Snow shields for metal roofing: selection and installation

In winter, the snow layers on the roof are stacked on top of each other, becoming a serious problem. High pressure and heavy weight contribute to the rapid collapse. Ice lumps cause irreparable damage to cars, gutters, ornamental plants and even windows, not to mention the danger to people. Installation of snegozaderzhi - construction of the roofing type helps to eliminate the danger. To install them, you must have a clear understanding of the methods of installation and configuration features.

What it is?

Roofs of metal have a smooth surface that facilitates the slope of the snow layers down.When heated by the warm air of the bottom plate of the professional sheet, an ice crust is formed. Hardened snow during sliding leaves deep scratches on the surface of the metal tile. In the place of damage during the destruction of the galvanic protective layer corrosion is formed. To prevent premature malfunction and leaks in the roof use snow holders.

Their work is based on two principles:

Snow thrower. Snow blocking barriers are mounted along the slope on the metal tile. The shape of the snow barriers resemble the fence, stopping the sliding and descent of the snow layers. At the same time, it is necessary to periodically clean the roof of snow so that the accumulated mass does not contribute to the deformation of the roof and the building frame. Experts of the roofing craft believe that the installation of snow catchers justifies the investment only in the presence of high strength of the foundation and metal tiles that can withstand a heavy mass.

Snow plows. These designs do not hold in ice layers and do not require regular cleaning. Their job is to divide the snowdrift into several small-sized elements.Light parts do not cause damage and do not pose a danger to others. The main advantage of the device is the ability not to accumulate heavy ice lumps, which exert high pressure on the foundation and the roof frame of the house. Detailed annotation when purchasing allows you to install snow blowers under any slope.

The optimal choice of design for the retention of snow is carried out taking into account three main criteria:

roofing;

angle of slope of the roof;

the amount of snow falling in the winter season.

When purchasing a snow guard for metal roofing, it is recommended to pay attention to the principle of self-tapping screws. With a safe avalanche, divided into parts, it is possible to do without cleaning in heavy snowfalls.

Kinds

The device of work of snegozaderzhatel is based on the blocking and cutting properties. In both cases, structures require high-quality metal for manufacturing. In harsh conditions, each element is subjected to the pressure of a snowball.

The following types of popular snow holders are in demand in the construction market:

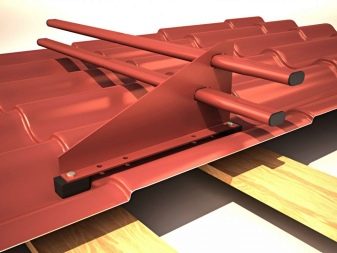

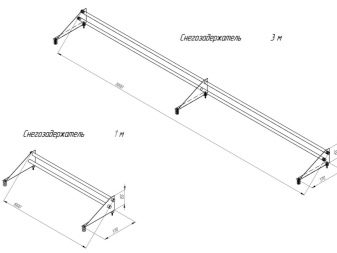

Tubular. The design is based on the connection of horizontal pipes with a diameter of up to 6-10 cm. The elements are fastened together with brackets and suffer installation in two rows along the roof. When passing through such a barrier, the snowdrift is divided into thin plates with a smaller mass. Partial gathering of snow ensures the safety of people passing below and does not overload the roof truss foundation.

Fixation of the tubular type of snow-cutters is carried out with the help of roofing self-tapping screws with a large length, as well as due to a special type of holders.

- Grid. This type is a lattice, fixed on the slope of the roof with brackets. The device helps to stop the snow layer, which under its own weight passes through the holes in the grid in small portions. In this case, the closer the rods are installed, the less snow will fall down. Ice and snow drifts of large masses remain on the grid, waiting for periodic cleaning.

Manufacturers of the design recommend to mount the device details on the roofing surface with a slope of 35-45 degrees.

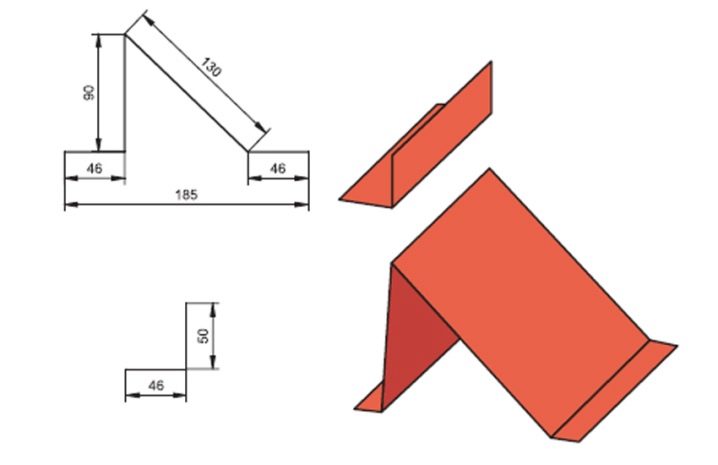

Corner. They have the simplest configuration to contain ice masses on an inclinedroof surfaces. Corner snegozaderzhateli are metal corners, made of stainless steel. Painting is carried out in the color of metal. The cost of one item ranges from 100 to 150 rubles, which can afford any owner of the site. Ribbon corners stretched from two or more rows in a checkerboard pattern.

It is possible to make a construction with your own hands in the presence of a metal sheet and the necessary tools. It is important to remember that the efficiency of the corners increases only in combination with the tubular and lattice type of products.

- Lamellar. Made of monolithic plates. Belong to the structures of the barrier type. Designed to hold the snow mass on the roof of the roof until complete melting. Installation on steep slopes of 50-60 degrees is prohibited, as the plates are not able to withstand high pressure of ice floes sliding at high speed.

Bend quickly and can damage the roof covering, aerator, ventilation pipes.

The cost of the demanded snow holders of tubular and lattice type of standard length of 3 m reaches 1000-1500 rubles.When installed on the entire perimeter of the roof, this can significantly hit the wallet. Therefore, experts advise to install protection from the descent of the snow mass only over the places of increased danger: above the parking lot, lanes, porch.

Tubular

The tubular type of snow catchers justifies its name. The design consists of several pipes of high strength, fastened together with special fasteners. In this case, the manufacturer does not use a round section type. Most often make oval pipes.

The configuration is not monolithic, which allows the device to pass through a certain amount of snow mass. Tubular snegozaderzhateli reduce the kinetic energy of snow when the ramp from the roof, minimize damage and the formation of corrosion. At the same time, the design does not allow a large snowdrift to slide, cutting the whole ice crust into small elements.

Construction features:

number of pipes - 2;

pipe diameter - from 1.5 to 3 cm;

the number of fasteners (brackets) - 2-4 pieces;

pipe length is up to 3 m;

construction height reaches 15 cm.

The basis of the manufacture of the device includes galvanized steel. To create a decorative layer, a high-strength paint with a long service life is applied to the surface. Painting also performs a protective function - the protection of the snow cap from climatic conditions. The hue of snow cutters is recommended to choose on the basis of the tone of the roof of corrugated board.

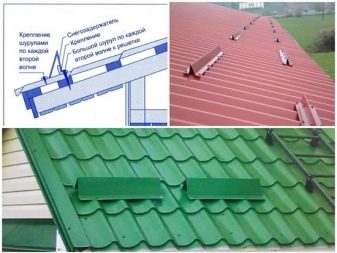

Brackets are used as fastening systems. Parts are supplied with special screws that carry out the installation of the structure. The installation of the first pipe at a distance of 2-3 cm from the edge of the roof helps to increase the functional efficiency. At the same time, it is necessary to keep the distance between the pipes up to 10 cm. Such parameters allow to achieve the maximum structural strength that can withstand high loads.

Tubular snow blowers are able to withstand installation even on a metal roof, where the angle of inclination of the roof reaches 60 degrees.

Tubular snow protectors are in demand on the construction market due to their reliability. The configuration allows to withstand the high pressure of the ice mass when using a pipe with an oval-shaped profile.Other types of pipes have lower efficiency, as they are subject to imminent deformation under heavy loads. Tubular snow cutters are installed not only on metal tile, but can also be mounted on corrugated, bitumen and natural tiles.

Installation is a single along the slope of the roof. In dangerous places - the edge of the roof over the pedestrian road, parking the car or over the porch, it is required to make an additional protective installation. In this case, the installation of snow cutters is carried out in two rows. In this case, the distance between them reaches 2-3 m. The fixation of the first row occurs at a distance of 40-50 cm from the eaves edge.

The choice of product when buying directly depends on the ability to withstand the high pressure of a snowdrift. At installation it is required to provide tightness of a design.

Latticed

Snegozaderzhatel consists of sections-lattices of various versions with special mounting brackets. The design differs in the main parameters: height, shape of the profile, purpose and length of the holes. Fixing on the roofing surface is carried out thanks to a system of brackets in a vertical plane.Installation under the ventilated ridge of a soft roof is possible, as well as wall installation. You can increase the length of the product by joining several sections with each other.

All parts are made of galvanized steel, which gives reliability and increases strength. However, in the absence of timely cleaning, the thin plates of the slatted snow shield are able to deform. Eliminating such a decrease in efficiency is possible by welding the grill rods to horizontal pipes. At the same time it is required to acquire massive brackets of great thickness. These manipulations allow to achieve maximum density between the elements of the snow guard. Also increases the lifetime.

The size of the device can vary. Lattice subspecies differ from each other depending on the height and shape of the profile. The latter includes a variety of cell configurations - in addition to classic cells, there are diamonds and triangles. The height is small - from 5 to 7 cm in size, as well as large lattices reaching 15–20 cm in size.

Lattice snow cutters are distinguished by the type of roof,Due to which it is possible to meet devices on the market suitable for:

metal profile;

roll roof soft type;

ceramic tiles;

faltsevy roof.

Therefore, before acquiring a snow holder, you need to carefully familiarize yourself with the type of coating and its purpose. It is necessary to accurately follow the labeling. The choice of colors will not cause problems, since the product can be painted in any shade with the help of powder dyes.

Fastening to the metal tile is carried out along the eaves. For additional strengthening of the structure, it is necessary to install a special beam to the edge of the lattice. In the absence of this solution in the process of installing the rafter frame, you can fix the design with an additional set of brackets.

Drag

Products are better known as pinpoints. Snow cutters are teeth and hooks of small size, located on the roofing slope in a checkerboard pattern. It is important to understand that small elements are not able to withstand a lot of snow mass pressure.

Professionals in the field of roofing work recommend installing self-tapping screws as additional elements totubular and lattice snegozaderzhateley.

The best option is the installation on the roof of shingles. The latter has a surface capable of holding back the snow on its own. The shingles require additional insurance, which will be provided by the drag-type construction. Hooks are installed at a distance of 0.5-0.7 m from each other.

Lamellar

Corner snegozaderzhateli represent barrier type of systems. Installed at low rates of precipitation fell during the month. The design is made of metal. Appearance corresponds to a plate compressed into a triangle with two faces on each side.

Installation is made on the protruding part to the base. The height of the snow catcher is up to 6 cm. It is recommended to mount on roofs that have a slope at an inclination of 30 degrees. Installation is made in a staggered (zigzag) order in two lines. Between the rows there is a distance of about 0.5-1 m.

It is important to remember that the system can not withstand heavy loads. Often used in combination with other types of snow guards.

Log cabins

The device involves fastening a wooden log with brackets. The invention of tubular snow cutters pressed demand in the market for this type of product. However, they did not disappear due to the change in the size of the logs, depending on the amount of precipitation.

When installing it is recommended to fix the brackets directly on the truss frame, since the wood has a heavy weight and high pressure on the roof. Installation is made at a distance of 2-3 cm from the coating. This distance is maintained for free outflow of melt water. A semicircular trough is created, in which in winter the main part of the snowdrift is held back on the roof until spring comes.

Accessories

Additional parts for metal roofing are necessary to make the components tight. When installing snow stoppers the junction bar should be invisible. However, to achieve full protection with the help of snow clamps alone is impossible.

You will need to purchase additional parts:

air element to protect the roof from precipitation;

aero element for the ridge - ventilation;

to create ventilation in the chimney requires a passage element.

Experts do not recommend saving on additional elements, because they provide protection of the interior from climatic conditions, and they are also heat insulating material.

How to install?

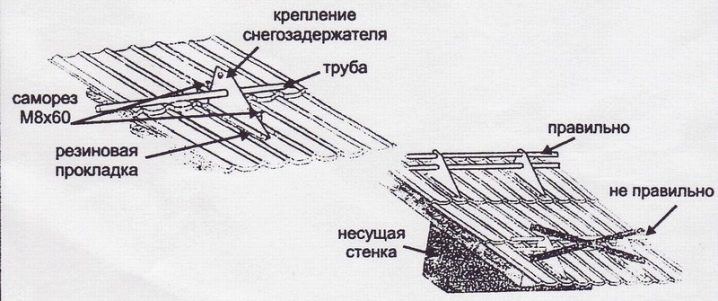

Structures are mounted in a staggered or linear order on the same level with the bearing walls. To reduce the load on the individual parts of the snow guards, installation in the form of parallel lines is possible. Rubber seals are installed between the fasteners and the roof, which provide the joint with high protection against moisture.

Protection elements are selected depending on the color range of roofing material. The aesthetic appearance of the building deteriorates when a large number of protruding different-sized elements.

Calculations

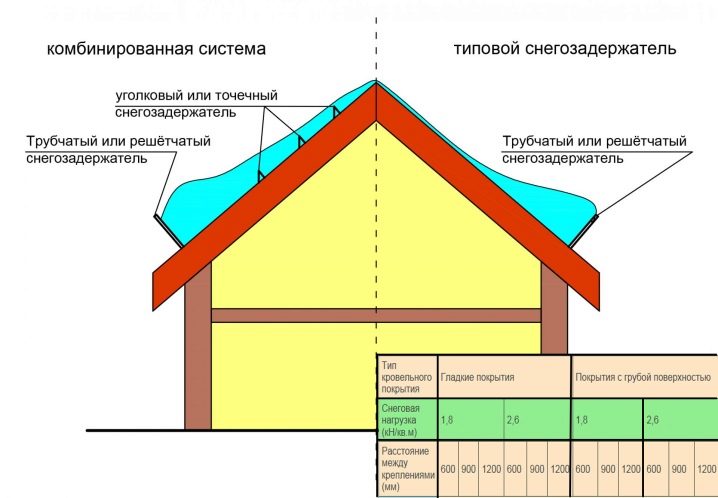

When calculating the number of snow holders, it will be necessary not only to install the structures in the appropriate places, but also to take into account the snow load. To make this calculation, a formula is required:

Q = G * s, where:

- Q - snow mass load;

- G is the mass of snow on a flat roof;

- S - coefficient of error (depending on the angle of inclination of the roof).

If the angle is less than 25 degrees S is taken as one. In the range from 25 to 60 degrees, a value of 0.7 is assumed. More than 60 degrees allows not to take into account the snow load, as the ice with such a slope will not be able to accumulate on the roof.

To provide the necessary protection, it is enough to install one row of snegozaderzhateley around the perimeter of the roof and to the chimney, if available.

Algorithm of calculation:

- Give an adequate assessment of the length of the overhang of the roof. This is necessary to determine the total length of installed snow guards. The best option should be considered the entire perimeter of the roof adjacent to the wall. In the presence of a chimney, the connection to the pipe is also taken into account.

- Determine the angle of inclination of the metal, as well as the length of the slope. Use the protractor.

- Identify which snowy area is located plot. The obtained information must be compared with the data in the table, which will make it possible to calculate the number of rows for snow retention. Also, the table will help determine the distance between the brackets. If you exceed the length of the slope of the table value, you will need to install two rows or more. With a smaller value, one is enough.

- The last step is to calculate the total length of the structures, revealing the required number of snow stoppers for 1 and 3 m.

As an example for the calculation, you can take the following parameters:

the site is located in the Moscow region - the third region;

tilt angle is 30 degrees;

the length of the slope reaches 7 m.

At the intersection of the data in the table is the value of 7.2 m. Therefore, the installation will require only one row of holder. The brackets are installed every 800 mm. Installing fasteners at a greater distance will require mounting two or more rows.

Preparation of all necessary

The installation process of snow catchers involves the use of certain tools:

Electric jigsaw. It is possible to replace the hacksaw. It is not recommended to use for cutting elements coated with a layer of polymer. The tool can damage the protective coating of metal, which will affect the strength of the surface. Increased risk of corrosion and reduced service life.

Screwdriver. Required for drilling holes with a metal drill with a diameter of 6 mm.With this tool it is easy to screw in screws and bolts.

Spanners (8 ÷ 13 mm) must comply with the parameters of the upper part of the roofing screws. It is possible to replace the end head for the screwdriver with six faces.

Measuring tape, level, marker. Necessary to create markup and calculations.

Upon completion of the selection of the required tools, the preparatory stage begins before installation. It is necessary to decide on the choice and method of installation at the initial stage of drawing up a draft of the roof. This simplifies the task of choosing a system and calculating the load. Next comes the markup step according to the developed plan.

Initially, the required distance is measured from the edge of the roof on both sides of the ramp. For example, 700 mm. It is recommended to install the first line of snow guards above the level of the roof overhang, which reaches the third row of tiles (located above the bearing wall of the house). Thanks to such actions, the reliability of the structure increases - the overhang will not be deformed and will not break off under a mass of snow and ice. At the same time, melt water will be free to drain the gutter.

At the end of the marking, through the marks of the marker, they pull the cord, which determines the level of installation of the snow guard elements. The cord is required to be tensioned and, according to its position, repulse the line of future installation on the roofing material. If there are plans to establish protection in several rows on the basis of preliminary calculations, the marking of several lines is made. Either these manipulations are carried out at the end of the installation of the lower level of the system. After the end of all marking go to installation work.

Description of the installation process

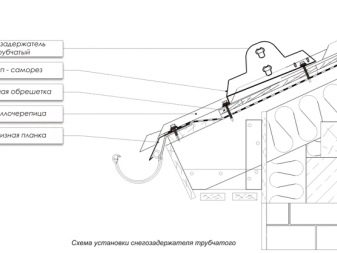

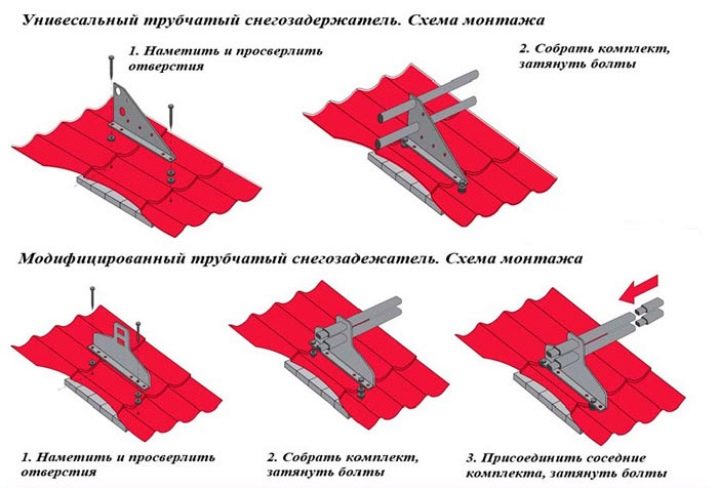

Tubular systems for metal tiles are purchased in the form of kits containing:

gaskets with a thickness of 7 and 14 mm;

screws 8 × 50 mm;

fasteners (brackets);

snow retention pipes.

The number of pipes will directly depend on the length of the roof slope. If the distance is less than 5 meters, it will be enough to install one row of the system. For longer surfaces, you will need to install a second row, which is mounted 3 meters above the initial.

In order to properly install the snow guard, you will need an instruction:

The bottom row of pipes is installed above the brick wall of the house.The distance to the cut of the roof should keep the figures in the region of 40 cm, which corresponds to the third row of tiles. Installation on the cornice overhang is prohibited. Thus, the snow guard will lose its effectiveness and will destroy the roof.

Installation of snegozaderzhatel begins with fixing brackets. To this end, at a distance of 30 cm from the side cut of the roof, it is required to drill holes for the first bracket. However, before this it is necessary to mark the drilling points. To create marks bracket impose on the tile so that the upper part rests on the previous row of roofing surface.

The entire load during marking should be taken by the sheathing bars, which are located under the metal tile. A waterproofing pad 7 mm thick is applied to the upper groove, while a 14 mm thick pad is applied to the lower groove. Such a difference in the location of the gaskets makes it possible to compensate for the height difference that appears due to the structure of the metal tile.

Upon completion of drilling, the bracket is installed and fixed. After 11 cm from each other in the same way, the following are screwed. At the same time a pipe is passed through the holes for the brackets.

The maximum removal of the free end from the last attachment should not exceed 30 cm. If necessary, the pipes can be interconnected with metal screws to increase the length. The excess parts are cut off with an electric jigsaw. Sections are sealed through the installation of plugs or simple flattening.

Installation of a lattice snow cutter is identical.

When mounting the corner snegozaderzhayu design feature over the bearing wall in place of the maximum mechanical strength of the roof. Professionals mark this place between the second and third row of metal tiles. The width of the corner should correspond to the length of one row. At the same time, it is possible to determine the upper edge when a right angle forms with it to the roof plane.

Fixing the corner to the surface of the tile is carried out thanks to screws. The main pressure will be concentrated on the upper face, so for its attachment you will need screws up to 70 mm long. This size allows you to securely fix the structural element, reaching the wooden crates under the tiles. The bottom edge should be fastened with screws of shorter length.

Final touches

Attach the snow cutters and put the snow barriers with screws and a screwdriver. It is important to remember that the sheet metal is not strong enough to hold the structure under heavy load. In places of fastening, where even long screws do not reach the wooden sheathing, for the greatest fixation wooden bars are placed on the sheathing. The latter compensate for the difference in height between the layers of metal.

At the end of the work, snow clamps of both types are recommended to be coated with an anti-corrosion agent and powder paint. This is necessary not only to protect the structure, but also for the aesthetic appearance of the product over a long service life.

Useful tips

It is necessary to get acquainted with the warranty conditions documents before purchasing a snow cap. In some cases, the installation of the design contributes to the loss of warranty. For work it is recommended to use only kits from the manufacturer.

Before installing snow catchers, additional markup will be required, which is carried out according to a previously developed plan.

When marking several rows of snow holders, it is recommended to use a paint cord.It is enough for the entire perimeter of the roof.

In the process of installing snow holders, the distance between the installation of supports or fasteners plays an important role - the smaller it is, the higher the structural strength.

It is important to observe safety precautions by considering insurance. The work process will occur at high altitude.

In more detail about how to make installation of snegozaderzhatel on a metal tile, the following video will tell.