Boilers "Lemax": types and rules of use

To choose the right boiler, it is necessary first of all to focus on the parameters, as many experts believe. And they will be partially right, because the reputation of the brand is also important, it gives at least some guarantee against cheating.

A bit about the manufacturer

The company "Lemax" began its journey in 1992 on the shores of the Azov Sea, and more specifically in Taganrog. Against the background of a dramatic change in the political situation in the present economic catastrophe, the creators of the organization managed to concentrate a cohesive group of performers who are able to fulfill any, even the most sophisticated order. As a result of many years of efforts, it was possible to ensure a stable position in the market, and at one of the most advantageous positions.

Boilers "Lemax" are considered one of the best in terms of cost and quality.The company produces single and double circuit systems, as well as columns for heating water.

Models and specifications

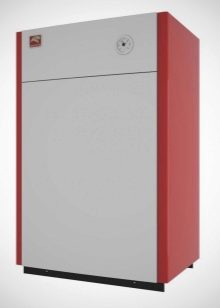

The boiler "Lemax" of any model from the line "Premium" is made of high-grade steel, the thickness of which is 0.2 cm. The metal is necessarily coated with a corrosion-resistant layer of the brand Certa, which can withstand heating up to +750 degrees. Additionally, treatment is carried out with a reagent that inhibits the development of corrosion. The heat exchanger is designed in such a way that the risk of exposure to mineral oils and dissolved salts in water is minimized.

The features of this line are also the following:

- the placement of the thermal regulator on the front panel;

- the ability to add room thermostats;

- compatibility with the Lemax turbine nozzle, which facilitates the removal of gases appearing during combustion;

- readiness for smooth start.

Any boiler model in this range is provided with an efficiency of at least 90%. The digital index of the model allows to determine its nominal thermal force. The 10N modification will be able to work at a nominal gas pressure of 1.3 kPa, and having consumed 0.6 cu. m of gas in 60 minutes, heats the water to +90 degrees.Versions 12.5 N and 16 N can be additionally equipped with a hot water supply circuit made on the basis of a copper heat exchanger. It is important to know that Lemax does not only produce natural gas systems.

An example of solid fuel floor heating boilers is the production of the Forward line. These are three devices designed for 12.5, 20 and 16 kW of rated power respectively. They cope well with the heating of both residential buildings and administrative buildings. The equipment is compatible with both gravitational and warm-up systems equipped with pumps.

For the production of heat, coal is mainly used (including coke), firewood is permissible as an additional source.

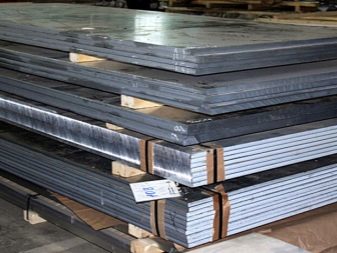

Any “Forward” model is equipped with a small and shock-resistant heat exchanger, securely covered with thermal insulation. In the production of steel using a special brand with a thickness of 0.4 cm, supplied by special order from Magnitogorsk. Grid-irons are made on the basis of the highest quality gray cast iron. Adding horizontal parts for heat removal increases efficiency, and fuel loading from above is very convenient for people.The developers have taken care of the use of a circular smoke channel with a section of 14 cm, which is connected very easily.

Among the floor heating devices of the company is such a device as Clever.

It has the following advantages:

- the formation of the gas infrastructure of the boiler from selected Italian components;

- power variation (for a number of models) from 20 to 55 kW;

- suitability for supplying heat to an indirect heating tank;

- compatibility with weather sensors, with a wide range of external pumps;

- automatic, providing modulation of the flame.

The allowable pressure of the gas stream is from 6 to 25 mbar, the device can be converted to the consumption of liquefied gas. The pressure recommended for all models of the ruler is 0.2 MPa, while testing at the factory implies a doubly stiffer bar. Any version is able to warm the water to +90 degrees and take it out through connecting pipes with a diameter of 2 inches. But the problem may be that there is not enough space for all the listed series for the boiler. Then you should choose a parapet "Patriot", equipped with a closed firebox and not dependent on power supply.

Such versions are also advantageous with the exception of the classic smoke ducts. For the removal of gaseous products of combustion and for pumping fresh air using direct access to the street through the coaxial channel. Sealing the combustion chamber in this case is absolutely necessary, since it reduces the need for ventilation and completely blocks the penetration of toxic gases into the interior. But it is important to bear in mind that the wall must be completely fireproof, and not just covered with protective material.

The opening for receiving air and dumping smoke is forbidden to be taken to the porch or unheated room, to the closed balcony or to the loggia - only on the street.

In some cases, all of the above types are not satisfied with the fact that they are placed on the floor. The solution is a wall mounted Prime. This selection is made strictly from foreign components, but when tested in Western testing centers it is checked according to the same program as all boilers adapted for Russia.

They have features such as:

- the possibility of using coaxial chimneys up to 450 cm;

- total soundproofing equipment;

- Perfectly thought over management;

- access to functions through services on modern mobile devices;

- suitability for high hydraulic head;

- enhanced protection of electronics against adverse factors.

If you go back to the mounted heating boilers, the model "Leader" fully justifies its name. The efficiency is even slightly higher than that of all the listed options, it reaches 91%. The operating pressure of the gas is 4 bar, the heat exchanger is protected from excessive heating. The designers thought thoroughly also about the prevention of the accumulation of soot, stopping the thrust, blowing by the winds. Allowed to reconfigure the consumption of liquefied gas.

User's manual

There is no doubt that the Lemax boilers can show their best. But a lot depends on the consumers themselves, because they comply with the provisions of the instructions or not. And the most important begins before the moment when there is a need to ignite the installed boiler. It is required to choose strictly such equipment which corresponds to the power of the heated room. Since exceeding the operating pressure is very dangerous, it is imperative to install a relief valve and adjust it properly.

The following actions are not allowed:

- the introduction of water into the system when the combustion chamber is working, as well as after it is stopped, before the coolant is cooled to less than +50 degrees;

- use of the boiler at the turn of the coolant, cooled to +50 degrees or less;

- use of heating devices with automatic components without grounding;

- installation of gas boilers, their launch into operation, prevention and any technical manipulations on the part of persons who do not have official access;

- the use of apparatus in conjunction with inappropriate smoke moves;

- overlapping vent ducts.

It is possible to turn on any boiler from the Premium or other series only after connecting to the chimney; it is also necessary to exclude its blocking and violation of normal draft. You should also check that the entire heating system is filled with water, so that it is not blocked anywhere by valves, air traps. In the event of a serious failure of the automation, you should immediately turn off the boiler, and also leave all attempts to start it until the defects are eliminated by professionals. If the coolant warms up to more than +95 degrees, the boiler is also turned off on its own or with the help of involved experts to eliminate the cause of overheating.

In advance, at the stage of selection and installation of equipment, it is required to prepare high-quality natural ventilation. It is recommended to install the steel sheet not only in front of the furnace, but also under the boiler itself, as well as around the perimeter.

There will be nothing wrong with the width of the sheet and its thickness being somewhat more than the regulatory data recommended by the manufacturer and the fire brigade. Moreover, security will only increase.

If there used to be some kind of boiler or stove, then they should be flushed when installing without replacing pipes and radiators. Violation of this requirement means that all claims on the capacity of the pipes, on the heating of the coolant and the room, on the circulation of water will not be accepted. When you start the gas boiler to work, first rotate the knob and only then proceed to the adjustment and start. The time to initiate gas ignition is from 10 to 60 seconds, depending on a number of unpredictable parameters in a particular case. After the end of the annual heating stage, it is impossible to drain the water from the boiler itself and the heating mains - this threatens to fast and powerful corrosion.

Possible faults

No matter how hard the engineers tried to prevent possible problems, no matter how attentive the owners themselves were, sooner or later everyone faces failures. If “Lemax Premium”, for example, goes out (the main burner stops without permission), We can assume the following reasons:

- weak discharge in the smoke course;

- gas outlet overflow;

- wrong setting of the thermostat.

First, inspect the channel through which smoke is removed. If any contamination or blockage is found, they are removed immediately. If this does not help or if nothing is interfering, it is necessary to adjust the controller.

In the event of a gas leak, you should abandon the idea to fix it yourself. All restoration work may be performed only by authorized specialists of gas services.

For your information: cleaning chimneys and burners can help in case of excessive lengthening of the flames that acquire an orange or even red tonality.

If there is no movement of water in the system, it is necessary to top it up. When such a measure does not help, you will have to redo the entire heating circuit. In the event of a sudden shutdown of the boiler due to a temporary failure in the gas supply, it is necessary to close the inlet tap.Then very unpleasant consequences will be excluded. If the boiler cannot be ignited, the problem may be associated with a pilot light or thermocouple. It is required to clean the contacts and replace the thermocouple. And sometimes it is necessary to work on the thrust sensor, connecting it not “to crimp”, but according to a more practical scheme.

Important: it is categorically not allowed to ignite if the fire from the igniter breaks out to the front, which is almost always due to the lack of traction and is a great danger.

Recommendations and feedback from owners

Consumers mostly rate Lemax boilers highly. They recommend to take devices with one circuit for non-volatile versions at summer houses and other similar places. The second significantly increases the fee for the equipment, while not always necessary in practice. When selecting power, it is better to provide some margin than to focus on the exact value. In houses with significant heat loss, it is necessary to increase power by 25% compared to what is calculated by area.

Review of the gas boiler "Lemax" - in the next video.