What you need to cut the laminate?

Laminate flooring is a popular flooring, as it has a chic design and a long service life. Products of this type consist of a woody base and a special decorative layer. The production technology of laminate allows you to give it not only a different color, but also the structure of various wood species. Laying this material is relatively simple, but almost always requires trimming boards. Therefore, before proceeding to the installation work, be sure to find out what you need to cut the laminate.

Cutting methods

Installation of laminate board involves fixing it to the floor with glue or special screws. But many beginners do not know how to cut laminate to get a quality and even joint.

You can cut vinyl or cork laminate at home with a few tools:

- Cutter. This design resembles a guillotine. To cut the board, it must be placed under the knife along the line of the cut. After that, with a certain amount of effort, the cutter is pressed in, which produces a cutting. If you have certain skills with this tool you can cut laminate even along.

- Jigsaw. Cutting with this machine is one of the fastest and most affordable. But for processing laminate it is important to use only special saws. To cut the desired piece, you need to measure the necessary dimensions and draw a flat line. After that, the board moves a little off the table so that the saw moves in the air and the cutting begins.

- Hacksaw. Cutting laminate with it can be performed both on the floor and at a certain elevation. To do this, you also need to mark the line and gently start sawing. Here it is important to consider the divorce of the saw, as it can take a lot of laminate. This in turn can lead to inconsistencies.

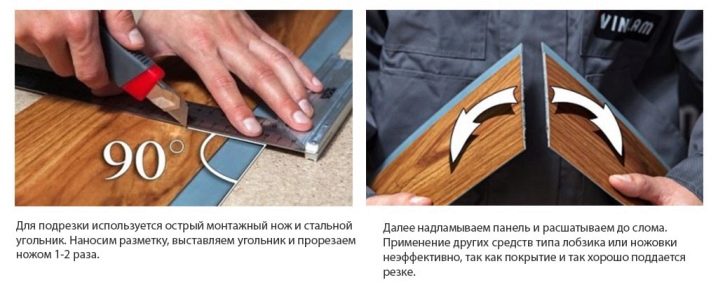

- Knife. The top layer of the laminate is a thin layer of film that is easily damaged with a regular stationery knife. The technology of working with this tool is quite simple.Along the marked line you need to hold the edge of the knife in such a way as to cut through the top layer. If you want to get a flat line, then in addition the board should be properly fixed.

When you cut the top layer, you need to break off an extra piece. To do this, laminate on the edge of the table along the cutting and sharply press on one of the sides. This approach is reminiscent of breaking ceramic tiles or glass after glass cutting.

- A circular saw. Cutting with this tool is much faster. To cut a piece of laminate, you should also mark up. After that, the board is fixed on the frame along the plane of movement of the saw. Place the product to the top of the laminated layer. In this case, the saw blades will enter the material, which will reduce the formation of chips and cracks. When everything is set, you need to slowly lead the board along the cutting line with the circular switched on.

- Bulgarian. This tool works like a circular saw. Similar types of cutting wheels are also used here. But cutting can already be done almost anywhere. But to get an even cut, you need to fill the hand that controls the grinder during processing.

Choosing a tool

As you already understood, there is no universal way to cut laminate. To do this, use a variety of tools that have their pros and cons. It is impossible to say which option is better, since everything depends on the individual situation.

To choose a quality tool, you should consider several factors:

- The required quality of the butt. If you need a minimum number of chips, use a hand cutter or jigsaw. In another case, all the considered cutting methods are perfect. They will allow you to correctly cut the board with minimal effort.

- Type of cutting. The easiest option is when you need to cut the laminate across. The length of the groove is relatively short, which minimizes the risk of a large curvature. When you need to cut along one of the sides, in this case it is better to use the cutter and a circular saw.

Please note that you can perform similar operations with other tools. It all depends on your capabilities.

- Form rezi. Practically all mechanisms allow cutting the board only in a straight line.If you need to get a complex form of laminate, then the solution to this problem will be a grinder or jigsaw.

A circular saw

Circular cutting is one of the most popular options, as it has several advantages:

- The ability to use discs with different sizes of teeth. This allows you to adjust the cutting process and the quality of the surface.

- The tool works on electricity, which eliminates the use of fuel.

- Processing laminate around is not accompanied by significant noise, which allows you to process the board, even in apartment buildings.

- High speed. The efficiency of the circular saw is one of the best. Therefore, it is used by many professionals who are engaged in laying such materials.

The only disadvantage of this mechanism is that in order to obtain high-quality cutting material, one needs to have certain practice and experience in working with it.

Electric jigsaw

It is pleasant and fast to work with a jigsaw. The tool has a small weight that allows you to keep it well during cutting. At the same time, the mechanism practically does not form dust, which makes it a unique option for private use.

The lack of jigsaw can only be incorrectly chosen file. Poor-quality products will simply tear the laminate, forming ugly ends, which will have to be further cleaned. To get a quality thread, the jigsaw must work at maximum speed.

Knives

Manual laminate cutting is relatively rare. For such purposes, use as office knives and hacksaws.

When using the latter type of tool, it is important that it has very small teeth.

There are several drawbacks to this approach:

- The cutting process with hand tools takes time. This in turn affects the efficiency of laminate installation.

- To get a high-quality cut, you need to act very carefully and slowly. For this you need to have a relatively large experience with similar materials and tools.

- Get cracks without chipping with a hacksaw is almost unreal. Therefore, the cutting position is often further cleaned.

Bulgarian

The grinder is a universal mechanism by which you can cut not only wood, but also concrete.For the processing of laminate used special discs, which are applied to the teeth, like a circular saw.

The use of the grinder has several advantages:

- It can be used to form both a straight and shaped cut.

- The ends obtained after cutting are of high quality.

- The operation of the grinder is possible even without prior preparation of the material.

But this tool has several bad sides:

- The weight of the structure is significant, which does not always allow quality control of the cutting process.

- During operation, the grinder forms a lot of fine dust. It is not always effective in residential areas.

- When cutting, the ends of the laminate begin to warm up, which leads to the formation of burning, which, together with dust, is very harmful to the human body.

Guillotine

The cutter is perfect for hand cutting. Among the advantages of this tool can be identified quiet, easy operation and high-quality cut. It is relatively simple to work with such mechanisms, the main thing is to observe only precautions, since the knife is very sharp. Cutting guillotine does not lead to the formation of dust, which makes it a professional tool.

The peculiarity of this material is that it is recommended to cut them laminate only in the transverse direction.

But if you train a little, you can work the boards along. The cost of such a tool is quite high, so for a one-time installation of laminate to buy it is not economically profitable.

Other options

An alternative option for processing laminate are special machines, with which you can get a high-quality cut. They are intended only to work with such a substance. Cutting laminate with their help is very simple, as they are equipped with special clamps and several types of knives for different layers. In everyday life, it is almost impossible to meet them, as the constructions are very expensive.

Cutting features

The cutting technology depends not only on the tool, but also on the correct approach to the processing of this substance.

Therefore, such operations should be carried out, guided by several simple recommendations:

- All cutting tools must be equipped with a saw with very small teeth. This applies to both a regular hacksaw and a jigsaw. Such an approach would eliminate the appearance of chips and ugly ends.Many experts recommend the use of metal saws for handicrafts.

- If you got an ugly cut, then try to hide this board under the plinth. Sometimes it can be trimmed again, but it is important that the length of the element after this is suitable for a specific row.

- Try to take measurements several times. Thus, you get more accurate data, and this will not lead to damage to the laminate.

- Depending on the tool chosen, the boards should be laid either up or down with a decorative layer. This will eliminate the formation of large chips.

- If you need to get a shaped cut, then the best option would be to use special templates. To simplify such an operation, you can stick a building tape along the entire length of the cut. The best tool for such processing is a jigsaw.

Cutting laminate is a simple operation, requiring only the choice of a quality tool. It should be carried out adhering to the basic safety rules, since the work is done with very sharp blades and saws.

You can watch one of the ways to cut laminate from the video below.