How to choose a sealant for laminate?

Laminate is considered one of the most popular materials. The reasons are that it is inexpensive, looks very advantageous, mimicking the most different varieties of trees. Not to mention the durability and good resistance to mechanical stress. Our article will help you choose the appropriate sealant for this material.

Special features

You can meet such coverage in business centers as well as in apartments or sports halls. Installation of laminate is not a big deal even for a beginner. It is only necessary to understand the sealants, without which the normal work of laying will not work.

Various components are added to this plastic material. First of all, these are fungicides that effectively counteract the fungus and the development of mold.

It is mandatory in the sealant are present:

- A piece of chalk.

- Quartz flour.

- Extenders.

Such additives significantly reduce the viscosity and give the substance greater plasticity. Dyes make it possible to obtain the necessary color, after setting it will be unrealistic to change, therefore it is recommended to select shades in advance.

This product can not be called a full-fledged glue, it performs several other functions. Sealant for laminate "works" as an elastic seal, protects the seams and joints from moisture penetration.

Different manufacturers produce products in different ways. Usually it is presented on the market in tubes or tubes.

In the kit, as a rule, there is a “gun”, which allows you to effectively use this substance.

Kinds

Silicone

It has the following performance characteristics:

- Good elasticity.

- Large supply of resistance.

- Durability.

Such a substance is reliable and durable, it does not let moisture through the treated seams and gaps.

The basis of silicone sealant is a material with the following advantages:

- Plastic.

- Good strength.

- Effective water tightness.

- Non-toxic.

Acrylic

Its distinctive feature is the long preservation of the original color scheme. Often various color additives are added to the natural white color. Acrylic material is often used as a "cosmetic" product that successfully hides various defects, for grouting tiles, etc.

The advantages of the material include:

- Ease of use.

- Lack of toxins.

Means does not leave marks after use. Acrylic sealants are well known and in high demand, have a richer range of colors, which also contributes to their demand.

Manufacturers advise the use of such substances in order to perfectly isolate all gaps between the boards.

The use of such material makes it possible to avoid wetting and significantly increases the service life of the product.

Advantages of sealant:

- Gives the chance to carry out all types of cleaning indoors.

- Universal in use.

- Increases noise insulation.

- Perfectly retains moisture.

- Forms seams which differ in the phenomenal durability and at the same time elasticity.

- Effectively hides a variety of laminate defects.

- It has increased adhesion, which eliminates the risk of cracking.

Antiseptics - special additives that do not allow fungal parasites to multiply. Color filler gives you the opportunity to have the necessary viscosity, quartz powder is usually used, there are other materials. Dyes give the necessary shade, it is worth remembering that there are also colorless silicone sealants.

The consumption of a substance is due to the depth of the grooves; usually one package is enough for 7-10 meters.

A colorless gel that can isolate locking joints is calculated like this: 1 tube per 10 meters.

Before you start working, you should:

- Insert the technical tube into the balloon at an angle of about 45 degrees.

- At the bottom of the tube should be pressed a little.

- Spread the content evenly across the plane.

- For a twenty minute pause.

- Remove excess with a knife or spatula.

Be sure to make sure that all the grooves are filled, this also applies to the joints; residues should not go outside. If at the edges there are residues of the substance, then within twenty minutes, until they are frozen, they are carefully removed with a spatula.If, however, traces are present on the surface, they can be easily removed with a rag dipped in white spirit or gasoline.

The docking places of the panels should be handled very carefully and carefully. The putty is usually applied from the side of the joint. The use of a special gasket will not allow the product to adhere to the interface plane, the substance should also not adhere to the gasket itself.

Which is better?

Acrylic and silicone sealants today are very many manufacturers from around the world. Among the most popular and well-recommended are the following:

Click Protect

Produced in Sweden, is inexpensive, about two hundred rubles per tube. (290 g). Hardens for half an hour, very economical consumption, one package is enough for fifteen square meters. This product is universal, it can be used not only for the floor, but also for all sorts of wall panels, for example, MDF.

Click guard

Another quality sealant. Produced in Germany. Differs in the increased resilience to moisture, has excellent wear resistance.

He has no equal in the processing of joints, effective during installation of the laminate.It should not be used only in places of high humidity. The sealant itself, however, confidently demonstrates increased water-repellent properties, is colorless, which is sometimes useful. Packed in tubes of 110 g, this amount is usually enough for ten square meters.

Masterfix

Produced in Russia. It has a number of universal properties, it is inexpensive. With this composition, you can work with any surfaces and joints.

Also suitable for any material:

- MDF.

- Parquet.

- Mixed materials.

Packed up in containers of 320 g.

Soudal

Acrylic sealant that is best suited for:

- Joint treatments.

- Processing the gaps between baseboards that occur after installation.

- Elimination of various traces of mechanical damage.

Adhesive properties are the best among substances of this class. Often used in the processing of tile joints. There are no smells, it is possible to apply only with the help of a special device "gun".

Rico aquaStop

The basis of this product is a natural wax, which is suitable for sealing joints, which allows you to reliably isolate the coating from the effects of high humidity.

Easy to apply to the surface using a brush. Effective to protect against the penetration of any liquid, you can seal a variety of seams, can also be used for floorboards, powders.

Homax click

It is recommended to use when grouting, it has a minimum time of "setting". There are products of this brand that have an unpleasant smell, there are those that do not smell at all.

The product is characterized by increased elasticity and at the same time durability. Effectively resists humidity and temperature changes. This product can close all the joints of the gap between the boards.

Other benefits:

- Does not leave marks, the remains are easily cleared.

- Does not contain toxic substances.

- It has good sound insulation properties.

When mounting at the ends of the slats, no residues of putty should be left; they should be necessarily removed. The locks are fragile, during work it is easy to damage them, you should be careful.

How to apply?

Installing laminate with a good sealant is simple and creates a good seal.

Operating procedure:

- Places of application of the substance thoroughly cleaned and cleaned, they should not be fine mechanical particles or dust.

- The seam is coated with an even layer on the intended site.

- Plank laminate before "setting" is placed in the groove of the slat series, which was before, then gently pressed and closes.

- The composition is covered side panel.

- After a couple of tens of minutes, the extra dried up "burrs" are removed.

Gaps that inevitably arise during installation work are conveniently sealed with sealant.

Procedure:

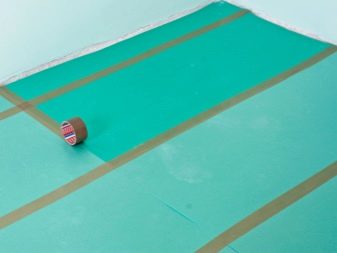

- Preparation of the site where the work will take place.

- Sizing adhesive tape in the places where the work will be carried out.

- The recess is filled with substance.

- Residues along the edges are leveled; this should be done after several minutes after applying the substance.

- The protective tape is removed.

Half an hour after the start of the operation, possible residual sealant is removed with a damp cloth. Similarly, it is possible to process not only the coating, but also, for example, to repair a chip on the floor or a seam on the tile.

Reviews

Customer reviews that have already managed to use acrylic and silicone sealants are mostly positive. In their comments, buyers note the high quality of products of famous brands. The material is easy to apply, dries quickly, has an economical consumption, neutral smell.Such tools can be used even in enclosed spaces.

With the help of products of different brands, it is possible to quickly and effortlessly impart waterproof properties to the finished coating in the most vulnerable places - the seams. Laminate coating looks very smooth, whole and aesthetically pleasing.

Successful examples and options

In order to properly apply sealants, you must be able to handle them and know some of the subtleties of technology:

- Before buying a product, you should take a sample of the laminate and check it with the color map, which is presented on the store counter or on the website of the marketplace.

- It is not recommended to adjust the panels too tightly during the operation, using a special type of sealant that prevents deformation of the laminate.

- Slats are fitted tightly to each other, with the locks must be in the closed position. All sealant should be removed before it is completely dry.

- It is recommended to use polyethylene gaskets to avoid contamination.

- You must strictly follow the instructions that are always attached when selling goods.

For how to choose a sealant, see the following video.