Lath for laminate

Currently, laminate is the most popular finishing material for the floor. The demand for such a coating is due to its excellent performance, beautiful appearance and the widest range. However, it is not enough just to lay out the floor with laminated panels. Its repair must be completed with special parts, such as powders. About these constituent elements and will be discussed.

Advantages and disadvantages

The main advantage of laminate thresholds is their function of protecting the floor from damage and dirt.By installing such a detail, you can significantly extend the service life of the finishing material.

In addition, a properly selected attractive nut can also perform a decorative function. The main thing is to get the option of a suitable color and texture. Fortunately, now in the shops you can meet the designs of any shades.

These elements have no significant disadvantages. The disadvantage of the threshold may be low-quality material from which it is made. However, this problem can be avoided by contacting a bona fide manufacturer.

Also rare varieties of linings are difficult to install.

Purpose

The correctly chosen nut is necessary to conceal the joints formed in the place of "collision" of two different floor coverings. For example, it may be the distance between the laminate and tile or soft carpet.

Also, with the help of these thresholds, you can cope with the ugly difference that appears at the junction of two materials.

In the joints of laminate and tile, the following types of thresholds are most often used:

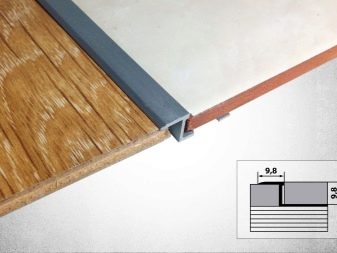

- Edging (he's leveling).This option is recommended to apply in case there is no too sharp and noticeable difference between different floor coverings. As a rule, these models are made of metal and are complemented with an anti-slip rubber grip;

- Decorative. Such attractive thresholds are most often used to design the transition from one room to another;

- Curvilinear. These types of thresholds are suitable for decorating dissimilar flooring, forming a beautiful junction with each other;

- The final one. Such a docking bar is especially used in the finishing of the edges of the laminate in the hallway. Also to the final models can be accessed to design a raised finishing materials. For example, it may be a transition from a room to a balcony (for this you need a special balcony option), a loggia or a staircase.

Design features

Without a properly matched threshold, a laminated floor will look unfinished and sloppy. These parts are simply necessary to close the joints between different coatings. Fortunately, current firms produce many varieties of thresholds that have different shades and performance characteristics.

The designs of the thresholds for laminate are different.First of all, all overlays are divided into levels.

The following options are different:

- multilevel;

- single level;

- universal.

In addition, there are such threshold constructions:

- Self-adhesive single-level. On the one hand, they are covered with a special adhesive composition that allows them to be attached to the base;

- Skid resistant. This profile is complemented by special linings made of polyurethane or rubber;

- With open cable channel. These options are a special wide guide (single-level), consisting of plastic or metal. At their center is a special cavity.

Kinds

You should not think that such a connecting detail, as the threshold, is presented in one available modification. In fact, there are several varieties of this useful detail. Consider them in detail:

Transient

As a rule, these types of thresholds are used in the decoration of compensatory slots. Mainly, transitional options are aimed at creating a smooth and attractive transition from one type of flooring to another. You also need to note that these elements are able to protect the laminate from debris, dust, dirt and other defects.Moreover, the coating having a transition threshold will be perfectly protected from mechanical damage. Many owners use these components for the unobtrusive visual separation of space into separate zones;

Multilevel

Such powders can have both traditional and unusual shape. They are intended for leveling the existing differences, which are formed due to the different height (and width) of the two finishing materials. The difference in two different coatings can be 1.5-10 (sometimes 20) cm and you can’t do without a nut. Most often in these designs there are the same systems of fasteners as in single-level copies (open and isolated). Today, in stores you can find more thoughtful multilevel thresholds, supplemented by a special fixation piping (L, Z-shaped).

Corner

As you know, laminate is extremely rarely used in the decoration of stairs and steps in the home. That is why special corner pieces are considered so practical and popular. Such options are made of metal, wood or MDF. They protect the flooring from dangerous slipping, dirt and ugly scuffing.Angular powders are fixed in standard ways: open and closed. If you chose a non-insulated mount, then the corners should be fixed with special hardware. If we are talking about closed fasteners, then you need to use edges of non-standard forms;

Edging

Most often, these strips are made of metal, which explains their strength and durability. In another similar thresholds are called marginal. They are an excellent analogue corner pads for the steps. Such options may have a different structure, but their attachment always remains closed. The sizes of edging strips can also vary. In order to correctly choose the optimal product, experts recommend going to the store along with a laminate sample (so as not to “miss” in the measurements);

Special

Also in many stores you can meet special sills for laminate. They can be single-level or multi-level. Special products are made from MDF or aluminum. A distinctive feature of such edges is the presence of special profiles (Z, H, F, L-shaped). Such thresholds are made joints of homogeneous materials with a single or different colors.Special linings are great for forming neat expansion joints. Fix these parts can be exclusively closed method.

Materials

Modern manufacturers produce harmonious and reliable sills, made from a variety of materials. Let's get acquainted with all existing options that are in great demand.

Of metal

Most often in the manufacture of thresholds used lightweight aluminum, and a little less - brass or sturdy steel. Such parts can boast durability, durability and practicality. That is why the metal lining is so popular and widespread today. Such designs can be used not only in home interiors, but also in public places and offices with high traffic.

The main advantage of aluminum thresholds is their non-susceptibility to corrosion. In addition, these options can play a decorative role in the room, as well as stainless steel products.

Anodized

These are the same metal products that have been processed by anodic oxidation. After that, a special metal film forms on the surface of the part,having the most different colors. It can be gold plated, silver plated, or even bronze paint.

Anodized specimens look very impressive and elegant. Many consumers choose them not only because of the original design, but also because of the excellent performance characteristics. Such elements are not susceptible to damage, the formation of scratches or chips, so they retain their beautiful appearance for a long time.

Painted

Such options from the top are covered with powder-polymer compositions of different tones. It can be not only a muffled and neutral shade, but also a very bright and juicy color that attracts attention.

Painted with special means thresholds are not subject to abrasion and fading, so you can safely talk about their durability.

Laminated

Reliable aluminum lining is often covered with a special PVC film, characterized by durability and texture richness. Many variations can exactly repeat the surface of the laminate.

Laminated thresholds are one of the most popular and widespread nowadays, as they look quite presentable and aesthetically pleasing, but at the same time they have an affordable price.

Chrome plated

Some defects are covered with chrome. The result is very spectacular and attractive parts with mirror surfaces. This coating lasts as long as possible and does not lose its beauty even after many years.

However, it should be borne in mind that the chrome thresholds will not look organically in classic or historical interiors. Their brilliance will attract too much attention to themselves, getting out of the not very modern ensemble.

Flexible

The easiest and cheapest is the plastic threshold. It can be painted in almost any color, since plastic is easily supplied to any treatments. Often, such parts have soft rubber lining, providing anti-slip effect.

Plastic structures are assembled from the following parts:

- mounting rail attached to the base on screws or special construction glue;

- profiled threshold that is inserted into the slot connector, where it is then firmly fixed.

Made of wood and MDF

Similar powders are not less common and demanded by modern consumers. First of all, they are chosen because of the environmental safety of complete safety.There are no harmful and hazardous compounds in their composition. However, there are such pads more expensive than the available options of plastic or metal.

Mounting and mounting methods

The durability and reliability of the design of the threshold largely depends on its proper and accurate installation.

First, you should familiarize yourself with the types of fastening of these elements:

- open;

- isolated (or closed).

In the plank with open fasteners there are initially prepared holes for future installation of the part. Some manufacturers do not drill such connectors, but this should not be a problem for you, as you can make holes yourself. Before directly mounting such a nut, you must carefully cut the distance between the boundaries of the coatings. It may be door jambs or baseboards.

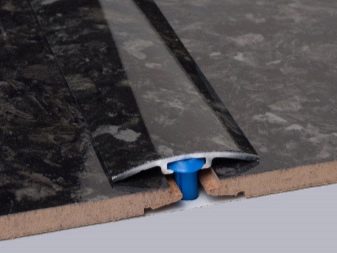

If the laminated panels lie on the base of the tree, then the threshold can be attached to it using ordinary screws. If the floor in the dwelling consists of durable concrete, then it is better to make special holes in the places of future fixings and install plastic dowels in them. Thresholds with hidden mounting systems are the most thoughtful and accurate.

For this perfect fit parts, composed of two main elements:

- Mounting. This part is attached to the base with screws;

- Ornamental. Under this detail all fasteners disappear. The decorative part is most often attached to the assembly component with the help of a standard lock fastening.

It is permissible to attach laths for laminate to the base with the help of special mounting glue. Some owners use a more affordable composition of PVA, but it can not be called the most reliable in this case.

It is also possible to refer to the combined option of fixing the threshold. In such cases, is used as an adhesive composition, and screws.

Most often, such an installation is resorted to in the case of large width and length parts or plastic products.

How to choose?

Do not underestimate the importance of such details as the threshold. Without it, the flooring may seem sloppy, which will negatively affect the overall look of the interior. The selection of the threshold should be in accordance with the following important criteria:

- The functional significance of the rooms. Interior threshold must be selected based on the functionality of the two rooms located at the junction of different floor finishes.So, it can be an entrance hall, decorated with wear-resistant laminate, and a kitchen decorated with ceramic tiles. Since the kitchen is a space with high humidity, the threshold should be selected from waterproof materials (plastic or aluminum);

- Materials The threshold should be made of high-quality and durable materials, and it doesn't matter at all whether it will be located: at the junction of two rooms or at the entrance door itself. The product made from low-quality raw materials will not last long and will quickly become unusable;

- Design. In choosing a quality threshold for laminate there are no serious rules relating to its design. In this matter, it all depends on the personal desires of the owners and the style of the interior. For example, in a classical ensemble there is no place for a metal chrome-plated part;

- Type of mounting system. The most aesthetic is hidden fasteners. Its installation is possible to do it yourself, without attracting experts. But It should be noted that the installation of open systems is considered elementary, since it initially contains all the necessary holes. Installing them, you only need to carefully and correctly fasten the bar in the right place.Self-adhesive profiles have another simple and affordable fixing method. They need only be securely fixed at the junction of the flooring and properly pressed (it is better to do it with someone together);

- Manufacturers. For the purchase of such items, it is recommended to contact well-known brands in order not to purchase low-quality goods. Unreliable and too cheap threshold can quickly fail and lose appeal.

Manufacturers

The following well-known companies produce quality and reliable sills:

- Russian manufacturer "Luka";

- firm "Profotdel";

- Viscount;

- Diflorse;

- "ADV parquet";

- Belgian firm Balterio;

- Classen brand from Germany;

- famous French company Tarkett.

All of these manufacturers produce high-quality and durable lining of metal, wood, MDF and plastic.

In their assortment there are both very cheap (but no less quality) and costly set-ups made from natural raw materials.

For how to install the threshold for laminate, see the following video.