Features of Baxi boilers

Autonomous heating with natural gas is gaining popularity in the private sector and in apartment buildings. Gas heating installations deservedly lead in terms of efficiency and ease of use. They are quite diverse and easily adapt to a specific situation.

Kinds

Baxi is a leading Italian company that has accumulated a decent experience in the production of boilers for half a century of its existence. She was one of the first in the industry who managed to obtain a transnational certificate of quality management ISO 9001. Floor-standing boilers can easily provide comfortable conditions in homes of over 1000 square meters. m. They serve longer wall analogs, even with comparable characteristics. And the equipment installed on the floor has the highest efficiency.

Other advantages of floor systems are compatibility with water circulation. Such devices are more reliable than suspended "colleagues". But they also have certain weaknesses - the most important of them can be considered excessively large dimensions. It is allowed to install a floor boiler only in a separate room. If the boiler is of an open type, you will have to equip the chimney, and the price of the system may be unnecessarily high.

If we talk specifically about the system Baxi, their positive aspects will be:

- resistance to significant pressure and its sudden drops;

- equipping with water filtering system and special duct sensors;

- automated diagnostic system;

- effective suppression of harmful microorganisms;

- prevention of overheating and excessive cooling of the coolant.

The company produces floor-standing boilers both single-circuit and with a pair of circuits. Carefully thought out powerful designs guarantee warming even large rooms. There are options with a locked or atmospheric gas combustion chamber. There are series with the dependence on the electrical network and devices that can work without being connected to it.The total cost of boilers also varies widely.

Baxi condensing boiler mainly belongs to the wall panel. According to the manufacturer, he is well supported by the required level of heat generation and has operated stably for many years in a row. Wall-mounted boilers using the effect of condensation and heat generation can be additionally equipped with a boiler. But a lot depends on the specific version; there are even options that are allowed to be placed outside the premises.

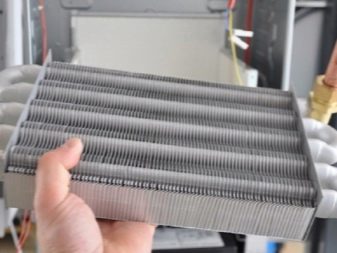

As well as similar generating installations of other manufacturers, these systems, due to the energy collection of exhaust flue gases, can demonstrate efficiency up to 109%. It is necessary to say that their heat exchanger is made relatively difficult, from a special alloy. Ordinary steel is unlikely to withstand the emerging hostile environment. Connection to the radiator heating system is allowed, but the best results are achieved when using such boilers in conjunction with heated floors. Separate condensing units have a secondary circuit for hot water.

All Baxi boilers working on this principle, whether mounted or floor-standing sample of any version, are connected with coaxial chimneys.If the heat generator is mounted on the wall, the smoke passage must be horizontal, and during floor mounting the flow of hot gases is oriented vertically. We'll have to take care of the timely removal of condensable moisture in the sewer. After all, after performing its function, it is no longer needed. Designers have provided a special channel that must be linked to the sewer system.

Models

Such wide and diverse possibilities are realized, of course, not with the help of a single modification. There are plenty of options for heating equipment of the Italian brand. Coppers of heating of "Baxi Slim" is the whole series including the heating equipment with power from 15 to 62 kW. Its feature is the stylish look of the case and the insignificant space occupied in the room. Provides automated diagnostics and modulation of the flame electronics.

This modulation is provided in both heating and plumbing modes. Ignition is performed as smoothly as possible, a burner made of stainless steel plays a significant role in this process. The entire line is adapted to the typical for Russia reduction of the initial gas pressure to 5 bar. At the request of consumers, a changeover to a liquefied type of gas can be performed.The initial heat exchangers are made of cast iron, the pumps use automated air vent.

Dual-circuit modifications are equipped with internal tanks for water supply to the DHW system. These tanks are serviced by separate pumps with post-circulation function. Accession of additional outdoor boilers is practiced at the request of customers. Thermal control allows you to set, in addition to the standard mode, another program for underfloor heating. The upper level of heating, respectively, reaches 45 and 85 degrees.

Separately, you can buy a remote control system with climate control. Internal automation that reacts to changes in weather conditions is easily associated with sensors that measure the outside air temperature. The boiler itself is able to maintain the set temperature in both the heating and plumbing circuits. Observation of characteristic ionization is used to track the flame. A timer operating in a programmable mode can be additionally connected.

Excessive heating of the liquid in the original heat exchanger is blocked with a thermostat.A special feature of the “Slim” line is that the modifications with an airtight compartment for burning gas control the evacuation of smoke flows with the help of a pneumatic relay, and the version with an open chamber with a thermostat. Provided prevention blocking the pump, which automatically checks its position once a day.

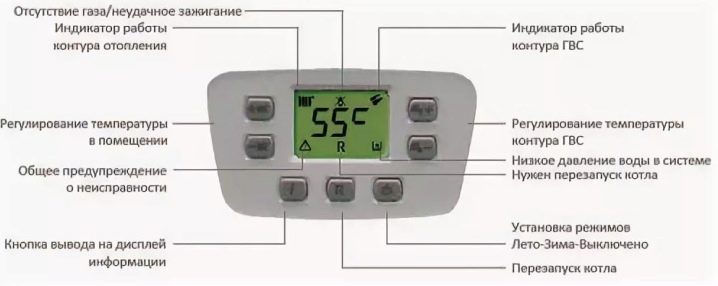

Quite good results can be obtained by the “Eco Four” collection. It includes only compact boilers of the latest generation (with dimensions of 73x40x29.9 cm). The line includes variations with one and two circuits, the gas combustion chamber is also made open or closed, its power reaches 24 kW. The manufacturer claims that all systems are installed and maintained very simply. Due to the large width of the LCD screen, you can monitor the actual condition of the equipment in real time. The same monitor demonstrates the settable settings. The use of flame dividers is quite reliable, these structures are formed from stainless steel grades.

In versions where a closed combustion chamber is installed, proprietary equipment is provided to control the flow of air.Like other models, these boilers can be converted to liquefied gas. Registration of a passing water flow is carried out by a turbine unit. The initial heat exchangers are made of copper, and a special coating helps to increase their protection against corrosion. The pump, which supports the circulation of fluid, is made of energy-saving technology, it has an internal air outlet.

The line is characterized by the presence of a pressure gauge and bypass. Designers have taken care of the post-circulation pump. All incoming cold water is cleaned, so there is no risk to the equipment. If desired, you can associate the system with a solar collector. The maximum warm-up bar is the same as in other versions - 85 degrees. Room thermostat and timer with programming function can be connected separately. The boiler is protected from pressure drop in the heating circuit, if this happens, the automation itself blocks the operation.

As for the Duo Tec Compact series, its characteristic feature is that the developers themselves declare flexible adaptation to the conditions in which they have to act.

Boilers will be able to adapt:

- to chimneys with different characteristics;

- to natural gas;

- to liquefied gas.

A high-quality burner pre-mixes the gas with air, and only then sets it on fire. The trademark description promises that it is very easy to install and use the boiler. At the same time, in terms of the application of modern technological advances, it is not inferior to the leading samples on the market. Power modulation can occur with a ratio of 1: 7, and the burner part itself produces a continuous heat flux of a given power even at a gas pressure at the input of just 5 mbar. The modulating system is made on the basis of the latest electronic circuits, the exhaust gases contain the minimum number of harmful components.

The energy saving pump is not the only advantage of the hydraulic part of the boiler. It is widely used composites, as well as provided for primary cleaning and post-circulation. Engineers reworked the control panel, and now it has become much more convenient than before. Weather dependent automatics are built in by default, it can independently adapt itself to actual conditions. Inside the boiler, water heating is measured on both the supply and return circuits.

Temperature adjustment can be made from 25 to 80 degrees. It is allowed to set up the boiler to provide heat for different sections of the house. The pressure gauge does not just measure the actual pressure - it is able to first warn about the reduction in pressure in the system, but when it drops to 0.5 bar, it blocks the operation of the heater. If consumers are interested in other Baxi boilers, which are distinguished by wide adaptation possibilities, you should pay attention to the “Luna Duo-tec +” group. Each such boiler is equipped with an internal pump operating at two different speeds. A modulation power of 7: 1 is achieved. 1. The boilers of this series continuously modulate the fire both in the heating mode and when the DHW is recharged.

In conclusion, the review of options is to say about the series "Main Four". These are wall-mounted heating systems, replacing the older Digit line. Small dimensions make it possible to install boilers even in cramped conditions. But the most modern information panel is based on liquid crystals. It allows you to get maximum information about current work and the main parameters of the system. Symbols are simple and intuitive.The flame is modulated continuously in two main modes, you can use (after appropriate settings) a liquefied type of gas. As part of the hydraulic components, a heat exchanger of bithermic type attracts attention.

The brilliant characteristics and reviews of the owners of the Baxi boilers are fully confirmed. Internal working parts are made of impeccable plumbing metals. High consumer ratings relate to the assembly, and to the functionality, and the subsequent installation. Careful review of the reviews suggests that any boilers of this brand cause positive emotions. But this applies only to copies purchased from official dealers and established by professionals.

Device and principle of operation

The chimney at any Baxi boiler is located at the top, just below it is placed a fan with a special tube and an exhaust hood. It helps to effectively remove the gaseous products of combustion. Moving further, it is possible to find the heat exchanger of the initial link on the lower tier. It combines the functions of a coil and a radiator.Looking to the left, there we will see a thermostat that protects from an unjustified increase in temperature. The temperature itself is measured by a sensor, also located nearby. The main gas-burning chamber is placed in the middle.

In this compartment are:

- burner;

- the electrode igniting the fire;

- electrode responsible for recognizing the presence of a flame.

The operation of the modulating burner is provided by a gas rail with nozzles connected to it; there is gas moving past the gas valve. Right into the heat exchanger entered the pipe, looking down. It connects to a water expansion tank and to a pump responsible for circulation. A pump that pumps water in is invariably supplemented with an automated unit that vents air.

The contour of the boiler in this part ends with a tap through which, if necessary, coolant is discharged. A pressure gauge is also provided. If you look to the left of the heat exchanger, there will be a pipe with a hydraulic pressure switch and a safety valve. Just from here, the water flow is sent to the heating system. To ensure reliable operation, docking of the two described areas with an automated bypass helps.

Two-circuit modifications of Baxi boilers, in addition to the listed components, are equipped with:

- plates of heat exchangers of the second level;

- apparatus for hot water supply;

- valve with three working strokes.

If we are talking about boilers equipped with bithermic heat exchangers, they can simultaneously warm both heating and tap water. This is achieved through the "tube in tube" technology. The operation of the Baxi boilers begins with the flow of liquid through the right pipe. Due to the efforts of the circulation pump, it reaches the heat exchanger. As soon as the system detects the cooling of the liquid to a temperature lower than that provided in the settings, the gas valve transfers a portion of the fuel to the burner and starts a spark.

The burning gas, in contact with the heat exchanger, gives it some heat. The heat flux passing further leads to heating and expansion of the coolant. Excess water is diverted to the expander. The bulk of it goes through the pipe on the left, touching the temperature sensor. As soon as he shows the heating of the water to the designated mark, the automation issues a command to block the passage of gas.

But this command can also be given by a thermostat in the room. If it is used, the cycles adapt to the actual heating of the room. The described variant reflects the functioning of the single-circuit boiler. In dual-circuit models, the logic is generally the same, but a three-stroke valve switches the system from heating to hot water and back as needed. It is possible to form a harness qualitatively, if you calculate the required number of radiators, draw up a diagram taking into account all the subtleties.

Installation and Setup

Having dealt with the basic principles of the operation of Baxi boilers, you need to find out further how to install such equipment according to the instructions. It is not always possible to adjust the burner, the simplest versions operate at constant power all the time. Models of the middle price range are equipped with stepped burners. The control system extinguishes them from time to time, after which it starts up again. Modulation is resorted to only when creating the most expensive and sophisticated boilers, but they can maintain the designated temperature with minimal error.

But before the burner starts adjusting to the actual conditions (or does not start), it is required to turn it on. Before starting, be sure to check the pressure of the fluid in the expansion tank behind the boiler. Next, find out whether all the valves are open (the boiler itself at this point should also be disconnected from the network). After increasing the pressure to 1.5 atm, the valve is closed and the air from the radiators is released. When the bleeding of all air (sometimes conducted more than once) is completed, the system is started up in a variant only for heating.

As soon as it was possible to achieve normal operation of the heating circuit, you can configure the hot water system. But before it is required to make installation of a boiler in due form. Only under this condition will the operation be correct. Italian automation, with all its reliability, must be connected via a voltage regulator. Replace or supplement the stabilizer will have an inverter, which allows you to smooth out the voltage spikes, and to achieve the optimal sinusoidal current.

If the goal is to radically reduce the dependence on power, you will need to add rechargeable batteries.To cover the device from the pulse currents will help the surge protector. Each section of the gas pipeline in the house and at the approaches to it must necessarily be equipped with current-proof inserts. Only under this condition, as well as under the condition that the boiler is properly grounded, can one not be afraid of the bad effects of lightning discharges.

Almost all Baxi boilers work quietly with heating systems into which antifreeze is pumped. But there are exceptions to this rule, so you must first carefully read the technical documentation. To reduce the frequency of maintenance, it is required to either completely abandon the dilution of antifreeze, or use only distilled water for it. The recommended vacuum in the flue exhaust pipe of the boiler must be at least 5 Pa, so it is necessary to design the chimney immediately.

If there is a higher building near the heated house, you will only have to install turbo boilers. Other systems will not cope with the weakening of thrust in such a situation. When the heated area - 200 square meters. m or less, it is advisable to estimate the required heat output by generating hot water.To convert any Baxi boiler to summer mode, you only need to switch the corresponding indicator. When this does not help, the duct sensor must be cleaned; with further failure will only appeal to a specialist.

Accessories and spare parts

No matter how good Italian-style boilers are, additional components are welcome. Thus, a room thermostat, sometimes called simply a thermostat, ensures that the required temperature is provided without the direct participation of the owner. Releasing time and not having to constantly be distracted are obvious advantages. But there are also deeper merits that are obvious only to engineers.

So, systematically repeated stops and starts of the boiler have a bad effect on its performance. Worse, the overall reliability of the system decreases. Continuous action of the circulating pump, albeit slightly, but increases the cost of electric current. So high-tech equipment, such as a gas boiler, is much more correctly to entrust the care of automation itself. Due to home and street temperature sensors, it is possible to ensure that work starts and brakes only when the actual conditions change.

This is a much more accurate method than the orientation simply to reduce the heating of the fluid. If the control device can be programmed, it is possible to set rational response thresholds and delay periods. Such a delay is important so that a draft from an open window or a door wide open does not lead to gas overspending. Careful adjustment helps to save up to 30% of an increasingly expensive resource. In the presence of funds, it is worth buying non-contact thermostats, they are much more efficient than connecting via cable and simply more convenient.

When choosing a voltage regulator will have to pay attention to indicators such as:

- switching speed;

- electric power rating;

- smooth signal processing;

- weight;

- dimensions;

- The way in which the device measures voltage.

The cheapest stabilizers collected in the countries of Southeast Asia, allow you to handle the voltage drop for 1 second. In the premium segment, the speed is 50 times greater, and this is not accidental - accelerated operation reduces the risk of damage to the automation. Thyristor devices are characterized by increased smoothness of the specified voltage compared with relay samples.As for the size and size, it all depends on the specific manufacturer. It is undesirable to buy stabilizers, in which the measurement error equals the switching step, all the more surpasses it.

The fact that the expansion tank, like the coaxial chimney, does not belong to the electronic and electrical parts of the boilers, does not make them less relevant acquisition. In Baxi boilers, the tank is a construction of a pair of compartments, the boundary between which is set by a rubber membrane. The compartment saturated with inert medium (air) can change its size, which directly affects the volume of the remaining part. Thus, the excess expansion is compensated by the action of heat. A tank built into Italian wall-mounted boilers is enough to cope with the expansion of water moving along a system with a capacity of 60-100 liters.

Faults and repair

In most cases, it is possible to remove the heat exchanger on the Baxi boiler by unlocking the clips. But first it will be necessary to dismantle the entire environment of the problem node. Even inexperienced in handling boilers, but knowing from which end to take a screwdriver, people will do the job in 20 minutes.If pressure drops, and attempts to pump up air are useless, you must first check the radiators, and then the boiler itself.

The test sequence is:

- radiators;

- energizing faucet;

- DHW heat exchanger;

- external boiler room lintel.

Following the advice of experts, it is recommended to fill the system with soft water in order to be less likely to face difficulties and malfunctions. In case of difficulties, it is quite possible to wash the heat exchanger and other internal parts of the boiler with your own hands. But this should be done competently, otherwise the work of repairmen will significantly increase.

If inside there is a circuit that heats the water, you will first have to clean the parts outside of the soot, and then get rid of the scale. It is removed with special reagents, using hydraulic equipment or in a specially directed electrical discharges. Cleaning is possible without dismantling the heat exchanger. To do this, remove the cover, take the brush from the hard nylon and overlap the gas nozzles. If it is impossible to do this when the soot "sits" very firmly, you will have to remove the part and maintain it in special solutions for several hours.

See the following video on how to clean the Baxi boiler from scale.