Criteria for choosing plastic windows

Today, no one can be surprised by the presence of plastic windows in the house, but some 20 years ago only wealthy people could install them. Now anyone can afford them. But there was another problem - among a large variety of models it is not so easy to choose a quality product, the price of which really corresponds to quality.

Special features

First you need to understand what it is - plastic windows, and how they differ from ordinary wooden models. The very first and obvious difference is the frame. As a rule, it is made of high-strength plastic, to which all internal components are attached.

The second is the presence of several glasses, not one. Previously, a glass sheet was simply inserted into a wooden frame and fixed with nails.Then this window was installed in the prepared doorway without the use of insulation and additional insulation.

Now it is a multi-part unified construction. It encloses several fixed glasses with hermetic air chambers between them, as well as a metal-plastic case and an insulating system in the form of seals, drains and rubber gaskets.

It is worth noting that such windows have a large number of additional functions. One of them is the ability to open up in different ways. Older models could not do that.

There are 4 types of opening sash:

- deaf;

- rotary;

- folding;

- rotary and folding.

Also a big plus is the availability of accessories. These include mosquito nets, handles with a lock (to protect children), a window opening angle lock, built-in blinds, etc.

Thanks to its holistic system, a glass unit has several advantages:

- Aesthetics and beauty. Modern PVC windows give the house an elegant, modern and well-groomed look. They can become a full-fledged interior decoration, as the variety of color palette and textures helps to realize the most daring design decisions.

- Durability and durability. If all the conditions of the correct (according to GOST) installation were fulfilled, the plastic windows will be pleasantly pleased with their long operational period. They must last at least 20-30 years. Moreover, they are not weather resistant. Quality plastic frames do not crack from overheating in the sun, do not absorb moisture, and the design of the glass unit can withstand temperature drops from -50 to + 70 °.

- Heat and sound insulation. Metal windows provide a high level of insulation. After their installation, drafts will disappear in the house, as well as heating costs will decrease (if there is a private heating). In winter, they will not need to be warmed with cotton and paper tape, as they used to do with ordinary wooden windows. Also the double-glazed window protects from noise from the street, and this is especially important in the metropolis.

- Availability. This type of window construction today is in great demand. Therefore, in the XXI century, you can choose the best option at an affordable price. Quality plastic windows do not have to be expensive.In this regard, everyone can afford to install your favorite model.

- Easy installation. The speed and ease of installation allows you to mount windows at any time of the year. As a rule, all work takes a maximum of 3-4 hours. More time is spent on metering and manufacturing.

- Easy operation. PVC windows do not require special care, and the appeared pollution can be removed with the help of ordinary detergents. They do not need to periodically tint or cover with protective solutions.

- Environmental friendliness. This design is made of a certain plastic, which is absolutely safe for humans and the environment.

- Fire resistance. Polyvinyl chloride is a special material that is difficult to burn. It does not contribute to the spread of fire around the house.

Regulatory requirements

Today, there are a number of regulations that describe the rules and regulations for the installation of PVC windows. There is also a list of requirements for the windows themselves and their components according to GOST, where their standard dimensions and general characteristics are indicated.

First of all, the profile should be made of environmentally friendly plastic, which does not emit unpleasant and caustic smells into the atmosphere and living space.Due to the deterioration of the ecological situation on the planet, an increasing number of companies are switching to a new plastic manufacturing technology, where lead stabilizers and zinc-calcium compounds are not used.

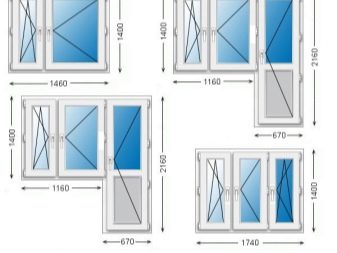

If we talk about the parameters of the window, today there are several standards, since all buildings and structures have their own characteristics.

In conventional panel houses, the window parameters are 1.2 by 1.2 m or 1.3 by 1.4 m. If a three-leaved window is installed, its dimensions are 2.1 by 1.5 m. For a window with two doors, dimensions 1.5 to 1.4 m.

PVC windows are considered non-standard if they are made to order. But here too there are some nuances that must be taken into account. For example, you cannot install a window already 40 cm. The height must be greater than the width if the sash can open sideways, and in order to maintain warm air in the room, it is necessary to produce a profile not less than 7 cm wide.

It is very important that the plastic window being installed has a properly distributed weight. Otherwise, it may just fall out of the doorway due to its own gravity.

As a rule, specially trained installation teams are engaged in installing windows. They can provide the company where the order was made. For more confidence, you can hire graduates. They must have a document that confirms their ability to install plastic windows according to GOST.

Installation must necessarily be in accordance with the norms and standards that are prescribed in GOST, since in the event of a disputable situation (the window functions poorly, the plumb lines fell off, the window box fell out, etc.) the consumer will be able to complain about the production. If the window was installed on its own without standards, then its claims about the quality of the window will not be considered even in court.

GOST has a number of applications where both mandatory installation requirements and related recommendations are indicated (they do not require mandatory implementation).

According to the standard, the foam joint is divided into 3 components: the main central layer, the outer sealing layer and the inner sealing layer. Outer and inner layers are required. Central is done at the discretion of the installation team.According to the documents it is only recommended.

The resulting assembly seam should be resistant to stress, not have holes or cracks. Polyurethane foam should fit snugly to both the window base and the frame.

Window box categorically can not be "laid" in the focus on a concrete or brick base. According to the rules, the frame can contact only with the support pads, which should be equidistantly located along its entire perimeter.

Must have an installation gap. The minimum value is 2 cm, and the maximum is 6 cm. Its value will depend on the curvature of the window opening.

If the foam joint is smaller (for example, 1 cm), it will freeze through in winter. When it is more than 6 cm, sound insulation will decrease.

The GOST also spelled the number of fasteners and their minimum number on one of the four sides. For example, you need 14 anchor bolts to secure a regular double-glazed window - 3 bolts on each side and 4 on top.

The type of anchor must be chosen according to the material from which the building is constructed. For brick buildings and stone blocks, they are fundamentally different.

If we talk about the surface of the window opening, then according to the standard before direct installation, it should not have dilapidated or crumbling elements, holes and depressions greater than 1 cm. All irregularities are necessarily cleaned with putty. Further, the entire surface is covered with a special primer. This is necessary for better hitch materials.

When a window is installed by all the rules and regulations, it should last at least 30-40 years. If in the first year of use from the window joints started to blow, drizzle appears on the window sill or mold has formed on the joints, then this is clear evidence of poor-quality installation.

In this case, an urgent need to contact the company that made the installation. They are required by the guarantee to eliminate all inconsistencies as soon as possible absolutely free.

Kinds

Today there is a huge species variety of plastic windows. Thanks to the work of designers and engineers, their design is constantly undergoing changes in order to improve quality.

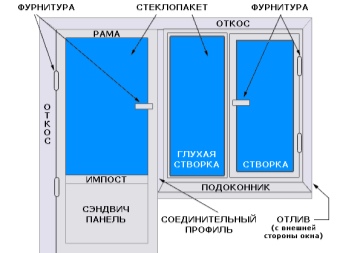

PVC windows are a complete system. It consists of the following elements:

- Frame and sash. The frame is the basis on which all component parts, including the sash, are supported.

- Double glazing. These are hermetically sealed glass with an air gap between them. Their number is selected individually.

- Accessories and accessories. These include window handles, fasteners, opening locks, etc.

The appearance of the window varies depending on its components and their functionality. In this regard, the following criteria are distinguished.

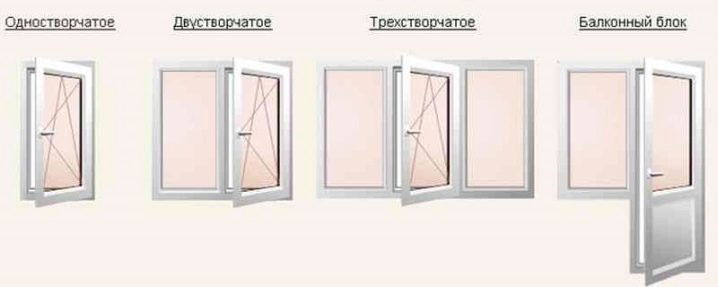

Number of window sashes

There are single, double and triple doors. As a rule, the number of valves is determined by the customer.

Window openings with one leaf are now installed extremely rarely, since they are inconvenient in operation. They are the easiest and cheapest form.

Double sash windows are more practical. Usually one part is deaf and the other is movable, but there are windows where both parts open. This option is ordered most often. To ventilate the room, you only need to open one of the doors, and not open the window as a whole, as in the first version.

If the window opening is large enough, then install windows with three doors.As a rule, only the middle part of it is fixed. Such windows are installed in living rooms, halls, halls, etc.

The method of opening the valves

In a blind casement, the glass is simply fixed in a plastic frame and does not have special fastenings for opening. This option is most often intended for a one-story house, since it will not be possible to wash the window from the outside from the second and higher floors.

The pivot flap opens only inwards. This method is more practical, but to ventilate the room or wash the glass, you must remove all items from the window sill each time. Otherwise, the window will not be able to open due to obstacles that interfere with the opening of the leaf.

The tilt-and-turn mechanism is one of the most convenient types of opening. This system allows you to open the window to turn and tilt at an angle. Because of this, you can open the window on a small crack and not be afraid that the objects on the windowsill will fall or will interfere with the opening.

Framuzhny casement is very rare, but also has a place to be. In fact, this is a hinged pane on the top of the window, and it can fold back from either the top or the bottom.Typically, such models are found in hospitals, schools and other administrative buildings.

Sliding windows work according to the following principle: the window sash is shifted sideways along special rails to the right and left side. This way of opening helps to save space. Typically, such plastic windows are large (most often from floor to ceiling). Therefore, they are installed on balconies or in private houses, where there is an opportunity to go out into the courtyard.

Often, opening methods are mixed in nature (tilt-and-tilt, tilt-and-tilt, etc.), as this is more convenient and practical. However, for such hybrids have to pay a larger amount than for conventional models.

Window frame shape

Modern technologies allow to manufacture plastic windows of any size and configuration. The following forms are distinguished:

- Rectangular. This is the most standard option that is used in almost all homes and buildings. Since it is very simple to measure a quadrangular window opening, frames and glasses are quickly manufactured and assembled into a finished structure.

- Triangular. It should be immediately noted that such windows will cost more than the usual option. They are most often installed in private houses, where there are triangular roofs, or in buildings with an individual design in the style of a loft or hi-tech.

- Round. This is a very beautiful and stylish form of PVC windows. They give the room a certain charm and a touch of romance. They are used in the interior of all the same cottages, private houses. Often they are in hotels, restaurants, cafes, etc. If we talk about the price, the cost of making this form is not too different from the production of standard window frames.

- Arched. This design is a hybrid of the other two - a circle and a rectangle. Semicircular windows can be found in churches, theaters, museums. Sometimes they reach several meters in height, which greatly expands the space of the room.

- Complex forms. These include window openings of non-standard type. As a rule, this is an individual order. These include trapezoidal windows, rectangular with rounded corners, in the form of a drop or head of an animal. Of course, the price will be high, but the result will please the soul for many years.

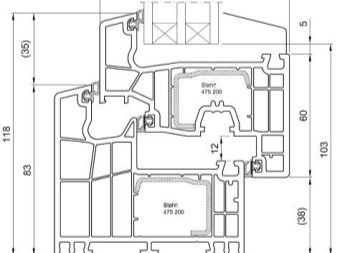

Profile view

The quality of the window is directly dependent on the performance of the profile from which it is made. It is divided into 3 categories:

- Class A. The outer wall of the profile has a thickness of at least 2.8-3 mm, and the internal wall - 2.5-2.7 mm. This view is great for homes and apartments.

- Class B. Here, the thickness is slightly less: the outer wall is 2.5 mm, and the inner one is 2 mm. Such windows have lower rates (they retain heat worse, they hardly hold back the noise from the street). This profile is used for office windows, store and other non-residential buildings.

- Class C. The thickness of the outer and inner walls is significantly less than the two above. Plastic windows with such a profile are installed only in non-residential premises, factories or enterprises where there are no established standards and requirements for heat and sound balance.

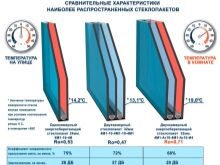

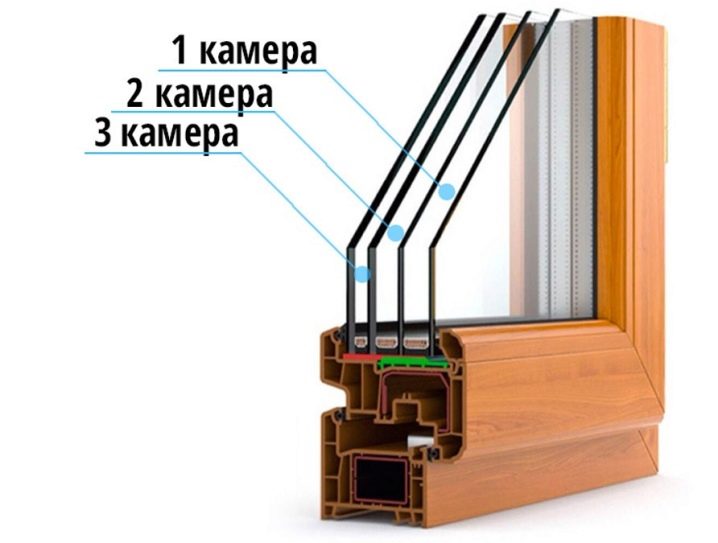

Double glazing type

Plastic windows differ in the number of chambers, namely the hermetic space between two sheets of glass. The double-glazed window is not all window design, but only its component part.

The single-chamber double-glazed window is a construction of two one-dimensional glasses, which are separated by a special distance metal frame. As a rule, the thickness between them ranges from 1.5 to 3.5 cm.Inside the separating profile is a drainage dryer. It is necessary to absorb moisture and condensate. The contour of this system is covered with a special primary and secondary insulating material.

This type is considered obsolete. In this regard, this type of windows is not installed in homes and apartments. It is suitable for balcony rooms, shops, offices, etc.

The two-chamber double-glazed window represents a similar construction, but already has two air chambers between three sheets of glass. The weight of such a window will not be too different from the above, but the mounting system must be stronger.

If we talk about his qualities, he is considered warmer, more reliable and practical.

The three-chamber window system consists of three hermetic chambers and four glasses. Many users and experts say that using a glass unit with three cameras does not make sense, since there is no obvious advantage over a two-chamber counterpart. The weight of the structure will be much greater, the rise in price is serious, and the effect is invisible.

Design

Previously, the windows had to perform only certain functions: to transmit sunlight and give way to fresh air in the house. Today they are an integral part of the interior.Without them, the room seems old-fashioned, tasteless, not brought to its logical conclusion.

Thanks to modern technologies, it is possible to produce models for every taste and color. Now manufacturers can change not only the color of the plastic profile, but also its shape and structure. The glass unit itself was not ignored.

The design of plastic windows can be divided into the following categories:

- form of window box;

- plastic color;

- the type of glass used;

- accessories and accessories.

If we talk about the form, then it can be absolutely anyone. In addition to the standard rectangle, people often order round windows, triangular, asymmetrical. In shopping centers or large modern buildings there are very unusual window openings.

It has become popular to make a frame in the shape of the body of animals (elephant, whale, etc.) or means of transportation (ship, car). And in order to create the most realistic look, outside the facade they make a special finish that imitates jungles, mountain ranges, waves in the ocean, etc. Of course, such design solutions are expensive, but thanks to this the building or house becomes unique and inimitable.

Previously, the plastic produced for the profile was only white or beige. Now it can be colored. Always try to match the color to the overall range of the interior.

Sometimes there are mixed versions, where the window frame and window sill, for example, are yellow, and the handle, beadings and plumbs are black. Not so long ago, they began to produce a window profile with a print, where flowers, birds, various ornaments can be drawn.

The choice of color solution depends on the taste of the customer and, of course, his solvency.

Particular attention is paid to the modernization and improvement of the quality of glass, which is used for the manufacture of glass. Today there are technologies that allow you to change not only their color, but also performance.

In especially cold regions of the country, glasses with a special coating are in great demand. They reflect the warmth of the room back into the room. Thus in the house heat losses are reduced. This configuration is called k-glass.

If the windows overlook the sunny side, then you can order a double-glazed window with a mirror tint. Sunlight will reflect and not interfere so much in the morning.

It is also possible to order plastic windows with stained glass. It can be film or real (drawing from colorful glasses is collected by soldering individual pieces). The second option is quite expensive.

To improve the appearance of the window sometimes installs. These are special decorative panels that are of three types:

- interglass (the panel is located inside the glass unit chamber);

- Venetian (spras is installed on the glass);

- constructional (data panels divide the window into separate units of the glass unit).

An additional decoration of the window opening is the window sill, slopes, ebbs. With their help they reduce heat loss and also increase soundproofing.

If we talk about the window sill as a separate element, then it can perform the function of the table. It can be made of wood or plastic. Combined table with a window sill has a lot of advantages:

- In the daytime do not need to use lighting. Sunlight is enough.

- No need to buy a separate table.

- Saving space in a small room.

- Very often there is a radiator under the window,where it will always be nice to warm your feet.

To make the window more elegant and beautiful, you can choose designer handles. They can have a body of different colors or ergonomic shape. Recently, choose vintage models, where the handle has an ornament or a convex pattern.

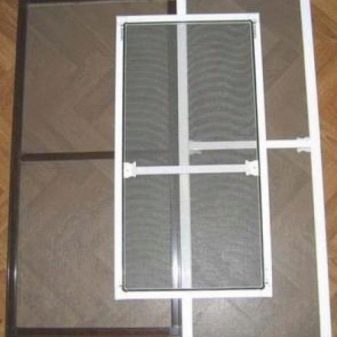

In hot summertime, the windows are always open. But do not forget about the protection of the room from insects, which are always "happy" to fly into the room. For this, a mosquito net is installed on the windows. Its design is also diverse.

Today there is a photo printing service on these grids. In this way, you can additionally decorate the nursery or living room.

Manufacturers

The primacy in the production and mass distribution of PVC windows belongs to German engineers. They started their business in 1959. Since then, the number of manufacturers for the manufacture of these products began to increase rapidly. Their number is growing to this day. In this regard, it is becoming increasingly difficult to find a suitable company among such a large variety.

There is a rating of the most popular manufacturers, who are valued for the excellent quality of plastic windows.

By law, Germany takes first place, namely KBE. It has established itself in the market since 1980. Its products are of high quality, reliability and long service life.

Consumers say that these windows have excellent heat and sound insulation qualities. They also withstand large temperature differences, which is very important for the Russian climate.

The price of a regular double glazing is relatively small - about 12-13 thousand rubles per window of medium size (1.5 by 1.6 m).

There are practically no drawbacks, but during the long service life of plastic on the profile and the windowsill may turn a little yellow.

KBE windows share a leading position in quality with Rehau. This is also a German company. They make environmentally friendly plastic, which is absolutely harmless to people and animals.

PVC windows of this company are also valued for the excellent quality and durability of the structures. Their service life is at least 30 years.

But consumers emit the following disadvantages:

- Non-compliance with Russian dimensional standards. Patriotic window frame slightly wider and lower.

- The price is relatively high - 13-14 thousand for a double glazing.

The products of the Austrian company Proplex are highly valued. They manufacture their products on German machines, and also have a patented mix for the production of plastic. It has a special whiteness and density. The company has a large network of distributors both in Europe and in Russia.

Windows differ from other companies in that they have an affordable price and high-quality component materials. But if we talk about the model range, it is a bit outdated compared to other brands.

For Russian winters, German Veka plastic windows are perfect. The company manufactures frames and shutters with a seal from high-quality rubber. They are not afraid of low temperatures and long pressing. They also help to increase the level of heat and sound insulation.

Consumers appreciate Veka for a wide variety of models and a long service life (over 40 years).

One of the oldest companies is Trokal. They began to produce the very first plastic windows. These window frames are characterized by increased rigidity and durability. Because of this, they can withstand heavy five-chamber windows. Prices for these products are very modest - 10-11 thousand for a regular window.

Montblank is also valued at reasonable prices for plastic windows.It provides a large selection of window profile and double glazing, as well as produces high-quality window sills and slopes. Only one product has a minus - the used seal has a sharp odor that needs to be weathered.

This is just the main list of the best manufacturers. Today there are a huge number of subsidiaries of European companies, which are located in Russia.

How to choose?

On the one hand, it may seem that choosing a plastic window for the house is not an easy task. But when it comes to direct selection and payment of the purchase, nuances begin to appear that need to be taken into account. It is worth noting that the price for the installation is rather big. In this regard, the buyer has a fear that he will give the money, but in the end will receive a poor-quality product.

First of all, the window must be durable, keep warm, do not let through drafts and absorb noise from the street.

In order for all the above conditions to be fulfilled, it is necessary to consider all the components separately.

Profile

The quality profile is made of polyvinyl chloride with a reinforcing metal frame inside.It is very important that its surface had a uniform structure and color, was smooth, without chips or scratches. Profile should not smell. If the smell of plastic is present, then this is the first sign that poor quality raw materials were taken for production. Usually, all body parts are covered with a special protective film, which is best removed after the window has been installed.

Particular attention should be paid to the thickness of the internal and external profile walls.. As mentioned earlier, it is divided into 3 classes. The best of them is class A. Windows from such a profile have excellent heat and sound insulation characteristics.

Masters recommend choosing a structure in which there are at least 3 cameras (air cavities), and the mounting depth is 6-7 cm.

Double glazing

It is a glass blocking incoming noise from the street. In this regard, for the house or apartment is better to take the two-chamber or three-chamber version. The main thing is that the glasses should be firmly and securely fastened, and also have a distance frame between them. Best of all, if they are made of plastic, not metal. This will avoid freezing of marginal zones.

Some buyers purchase models where the air chambers between the panes are filled with argon. Manufacturers claim that this improves thermal performance.

Alone without special equipment can not check what gas is in the structure. Plus to all, argon is an inert gas that after about a year and a half will just evaporate. Therefore, experts recommend buying a regular window.

If we talk about glass, then it should be smooth, without chips and manufacturing defects. Most buyers recommend purchasing k-glass, which allows sunlight and heat into the room, but prevents the output of thermal radiation from the battery. In this way, the room will be kept warm and the costs for heating the room will be reduced (provided that the house has its own heating boiler).

It is worth paying attention to the thickness of the glass. It should be at least 0.4 cm. If we talk about the distance between them, the recommended value is 1.6 cm. Too large a gap (more than 2 cm) can reduce the insulating properties of a glass unit.

Compactors

They are necessary for a more snug fit of the movable sashes to the window frame. They have a small color palette: white, black and gray. Color does not affect the quality, but can improve the aesthetic appearance of the window.

It is best if they are made of high-quality rubber, and not compacted foam rubber. The seal should be elastic and keep the shape (even after a strong finger pressing).

Accessories and accessories

During the operation of a plastic window, users often complain that the handles quickly break down or the hinges start to function poorly. It is recommended to give preference to German manufacturers of accessories. They differ in reliability and durability.

If there is a small child in the house, then it is better to get handles with a lock or a special lock.

Often, the stores offer to buy a comb - this is a small plastic construction (15 cm), which helps to regulate the opening angle of the sash window. To install it, you need to make holes in the frame. Few know, but this design can be replaced with a cheap analogue - a three-stage opening mechanism that is mounted on the inside of the window frame.

Almost every window comes with a mosquito net.It should clearly fit the size of the window, consist of strands well stretched among themselves and not have torn sections.

All specialists and direct users are advised not to save on handles, gaskets and window hinges. Let them be a little more expensive, but they will last more than one year. When there are not so many funds for the purchase of a window, but I want to choose a quality product, then we should ask you to calculate several options so that there is an alternative to the choice.

Do not forget about the warranty period. It must give at least six months. If the company does not provide a guarantee, then it is better to refuse its services. It is also necessary to try to consider options for plastic windows for several companies, and not for one. It will take more time, but there will be more chances to pick up a quality product.

How to install?

Installing a plastic window consists of a series of clear instructions that must be followed. Otherwise, the result will be disastrous.

The work is divided into the following stages /

Window opening measurement

Perhaps this is the most important and fundamental process in the installation of PVC windows.If it is not accurate to take measurements, they will make a construction that is unsuitable for the opening. Therefore, you have to do the work again.

Everyone wants to save on the glazing at home and therefore try to make measurements on their own, but it is best to invite an experienced person who knows his business. As a rule, this service is provided free of charge from the selected company for the production and installation of windows or is quite inexpensive.

A standard rectangular window opening is much easier to measure than a triangular or trapezoidal one. First, the width of the window is measured along the inside of the slopes, then its height from the upper inner slope to the window sill. Professionals are advised to take measurements at at least three points, as the windows are not always perfectly smooth. From the numbers obtained, the arithmetic average is taken to obtain more accurate data.

Also with the help of a special plumb (rope with a load) the angle of deflection of the window along the vertical axis is set. Horizontal curvature is measured using a level. It should be put on the windowsill. As a result, there should be an exact drawing, according to which a plastic window with all the components will be manufactured.

Training

First you need to dismantle the old window.You can remove it yourself or use the help of specialists. It is very important that there are no debris, plaster or paint residues left. Next, the window opening is checked for the presence of crumbling and cracked bricks. They need to be removed and replaced if necessary with integers. Then all edges are aligned and strengthened.

The space in front of the window also needs to be cleared: move the furniture away, remove the flowers, and the floor and battery are best covered with construction cellophane or unwanted cloth.

After the installation site has been prepared and the window has already been made, then you can proceed to the next step.

Installation

First installed window box - frame. It cannot be mounted directly to the surface of the opening. Pre-laid bearing support. They can be wooden or plastic. In order for the structure to stand smoothly, it is necessary to periodically measure the flatness of the surface using a level. If necessary, enclosed support.

Next punch drilled holes in the opening. Then the frame is attached to it with anchor bolts around the perimeter. They are not killed until the end, to be able to align the frame in the opening.

It should be noted that the depth of attachment is different from the material from which the walls are made. If it is concrete or solid brick, then the recess should be 4 cm. For a slit-shaped brick - 6 cm. Natural stone - 5 cm.

The next stage is the installation of low tide. First, a special diffusion tape is attached to the sub-profile by means of foam. Next, a small layer of foam is applied on top of it and an ebb is put. To reduce the noise from raindrops, the masters recommend sticking full-butyl tape on the end portion. Then ebb screwed screws to the profile in 2-3 places for structural strength.

Then you can start foaming the gaps between the frame and the window opening. If the distance between them is more than 6-7 cm, then first it is better to fill the cavities with foam or brick.

When all the gaps are filled with high-quality foam, it is worthwhile to proceed with the installation of the glass unit and movable doors. Hermetically packed double-glazed windows are inserted into the finished box and fixed with plastic slats. The doors are hung next, and handles are attached to them.

The next step is the installation of a windowsill. First, it makes markup on which the correct shape is cut out. It must clearly correspond to the size of the window opening and the depth of the slopes. Secure it with pressure plates.

Before installing the window sill profile is thoroughly foamed. From above it is better to put a small load so that it helps it to consolidate itself in an even position.

The final touch will be the installation of slopes. Before installing them, it is necessary to make repeated measurements, which will be used to cut two side panels and one top. Next, the surface of the window slopes is covered with mounting foam, on which ready-made panels are laid.

When all components are installed, it is necessary to check the operation of the window handles and the course of the opening of the valves (if there is a bias, then the valve can jam or malfunction). All manipulations should be smooth without effort.

If defects are found, they should be fixed as soon as possible. Otherwise there is a risk of damaging the entire structure.

How to adjust?

Over time, any thing or product is subject to deformation. PVC windows are no exception.

If we talk about the sash, then there are many reasons because of which it is necessary to regulate.

Began to cling to the frame when opening and closing.

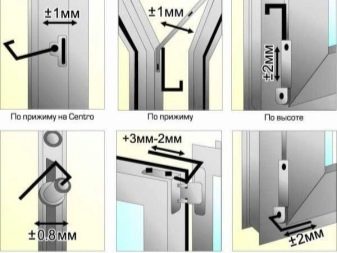

It often happens that the sash begins to go tight and rub against the top or bottom of the frame. This indicates that it is necessary to lower it down a little or, on the contrary, raise it. To do this, take a hex key (4 mm), which is inserted into the adjusting screw on the outer bottom loop.

The sash will rise if you turn the key clockwise and vice versa.

If the sash began to rub against the side parts of the frame, then it should be moved to the right or left. This is done by the same hexagon. The screw, which is responsible for the lateral movement, is located on the inside of the lower hinge. Therefore, you need to open the sash.

The design will shift to the left if you turn the key clockwise. If you turn in the opposite direction, then to the right. In this situation, this adjustment may not be enough. In this case, you need to adjust the design of "scissors". It is located on the upper outer edge of the window casement. It is customized in a similar way.

The flap must be switched to summer or winter mode.

In the cold season it is very important to keep the heat in the house and avoid drafts. In this regard, the sash should fit as closely as possible to the window frame. To do this, you need to adjust the trunnion. This is one of the elements of fittings, which is located on the inner side of the window sash (from the side of the handle, not the hinges). These eccentrics (professional name) abut certain openings in the frame. In the movement of their pen leads. Their number varies from 4 to 7, it all depends on the model.

For a tighter grip, you need the same 4mm hex key. It is necessary to scroll through each pin, otherwise it will be skewed. If you rotate the key clockwise, the flap will be pressed closer. Rotation counterclockwise will weaken the fit.

In the warm summer season, masters recommend reducing the squeezing force of the sash so that fresh air enters the room. It will also help to extend the operational life of rubber gaskets and insulation.

It should be noted that not all models of plastic windows have the possibility of such regulation.

Sash sagged during long use

In this case, you need to make a split, as the usual twisting loops will not help here. To begin with, a special hammer with rubber dies and a chisel are taken. With their help, the sash paneling is performed - plastic beadings are removed. This should be done as carefully as possible so as not to damage the glass. First, side vertical ones are removed, and then horizontal upper ones.

Further the space between the glass unit and the profile is expanded. This manipulation is performed only with a special plastic rasklinochnoy shovel. In the resulting gap are laid rubber support pads. Their thickness will depend on how much the sash has sunk. If, after laying the lining, the sash began to open and close normally, then you can put beadings in the same place.

The flap begins to fall in two positions when it is opened

It sometimes happens that the sash sometimes falls out when the handle is in an intermediate position. It turns out that it clings only to the bracket and the lower loop. Such a window work is unacceptable.

No tools are needed to fix this defect. Everything is eliminated quite simply.

On the front side of the sash there is a special locking-lift. It is placed vertically down. To do this, you just need to lightly press a finger. When the “flag” is pressed, it is necessary to move the handle to the upper position, i.e., to air. Further, the upper corner of the sash neatly moves to the frame so that it fits into place.

Then the knob is rotated to a stationary position. At this time, the lock is still down with a finger. Pressing lightly, the window must be closed. After these manipulations, the sash is in place.

You can adjust the operation of the window yourself, but if you are not confident in your abilities, then it is better to call an experienced master. As a rule, these services are inexpensive.

Care

Caring for plastic windows is very simple and straightforward, but here too there are some peculiarities and nuances.

First of all, it is necessary to clean the plastic profile, slopes and window sills at least once a month. To do this, use the usual soap solution without abrasive particles (they can scratch the plastic, and even more dirt gets clogged up in small scratches) or with special tools for PVC windows. Wipe the surface best with a soft cloth.

Masters do not recommend wiping the window with a dry cloth, as static electricity can form, which will attract dust and dirt.

If we talk about washing windows, then any wipers are suitable. It is worth noting that the glass must be washed immediately from drops of cement, foam and other mortars, otherwise there is a risk that they will remain on the surface. It is best to protect the window with ordinary paper or cellophane when installing the window or when carrying out repairs in the room.

On the pretended part of the PVC window there are rubber seals, which also need cleaning and maintenance. They must be periodically lubricated with a special silicone grease (at least 2-3 times a year), after clearing the surface of accumulated dirt. If you do not do this procedure, the rubber will crack with time and lose its elasticity and firmness. As a result, the level of noise in the house may increase, drafts and other unpleasant consequences will appear.

Accessories also need to be lubricated. Before the procedure, it must also be pre-cleaned.WD-40 aerosol is used as a lubricant. It is applied in small quantities to all moving elements around the perimeter of the sash. It is better to clean the excess immediately, otherwise dust will quickly settle on them.

At the bottom of the frame are drainage channels. They are necessary for removal on the street of the accumulated moisture inside the glass. They are usually cleaned 3-4 times a year so that moisture flows freely and does not stagnate.

Tips

Today, plastic windows are purchased with the hope that they will last at least 30 years. And because of a fairly large price it is very difficult to make a choice. A person always has fears that a company or a store can deceive him and sell a poor-quality or inappropriate product.

The type and type of plastic window are always selected taking into account all the features of the building. For an apartment or a private country house, the choice will be fundamentally different (the noise level and temperature conditions in the rooms are completely different).

In order not to become a victim of fraud, it is best to consult with several experts and chat with people who have already purchased PVC windows.

Unfortunately, there are firms that cheat on their customers.They use all sorts of tricks and tricks to cash in on the customer. The following are common types of deception and ways to recognize it.

- Instead of a window with energy-saving glass, they installed a regular glass unit. There are several ways to check. The first is visual. K-glass will have a bluish tint if viewed at an angle. The second method requires the use of live fire. You can take a candle or a lighter. Flame is brought to the glass. On energy-saving glass, it will be reflected in a slightly pinkish color.

- Install the profile without metal inside. If the window profile is without a metal inner case, then the frame under its own weight will sag, and the casements will function poorly. In the future there will be cracks, drafts and other inconveniences. Determining the presence of an inner metal case is very simple. It is necessary to attach an ordinary magnet to the window frame or sash. If it is magnetized, then this is clear evidence that metal is present. Also, the "noble" profile will be obligatory to have markings that will testify to its quality and mandatory certification.Do not confuse them with stickers.

- The inconsistency of the camera glass. For example, a person ordered a two-chamber glass unit, where there should be 3 glasses and 2 airbags, but instead they install a single-chamber window. Visually, they are very similar. To determine the number of glass sheets, again you need a candle or a lighter. If you bring the flame to a double window (5-6 cm from the surface), then you can count the number of its reflections. In a two-chamber double-glazed window there will be 3 of them, as 3 glasses are installed. In a single-chamber double-glazed window there will be 2 of them.

From the above, it is clear that it is quite simple to identify inconsistencies. The most important thing is not to be shy about identifying them and making claims to the company. You will learn more about how to choose plastic windows in the following video.