How to choose the thickness of the metal tile?

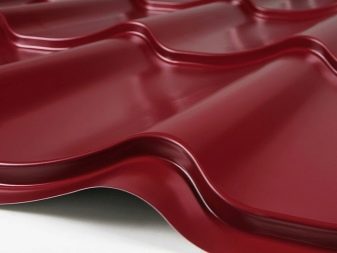

Metal tile is a modern material used as a roof. It is an aluminum or copper sheet made using the cold stamp method. On the territory of Russia, galvanized steel is most often used, the finish is more like natural ceramic tiles. In order to protect the material from adverse weather conditions, it is treated with several layers of a polymeric substance.

Metal tiles are extremely popular with developers, every year its sales volumes increase. This is largely due to the versatility of the material. It is equally well suited for municipal and individual construction projects. The main thing is to choose the right thickness of the metal tile.

The pros and cons of the material

Low prices, wear resistance, relatively long service life, low weight, attractiveness of external coating and fire safety can be attributed to the positive sides of metal tiles.

Another advantage of the material is resistance to adverse weather conditions. Although it is worth noting that the product of each brand may manifest itself in this in different ways. Much depends on the quality of the polymer coating. That it is responsible for protecting the metal surface from the occurrence of rust and various defects. High-quality polymer is resistant to aggressive environment, ultraviolet and mechanical stress (for example, to hail). Such metal tile will not lose appearance even in an extreme climate zone.

Lifetime also depends on the quality of the material (and metal raw materials, and the polymer substance). Plays an important role and the thickness of the metal sheet.

So the life of the metal economy class can vary from 10 to 25 years. High-quality material from famous brands copes with its task for much longer (about fifty years).

As for the weaknesses of this product, there are several highlights.

- Excessive metal sheet during installation work. This is due to the fact that the dimensional parameters of the metal sheet have standardized indicators. In this regard, the trimming of the material is inevitable, especially when working with complex forms of the roof.

- Fast wear resistance in violation of the upper layers of metal. The most common problem of the upper layer is the appearance of chips, cracks and peeling of the protective coating. For example, damage is easy to get with rough loading or careless transportation of material. At the damage site, corrosion occurs instantly, which leads to loss of impermeability of the coating.

- Relatively low noise insulation. This situation is possible if you mount metal sheets directly to the frame structure.

- Potential risk of falling snow.

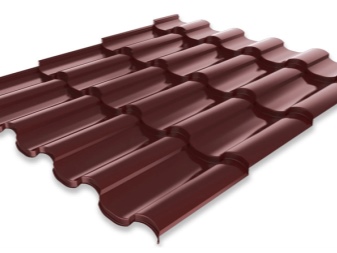

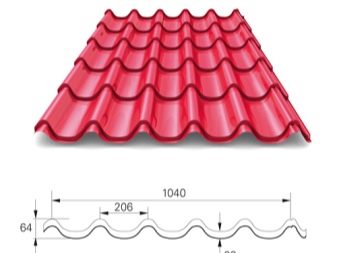

Size and technological properties

The geometric dimensions of a sheet of metal tile - is the width, length and thickness. There is a state standardwhich obliges manufacturers to produce shingles with already set parameters: a width of one hundred and twenty centimeters (in this case one hundred and ten centimeters is considered a working width), fifty to nine hundred centimeters long and 0.5 to 0.6 mm thick.

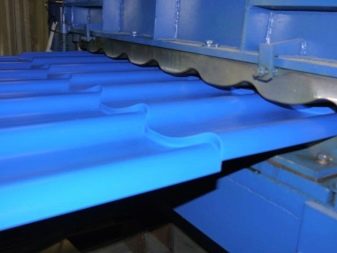

Sheets of metal tiles are formed on the rolling mill of metallurgical industrial enterprisesin which they use standardized equipment with predetermined parameters of rolling shafts. The width parameters for tiles, regardless of the type, brand and length, are always located within the boundaries of one hundred and sixteen to one hundred and nineteen centimeters. This is because the manufacturer needs to bind the width parameter of the tiled sheet to the width parameter of the raw material used.

With a large variety of options you will come across and in the selection of the required length of metal. Metal products that come to enterprises can reach nine meters in length. Naturally, this significantly reduces the costs associated with shipping and transportation. However, installation work with such products can be extremely time-consuming.In this regard, the metal sheet that the manufacturer offers you is much smaller.

The length parameters are set by the manufacturer.

It may vary, but often the most optimal solutions are applied:

- super short length - fifty centimeters;

- small length - one hundred twenty centimeters;

- average length is two hundred and twenty five centimeters;

- great length - three hundred and sixty centimeters;

- a very large length - four hundred fifty centimeters.

The optimum material thickness should meet your needs. The thickness of the metal sheet is the thickness of the metal layer. If the two previously mentioned parameters (length and width) characterize the comfort of the installation, the thickness parameter of the metal tile also has operational characteristics.

Also, manufacturers involved in the manufacture of roofing, determined the optimal proportion of metal tiles. This value is one cubic meter per six kilograms. This value contributes to convenient installation work and the almost complete absence of additional pressure on the supporting structure of the roof covering and the foundation.

Nuances

When buying metal tiles you need to be on your guard. Many dishonest consultants in hardware stores cheat. For example, the most common thickness parameter is 0, 45 millimeters. But on the part of the consultant, this parameter can be rounded up to 0.5 millimeters - the optimum thickness of the metal sheet. In fact, acquiring a similar product, you become the owner of economy-class metal tiles.

When choosing metal sheets, do not forget that the thickness of the zinc layer, which protects the material from adverse weather conditions, can vary from 0.1 to 0.2 millimeters. The decorative layer, taking into account the polymer deposited at the manufacturing stage, reaches 0.2 millimeters. Thereby acquiring sheets with the specified 0.45 millimeters, you actually get steel metal sheets with a thickness of 0.42 millimeters.

This size is not enough for high-quality installation work. Even a slight load or pressure on the material will cause the formation of dents and irregularities. After a short period of time, such defects become the cause of the deformation of the entire metal sheet.

Do not expect from a similar material long life. Such a coating will last from three to five years, after which there is a high probability of corrosion on the entire surface of the roof. However, there is another scenario. A decorative coating after a certain period of time may begin to “peel off”. This is due to the technology of manufacturing metal shingles of the economy class and the use of cheap raw materials, which often turn out to be of poor quality.

The metal tiles are made using profiled cold and hot rolled steel with a protective zinc and decorative polymer substance in advance. Due to this manufacturing technology, surface load appears on the sections of metal sheet bends, which is often the cause of the appearance of microcracks on the protective layer of the product. In turn, microcracks in the future may contribute to the detachment of the polymer layer from the entire roof covering.

Selection Tips

Feel free to use specialized device,which will allow you to verify the accuracy of the specified thickness of a sheet of metal tile. The micrometer allows to measure even the smallest linear values. Do not forget that the optimum thickness of the metal sheet ranges from 0.5 to 0.55 millimeters (taking into account the coating applied).

You also have the right to request a certificate and a document from a home improvement consultant.which can confirm the declared protective characteristics of the material. Prefer metal tiles with a protective layer of zinc two hundred seventy-fifth grade.

To find out how to choose a reliable metal tile, see the following video.