How to cut a metal tile?

Cutting metal tiles is difficult and crucial, especially for those who have not previously encountered similar work. If you do not have adequate experience in this area, then difficulties will arise not only in the process of cutting, but also when choosing a tool to do this work.

Wrong tool selection leads to excessive consumption, poor cut and deformation of metal tiles. In this article, we will look at how to choose a tool for work and how the process in question should be implemented.

How to choose the right tool?

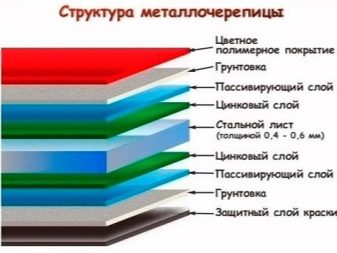

The complexity of the process under consideration lies in the characteristics of the material that is being cut. Sheets of metal tiles pass through a special processing stage, which provides for their coating with protective varnish. This layer helps protect the material from mechanical damage and rust. This feature of the product must be taken into account when performing cutting. If during the implementation of works to damage this protective layer, the metal tile will quickly lose its original appearance and properties.

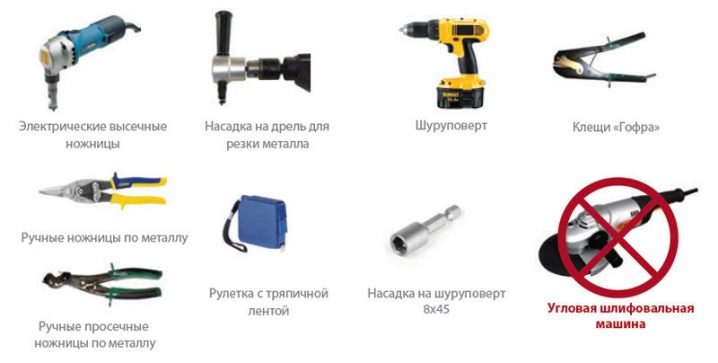

Metal tile is best cut with tools that are designed for this purpose, because it is easy to damage:

- Carved scissors. Oriented to perform work on the inner side of the metal. With this tool you can make holes of different shapes.

- Electric scissors. Allow you to quickly perform this work. They perfectly cut the sheet metal, including shingles from the same material. The main advantage of this tool is that it allows you to create a thin and clean cut, while saving material consumption.

- Special nozzle for a drill. Used for quick metal cutting. With it, you can easily make round holes.

The presented tools are suitable for cutting other elements that are required for the implementation of the installation of metal tiles. To select the most optimal variant of the three presented, it is necessary to consider the technical characteristics of each of them and the method of their involvement.

Carved scissors

With the help of the presented device it is possible to perform practically jewelry work. As a rule, they are used to create round holes that are designed for the chimney. Since the standard cutting process is complicated by the bending of metal tiles, it is necessary to ensure a uniform cut where there will be no torn edges.

A similar task for a metal tile can be performed using carved scissors, which characterized by the presence of a large list of advantages:

- Different metal thickness can be cut with this device. This ability allows you to use these scissors for cutting various types of tiles.

- It is characterized by the presence of a convenient handle,with which you can easily adjust the direction of the slice. Res will be the highest quality.

- Equipped with a strap, with which you can perform even cuts. Such scissors are not used to simultaneously cut several sheets at once. They are intended to work with only one sheet.

Electric scissors

When it comes to laying metal, the presented tool is indispensable. It is very effective in the implementation of a perfect flat cut sheet in half. This device, just like the previous one, has many advantages, which you definitely need to familiarize yourself with:

- Ability to create perfect smooth cut With the help of the presented scissors, quality work is carried out. In a cut there are no ragged sites, and the sheeting remains intact.

- It features a powerful engine. This leads to the fact that the presented device is focused on the implementation of large amounts of work. This ability makes it possible to use it in professional construction.

- Convenience of operation. As accurately as possible with the help of electric scissors you can cut the material.The presence of chip removal to the side allows you to save the protective layer, which was already mentioned earlier.

Special drill bit

This is a unique opportunity not to spend money on the purchase of expensive tools. This method of implementation will be relevant when the work on cutting is carried out independently. In this situation, you will only need to purchase a special nozzle for a drill, which on average costs 4,000 rubles. Its use allows to achieve the same quality of cut as in the application of the two previously discussed tools.

In addition to the above, this nozzle has some advantages:

- Differs in small weight. The average weight of the nozzle does not exceed 300 grams. This is a mobile product that can be placed in a box with other attachments.

- Allows you to cut even in hard to reach places.

It is important to note that the instrument in question acts as an additional one. It is not focused on use with a large amount of work.

It is important to note that the tools presented earlier are not the only options for cutting.In addition to the presented scissors, there are also Spoke models, which provide an open method of cutting. They differ in convenience in operation.

Knife tools with 2 blades are also used to cut tiles.which carry out clamping movements, cutting a tile. Electric saws are also actively used in this business. They demonstrate ease of use, but be sure to ensure that the surface of the metal tile was protected.

What can not be done cutting?

Before starting the work, it is required to study the structure of the chosen metal tile. It, as a rule, has several layers: the central and two side layers, between which it is located. The base is a thin sheet of steel. It is covered with a layer of zinc and various substances. Additional components depend on the type of tile chosen.

Many novice builders are interested in why the Bulgarian is ineffective in this case. This is due precisely to the structural features of the material. In addition to the grinder, the tools that can not be used for cutting metal include:

- any types of abrasive wheels;

- spraying saws or files;

- hand saws that are focused on cutting metal.

On the last tool you need to pay special attention. Conventional metal saws are often used at home. The master must understand that these saws have teeth that leave notches on the material. This damages metal shingles, which can subsequently cause corrosion on it. In addition, these tools affect the state of the building material: they deform it, having a negative impact not only on the structure, but also on the form. Such deformation is unacceptable in the work where the creation of complex structures is envisaged.

Theoretically, this work can be done with the help of a grinder, but in this case it is necessary to be extremely careful and focused. For cutting metal should use a diamond disc, which provides a more even and neat cut.

However, this hard work is accompanied by various difficulties: it is necessary to make a mistake, and all the work done will be of poor quality.

To achieve normal results when working with a grinder, you need to follow some recommendations:

- You need to cut at low speed. This will reduce the likelihood of sparks, and the instrument will not heat up as much.

- Tiles around must be covered with corrugated sheet metal sheets. This is necessary to protect it from sparks and other flying particles. After all, if they fall on the tile, it will certainly damage its surface.

- When performing work, observe the safety technique. Be sure to wear tight gloves and goggles.

Difficulties of using the grinder

Manufacturers of metal tiles are strictly forbidden to cut it with a grinder, despite the fact that this device is still very popular in construction. Often the master, not wanting to spend money on the purchase of another tool, trying to perform the work in question through the use of grinders.

Of course, it cuts quickly and easily, just like a circular saw. But why is it still not suitable for cutting metal? UhThis is due to some points:

- torn edges are formed, which later begin to oxidize and rust;

- during the work the Bulgarian gets very hot, and at the same time it heats up the tiles, which due to this deform;

- Italian-made tiles receive a guarantee for a period of 15 years, however, if it is revealed that the cut was made by a grinder, the guarantee will be voided;

- use the grinder on the roof is not safe;

- when cutting with the help of the grinder, metal filings fly off, which adversely affect the appearance of the roof;

- waterproofing, which fits under the tile, can be burned.

Based on the above, it becomes clear that to perform a professional roof is required to use a quality tool for installation.

About how to cut metal, see the following video.