The subtleties of repair of the roof of metal

Metal tile - one of the most common materials used during roofing. It is durable, long life and can be laid independently. In severe weather, hurricanes or emergencies, the roof can leak. To fix it, you need to know the subtleties of repair of the roof of the metal.

What is a metal tile

Roofing material is a steel sheet with zinc coating, resistant to the effects of liquids and sudden temperature changes. Coating is not afraid of corrosion, and its service life can reach tens of years with proper maintenance. To create a material, metal sheets are rolled using special equipment: this is how a drawing is applied to the surface.The last step is the application of a protective polymer layer.

The coating is available in several colors. It happens as a neutral gray metal tile, and bright red, attracting the attention of others. The paint layer performs several functions. In particular, it reduces the negative impact of ultraviolet rays, due to which the saturation of hues will gradually decrease.

When the polymer coating is destroyed or erased, rust may form, therefore during the planned inspection of the roof it is necessary to additionally check the integrity of the protective layer.

What is the roof

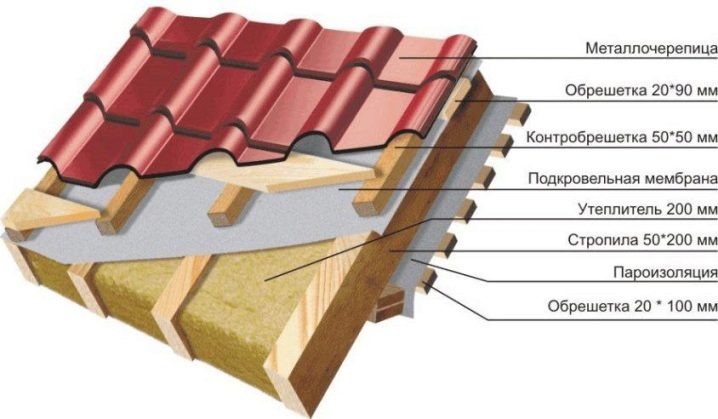

Roofing requires knowledge of how the roof is constructed. This will avoid unnecessary mistakes and will increase the life of the material. First of all, there are two types of roofs: with or without insulation, which is the reason for the presence or absence of additional elements in the structure.

The basic version of the structure of the roof includes the following components:

- decoration in the attic or attic;

- a layer of vapor barrier materials;

- thermal insulation used to separate runs and rafters;

- the bearing elements - rafters;

- airbag responsible for ventilation;

- waterproofing film that prevents the penetration of moisture into the room;

- the contour of the batten fixing adjacent layers;

- crate - slats, boards, plywood;

- metal tile.

When the roof is installed in harsh winters, a heater is placed in the structure, which is located above the vapor barrier. For fixing the components used additional obreshetka.

To prevent insects from getting inside the house, an anti-mosquito net is placed on the roof with a separate layer, and for frequent rains it is recommended to equip the roof with a gutter.

Types of repair

Features repair roofing associated with many factors. The life of the roof, its current condition, the occurrence or absence of emergency situations, and the quality of the initial installation of the metal tile are taken into account. This material has a high level of strength, but it cannot last forever, therefore it is necessary to regularly check the coating for defects. Depending on the condition of the roof, a partial or full replacement of the structure is carried out.

There are three main types of repair.

- Planned - a set of events, thought out and prepared in advance. They are carried out regardless of the quality of the original installation and the materials used. It is necessary to inspect the roof every few years to prevent its emergency breakdown and premature failure.

- Emergency - fast repair, carried out in case of emergency. It is made when damage occurs to the elements of the roof in hurricanes and storms, as well as in the event of severe leaks. To protect the room and make it livable, a point restoration is carried out. If it was made partially, then it is required to carry out a full repair.

- Capital. In this case, the complete or partial replacement of the roof. Such repair is the most difficult, requires the involvement of a large number of people, as well as material and financial resources. Laying a new metal tile is required in cases where the old becomes unusable, or if the rafters are too damaged.

Before work is carried out external and internal inspection of the roof. Analysis of the state of the roof occurs in the daytime and when exposed to precipitation - this is how you can determine the presence of leaks.

When holes are found, they are marked with paint or chalk to simplify the calculation of the required materials. Possible problem areas can also be noted: thanks to this, it will be possible to prevent the occurrence of future defects.

The reasons for the failure of the roof of the metal are different.

- Dents. They can be the result of walking on the roof. Because of this, gaps between the sheets may appear on the roofing. To initially prevent the occurrence of such defects, it is recommended to choose a thicker metal tile from 0.45 mm. To simplify the maintenance of the roof bridges and stairs are placed on it.

- Holes after cleaning the roof. Holes may occur when snow or ice is not properly cleaned. This happens when the roof is over-beaten, shovels and crowbars are used.

- Small bias. Such a roof is initially considered defective. Due to design features, rain and melt water will accumulate at the joints of steel sheets, gradually destroying the roof.

- Incorrectly installed screws. Breakage may occur due to weakened or crookedly mounted fasteners. In this case, the holes will not be completely closed, and water will penetrate there, increasing the risk of rust.Problems can arise from the use of screws with gaskets made of cheap rubber. Such elements will not withstand the constant effects of precipitation and will become unusable after 2 years, which will cause holes.

- No anti-condensation layer. A special film prevents the accumulation of water inside the structure, and its absence will cause the appearance of rapid leaks. First of all, this problem occurs in the winter time of the day.

- Incorrect assembly of components. The cause of leakage can also be the erroneous location of the roofing material in relation to the walls of the house and pipes.

To prevent many defects, it is required to install the roof correctly from the very beginning, otherwise the coating will become unsuitable at the first collision with adverse environmental effects.

To avoid other damage, it is enough to regularly inspect the roof, cleaning it from leaves, debris and snow with a brush or soft jets of water.

Preparation for repair

The work is preceded by a preparation stage. It includes both the analysis of the condition of the roof and the calculation of the required materials, as well as the preparation of the necessary equipment.Metal is purchased based on the number of problems. Major repairs require large amounts of cover, while in the presence of holes with a diameter of 5-7 cm, it is enough to make small patches.

Works are carried out in clear weather at a temperature not lower than -5 degrees. These conditions are necessary to ensure the most effective adhesion of the waterproofing layers. Required to acquire special adhesives for outdoor use, resistant to aggressive environmental influences. With their help, the construction will serve as long as possible, and it does not require premature repair.

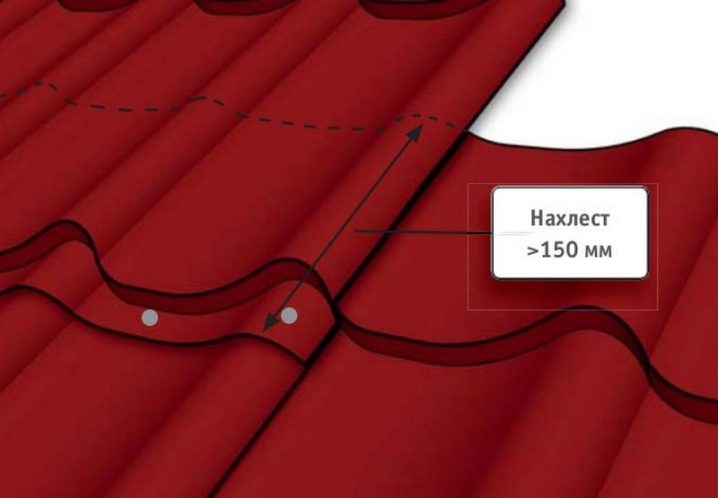

The length of the metal should not be too large. Otherwise, at the joints the sheets will be affected by excessively strong stress, which is fraught with loosening of the screws and the appearance of leaks.

The average length of the elements is 3-4 meters, and their subsequent installation should be made in waves.

Before work is required to purchase the following materials and tools:

- sheets of metal;

- liquid mastic;

- spatula or brush;

- fiberglass;

- paint matched to the coating;

- fasteners for connecting components;

- seal, which is used as a tape;

- devices for measurements (tape measure, pencil, level);

- scissors for cutting metal, a knife or a hacksaw used to cut sheets into pieces;

- drill and screwdriver;

- trowel, which will clean the tiles on the repaired area;

- nail puller;

- soldering iron, which is used when working with holes.

The set of equipment varies depending on the features of breakdowns and their scale. To work effectively, you need to take sharpened tools and high-quality fasteners. When carrying out repairs, gloves are used to avoid injuring hands on the sharp edges of the metal tile.

Roofing

The simplest is point repair. Initially, the roof surface is cleaned of dirt, rust and old coatings. For these purposes a special brush for metal is used. When the hole diameter is about 5 mm, it is necessary to apply a solvent and a sealant to fill the free space. The composition is located on the inner and outer sides, comes to 3-4 cm from the edge.

When working with holes of larger diameter (5-10 cm), special fiberglass patches are used. They are applied to the metal, and then covered with layers of red lead.A special tape can be used to close the gaps between the sheets.

When the size of the holes reaches 10-15 cm, part of the old coating is completely removed by the grinder and replaced with a new one.

If rust appeared at the junction of the tile with gutters, it is necessary to completely replace the roof. In this place, snow often accumulates in winter time, so damage can occupy a large surface of the roof and anti-icing systems. To prevent this, it is recommended to install snow delays in advance. In the case when defects occupy almost half of the coverage, it is most logical to replace it completely, as well as to install new rafters.

Places of metal tile cuts are treated with protective compounds to prevent corrosion, and large holes caulk. When it comes to insulated roofing, replacement of steam and waterproofing materials may be required. Since the repair of these layers is costly in terms of effort and finances, the installation of components should be carried out with special care.

Stages of placement of the frame system:

- Broken elements are equal with a jack.

- Next to the rafters stacked bars, fastened with nails and other fasteners.

- Holes for studs and nuts are drilled on both sides of the rafters.

It also happens that the elements of the structure completely rot. In this case, you need to remove the crate and fix the rafter legs using temporary racks. Defective elements are replaced with new bars, and after work all props are eliminated. Three months after the work, it is recommended to carry out the fastening of fasteners, otherwise self-tapping screws can loosen and cause leakage.

On what mistakes can not be done when fastening metal, see the following video.