Wood stain: pros and cons

Even after the appearance of metal and various modern synthetic materials for construction, wood remains popular and in demand, as it is a high-quality and environmentally friendly raw material. And thanks to the huge choice of various paint and varnish compositions, such as wood stain, it was possible to significantly improve the appearance of wood products, and, importantly, prolong their operational life.

Special features

Under the influence of aggressive environmental factors, including all sorts of bacteria, mold and insect pests, the tree can deform and start to rot. In order to minimize the risk of such problems, it is very important to take care of wood in a timely manner.The most effective option to deal with such circumstances is wood stain. The tool is a liquid composition, giving it the desired tone from a mass of variants of colors and shades. This allows you to improve the natural color of wood or drastically change it.

In addition to the aesthetic functions, the main feature of the composition are antiseptic properties. Thanks to the use of wood can serve you twice as long.

Another feature of almost all types of stains is the ability to penetrate deep into the tree without harming the pattern and texture, unlike enamel or paint.

Wood stain has some advantages:

- the possibility of combining different shades of color;

- strengthening and preserving the structure of the tree;

- increases the operational life of products;

- increase the resistance of the tree to moisture.

The stain is not only a varnish for wood, thanks to its use, you can create a unique interior indoors or completely transform, at first glance, ordinary home furnishings or furniture.

The following liquids are used as the basis for the production of stain: oil, water or alcohol. This separation allows you to select several types of this composition.

Kinds

Allocate 2 types of funds - water and non-aqueous (oil and alcohol) stain.

Water based stain offered by manufacturers in ready-to-work condition or as a powder (dry mix). This type of composition is used most often because it has a very diverse color range. The color of the powder stain can be easily adjusted, it directly depends on the amount of granular matter, that is, the more of it, the richer and brighter the result will be.

The composition of water-based has the advantage: there is no unpleasant smell, thanks to this wood stain can be used inside the premises. The disadvantages of this type include the ability of the tool in the process of processing them to raise the surface of the fiber. At the expense of it moisture resistance of a tree decreases. The time required for complete drying of the stain, varies within 10-14 hours, which can also be attributed to the minuses of the variety composition.

The technology of working with water-based wood stain requires first wetting the wooden surface, then sanding. Composition before use filter. Only after performing such preparatory work can the tree be painted. This tool is not desirable to use for resinous woods.

Oil formulations include dyes dissolved in linseed oil or oils. It is possible to work with impregnation of this type with any tool. The tool does not lift the fibers of the raw material and does not allow it to be fed with excess moisture. Using a similar composition, you can get any color and shade, additionally using dyes. They are produced in the form of powder, white spirit is used for dilution.

According to experts, the oil stain is the most simple and convenient to use. Impregnation on an oil basis is very popular among decorators and designers due to the ability to get the desired color.

The advantages of oil stain should include its environmental friendliness, since the most common basis for it is linseed oil. It takes about 2 hours to completely dry the surface. The composition does not stain.

Alcohol-based stain Is a dissolved aniline dye. Impregnation is available in finished or powdered form. The main task of the composition is to protect the wood from the damaging effects of moisture and ultraviolet radiation.

The main advantage of alcohol stain is its ability to instantly be absorbed into wood fibers. Dries the composition on the surface in 30-40 minutes.

The disadvantage is the fact that the manual method to apply the composition to the tree does not work, because the alcohol will evaporate very quickly, which can lead to stains. For work it is better to use the spray gun.

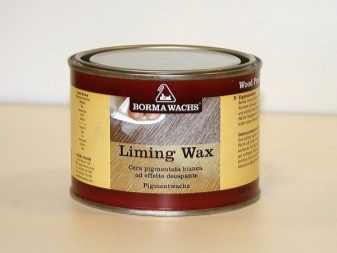

Along with the above types of wood stains, a fundamentally new product began to appear in the assortment of building supermarkets. Modern technologies have allowed manufacturers to offer the consumer acrylic impregnation on a water basis, as well as wax composition. New tools were developed in order to eliminate the main disadvantages of existing compositions.

These tools fit well on the surface, most often they are used for painting and processing the floor.

Wax stain restore old wooden coverings, it perfectly paints discrepancies in color. In addition to the above characteristics, the positive qualities of modern compositions can be attributed to their excellent moisture barrier properties. However, these tools are very vulnerable to mechanical damage, so they should be varnished. Acrylic and wax liquids are represented by a large variety of color palettes. They well emphasize the structure of wood.

The disadvantages of acrylic stains are their high cost, as well as the possible formation of stains on the surface when applying two or more layers.

The main disadvantage of wax compounds is that they are not able to penetrate deep into the wood. The tool only forms a protective layer on top of the material. This composition should not be used before processing wood with two-component varnishes or polyurethane.

Since the composition perfectly preserves the texture of wood and protects against the negative influence of many external factors, thereby prolonging its operational life, the answer to the question of whether to buy varnish or stain becomes obvious.

Color spectrum

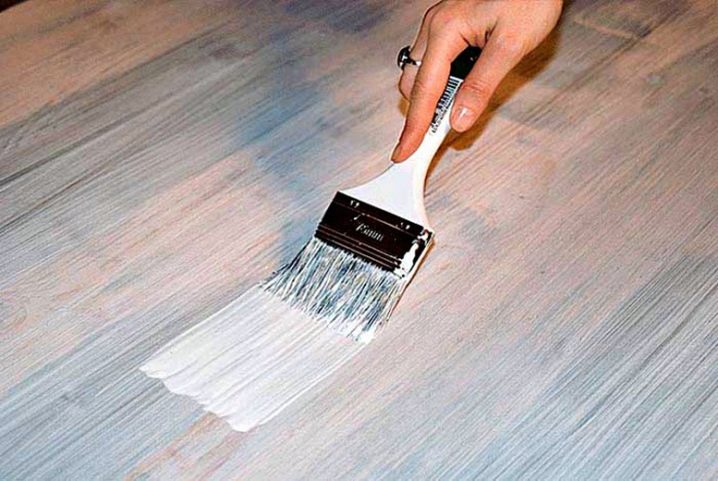

Alternative types of stain can be attributed to the white composition. This tool is the most environmentally friendly and inexpensive. Along with this, the white stain is represented by a large variety of natural shades.

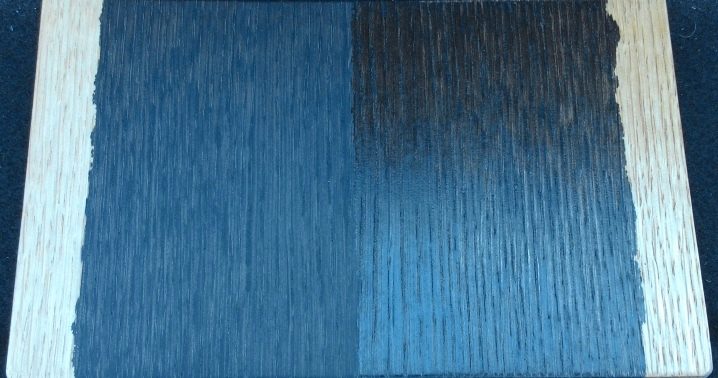

Today, the range of such tools for coating and painting wooden surfaces will be able to meet the needs of every customer. Such products allow the master to give the wood almost any color. Recently, black stain is in demand among specialists, which gives the treated surface the appearance of a black mirror. The technology of applying the composition of black color requires preliminary polishing of the base.

Shades of gray will help the surface to blend harmoniously into the interior of any room. However, the use of this color will be successful only if the walls and interior in the room will be bright. Gray color can cause apathy, and products painted in this color will be lost against the background of the rest of the decoration.

According to psychologists, the most optimal color for a person is green. It evokes positive emotions and is suitable for painting walls and ceilings, as well as for furniture and other things.

Blue color gives expressiveness and depth to the processed product. The stain of this color will be well combined with white and yellow tones.

In addition to the multi-colored compositions, there is a colorless impregnation on the counters of the stores, which makes it possible to preserve the natural color of the material.

The total color of the tree depends on the number of applied layers of the product.Therefore, experts advise to make a final decision only after the test coloring. Material for trial coloring is ground and cleaned. Next, proceed to the application of the first layer of the composition. After it is completely dry, a second layer is applied, but on a smaller area. The third layer is processed material on the area of wood, which will be even less than the allotted space under the two previous layers of stain.

When all the plots are completely dry, comparing the results you can choose the color you like.

Manufacturers: review and reviews

Today, products of foreign and domestic manufacturers are on the market.

"NovbytHim" IIt is a company that specializes in the production of construction and household chemicals.The range of manufactured compounds are various varnishes, paints, decorative materials, as well as stains on a different basis.

According to the majority of buyers, the compositions for wood from the company “NovBytHim” for processing and painting wooden products have a strong smell, but do an excellent job with their task, and also dry quickly. Therefore, painting work should be carried out as quickly as possible. The composition lays quite smoothly, the color is uniform.

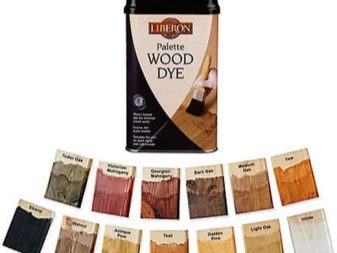

Trademark Liberon works as a part of V33 company - an international leader in the production of paint and varnish materials for wooden surfaces. Products of this brand are popular all over the world, as they are intended for caring for wood, as well as for restoration work with antique interior items and furniture.

The French compositions for Liberon wood in the domestic market are represented by decorative protective stains, wood fillers, wax removal agents.

Consumers point out some benefits of the Liberon tree:

- convenience and ease of application of the composition;

- no smell.

The disadvantages of such products include some discrepancy of the stated color indicated on the packaging.

The most famous German companies that specialize in the production of wood products are firms Flamingo, Dufa and Caparol.

Caparol has a separate line of products for protecting wooden surfaces.

No less popular products for the care and dyeing of wood are considered compositions that are produced by Turkish companies. The leaders among them are manufacturers Betek, Dyo, Marshall.

Specialists who are engaged in repair work, note the high quality of German wood compositions.

Only positive reviews have Turkish means for painting wooden surfaces.

Tips for choosing

Stains can also be classified by purpose - tools for interior work and compositions for outdoor use. The main and only criterion for their difference is the presence in the composition of the means for external work of the pigment, which provides protection against burnout.

When choosing a tool, it will be useful to decide on the tool that will be used for surface treatment with the acquired composition. There are wood stains that cover a wooden surface with a brush, for some you may need a spray gun.

For interior work, for example, if processing of pieces of furniture is required, it is better to give preference to wax or oil formulations. There are almost no volatile compounds. Almost all the stains are compatible with paints for painting.

Alcohol-based products have their own characteristics. They are ideal for tinting furniture, wood products or doors. And for a staircase or a parquet you should choose another type of stain. Alcohol formulations should be applied to the surface with an airbrush, since any error or delay in work will be fraught with the formation of a stain, as a result of which repair or construction work will have to be started anew.

Powder alcohol products need to be diluted with only 96% alcohol. But there is no guarantee that the purchased alcohol will meet these requirements. Therefore, it is worth buying a liquid composition that is ready for use. This will help to avoid troubles associated with the repair, construction or restoration work.

Oil or wax based paints have a high cost, unlike other types. But the method of applying them to the material can be any.It is recommended to carry out the restoration work with this type of wood treatment, since it is absolutely safe for human health due to its eco-friendly composition.

How to apply?

To properly apply the composition, you need to pay attention to the choice of tool that will be used for work.

To determine this issue, you should consider the following points:

- size of the working area;

- the saturation level of the surface color.

There are four main ways of processing wood stain:

- painting by rubbing - applying the product to the surface with further rubbing over the whole area. It is best to cover porous wood types in this way;

- spraying - a manual or automatic type sprayer is used for this;

- painting with a roller - using foam tools. This technology will avoid divorces and reduce the consumption of the composition;

- use a brush. With this option, the surface will have a bright color. Work with a brush is not possible with all types of stain.

In order to saturate the wood well, it should be painted strictly along the fibers - this will reduce the consumption of the composition.For ease of use, the stain should have a comfortable consistency for application.

It is necessary to apply wood stain gradually and evenly so that it can dry out in all places without exception. The first layer should be thin, it will create a foundation that will dry quickly and allow you to continue working.

Means cannot be applied on one place two times. Such an error will lead to the formation of dark spots.

The water stain after processing lifts the fibers, so after applying they need to be cleaned with a cut of coarse fabric. This is done in a diagonal or longitudinal direction.

Surfaces treated with alcohol or water are dried after 2–3 hours, oil stains will take more time — about 2–3 days.

To determine the approximate consumption of the composition per 1 m2, you need to take into account the porosity of wood. On average, one liter of stain is enough for 10-15 m2.

Step-by-step instructions for processing a wooden surface:

- remove all dirt and protruding fibers from the wood;

- pour the stain in a small and convenient container, strictly following the instructions for breeding;

- With the selected tool, carefully spread the solution over the surface.To cover the tree faster, do not try to take as much wood stain as this method will increase its consumption and reduce the quality of work.

All recommendations are the same for both external and internal work.

How to apply the stain on the tree, see below in the video.