Metal tile "Cascade": features of the installation

Lack of attention to the installation of the roof can haunt the freezing of the entire dwelling in the frosty season, the murmur of streams dripping from the ceiling, the rapid destruction of the house. In order to prevent this, it is necessary to get acquainted with the peculiarities of laying the metal tiles of the “Kaskad” plant.

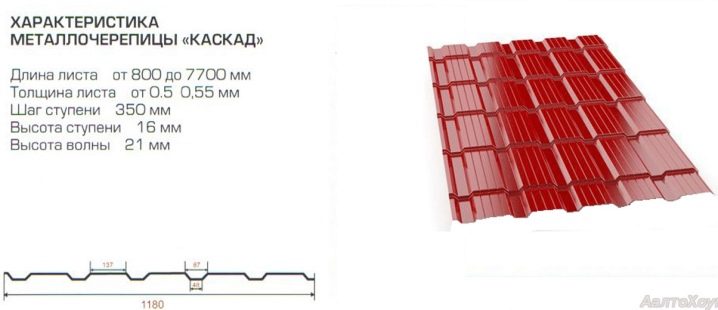

Specifications

Astrakhan plant "Cascade" is the first and only manufacturer of the roof of galvanized metal. Taught by the experience of generations to build their houses from improvised means, the modern owners decided to try the novelty. And not lost. Technical characteristics of cascade metal tiles allow this material to be strong, durable and cheap raw materials for the roof.

The metal tile "Cascade" is a galvanized sheet metal profile. Its thickness is 20-40 mm. At the same time, the manufacturer itself insists on acquiring the most thick metal that can withstand a large load of its weight (1 m2 weighs about 5 kg), the weight of snow, water, and the force of wind. The design of the cascade sheet is made in the form of alternation of longitudinal grooves and waves with additional rigid edges. The cascade roof resembles a chocolate bar, especially.

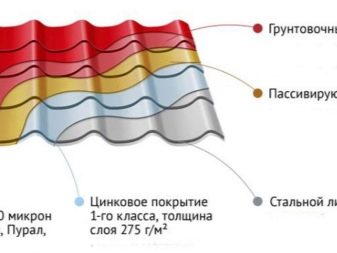

The color of the metal tiles give polyester, plastisol or pural. The first is a bright glossy surface, the second - a kind of Teflon (matte tiles). The third is a polymer coating that increases the service life of the roof up to 50 years. Pural is characterized by the fact that it is completely immune to ultraviolet radiation, retains the paint and the technical characteristics of the material in any weather.

The clarity of lines in the construction of metal tiles advantageously distinguish it from the mass of other roofing coatings. High dimensional accuracy of sheets allows you to make the correct calculation of the material with virtually zero percent waste. Laying slabs with an overlap with a minimum gap saves the amount of coating used in the installation of the roof.

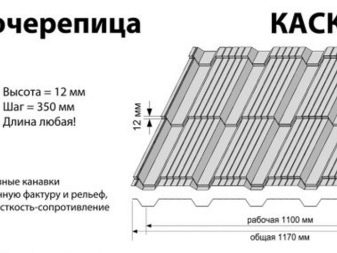

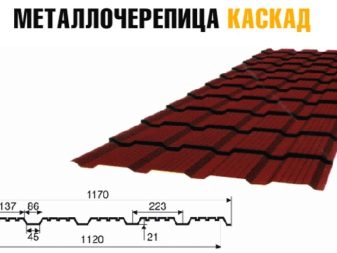

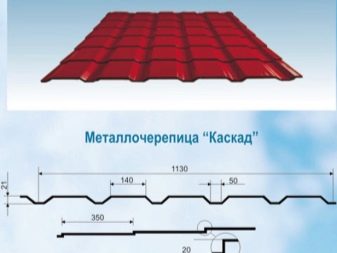

The main metric parameters of one standard sheet of metal "Cascade" are displayed in such indicators:

- useful and total sheet width - 1.06 m and 1.16 m;

- wavelength is not more than 35 cm;

- Sheets are produced in sizes from 50 cm in length to 6.5 m (the most popular are 0.5 m, 1.2 m and 2.25 m).

Advantages and disadvantages

The main advantages of this roofing material are the following statements:

- has immunity from scorching sunlight, heavy rainfall and sudden temperature changes;

- does not burn, and therefore fire safety at the highest level;

- high durability of the coating is fixed on all parts of the sheet;

- low weight has a positive effect on the convenience and speed of installation, saving on delivery;

- in its composition it has no harmful impurities and substances, it is considered an environmentally friendly material;

- relatively low price for domestic products;

- high anti-corrosion treatment;

- warranty from the manufacturer (up to 14 years), the maximum lifetime depending on the finishing color coating (from 20 to 50 years).

Among the disadvantages of the material emit:

- noise generation during precipitation;

- risk of snow avalanche.

Special attention deserves the coverage of "Prism". Reviews of this material are mostly positive. It differs from the classic analogue in the presence of an aluminum additive. This provides maximum corrosion protection even in the event of mechanical damage to the outer layer.

Production

Metal tile "Cascade" is used for the construction of the roofs of low-rise buildings.

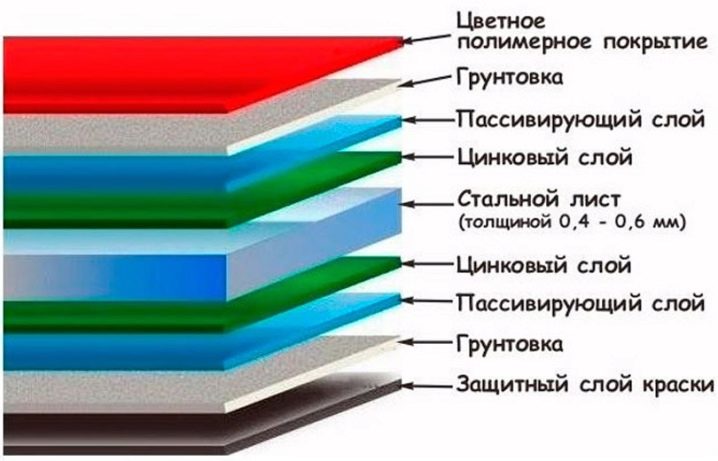

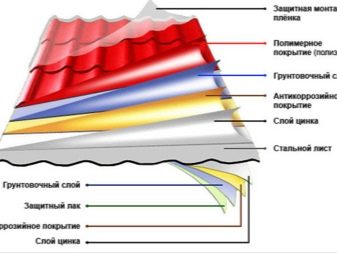

Before considering the process of production of the material of this coating, it is worth getting acquainted with its main components:

- color (polyester, teflon or pural);

- top coat primer;

- top anti-corrosion layer (oxide protective film);

- top zinc layer;

- steel sheet;

- lower galvanization;

- lower treatment with concentrated HNO3;

- undercoat primer;

- drawing a protective varnish coat.

A sheet of metal resembles a thin sandwich. Thanks to each element in this pyramid creates a unique durable coating, not subject to the effects of the environment for many years. At the initial stage, the steel sheet (flat and flat) galvanized on both sides is treated with anti-corrosionmeans. Next, apply a primer (also on both sides), which serves as a starting coating for the finishing layers. From above impose a polymer layer with paint, from below the surface is treated with varnish. The processed sheet of metal is placed in a rolling machine, where tiles of a certain size metal are formed. Despite the large number of chemical elements that process the surface of the coating, its production process is recognized as one of the most environmentally friendly today.

Kinds

Cascade metal has one type, but the sheets differ in size and color. Modern production is so individually suited to the creation of new roofing that decorated metal sheets look like high-quality clay tiles.

Dimensions

Each sheet has its own parameters. Manufacturers individually address this metric issue.

There are well-established GOST standards that must comply with all:

- sheet width can vary from 116 to 119 cm;

- the length of the metal tile plate reaches 50 - 900 cm;

- thickness reaches a maximum mark of 0.6 cm, with a minimum of 0.4 mm.

The width directly depends on the steel sheet supplied to the manufacturer.In terms of length, manufacturers are not limited. Here the size is determined based on the appropriateness of use, consumer demand and ease of installation. The last criterion is the most categorical, since it is more difficult to lay metal roofing the longer its sheets.

There are several common and fixed by the state standard lengths of the metal roof:

- ultra small - 0.5 m;

- small - 1 m 20 cm;

- average - 2.25 m;

- large - 3.6 m;

- extra large - more than 4 m.

If the standard choice of sizes does not fit, most manufacturers have in their price list a service for trimming metal tiles and adjusting them to personal parameters. There is such a thing as a wave. This is a vertical line of two cells. The wave has two important parameters: step and height. The first is determined by measuring the length of a segment from one groove of a wave to another. The height is calculated from the length of one cell from top to bottom.

In connection with these measurements, the waves are:

- low-altitude (2 - 3 cm);

- medium-height (3 - 5 cm);

- tall (5 - 7 cm).

The wave step is predominantly fixed. It has two generally accepted indicators: 185 mm and 350 mm.

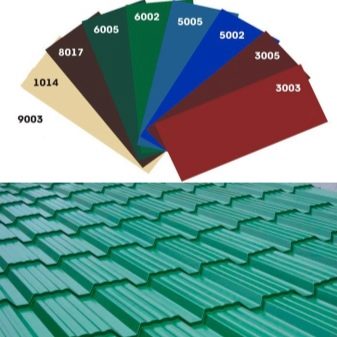

Colors

Color solutions for metal "Cascade" do not have particularly large ranges. However, there is plenty to choose from. The buyer has 10 standard colors.

The most common ones are:

- ripe cherry;

- brick;

- Navy blue;

- dark green;

- chocolate.

All colors have high durability. They do not fade in the sun, do not turn pale from snow or rain. The cascade metal tile of color of a ripe cherry or a brick reminds by its appearance a ceramic or clay tile. And the brown tint makes it look like a chocolate bar. In order for “Cascade” to serve as long as possible, all the basic recommendations of installation professionals should be followed. It is better to hire special roofers for this. However, it is also necessary to have an idea of what will happen to the roof.

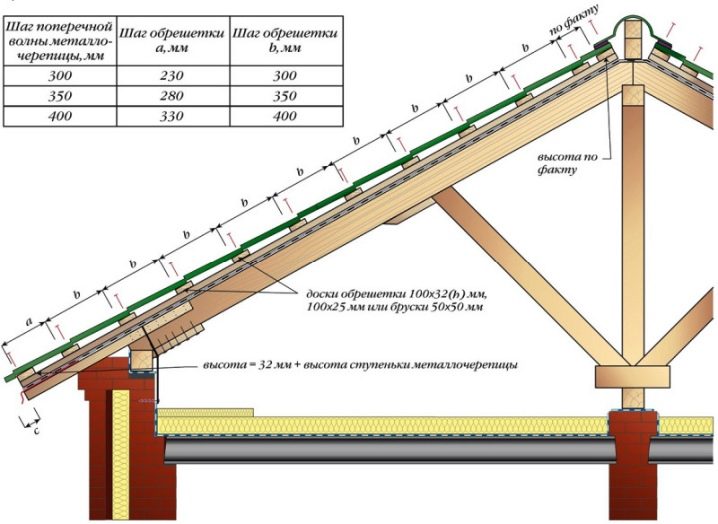

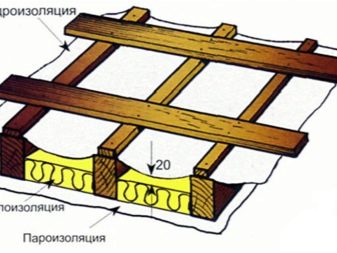

Installation

Before proceeding with the laying of sheets of metal, it is necessary to make sure that the frame of the roof itself is executed correctly. The roof should be mounted on a wooden crate, sheathed with insulation, as well as waterproofing and vapor barrier film. The frame material must be treated with an antiseptic. The pitch of the batten depends on the pitch of the wave of the roofing material.It is necessary to take into account the fact that the first board is installed along the edge of the roof (eave), the second is mounted at the minimum possible distance.

Each subsequent step has the same length, but more than the second.

- The 300 mm wave spacing is equal to the second wooden frame pitch of 230 mm, the third and subsequent ones - 300 mm.

- The wave spacing of 350 mm is equal to the second pitch of the grating 280 mm, the third - 350 mm.

- The 400 mm wave pitch is equal to the second pitch of the grating 330 mm, the third 400 mm.

Having dealt with the frame of the future roof, we proceed to measuring the total area and the consumption of roofing material. When counting the number of metal tiles for a simple dual slope roof, it is necessary to know the length and width of the future structure. Knowing the size of future cascade sheets, it is easy to calculate the approximate amount of this material for the roof. In the case of a complex roof shape, it is better to contact a specialist in order to avoid large amounts of waste during installation. When buying consumables or additional materials, it is necessary to take into account various nuances. For example, screws are consumed in quantities of up to 8 pieces per 1 square meter.

Instructions for laying metal "Cascade" with a minimum slope of 14 degrees, is as follows.

- First you need to correctly put the first sheet.If the first panel lay exactly in the wooden square of the batten, the rest will go behind it in a single file.

- Installation takes place from left to right, the sheets overlap one another. The extreme groove of the next canvas is embedded in the extreme groove of the previous one.

- Fixing the roof occurs with special screws with rubber gasket. It is important to precisely tighten them. The problem may occur with a strong tightening and insufficient.

- Fill the roof with additional elements. Use skates, slats, drips, caps.

Expert advice

The main points are the features of the shelter and facade of the building, as well as the prevailing weather conditions.

Roofing professionals are advised to think about a few nuances.

- The thickness of the profile sheet depends on the angle of the roof slope. The larger it is, the less this parameter should be.

- Installation of a cascade metal tile on a flat surface is allowed. But the thickness of the material should be at least 50 mm.

- The preferred galvanized layer for metal tiles is 100 mm per square meter. m, which ensures maximum protection of the roof and the entire dwelling.

- All color coatings have high durability and durability.

- If the house from all sides is under the scrutiny of the sun, it is better to give preference to light shades of cascade metal tiles. In the shade quietly settled dark color options.

- Do not use for trimming sheets Bulgarian. It will damage the appearance of the material and make it dangerous to humans.

- It is worth working with metal tiles in special gloves and glasses. It is important to use metal shears for cutting.

Review of metal "Cascade", see the video below.