Wood stain: types and subtleties of choice

Wood remains one of the most sought-after building materials, mainly due to its density, strength and environmental friendliness. At the same time, wooden surfaces and furniture do not tolerate moisture and are susceptible to biological and atmospheric damage.

To minimize the negative effects of wooden objects are covered with a protective layer of varnish, paint or special impregnation - stain.

Special features

The stain is usually attributed to paints and varnishes, but, unlike varnishes and enamels, it tints the surface without forming a visible film and emphasizing the woody texture. The wood fibers absorb the composition to varying degrees, due to which the natural pattern becomes more expressive, and in some cases, embossed.

This process is influenced by such factors as:

- Tree moisture. The solution penetrates better into wet and loose surfaces.

- Gummy. Coniferous species before processing the stains additionally grind off.

- Wood density. The higher it is, the worse the dye solution penetrates it. Therefore, less dense areas, such as the spring part or sapwood, acquire a more saturated color than the core or summer part.

- Wood species. The same stain will differ in color on different breeds.

- Age. The older the tree, the higher its density.

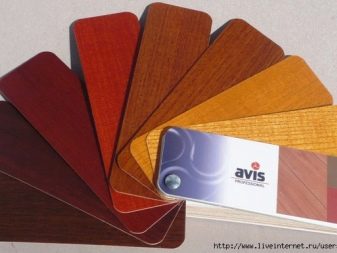

Compliance with the technology of application allows you to imagine the structure of the tree in all its glory. Often with the help of stain imitate precious woods using natural shades (walnut, oak, ebony, rosewood, etc.). It should be noted that the color range of this type of impregnation is almost unlimited, so those who like experiments will be able to choose a suitable option for themselves.

Some modern types of stain perform a protective function (antiseptic, anti-corrosion). However, the traditional composition does not possess such properties, therefore, to protect against atmospheric and biological effects, wooden surfaces are additionally coated with a suitable varnish.

The properties of the stain depend, first of all, on its composition, but regardless of this, the service life of the tree increases to some extent.

Kinds

All types of stains can be divided according to the method of coloring on penetrating and covering.

- First view due to the deep penetration of the dye allocates the texture of wood and hides minor scratches and defects. As noted above, the depth of staining will directly depend on the density of the wood. For example, soft varieties can be soaked through with a solution, and harder ones - per millimeter fractions.

- Second kind - covering stain, in fact, is a translucent varnish or paint, which softens the sharpness of the picture.

Penetrating compositions, in turn, are combined into several groups depending on the solvent:

- Alcoholic - are a solution of organic dyes in technical alcohol. Available as ready-to-use liquid and powder.

- Water based - one of the most popular types of impregnation. In this group, the most emit acrylic stain.

- Oil stain - Perhaps the easiest to apply material.It is made from colored pigments and oils capable of polymerization. When dried, a thin film forms on the surface. Dilute such a composition with all known white spirit.

- Chemical.

Specifications

Water based impregnation

One of the most common due to low prices. It is found in two forms: liquid and dry in powder form, which is diluted with warm water before use. Color saturation can be adjusted by the amount of water.

Main characteristics:

- Ease of application. You can use any convenient method (brush, spray, roller).

- Even staining. Wood absorbs exactly the amount that its structure allows. Excess can be removed with a cloth.

- Efficiency. Consumption of aqueous solution is less than alcohol or oil.

- Deep penetration in the pores of the wood.

- Environmental friendliness. The smell is almost absent, which allows its use in enclosed spaces.

- Drying time - 12-14 hours.

- Pile raising. On the one hand, this makes it possible to even more distinguish the pattern of the tree, on the other hand, the surface after drying remains roughened and vulnerable to moisture.Eliminate this defect by additional grinding after drying. Avoid the unpleasant effect of pre-moistened wood. When the fibers rise, the surface is sanded and only then it is sealed.

- Color spectrum It is presented only in natural shades from light to dark.

- Only tints. To protect the tree, it is necessary to additionally treat the area with varnish.

One of the modern variations of water-based stain is acrylic stains. Unlike traditional compositions, they do not penetrate deeply into the structure of the tree, practically do not lift fibers, have a wider color gamut, and are more resistant to fading. Their only disadvantage is a significantly higher price.

Alcohol impregnation

As well as water, it is presented in the market in liquid and dry forms. The powder is usually diluted with technical 96% technical alcohol. Due to the difficulty of obtaining the required percentage of solvent, it is desirable to obtain ready-to-use solutions. Specifications:

- Dries quickly (15-20 minutes). This is rather a drawback, since in order to avoid noticeable boundaries, it is necessary to work quickly, without interruptions and as carefully as possible.Stains and blots are removed only by sanding an unsuccessful area and re-applying the solution. Of all the methods of applying the best sprayer will be.

- Does not cause swelling of the fibers. The coloring pigment penetrates into the surface, and the alcohol evaporates. This eliminates the need for additional grinding work.

- There is a strong smell of alcohol. Recommended for use in ventilated areas.

- Greater weather resistance.

- Additional varnish processing is optional.

- In addition to natural wood tones, color variants are also possible (white, green, red, yellow, etc.).

- Can be mixed to get new color.

Oily

Unlike the previous species, oil, most often linseed, acts as a binding component in the oil stain. To reduce the drying time, siccativa is added to the composition, which stimulates the polymerization process. After combining all the components a thick mass is formed, which must be diluted for uniform application.

Benefits:

- Ease of application. Does not require special skills and tools, does not leave streaks, visible borders and smudges.The best result is obtained when using a conventional brush.

- No fiber swelling. Additional work on the preparation and grinding of the surface is not required.

- Resistant to fading.

- After complete polymerization (drying), the surface can be treated with almost any paint and varnish product.

- Surface preparation consists in thorough removal of dirt and traces of previous dyes and adhesives, and degreasing the surface. In the presence of visible scratches polished. This is one of the important points, since a larger amount of dye will accumulate in such defective areas, thereby highlighting them, rather than hiding them.

- Requires a topcoat. Without it, it quickly loses its attractiveness, especially with frequent mechanical action.

Chemical

The peculiarity of the composition of this stain is the absence of coloring pigment. They are marketed under the name of double staining, as they consist of two substances that are applied in stages. The composition of the preliminary application contains tannic acid (tannin, gallic). It is applied if the wood contains a small amount of natural tannins.

Final stain - These are salts of heavy metals, which, reacting with a tanning agent, give the necessary shade of staining. The product of such a reaction under natural conditions is the well-known bog oak, which is mined from the bottom of reservoirs. Tannins in the wood, in the absence of oxygen, reacted with iron salts, resulting in a beautiful material with unique physical properties and natural protection.

Application area

The scope of the stain is applied to any objects and surfaces made of natural wood, plywood, MDF, particleboard, fiberboard. The task of all lovers of natural - to preserve the natural beauty of the tree as inviolable as possible. With this, the wood stain will help you to quickly and cheaply, while its property of giving a noble shade to inexpensive breeds, such as birch, ash, pine and others, will allow you to add a touch of luxury to the interior.

Morenning followed by varnishing is a good choice for processing a new floor, wall paneling or parquet.

On such surfaces, the solution on any basis lays better and the desired result with its help is easier to achieve.Otherwise, the surface requires careful preparation: removing the old coating, traces of glue, scratches and chips.

As it turned out, the stain can be successfully used not only for its intended purpose, but, for example, for painting unpainted skin. Its advantage over special paints is not only in price, but in the ability to penetrate into the fibers of the materialtherefore, the resistance of the coating to mechanical stress is higher.

The downside can be called pale translucent tones. That is, to block the previous color by the stain will not work.

The end result of dyeing depends on the basis of the dye. Aqueous solutions give less bright color than alcohol or oil. Alcohol dry quickly, so you should not share the work on one site, as the borders will be visible. Oil, perhaps the most suitable option, as they give a fairly bright color and, unlike the first two, do not change the rigidity of the skin, but they are more expensive.

In addition to tanners, the stain is successfully used by lovers of basket weaving. Since the traditional material is not enough at all, newspaper tubules are used to this. To make them the color of natural vines help stain of natural shades. Most often, masters use alcohol-based solutions.but it is not an axiom. Experiments and color combinations sometimes lead to interesting results.

Manufacturers

Manufacturers of stain on the market quite a lot. Among the most famous can be noted Novbythim. They have an assortment of water-based dyes, organic solvents and a non-aqueous base.

Non-aqueous solutions are designed to paint and protect wooden products both indoors and outdoors. They do not require a topcoat, but you can additionally apply a varnish to impart gloss.

They do not wash off with water and give fireproof properties to wood. Water stain is mainly used indoors, as for exterior work necessarily lacquer coating. It is environmentally friendly.

Acrylic products of domestic brand "Rainbow" designed for interior work. It contains antiseptic, therefore it protects wooden surfaces from mold and fungi. Odorless, non-flammable, non-toxic. Easy to apply without special skills. Shows good adhesion with both natural wood and wood composites.

Trademark Liberon manufactures products for the restoration of wooden products. This water-based stain is suitable for indoor use. Theoretically compatible with any finishing coating, but users recommend products from the same manufacturer.

Water stain Zerwood companies used indoors, for external use, it is desirable to fix varnish or akvalazuryu. The colors are natural and beautiful - from light pine to dark ebony. Odorless, eco-friendly and economical.

Among proven products it is also worth noting oil-based stain. "Varathane Wood Stain", popularly called "Varatanovskaya".

This product is an American company. Rust-Oleum presented in a wide color palette, safe, easy to apply. Reliably protects wood from adverse effects, suitable for use on all types of wood products and surfaces. Dries quickly (about an hour).

Tips and tricks

Toning wood stains begins with preliminary preparation. The surface is carefully sanded, then ground,this removes the old coating (if any) and defects. The resulting dust is removed using white spirit, while the surface is further degreased. In addition, coniferous wood is degummed with special compounds.

If a water-based composition is selected for staining, the product is moistened with water and re-polished after lifting the fibers.

Another mandatory preparation point is the color test. This will allow you to find out how the selected dye will interact with a particular tree variety. To do this, apply the stain on the hidden part of the surface and wait for drying. If the result is not satisfactory, you can apply a second layer for a more saturated color or, conversely, dilute it if you need a tone lighter.

If for some reason the desired color of the stain can not be found, you can try to make it on their own. The most common recipes are strong tea and coffee.. The shades are obtained respectively brown, and the saturation of the tone will depend on the strength of the drink.

Cherry and dark brown color can be obtained using ordinary potassium permanganate. The approximate ratio is 1 liter of warm water per 50 grams of substance.

Bright atypical colors are obtained at home with the help of alcohol and food coloring (1 tablespoon of alcohol per several grams of dye).

Another tone wooden products can be given using decoctions of plants. Larch bark or onion peel will give a reddish tint. A strong decoction of oak or alder bark will allow you to get a deep black color.

Doing your own hands does not require the use of any specific tools. For these purposes, the usual brush, paint roller, rags, spray gun will do. True, there is a small nuance: quick-drying alcohol solutions are sprayed, because with other tools it is difficult to achieve a uniform coating.

About the features of work with the stain, see the next video.