Screws for metal: the subtleties of choice and installation rules

A very important fastener used during installation of the roof is a self-tapping screw. This detail is the guarantor of the quality of reliable fixation, determines the durability and strength of the future roof.

In order to avoid unpleasant situations during the installation of the structure, it is necessary to find out in more detail what the self-tapping screws are for the metal tile, and also to study the subtleties of choice and the rules of installation.

Special features

The presence of the washer is the main distinguishing feature of roofing screws. The main task of the auxiliary element is to evenly distribute the pressure of the head on the surface of the roof covering, as well as to completely seal the mounting hole.The functional features of the screw washer for metal tile influenced the fact that a rubber sealing ring appeared in this product.

Since the roof is influenced by precipitation, it is important that the seal material is of sufficient quality. On this basis, the best is considered to be an EPDM rubber sealing ring. This material perfectly tolerates temperature drops and other negative factors, while maintaining its main characteristics for a long period of time.

Estimated structural load affects the type of roofing screws. According to this criterion, fasteners are divided into two categories: metal – wood and metal – metal. This classification should not be neglected, self-tapping screws must be used strictly for the intended purpose.

You should not worry about the fact that the washers screws can be allocated on the surface of the roofing material.

At present, in the construction market it is quite easy to find the necessary shade of self-tapping screws, which fully corresponds to the color of the metal tile.

Specifications

Usually roofing screws are made from galvanized carbon steel.Anti-corrosion coating increases the period of operation, which can last up to 50 years.

There are also stainless steel screws, used preferably in places that require strict increased security and strength of the roof. Their price is much higher than galvanized.

Screws for metal are also classified according to the shape of the cap, which is:

- standard, fitted with a screwdriver or screwdriver;

- hex, requiring the use of special bits.

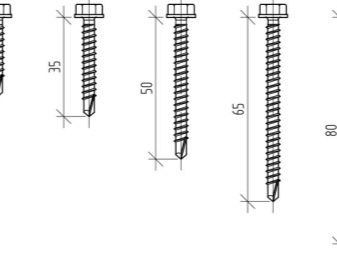

Different self-tapping screws and markings, each has certain technical characteristics:

- material hardness;

- product length;

- thread pitch;

- flange thickness;

- diameter and height of the cap;

- the size of the key.

Among the large variety of options for fixing elements, you can choose suitable fasteners that have the necessary technical characteristics in a particular case.

Kinds

Roofing screws are divided into two main types:

- for wood;

- for metal.

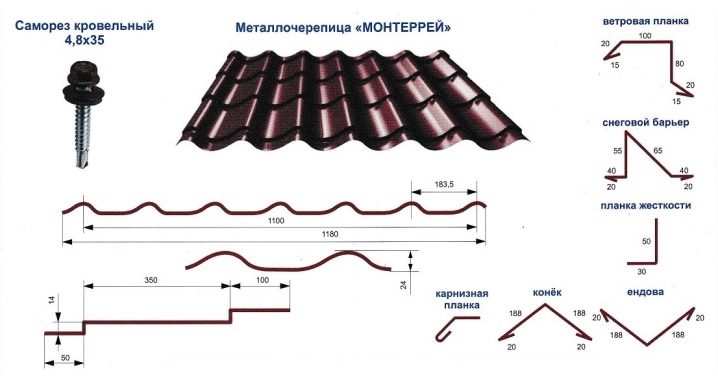

Screws on wood have a rather rare thread and a tip decorated in the form of a drill. Screw screw on the tree in the metal is quite difficult.You may need these fasteners in the case when it is necessary to fasten a metal coating to a wooden crate. The most used sizes of wood screws are 4.8 by 28 mm and 4.8 by 35 mm. Wood screws are equipped with a press washer with a compactor, this design performs a waterproofing function.

Self-tapping screws for metal have a frequent thread, they are slightly larger in diameter than those described above and practically do not stick in wood, therefore they are not used for fastening to wooden structures.

Used for fixing the roofing to the crate of metal profiles.

The most used sizes of self-tapping screws on metal:

- 4.8 by 19 mm, with a metal thickness of ≤ 3 mm;

- 5.5 per 25 mm, metal thickness ≤ 6 mm;

- 5.5 by 35 mm and 5.5 by 50 mm for drilling metal ≤12 mm thick.

Both types of self-tapping screws have either a standard or a hex head, a washer with a gasket, a thread and a tip with a drill. They produce these fasteners in different colors, corresponding to the color palette of the professional flooring or such lining as metal tile.

Material consumption

Experts recommend buying a full set of screws, and not individually their different options.In this case, it is necessary to make a calculation in advance of the consumption of roof fasteners in full compliance with the roof design.

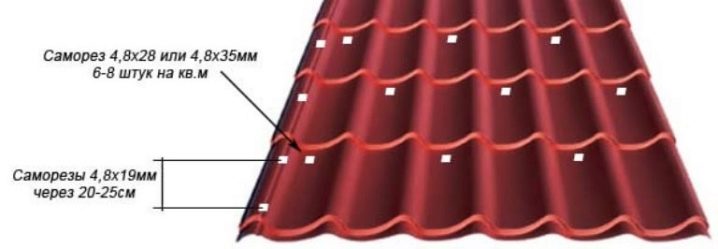

Purchase fasteners should be based on an average of 8-10 pieces per 1m2 roof area. It should be understood that the number of screws that goes on the square can be increased in the case when the roof has a non-standard geometric shape or some additional elements.

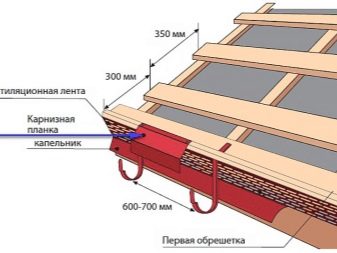

In the lower part, it is recommended to place fasteners through a single wave in each of the sheets of metal, while the screw is screwed in places where the trough of the wave rests on the profile. It is considered a blunder to fasten through the crest of a wave - it can deform the metal tile. Then the screws are screwed through the wave, observing the rows in a checkerboard pattern.

Sheets of metal on the side stacked overlapThese seams should be fastened along the crest of each of the waves. The end bar is fixed, observing the pitch of the screws 500-600 mm. The fixing of the ridge planks is carried out with special ridge screws, they are also screwed into the roof covering through a single wave.

Criterias of choice

Buying screws in the hardware store (in order to avoid buying low-quality goods), Details need to be tested on several indicators.

- Test for the quality of the protective coating.To do this, squeeze the press washer strongly with a pliers. A product with a poor-quality coating, will surely give cracks. In most cases, zinc is applied as a coating by electroplating. This helps ensure maximum adhesion of materials.

- You should check the strength of the gasket to the base and the quality of the rubber washer, which is located directly under the cap. The sealing ring ensures the tightness of the attachment of the screw head to the sheet of metal tile, the durability of the roof covering depends on it. Pads of poor quality over time are destroyed by the negative effects of the atmosphere, begin to leak moisture, which leads to corrosion of the coating.

- It is necessary to check the presence of appropriate markings on the cap. The absence of such may be an indicator of inconsistency with quality.

For a guaranteed purchase of high-quality self-tapping screws, experts recommend products of European brands. Of course, these products are more expensive, but the high quality of the material, proven strength and reliability of products (along with a long warranty) compensate for the costs incurred.

Fastenings for roofing are made of high carbon steel and must be tested before going on sale. Manufacturers of quality goods guarantee a long period of operation, which is about 50 years.

During testing, the screws are subjected to severe deformations:

- about 20,000 bends at 5 degrees;

- 2000 bends at 10 degrees;

- 100 bends at 15 degrees.

The required dimensions of the roofing screws, as well as the thread pitch are determined based on the materials being fastened, their thickness and the desired depth of penetration.

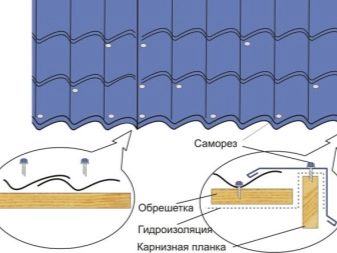

Installation Features

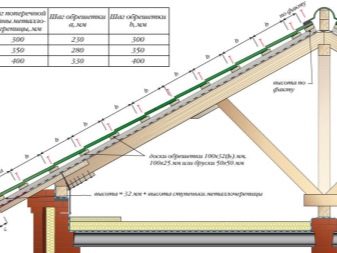

Fastening metal tiles is not an easy process that requires certain knowledge and skills. Starting installation work, first of all, you should worry about the quality preparation of the base or crates, to which the metal tile will be attached in the future. This design is made of wooden slats, the horizontal step between which should be a multiple of the size of the sheets of roofing material.

For example, the width of the tile is 1000 mm, which means that the pitch of the batten is better to be equal to 500 mm - this will ensure the fastening of one sheet of tile to three strips at once. After that, you need to think over the mounting scheme of the roofing material with self-tapping screws.

Basic requirements and features of installation.

- Do not use tools for mounting screws without the ability to adjust the speed.

- When screwing the roof fasteners on wood, the number of revolutions on the device should not be more than 1800 r / min (more than 1500 r / min - for screws for metal).

- Screws need to be screwed in only at a right angle to the plane of the roofing material using magnetic nozzles.

- It is necessary to adjust the force of the self-tapping screw so that, after screwing in, the edges of the seal protrude beyond the edges of the press washer by approximately 0.5-1 mm;

- Damage or breakage of the screw is not allowed, including the removal of any part of it.

- It is considered correct to fasten a thin metal to a thicker one; on the contrary, it is not recommended.

Technological features of the installation process depend on such factors as:

- the type of products used;

- their thickness;

- characteristics of crates, etc.

In this case, in any case, the total thickness of the fastened products must be at least 3 millimeters less than the length of the roofing screw.

In most cases, self-tapping roofing screws are attached to any material withoutdrilling. However, there are situations that require through drilling before screwing in the screw.

Most often it is found in working with metal products that have a sufficiently large thickness. Drilling is carried out by means of a drill, the drill diameter of which is 0.5–1 ml less than a self-tapping screw. For screwing in self-tapping screws, various tools are used, the choice of which depends on the type of fastener cap.

On how to choose screws for metal, see below.