Pellet heating: advantages and disadvantages, composition and consumption

In order for the house to be as comfortable and livable as possible, it must have high-quality and efficient heating. Here we must take into account that not every building has the ability to connect to the central gas supply, and electric heaters can lead to too much waste. Special pellets are an excellent alternative to heating.

What it is?

Today, pellets are called special wood pellets. In simpler terms, these products are ordinary waste from the woodworking industry. They are pressed in the form of small granules.As a rule, produce such products from environmentally friendly raw materials, in which there are no hazardous chemical compounds. Pellet heating belongs to the category of modern heating systems.

What are pellets made of?

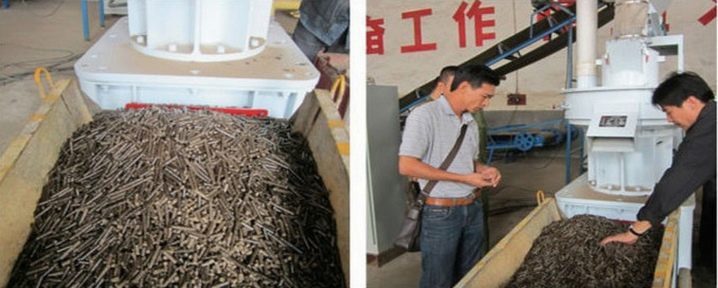

Many owners of private houses are wondering what are pellets made of. It is worth noting that people often make similar products on their own. It is enough to stock up on a crusher, a sieve, a dryer designed specifically for sawdust, as well as a pelleting machine. The optimal raw materials for the manufacture of such products are waste wood industry:

- sawdust;

- trimming;

- shavings;

- croaker;

- wood flour from hardwood and softwood;

- other waste received during the processing of wood.

The granules that are made from wooden waste are light, gray and black.

For example, in the production of gray granules, wood waste is often combined with bark. Pellets of this type are usually laid out in large bags. They are very often used in the European boiler rooms, differing in impressive power.Wood fillers for trays of domestic animals are produced using a similar method. Pellets are also made from agricultural waste. In this case, straw or dried hay may act as components. Today, many farmers create pellets for heating from such raw materials as:

- reed;

- sunflower husk;

- hay;

- rice husks;

- other agricultural waste.

If you take all the waste, then with the exception of rice husk with their processing there is no difficulty. For this, it is sufficient to use simple equipment equipped with a ring-type matrix. The processing of these components takes a minimum of free time, and large investments will not be required.

If the pellets are made from a more capricious rice husk, then use a more reliable and wear-resistant technology, made of stainless steel.

Pellets are made from such raw materials as peat. Such products are characterized by impressive calorific value and high ash content. For the manufacture of such options requires specialized equipment and good resources, because the harvesting of peat raw materials is a seasonal procedure that requires certain costs.

Advantages and disadvantages

Today, pellet heating is chosen by many owners of private houses, which cannot be connected to the gas main for a number of reasons. People prefer this method of heating the home, because it has significant advantages.

- Pellets are made from safe and environmentally friendly materials that do not harm health.

- Pellet heating has good security characteristics. Granulated fuel from natural raw materials is not explosive, unlike, for example, from gas.

- In most cases, pellet heating is characterized by low ash content (there are also exceptions, for example, in the case of peat pellets).

- In the case of the use of pellets it is possible to use the ash in the future.

- Heating of a private or suburban structure with granulated pellets does not need to be approved for connection (as opposed to gas-powered options).

- For the storage of pellets there is no need to separate the separate structure - it is enough just to choose a dry room.

- Pellets are made quite simply when it comes to conventional granules from wood waste.Moreover, they can be produced at home, having the appropriate equipment.

- Particles from sawdust and agricultural waste can be easily stored in a convenient place for the homeowner. In addition, they are easily transported.

- Pellet boilers can boast a high efficiency.

- In most cases, the pellets during combustion do not emit sharp odors. In addition, they emit almost imperceptible smoke that has no color.

- Pellets have a high calorific value. For example, in the process of burning 1 ton of wood elements produced the amount of energy as when burning 1.6 tons of wood or 500 liters of diesel.

- Boilers operating on such biofuels are very convenient to use - a person has to participate in their work no more than once a week, since all processes are carried out automatically.

In the age of high technology, environmental safety of fuel has become a priority - that is why many homeowners choose pellet heating. However, even this relatively new development has its weak points.

- Boilers that run on pellets are quite expensive (the cost is several times higher than that of the classic gas options).Of course, you can purchase simple burners that can be supplied to an existing solid-fuel unit.

- For this technique need constant care. Every week the heat exchanger in the pellet boiler must be cleaned using a special brush. This is especially true of old units. In more modern boilers, there is often a special self-cleaning system.

- Pellet fuel itself can cost homeowners more than regular firewood.

- Maintenance of pellet heating units often cost the owners a tidy sum.

- The manufacture of some varieties of pellet fuel is quite expensive (as is the case with peat species).

- Many models of pellet boilers are not suitable for use in the Russian climate.

Consumption

It is necessary to take into account that granulated pellets are a packing product that is sold in bags of a specific volume. That is why to calculate what will be the consumption of pellets per 1 kW and 1 square. m. not be difficult. It is not necessary to convert the weight into volume, because the manufacturers of such a product always make out the goods produced in kilograms, and the unit measuring heat is kW.

The correct calculation of the consumption of granules is carried out in several steps. The result will be the monthly fuel consumption of the boiler during the entire heating season, as well as its average cost. Below is described in detail how to make all the necessary calculations on the example of an area of 100 square meters. m

First, it is important to understand how much heat actually penetrates the heating system when 1 kg of pellets is burned. This stage should be taken into account, since boilers operating from solid fuel are not ideal in order to direct absolutely all the heat energy received to warm a private or country house - part of it is redirected to the chimney pipe. To this end, the heat of combustion of the particles is multiplied by the efficiency of the heat generator, divided by 100:

5 kW / kg x 80% / 100 = 4 kW / kg.

To make calculations easier, you should refer to the reverse action in order to find out how much pellets you need to burn to generate 1 kW of heat energy in the circumstances:

1 kW / 4 kW / kg = 0.25 kg.

Since during the heating season the weather in the yard usually remains unchanged, and the temperature regime varies in figures from +10 to -30 degrees, the specific heat consumption per season in a house of 100 square meters. mwill not be 10 kW, and two times less, that is, 5 kW. If we take into account that all units of power belong to a time of 1 hour, then heat consumption per day will be:

5 kW / h x 24 hours = 120 kW.

Same for the month:

120 W x 30 days = 3,600 kW.

Then you can calculate the approximate cost of pellets per month when the house is heated to 100 square meters. m. throughout the heating season:

3,600 kW x 0.25 kg / kW = 900 kg.

If you need to know the approximate consumption of wood pellets from wood waste per day, you should carry out the following calculation:

120 kW x 0.25 kg / kW = 30 kg.

By a similar principle, it is possible to calculate what the consumption of such a granulated product will be when heating houses of 150, 200, 300 and more square meters. m

Features pellet boilers

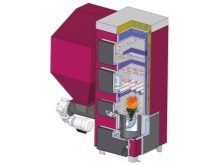

As mentioned earlier, pellet boilers are characterized by high efficiency, but they are quite expensive. Such units have in their design the following components:

- compartment intended for pellet granules;

- the mechanism responsible for feeding the pellets;

- autofuel module;

- burner;

- control module with sensors responsible for temperature.

These heating units can be equipped with different types of burners.

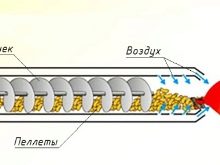

- Flare. Combustion of fuel in the burner of this type is carried out in the air flow, which comes from the supercharger, forming a kind of torch, consisting of hot coals. The temperature when using such a burner can reach 1200 degrees.

- Chimney. Otherwise, such a detail is called a grate. In this case, the granules themselves are poured into the burner bowl from the compartment with the dispenser. The air in this design comes from the side duct or holes in the bowl itself.

- Volumetric combustion Such burners are called rotary burners. They are a bowl of cast iron or steel, into which the granules fall through the central part of the retort - from the bottom, and the burning takes place over the entire surface.

A bunker for storing fuel in such a unit can be built in, that is inseparable from the device itself, and external. In the second case, any design can be used - a plastic barrel, a container with plywood walls and other similar devices.

As for the fuel supply mechanism, it can be:

- screw;

- pneumatic.

Automatic systems in pellet heating units are also different. For example, such:

- lambda probes;

- local control systems;

- GSM management systems;

- control over the Internet.

It is in the well-thought-out automation that the main distinguishing characteristic of pellet boilers lies. Due to this feature, these units are the most convenient to use, since they do not have to be constantly monitored.

However, we must not forget that today pellet granules of the highest quality are very common. Low grade fuel may adversely affect the operation of the boiler. It is also worth considering that in most cases this technique is dependent on electrical energy. If the house is built in an area where frequent interruptions in the operation of electricity is a common thing, then the heating of the dwelling may be at risk.

The main disadvantage of such units is the high cost of the pellet-type burners themselves. In the modern market for the most part there are models produced in Germany, Italy and Spain. The cost of some products from well-known and reputable brands reaches 3000-6000 thousand euros. Of course, in stores you can find domestic-made burners, which in many ways are similar to foreign versions, but are much cheaper.

Owner reviews and professional advice

If it was decided to turn to the pellet heating of your home, then you should heed some of the advice of professionals. High-quality units working on pellets can be safely used both for heating the whole building and for its supply with hot water. For example, units with a power of 15-100 kW, usually installed in the basement or ground floor.

If the dwelling is heated by an old pellet boiler, then we should not forget about its regular cleaning, because otherwise the unit may work less efficiently or be completely damaged. Do not forget about the filling of granules in the appropriate bin during operation of the boiler (if required). From time to time it is necessary to check the draft in the chimney of a pellet boiler.

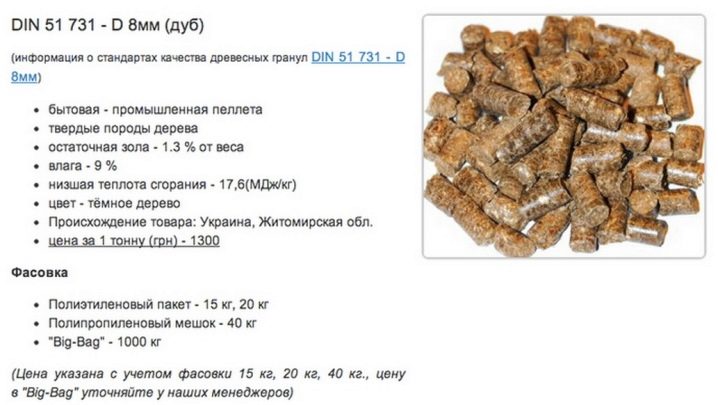

The granulated pellets themselves should be stored only in dry rooms, for example, in a separate small building. But many people do without them, finding a suitable place in the existing areas of the house or outbuildings. Choosing quality pellets, you need to pay attention to some criteria. For example, their smell should be unobtrusive, should feel a slightly sweet aroma of glue,length - no more than 50 mm, diameter - 6, 8 mm, slightly less - 4, 10 mm, and you should also pay attention to the surface - smooth elements will be more durable.

If it was decided to make pellet fuel on their own, then it should be noted that a component such as rice husk can be quite demanding to use. The composition of this ingredient has a large percentage of silicon, because of which the equipment wears out quickly during the processing of such raw materials. For this reason, it is worthwhile to turn to high-strength equipment made of stainless steel.

If you want to buy a quality pellet boiler, then you need to keep in mind that it will not cost too cheap. A suspiciously low price should raise doubts with the buyer, especially when it comes to the brand model - such products can cost a very large amount. Many people believe that pellets and firewood burn the same, and the main difference between pellets is only their shape - such details do not need to be cut or chopped. In fact, this is not entirely true. Firewood is more humid than pellets, so when they are burned, the lion's share of time is spent on the evaporation of excess moisture - only after that does the material start burning.

Pellet are not only heating boilers, but also fireplaces.The latter not only warm up the living space, but also become spectacular components of the interior ensemble. With such a unit, you can admire the flame, and let it through a special protective glass. It is necessary to acquire pellets in checked outlets in order not to run into a low-grade product (low-quality variants are found too often today).

When choosing the perfect pellet boiler or fireplace, you need to consult with the sellers. The fact is that not all European models are designed to work in an environment of harsh Russian winters with frequent interruptions in the operation of electricity.

Currently, many homeowners choose the pellet heating method of the dwelling. The main characteristic that consumers have noticed is the environmental safety of such a system. When burned, this fuel does not emit sharp and unpleasant odors, as well as acrid smoke. Homeowners also like the fact that the pellets themselves are sold in packaged form, so it is more convenient to store and transport such fuel.

Many consumers liked the fact that pellet heating units are quite effective.With these models, a comfortable temperature is always maintained in the dwellings. This quality attracts most buyers. In addition, the use of pellet equipment is very simple, which is also indicated by many homeowners.

However, people noticed some shortcomings in this type of heating. For example, many homeowners claim that pellet heating equipment requires expensive maintenance and regular maintenance, if not new. The customers didn’t like the fact that some models of boilers consume granulated fuel in a rather large amount, and this leads to significant expenses. Also, people often complain about the too high cost of pellet boilers and fireplaces when it comes to foreign copies.

For the disadvantages and advantages of pellet heating, see the following video.