Brazier made of metal: the nuances of manufacturing technology

Barbecue masters can cook this dish even in the middle of a deaf forest without a single device for this. But still it is much more pleasant and convenient to use reliable, proven and durable devices for cooking in nature. But most often this process occurs with the participation of braziers.

Special features

The most common barbeque fixture is a metal grill.

Here are its main advantages.

- Simplicity. Most often, the brazier is a box with legs, into which firewood or coal is poured, fire is set, and a skewer with meat or a grate with vegetables is placed on top.

- Mobility. Some metal models can be used anywhere: on the ground, on a concrete platform, on a terrace, or even on a sandy beach.

- Functionality. Even the most simple of the invention can be decorated with ornate forging, which can serve as additional hooks for hanging skewers or mesh. You can build a structure with a roof or with additional shelves.

- Security. The metal does not burn, does not melt and does not create fires. And this is a big plus.

- Efficiency. Even in the absence of the necessary material and the desire to make a grill of metal on your own, you will spend a small amount of money to purchase it.

The disadvantages are not always the aesthetic appearance and the fragility of some models. However, all these nuances are eliminated and regulated individually for each user and for each case.

A unique feature of metal grills is that they can be easily made independently.

You do not need to have any special knowledge or skills. It is only necessary to determine the model and materials, to listen to the advice of professionals or simply knowledgeable people, and also to be sure that your plan is implemented on all 100.

Device and principle of operation

Starting to consider the device from the bottom up, be sure to pay attention to the legs. As a rule, these are four metal corners, pointed downwards so that they can be stuck into the ground. The height of this element is selected individually, if the product is made to order. In the building and gardening stores, you will most likely find standard universal models from 80 to 120 cm long. Metal reinforcing bars are sometimes chosen as this element, some craftsmen resort to wrought barbecue base.

There are also unique home-made designs installed on the lower iron part of sewing machines, unusable tables, and so on. Practically everything that stably holds on any surface and is able to withstand the mass of a metal box and its contents in the process of cooking on fire is used.

The steel box, which consists of four sides and bottom, is the basis of the mangal construction. Often, the lower part of this box is made reinforced in order to increase the lifetime of the entire structure.The side walls must be perforated so that the heat does not accumulate in one place and air is circulated. Thus, it creates a kind of blower, as in the ovens.

At the upper edges of the long sides of the metal box, grooves are made into which a skewer is then very conveniently inserted. This minimizes the movement of mini-skewers on the metal.

The principle of operation of such braziers is known to everyone. Coals or logs of firewood are laid on the bottom of the metal box, the fire is kindled. When the fire subsides, and only coals, ash and heat from them remain in the grill, a skewer with pre-prepared meat or vegetables is laid out in orderly construction. The heat in the hearth is supported by improvised means that create a powerful stream of air inside the structure, but do not re-fire the fire in the ashes.

Types of designs

As for the various constructions that imply comfortable cooking of kebabs, here you should first understand the main types of metal grills.

Only four of them.

- Disposable. Barbecue in a hurry. Everything that can be found nearby is used - from tin cans to two U-shaped metal profiles.

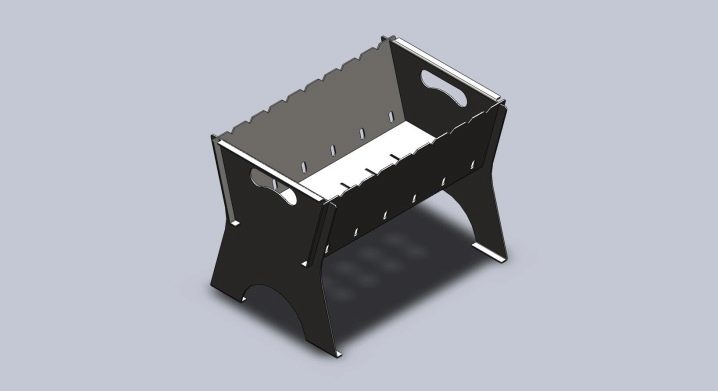

- Stationary. The second step in the evolution of metal braziers.Simple, economical, sustainable. It is possible to use both in the open air, and under a canopy. If necessary, you can add a roof, an exhaust hood (or even a chimney), a stand for pots and a double bottom.

- Demountable. It differs from the stationary way of fastening the elements of the barbecue to each other. In the first, all the joints are spot welded. In the second they are fastened with metal bolts or hinges, which allows it to be disassembled for a time when it will not be used.

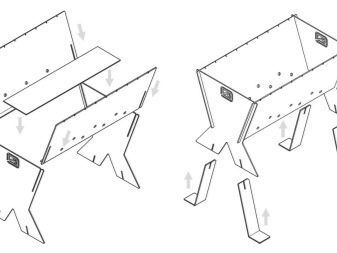

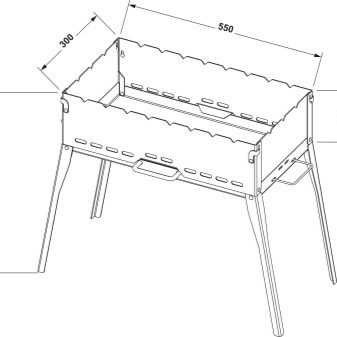

- Folding. Original models of mobile barbecues made of metal, which are very convenient to store right in the trunk of the car in case of a sudden trip to the countryside. They are suitcases, inside which you can fold the skewers and legs of a folding metal structure.

Each of the modifications has both positive aspects and disadvantages. Making a metal grill with your own hands, you take responsibility for its design and operation. And this is good for you.

Having decided on this crucial step, you can plan the presence of a smokehouse or barbecue grill.

Some projects include a cover in the common construction of the barbecue. Having covered a shashlik house, you can achieve the quickest preparation of your dish and be sure that all the most valuable and useful properties and vitamins will remain in it.

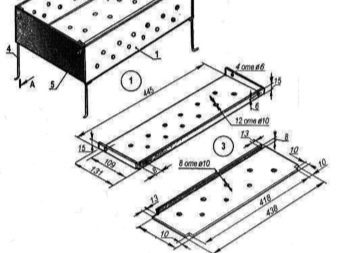

In order to ensure proper air circulation inside the metal box of the brazier, the slits, called the blower, should be made at the bottom of the sidewalls of the structure. Special openings with a diameter of 10–12 mm are made in the bottom so that the oxygen entering these openings will burn out, thereby enriching the meat above the fire.

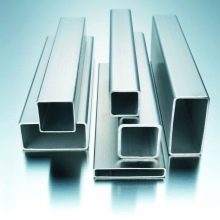

For the brazier legs, metal rods or even pipes are sometimes easily used. The main thing is to properly cut, weld or bond with the main structure.

Craftsmen make metal grills almost out of thin air.

So, there are options from the barrel, gas cylinder and even from the drum of the washing machine-automatic.

Drawings and sizes

Before proceeding with the production process, it is necessary to determine the model, size, material. The next step will be to create a small but correct project plan in which you need to display all the nuances and the necessary figures. On the sketch you need to schematically depict the future design.

Consider the basic components and tools that will be needed for work.

- Sheet metal or its pieces. The thickness of the material, according to the recommendations of professionals, ranges from 3 to 5-7 mm. Of course, the more this indicator is, the longer the service life of the metal structure itself will be. It is convenient in this case to make the manufacture of a prefabricated structure, when the bottom can be made denser and the walls thinner.

- Metal corners or shaped tubes. The first ones are suitable both for the device of the brazier legs and for strengthening the thin-walled sides of the box. The pipes, however, are only suitable for creating two pairs of legs on which the entire structure will stand.

- The Bulgarian with disks on metal.

- Drill for drilling vents or holes for mounting.

- Welding machine, if you decide to make a stationary grill from one or more sheets of metal.

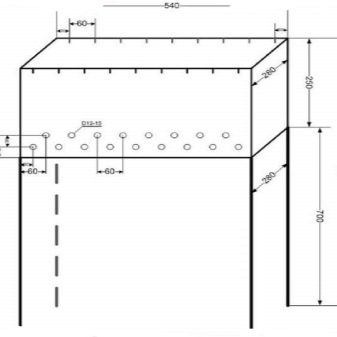

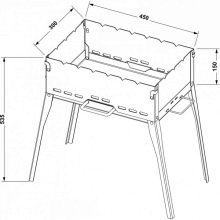

The main dimensions of a standard stationary metal grill are shown in the diagram. But in order to make your measurements, you need to understand why such figures are chosen. The width of the box is always focused on the length of the skewers minus 8-10 cm.On average, it will be somewhere around 30 cm.

The length depends on the number of skewers that will be simultaneously involved in the preparation of kebabs. It also takes into account the distance from one semi-finished product to another, because they should not fit tightly to each other. Thus, the figure is taken as the basis - 10 cm for one skewer strung together.

The depth of the metal box of the brazier is calculated clearly and has parameters of 20-25 cm. This distance is sufficient to fry the meat, but not to burn it. If you make a depth of more than 25 cm, fuel consumption and cooking time of the kebab will increase.

There are also original mini-models, all sizes of which will have to be cut, depending on the reduction of the layout itself.

They usually have short legs and are located close to the ground. But even such designs look beautiful and practical thanks to a systematic and attentive approach to manufacturing and assembly.

Step by Step instructions

It is necessary to understand the phased process of creating stationary metal grills with their own hands.

The first step is markup. On a solid sheet of metal we draw the silhouette of a future structure in a disassembled state. You should have a cross.

The second step is to cut out a drawn figure with the help of a grinder.Next you need to bend all sides and weld them together. The box is ready.

Then we drill holes in the bottom for air and cut the blower in the walls of the box. It is also important to comply with a particular system. Holes must be approximately the same distance from each other and from the edges of the box. Approximately - about 60 mm in the same row.

Given that the holes are arranged in a checkerboard pattern, the distance from the bottom to the top is only 30 mm. This is necessary for oxygen to enter the grill evenly.

The next step is cutting grooves for stable fixation of skewers on the grill. These "cloves" are located in the upper side of the long sides of the structure. Making and fixing the legs is planned to be the last.

Stationary metal grill ready. You can attach additional handles (for convenience of moving from place to place), hooks, grilles and even wheels for transportation.

Collapsible iron grill to give yourself can do.

All work is carried out in four stages.

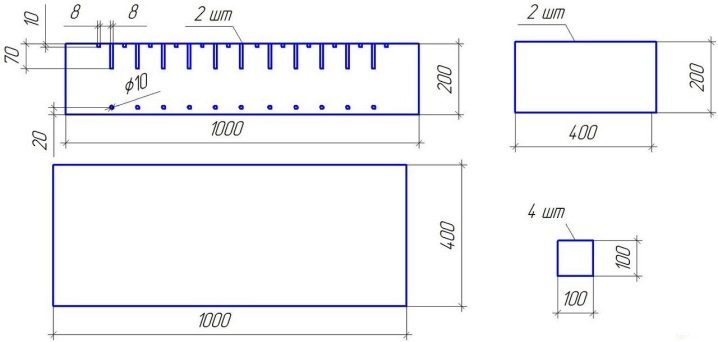

- Marking and cutting walls and bottom. All elements must be designed to fit the seam allowance.

- We make blowing and air ducts in the walls and bottom.

- On allowances left when cutting elements, holes are made for fastening them to each other.

- The legs will also be attached without welding. Here a metal corner will fit, which will fasten to the box with fire-resistant screws or self-tapping screws. It would also be a great idea to use the pipes on which you need to make the thread, and to weld bolts to the construction and screw the legs-pipes into them.

Homemade collapsible iron grill can be used for its intended purpose immediately after the completion of all work.

After cooking it is easy to fold and put in a shed or garage. It will not take much space and will not interfere.

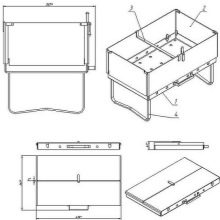

Traveling "suitcase" is also easily made at home. For this it is necessary to carry out a drawing on a metal sheet, where 4 cm is added to each side. Holes are made on the long sides. The bottom and walls are fastened together by door canopies. Bolts for fixing the legs are welded to the bottom. We complement the design with a hook with a loop so that the brazier does not decompose. Weld the handle to the side in order to comfortably carry a metal “suitcase”, even if you drive into the nature by public transport.

Making an original kebab from scrap materials is easier than ever.The most popular projects for today are the brazier from a metal barrel, from a gas cylinder and a washing machine drum.

The design of the barrel can combine two functions at once: a barbecue hut and a smokehouse.

There are at least three ways to make it. At the first barrel is laid on its side, its upper part is cut, leaving the ends intact. The carved cover is attached to the main body of the future barbecue with ordinary door canopies. Legs are welded to the ends of the barrel, for example, metal rods. At the line of the upper sections, the corners are attached with a welding machine, where notches are made to fix the skewers.

The second option for trimming the barrel is to divide it into two parts. Putting the base of the brazier on a flat surface, we make a vertical cut from the top to the bottom. The percentage of parts can be different: from 30/70 to 50/50. But the bottom must be greater than or equal to the top. Further, the whole process is identical.

Make the perfect smokehouse is also easy. But for this you need two barrels. One will become a base for a smokehouse, inside of which a fire will be made.The second will be cut into two parts horizontally and will become the unit itself for smoking. Sawdust must be placed on the bottom of this barrel. The lid must be in the closed position throughout the process.

The manufacture of a metal barbecue from a used gas cylinder is very schematically very similar to that of a barrel.

The main nuance to which attention should be paid is the preparation of the used container for operation.

The cylinder must be at least 50 liters in volume so that the grill is good. The next step is to clean the tank from the remnants of the gas.

For this you need to do three things.

- release residual gas through the valve and turn the cylinder upside down;

- wet the valve with soapy water, in case of bubbles or the corresponding odor, the gas has not left all, you need to wait

- Rinse empty container.

In order to carry out the third step as safely as possible, it is recommended to perform this procedure with an assistant.

First of all, while one saws off the faucet with a grinder, the other periodically pours water on the cut point so that sparks do not get inside and react with residues of gaseous matter on the walls of the cylinder.

A hose is inserted into the hole, from which water is supplied under good pressure. While the liquid goes inside, the balloon is periodically shaken to thoroughly wash all the walls. Pour full capacity and leave for a few days. After the allotted time, water is drained, but remember that this is already poison. In order to remove the pungent smell of gas from a cylinder, it is burned inside before proceeding to the production of barbecue from it. Further manipulations look and are produced in the same way as in the case of a metal barrel.

Original designs braziers are obtained from old cars. Using the hood and the front of the old vehicle, you can get a great heat-resistant and unusual grill with a lid.

The simplest is the brazier made of improvised means.

The fastest and most durable in this category is a roaster from a washing machine drum. The average time required for processing is 10-15 minutes. The main condition is to find a drum. It can be used completely, and you can cut off the unnecessary part, if you think it is too high. As for the support, the convenience of this option is that it can be put directly on the ground, bricks or stones.And you can make specially for him legs from the bars of the armature. Both options deserve attention. Pick it up individually for yourself.

Operation Tips

It is impossible to get along with the assembly of the components of the metal barbecue alone. There are a number of features in the operation of this device that must be adopted and implemented to improve its functional qualities and performance characteristics.

After all the manufacturing work is completed, it is necessary to clean the grill from dirt and rust. To remove the latter, use a grinding machine or a drill with a special nozzle.

The internal walls of the barbecue already in the process of operation do not need to be cleaned of carbon. It is believed that this is what gives kebabs a special flavor and "health".

It is recommended to paint metal structures only with heat-resistant paintwork materials. To induce beauty, a process called bluing is performed.

It occurs in two stages:

- surface degreasing;

- maintaining the elements of mangal in a solution of caustic soda for about one and a half hours.

Such treatment will not only provide a special heat-shielding film, but also protect against metal corrosion for the entire duration of device operation.

If wooden parts are used in the general construction, special attention should be paid to their treatment with various antiseptic, moisture-proof and heat-repellent agents.

The place where you plan to place the brazier, you must release in advance from dry grass, branches or other flammable objects and be sure to install a tank of sand next to which, in case of a fire, the center will be extinguished.

To the acrid smoke from the fire did not interfere with cooking and enjoying nature, you can independently build a hood for a metal barbecue. It is made from the same material as the device for cooking in nature. It differs from the standard mangalny structures established indoors that has an appearance of the cut-down pipe. The area of the dome hood is usually equal to the area of the mangal. This allows you to minimize the emission of smoke outside the cooking site. The hood hood is welded to the brazier body.It is also important to take into account the weight of the structure, so that everything stays stable.

Beautiful examples

The original stationary grill of metal, made with elements of forging. In this case, forged parts are a table-stand under the roaster. Under the table there is a place for preparing firewood or coal, so as not to run behind them far. This grill will not be easy, but quite mobile. That is, to rearrange it in a convenient place or to remove it for the winter to the barn will not be difficult. Forged products about

Metal grill with a roof allows you to cook meals on a fire even in bad weather. If you do not have a shed or a gazebo in the yard, and you want meat or vegetables roasted on a fire, this option is an excellent solution. In addition, the design is equipped with a stand for installing a cauldron and also a convenient place to place fuel.

Unusual models are also found among stationary barbecues. Two large wheels are very successfully attached to the legs of this design. Imitating a garden wheelbarrow, the device easily moves on your site and firmly and steadily becomes where you need.

This configuration of braziers made of metal in the form of a boot is quite common. It combines a kebab, barbecue and even the possibility of cooking meat on a spit.Comfortable table-lattice allows you to optimally arrange all the necessary tools and ingredients at hand.

Folding metal grill in the packaged form resembles a suitcase. This allows you to take it with you wherever and whenever you want. If necessary, the inside can be folded skewers and other necessary stuff. The only disadvantage of this design is the height. It is as compact as possible, and therefore it will be necessary to cook on it only in a sitting position.

Another example of a suitcase barbecue, which is already equipped with legs. These extra parts are conveniently fold into the box, which closes with a special clasp so that nothing is scattered. The photo also shows other models of folding barbecues, which also have compact dimensions and are convenient in their operation.

Spacious stationary grill, made of sheet metal with the addition of forged patterns. It is also equipped with a device for cooking in a cauldron, has a convenient side mini-table and a place for firewood or dishes under the box itself.

The original way to install a hood over the brazier. Suitable for those who do not want to fix the kebab in one place and install a bulky exhaust structure in the gazebo or on the veranda. All the nuances have already been taken into account.Some manufacturers even offer benches and high chairs in the same style.

The fantastic brazier in the form of a carriage with a roof will not leave indifferent even the most skeptical buyer. However, the price of such a forged model may not be the most pleasant value. Of the features of this design, it is possible to note the presence of a lid on a barbecue grill.

The original hearth is obtained from the front of the car. This allows you not only to surprise your guests and get a convenient device for cooking on fire. Thanks to this non-standard approach, you also get rid of an unnecessary vehicle that only took up space.

A chic wrought brazier in the form of a caravan equipped with a roof and a chimney will become a true decoration of your site. The design is cumbersome, but it allows you to cook directly on a large company both on skewers and on a barbecue grid.

There are a lot of beautiful and practical examples of metal barbecues. It is important to remember all important safety measures when using them so that external aesthetics does not turn into troubles.To make metal grills for your own use by yourself and by your own hands is a responsible and creative process that requires concentration, caution and an individual approach.

How to make a metal grill with your own hands, see the video below.