How to cut drywall?

Each of us ever made repairs in our lives. And many do it every couple of years. We often use materials such as drywall to insulate our home or create beautiful pieces on the ceiling, in the bathroom or any other rooms. And many of those who prefer to do the repair with their own hands, wondered whether it is possible to make a drywall cut yourself at home, and how difficult it is.

Most often, the owners resort to the help of outsiders (specialists), while spending large sums of money. This article will help you to cope with this process yourself, do not waste time searching for specialists, and help you to get exactly the result you want.

Special features

Drywall is a relatively young material used in the performance of construction work. He gained wide popularity due to its safety, versatility, good sound insulation. The GCR itself, as the name implies, consists of two sheets of cardboard and plaster placed between them. The standard width of one sheet is one hundred twenty centimeters. Since drywall has a large size, during construction work it is necessary to resort to cutting it.

For cutting on drywall, we need a tape measure to get the right size (a ruler can also be used), a pencil, a pen (or any other similar tool), with which we will put the figures we need on the sheet, the tool for the cut itself (hacksaw, Bulgarian, jigsaw, cutter), roughing planer (for processing edges after cutting), saw (maybe circular or ring), or a drill with a crown. The drywall cut, though not difficult, but cutting it incorrectly leads to a large waste of material and, consequently, a waste of money.

Cutting out the GKLV is not labor-intensive work; any newcomer, if he so desires, is able to make the cut himself, without the help of professionals.

A brief process for cutting drywall is as follows. First carried out the cutting of drywall, after the breakdown. Also, the simple composition of drywall is easy to drill, which is necessary for making various holes.

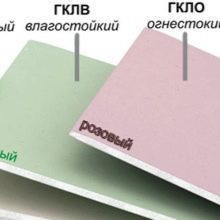

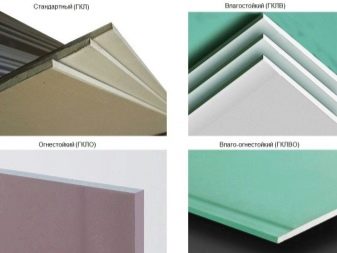

This type of material is divided into different types depending on the functions allocated to it:

- moisture resistant;

- standard;

- fire resistant;

- acoustic;

- increased strength.

Moisture-resistant drywall is needed when used in rooms with an increased amount of vapor in the air. Fire-resistant drywall is used where there are fireplaces, and near places with sources of open fire.

Initially, drywall was used only for leveling surfaces.

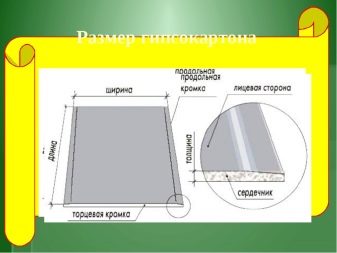

There are three standard types of sheet:

- 3000х1200 millimeters;

- 2500х1200 millimeters;

- 2000х1200 millimeters.

Depending on the type of drywall, their thickness varies, which affects the complexity of cutting.

Ceiling drywall has a thickness of 9.5 millimeters, wall - 12.5 millimeters, arched - 6.5 millimeters.

Consider several features when cutting drywall:

- It is necessary to place a sheet of drywall on a flat and stable surface, as it is very flexible.

- If the drywall sheet is large, the cutting must be done gradually.

- Before placing the sheet on the work surface, make sure it is dry. Wet leaf will be unsuitable for work.

- Cutting is recommended from the side that will be located against the wall. This will allow you to subsequently hide the possible shortcomings resulting from cutting.

- Protect your eyes and respiratory organs with personal protective equipment.

When cutting drywall is not allowed to use a circular saw because of its ability to create a large amount of harmful dust.

What is the best cut?

Cutting drywall is made by various types of tools, some of which are:

- assembly knife;

- hacksaw;

- Electric jigsaw is a handheld power tool, with which the various types of materials are cut using the reciprocating motion of the saw blade.

Consider separately each of them.

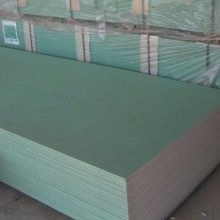

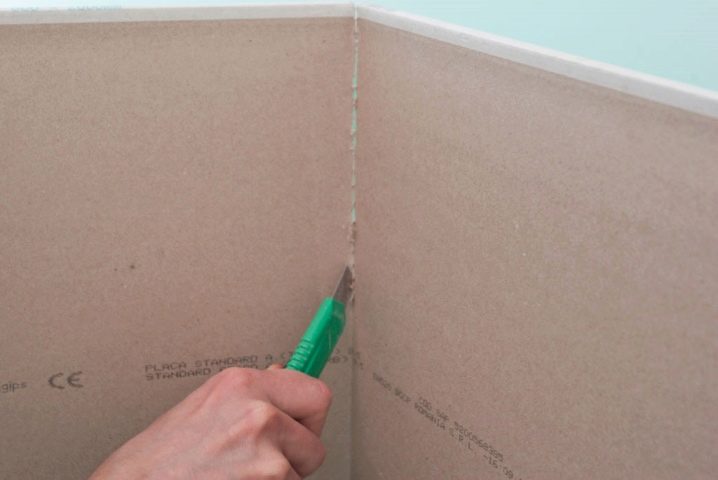

Mounting knife

In this way, we need a drill and, in fact, a mounting knife.

To cut the drywall with a mounting knife, it is necessary to measure the required size of the drywall in length or width. We also need a metal ruler. We apply it to the cutting line. After that, this material is cut. The process itself is quite simple, it will not take much time. The sloppy edge left after the cut can be corrected with a planer. It is recommended when drywall breaks on the table so that the edge protrudes one or two centimeters, and when cutting on the floor, place any object resembling a bar under it.

When cutting one drywall with one person, a rather convenient way is to cut a part on one side, after which the drywall gently turns over to the other side and continues to be incised on the other side. This method allows, if necessary, to cut thin strips of drywall with minimal damage to it.

Hacksaw

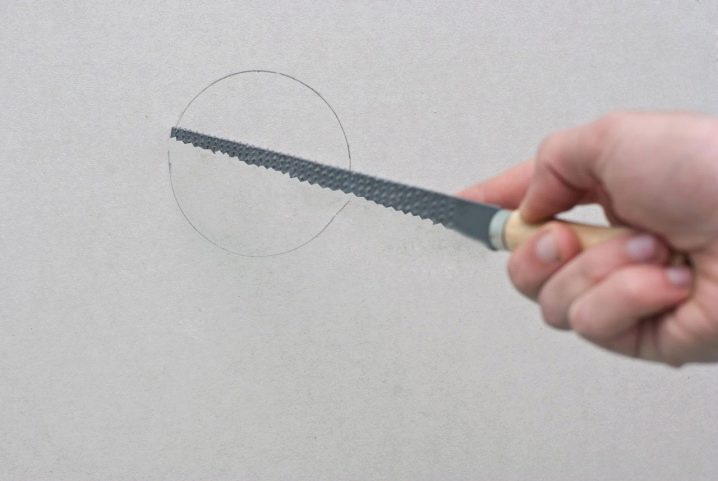

This tool will allow us to cut only small shapes, such as a circle, square, rectangle, rhombus and others.For best results, it is recommended to use a hacksaw with a thin blade.

We draw the figures of the appropriate size we need, then with the help of a drill we make a hole corresponding to the size of the blade of our hacksaw. Then we cut out the figures we need. Just as in the previous method, to achieve neat edges, you can use a plane or a file if the size of your parts is too small. It is recommended to use a hacksaw for metal, but in its absence it is possible to use a hacksaw and for wood.

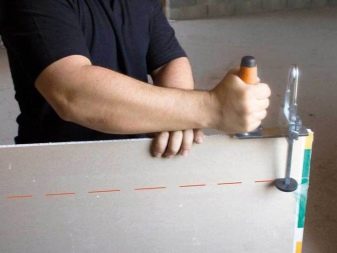

In more detail this process can be described as follows. A drywall sheet is laid on a flat surface (you can use a stack of drywall sheets). Further, the necessary measurements are made, and the dimensions are applied with a pencil (or any other object) on the sheet. The marks are applied on both sides of the sheet, starting at the edge of the sheet. Further, they are interconnected, forming the desired line or figure. In some cases, use a marking thread. The lines are marked on both sides of the drywall.

The next step is directly cutting the drywall.The length of the blade of our tool should not exceed the thickness of the sheet. A sheet is cut with a knife (preferably several times to achieve the best effect), the sheet is turned over to the other side. Next, several times knock on the cut line, and cut the remaining part of the drywall with the same knife.

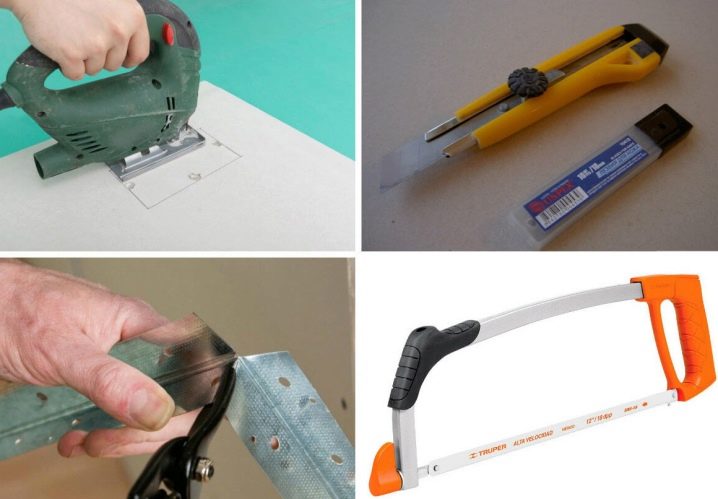

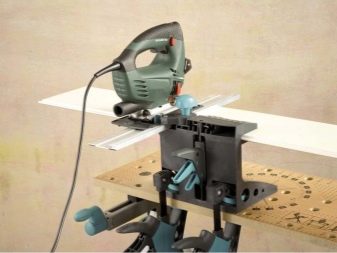

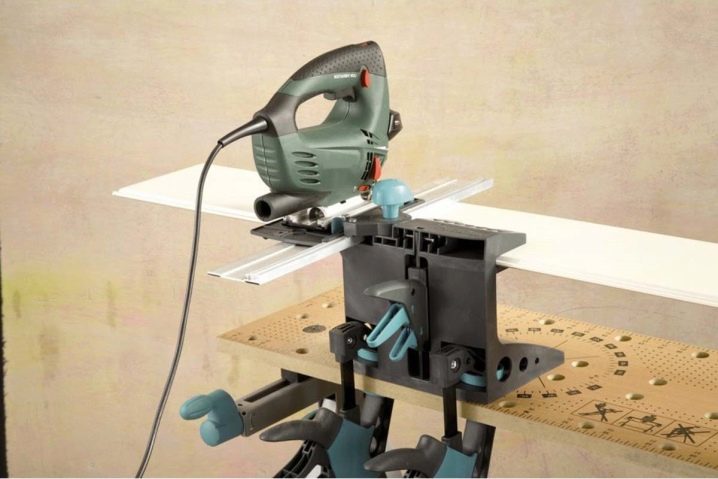

Jigsaw

Cutting with an electric jigsaw is the fastest of all, but at the same time quite expensive. Its price varies from 1500 to 10 000 rubles. Price depends on the quality of the product. But the costs are absolutely justified. Our possibilities for its use are greatly expanded. It becomes possible to cut lines and shapes of various shapes, including curved ones. Also, the amount of waste is significantly reduced. When working with a jigsaw must comply with safety. And before starting work, check the integrity of the wires and the health of the instrument.

To achieve the desired effect, we apply the correct forms or drawings to a sheet of gyrboard. Next, place it on two stools (or any other supports) placed on both sides of the sheet. After that with the help of jigsaw we cut out the figures we inflicted.

When cutting round holes, it is recommended to draw them with compasses, and when cutting, drill a hole inside the circle. The edges after the cutting of drywall need minimal processing, which also saves our time and effort, being a significant advantage.

When the cut is not recommended for a long time to linger in one place, as well as to press on the sheet, using great force, in order to avoid breakage of the jigsaw and the sheet. You need to carefully handle the edges of the gypsum before you hang, for example, a spotlight or a socket.

Subtleties of the process

When cutting drywall, it is customary to observe certain rules, such as:

- placing the sheet on a flat and stable surface;

- the surface must be dry and free of debris;

- use personal protective equipment for the eyes and respiratory organs, as when cutting there is a large amount of small debris and dust.

It is recommended to cut a large sheet in stages.

In the implementation of the cutting profile are used various types of tools:

- Hacksaw. This type of tool, regardless of whether it is narrow or wide, has a high flexibility of the cutting blade,which allows it to deviate from a given direction. This reduces the quality of work, and also increases the time spent on cutting.

- Bulgarian. The tool is one of the best in carrying out construction work, including when cutting drywall.

- Metal scissors

- Jigsaw.

Also in our life there are moments in which it is necessary to make a cut on an already installed sheet of drywall under the lamp, paintings or any other things. In this case also has its own way.

First you need to make sure that the plasterboard is secure, then the small holes we need are carefully cut with a jigsaw, a drill with a nozzle or an electric drill. Large holes are recommended to cut with a knife on the applied marking. Upon receipt of uneven edges, they can be removed with sandpaper or a hacksaw.

When cutting circles there are a number of nuances. The easiest way to cut a circle in drywall is to apply the desired size on a sheet, then carefully cut the blade in a circle, and knock the core out with a hammer (with a little effort with any similar object).There is also the easiest way to save time and effort - the use of a drill with a special cylindrical nozzle. This type of nozzles is usually used when a lock mechanism with a latch is inserted into the door.

There is also a so-called two-sided cut, which occurs when various obstacles appear in the path of the sheet, be it doors, aperture, a beam or any other. When such a situation arises, you have to cut (or cut) from the right side and shape. This manipulation is quite simple, but requires concentration, accuracy and attentiveness. One side of the sheet must be sawed with a hacksaw, and the other side should be carefully trimmed with a knife. After you finish the work, make a break and treat the edge with a plane.

When cutting drywall - it folds. It is advisable to do this carefully, without damaging the sheet. There are three possible ways to bend drywall. The easiest way is to attach the desired workpiece to the profile and fixing it in the desired position with screws. This method is used for small sheets with a size of 20-30 centimeters and a small size of the arc.

A more complicated and second way (for dry plasterboard) is making transverse cuts in drywall. They are made on the outside of the arc. The depth of the cut is usually not to exceed four to five millimeters of panel thickness.

Also talk about the bend sheet for the door arch. The method has the tacit name "wet." First of all, measure the required size of the arch and applied to the sheet. Next, the sheet is cut off, and blind punctures are made on it using a needle roller. In the absence of a needle roller, the use of conventional awls is allowed. With the help of a roller, sponge, cloth or any other fabric, the punctured side is moistened with water so that the other side remains dry. After 15-20 minutes, the sheet of drywall is placed on the template with the wet side. Next, carefully give our panel the shape of an arc. The edges are fixed with screws or clamps. Leave for a day. After that, the sheet can be used for installation.

Tips and tricks

When using any of the presented methods (if the cut is made on two chairs), the sheet of drywall in no case can not be bent.

Otherwise, the integrity will be broken, and drywall may crack. To cut this sheet will be unsuitable. Which will lead to additional financial costs.

Successful examples and options

The lightest is the standard drywall cutting. Following our instructions, dealing with it will be quite easy.

Figured cutting will require more skills from you.

Having studied these methods of cutting drywall, you can easily carry out this construction process on your own, without the help of professionals, which will save money and also gain valuable experience in construction work.

How to cut drywall quickly and smoothly, see the following video.