Wind strip for metal tiles: types and methods of fastening

Roofing is an important element of every home. This design performs a protective function, preventing the destruction of internal materials under the influence of water and temperature drops. The quality of this system depends not only on the roofing material, but also auxiliary elements. One of these products is wind strip, installed on all types of pitched roofs. Consider its features, types and methods of attachment.

Features and Purpose

Metal tile - quite popular roofing material.It is used more and more often, as it is practical, durable and has unique decorative qualities. A mandatory element of such structures is the wind strip. It is used for metal tiles and other roofing materials.

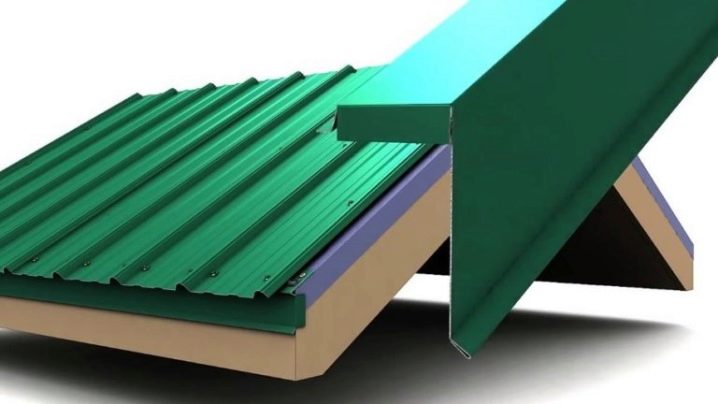

Planck is a metal flat plate, which is installed on the end surfaces of the roof covering. There are varieties that are L-shaped. It allows you to speed up and simplify the installation of the product.

Wind slats solve several basic tasks, which include protective and decorative functions. These designs prevent the ingress of moisture under the sheets of metal. Wind does not get into the closed ends, which can create an additional load on the sheets. This allows you to extend the life of the entire roofing pie.

The bar is chosen according to the color of the metal, which allows you to give the roof a beautiful appearance. Selecting a particular shade helps maintain the visual integrity of the structure.

Wind strips are used only on pitched roofs. If the structure is made of concrete, then its use is not necessary.

Species

The design of such a product is simple. Many manufacturers of metal provide an opportunity to purchase wind strips immediately with roofing material. Wind strips for metal used in various places of the roof. Depending on their place of attachment, there are 2 types of slats.

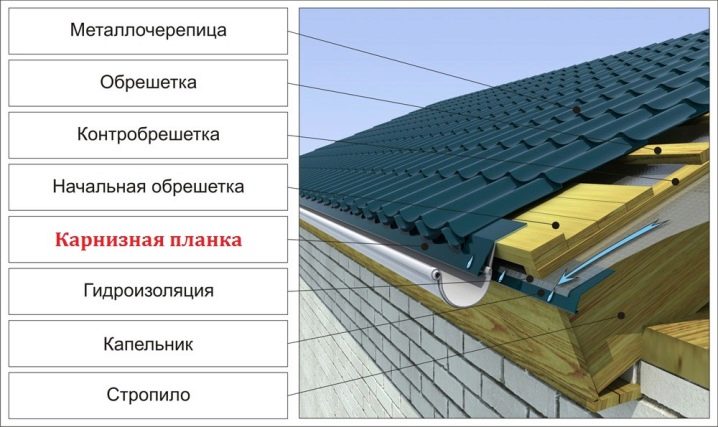

Eaves

The fastening of these elements is carried out on a protective board, which is called a frontal one. Eaves levels prevent moisture hit directly under a metal tile. This minimizes the risk of corrosion from the inside with frequent condensation.

Butt end

The gable structures are installed directly on the side surfaces of the roof (along the slopes). Their main purpose is to protect the roof from strong winds. To enhance such a system, they are supplemented with wooden elements that are located under them.

Both of these elements are almost identical. Sometimes they may differ slightly in shape or size.

When buying end strips should pay attention to the width of the sides of the corner. The wider they are, the better the product will be better able to resist external loads.

Specifications

Wind slats are thin sheet products of simple form. They are used for almost all types of roofing systems. The reliability of such products depends in most cases on the material from which they are derived. Today on the market there are several types of slats.

Metallic

Often they are made of sheet steel. This material is easy to process. Get strips on special rolling machines that can give them the desired shape. Sometimes on the market you can find options made of aluminum. They are not popular, as this metal is quite expensive. Metal protective systems do not withstand the effects of moisture, so they are all covered with special protective paints and solutions.

Plastic

The main raw material for the manufacture of wind slats is polyvinyl chloride. It is highly resistant to UV light. At the same time, the material is optimally light. But plastic is not as durable as metal, it is not able to withstand high loads. It is not recommended to fasten heat cables to such systems., because when temperature drops, polyvinyl chloride gradually loses its original properties.

Dimensions

Wind strip today released, according to modern standards. The width of one side is adjusted to the size of the timber. Therefore, this value varies in the range from 15 to 30 cm depending on the manufacturer and destination. Sheet thickness does not exceed 1-2 mm, which is enough to solve the most complex tasks. If you need products of non-standard shape and dimensions, you can order them directly from the manufacturer. However, they will develop certain modifications only with significant production volumes.

Mounting technology

Installing wind bars is a simple operation. To get a reliable design, you should follow simple rules:

- Eaves levels need to be fixed just before laying a metal tile. This is important because the roof completely overlaps the support beam after installation. It will not be possible to access it.

- The width of the slats is adjusted to the size of the wood. It is desirable that these elements completely cover the holes, preventing the ingress of moisture.

- End strips are mounted after laying the roof. These elements are located on top of the overlap. It is necessary to apply one bar to another with an overlap of not more than 50 cm.

The technology of mounting wind slats can be divided into successive steps.

Frame preparation

Often, the support act wooden boards. Some of them are fastened along the eaves, others are nailed along the entire end. The thickness of the board is selected individually. It depends on the type of roof and the strength of wind loads. Nail the wood to the crate with nails or screws. It is important to close the entire surface as much as possible so as not to get breaks.

Mount

Installation of slats by using self-tapping screws. It is important to use special fasteners that prevent moisture from getting under the caps, which can lead to the rapid spread of corrosion. If it is not possible to use such hardware, they can be replaced with ordinary nails. Eaves bar nailed to the frontal board. Before this, it is desirable to attach the suspensions under the drainage pipes.

Fastening the end strips after the installation of metal tiles involves the use of silicone sealant. They need to soak all the joints.This will not allow moisture to penetrate between the joints, remaining inside. Eaves levels can be connected with an overlap to 50 cm. Such approach allows to exclude cutting of material. This indicator for end products should not exceed 5 cm.

When installing the latest options, it is desirable to place under them sheets of insulation and waterproofing film. With their help, you eliminate the rapid destruction of the material, and also get a more hermetic and durable system.

When installing wind strips, special attention should be paid to the tightness of this design. Therefore, it is important to constantly monitor the quality of the joints.

Wind strips for metal tiles are important elements of roof structures. Their installation can be carried out independently. To obtain a durable and resistant roof, you should use only proven and high-quality materials. If you are not sure that you can do the installation yourself, it is better to entrust the solution of such tasks to a team of experienced specialists. They will carry out the installation quality and in a short time.

And in the next video you can see an example of how to fix the wind strips.