total length of sheets of material from the Swedish company Mera System is 3620 mm, the useful length is 3500 mm, the actual width is 1160 mm, and the useful length is 1080 mm.The metal tile of the Grand Line company has a total length of 3,630 mm, and the useful one is 3,500 mm, the total width is 1,160 mm, and the useful length is 1,110 mm.

The calculation of material consumption is carried out from the working dimensions, as the installation is carried out with an overlap. One panel slightly overlaps another. This installation allows for greater tightness. Improved material resistance to snow and wind loads. The amount of overlap is often associated with the slope of the roof. Usually it is about 60–80 mm. With a slope of more than 15%, the overlap is 100-120 mm.

Significantly reduces the amount of waste when laying a choice of sheets of different sizes, but of the same type.

If we consider the sheets "Monterey", then on sale you can find options with the following values:

- length - from 0.5 to 9 m;

- width - overall parameter - 1.18 m, useful - 1.1 m;

- wave step - 35 cm.

The length of metal tiles varies considerably, as manufacturing companies often offer products to order. Long sheets make assembly much easier. Some difficulties may appear during transportation and when lifting material to a height.

Too long sheets are often deformed during the installation process.Experts do not recommend ordering sheets more than eight meters. For wind strips it is better to make separate parts.

Parameters of additional elements

The presence of quality, purchased in sufficient quantity of roofing material is not enough to create a reliable roof covering. Details such as additional parts are important. They also need to be able to choose and mount. Parts are usually selected in the same tone along with the base material. Functions of additional elements are protective or decorative.

All joints are formed with protective components, joints and joints are strengthened. Protective elements do not allow water and debris to get under the roof. Decorative components give originality. Thanks to them, the roof becomes more attractive.

A set of parts varies depending on the coating used.

Together with metal usually buy the following parts:

- frontal slats are part of the protection of the end of the roof;

- the adjacent plank is also an element of protection for the parts adjacent to the chimneys and parapets;

- roof ridge is an element of protection of joints and slopes;

- Endovy is a security feature that redirects rainwater flows;

- adapters - needed on non-standard roofs;

- drains are an element of protection;

- snow holders are also an element of protection.

The manufacture of additional elements is usually individual. These often include spiers, weathervanes and other decorations. They do not carry functionality, they are decorative elements. Before acquiring certain items, it is important to make calculations. For example, a wind vane can be installed not on all roofs, since the location of the element must be taken into account.

To eliminate unnecessary spending, it is recommended to buy protective components from the same company from which the roofing material was purchased. A one-time purchase of all parts will save on the services of transport companies. Experts do not recommend saving on the quality of additional elements. In addition, the important quality installation of these products. Therefore, do not forget to purchase mounts. Modern fastenings of additional elements are bolts, screws or screws with gaskets, but in no case nails. The last option of fastenings will spoil any, even the most qualitative roofing.

The parameters of the additional elements are always interrelated with the specific configuration of the roof. In most cases, the installation needs a special project. It will allow you to optimize costs and select the exact number of components for a particular roof.

The total number of finishing elements is calculated from the total length, for example, of the skates. All lengths, where they should be fixed, are added, still have to take into account overlaps. Elements such as snow catchers and other items are purchased according to the required quantity. The required amount is related to the configuration of the roof. Fasteners are purchased at the rate of about 8 pieces per square meter. For additional elements, the standard fastening pitch is taken into account - 12–15 cm for one screw.

How to optimize costs: recommendations

Since metal tiles can not be cut, you should take into account the useful recommendations of professionals. They will help to optimize costs when buying material. Roofing is an expensive service, but you can save on it by making independent calculations.

First you need to determine the area of the slopes. Measurements should be made on the finished truss system.When using design figures, deviations of indicators are possible. The roofs of houses are different: single, double gable, three slope, hip. For the sheets to be enough, but not too much will require measuring all the ramps. An assistant will be required for measurements.

The most economical and practical option of arrangement of the roof - it is shed. It is often used above garages, verandas and other outbuildings. Calculation on one slope is the optimal placement of sheets in all parameters of the design. Sheets with a length of 0.5 m to 3.65 m are suitable for such a roof. Installation of long sheets for such roofs is unprofitable, and very labor-intensive.

If a shed roof has the following dimensions:

- length - 10 m;

- width - 9 m.

9x10 = 90 m², 9: 1.1 (useful width of the sheet) = 8 rows, 10 + 0.3 (2 overlaps of 0.15 each) +0.1 (accounting for the height of the rafters) = 10.4 m (total length of the slope ); 10.4: 3.5 = 3 sheets in length; 3x8 = 24 sheets for 1 one slope. When it is impossible to pick up the sheets ideally, the trimmed ones hide with an overlap and close intact.

If the roof is gable, but with an approximate area of one slope of 90 m², the results obtained above can simply be multiplied by two. Total leaves 48 sheets on both ramps.If the number of roof slopes is greater and they are different in size, the calculations are made taking into account the area of each slope. Then the data of each individual part of the roof are summarized.

To calculate the total number of sheets, you should not subtract the area of the attic frames, pipes, ventilation. This extra margin in unforeseen circumstances will eliminate unnecessary costs. When laying metal tiles professionals do not recommend the use of trimming. This will reduce the quality of the coating, and thus reduce the operational time.

To learn how to make a roof of metal, see the following video.