Kiturami diesel boilers: types of construction and tips for use

Heating has long been made not only with the use of wood, electricity, gas or coal. Heating of buildings with diesel fuel has become quite widespread. Particular attention of consumers is now attracted to products of the company Kiturami.

Special features

The Kiturami diesel boiler is a product of a South Korean company that has experience in designing and manufacturing heating equipment since the early 1960s. Its products are shipped to industrialized countries, including the North American continent.

Branded concept provides maximum use of the latest technology. And not even the latest ones, but those that have no analogues in other places, or create a narrow system specialization.

It is often said that the use of diesel fuel for heating is impractical and less economical than the use of electricity, gas or even just firewood.

But the situation is fundamentally changing when it comes to remote areas inaccessible. Many areas in the Russian Federation are still not gasified - and with the current gasification rates the pipes will not be stretched to them yet. Yes, and with the possibility of connecting physically this is complicated by bureaucratic obstacles and material costs.

Diesel fuel is much easier to transport and store than gas, it is less dangerous in terms of fire and explosiveness. Compared to solid fuel systems, diesel engines provide more uniform heating, it becomes easier to control the fuel consumption.

Advantages and disadvantages

South Korean boilers are made using the maximum of the original design and unique layout. This somewhat reduces the suitability of equipment for repair, but it manages to increase the efficiency and ensure stable operation if the simplest requirements are followed.

In addition, improved performance does not entail excessive payment in comparison with peers. That is why you should pay attention to products under the brand Kiturami. The performance of the equipment is very high, since the burning of liquid fuel is accompanied by the release of a significant amount of heat.

Additionally, it is worth noting that diesel boilers can be fully automated. In this regard, they bypass the coal, wood, and pellet counterparts.

Consumption of electric current is quite small, it is required only for the action of pumps and automatic systems. Even if power supply interruptions are likely, you can safely install a device for diesel heating. Boilers can be used to heat a house of a large area, so long as the power is selected correctly.

As for the shortcomings of such equipment, it is worth noting the following:

- it is necessary to have a separate technical space, and not just about anything, but equipped with solid ventilation and fully finished with non-combustible materials with a ceiling height of at least 2 m;

- only steel tanks or tanks made of special plastic should be used for storing fuel;

- diesel fuel during combustion emits a lot of soot, which means the need for systematic cleaning of equipment;

- if the fluid temperature drops to +4 degrees or less, it becomes too thick and does not pump well.

Specifications

The most important characteristic of any diesel boiler is fuel consumption. All those figures that are given in the passports of finished products, not to mention the advertising booklets, are always approximate and need to be clarified. Even the most trained and conscientious engineers can evaluate only the efficiency and power of the installation itself, but they cannot foresee the heated area, its insulation and the actual weather. With good insulation, it can be considered that it is enough to burn 1 liter of diesel in 60 minutes. At the same time, 10 kW of heat energy will be released, which will help to heat up to 100 m².

When selecting equipment for your home, it is useful to pay attention to such parameters as:

- work with two or one contour;

- connecting dimensions;

- water or air heating systems;

- composition of used automation;

- mass of the structure;

- floor or wall execution of the device.

Types and models

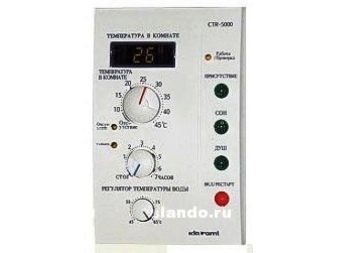

Kiturami 17R diesel heating has a total heat output of 19.8 kW.Model 17 is among the two-circuit, equipped with a closed combustion chamber and a heat exchanger of high-grade alloyed steel. The basic package includes, in addition to the boiler itself and its burner, a computer control unit and a remote control thermostat. The system is able to warm up to 190 square meters. m

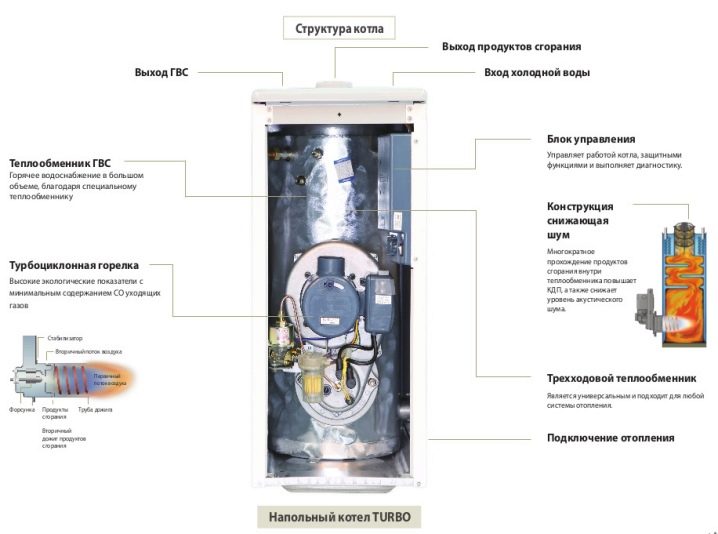

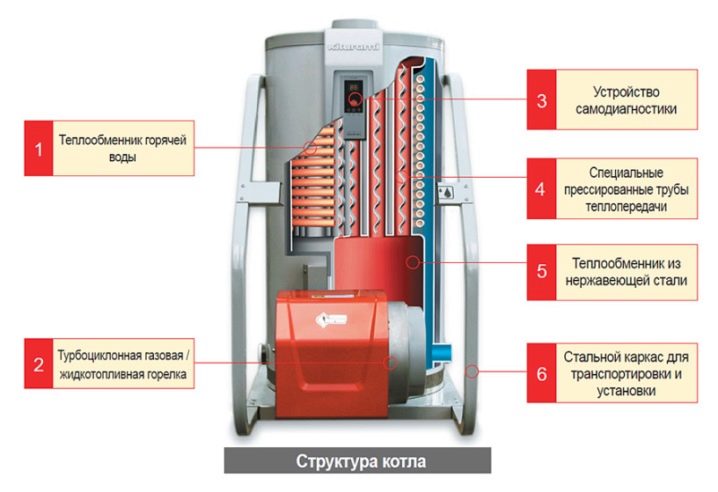

Combustion of diesel fuel occurs in the burners of the turbo-cyclone type, throwing out a strictly limited amount of nitrogen oxides.

The efficiency reaches 88%, and the installation of the boiler is made only on the floor. The secondary (water) heat exchanger is made of copper.

The device must be connected to a single-phase mains, for an hour will burn 2.15 liters of fuel. Instead of it, 11.3 l of water will flow out of the water tap in 60 seconds when warming up to +25 degrees or 7.1 liters if you raise the bar to +40 degrees. The system can heat the water to a maximum of +85 degrees.

The highest design pressure in the heating system reaches 2 bar. And also provides the function of automatic ignition and infrared remote control.

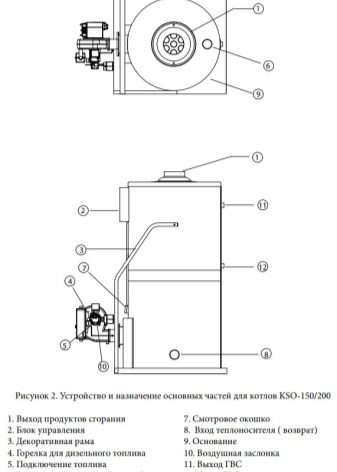

Very good results are demonstrated by the KSO 150R. This boiler can generate 174 kW of heat in a closed combustion chamber.Designers preferred to use stainless steel for the heat exchanger. Heated space can reach 1740 square meters. m

Among the floor boilers stands out 13R Turbo. This double-circuit unit with an open hearth burns diesel fuel with an efficiency of 86%. The control system operates on the basis of modern electronics, inside there are steel and copper heat exchange units. In 60 minutes, less than 2 kg of fuel burns, the coolant can be warmed up to +85 degrees.

In a minute in a water supply system it is given out to 5,2 l of water at a temperature of +40 degrees.

The heating system is equipped with means of automatic diagnostics and overheating prevention. The device is able to recognize the threat of freezing and prevent it. Connection to the heating system is made through the pipe 1¼, and to the hot water supply - through the pipe ½. For discharge of combustible gases, a pipe with a diameter of 8 cm is used.

The design of the 30R, unlike the model 13, has a slightly higher efficiency - 87%; but the firebox is also used open performance. For an hour, the system will burn 4.3 kg of diesel, capable of heating the coolant to +85 degrees. Within 60 seconds up to 20 liters of water warmed up to +25 degrees will flow from the tap. If you raise the bar and warm it to +40 degrees, the output will decrease to 13 liters.The device is well protected from freezing and excessively intense heating.

Important: Kiturami does not produce single-circuit diesel boilers. All its products are invariably equipped with two circuits. Wall models in the lines of the company either.

Modification of the Turbo 30, like any other, is capable of operating with standard electrical network parameters: 50 Hz and 220 V. The device has a weight of 85 kg, dimensions are 36.5x65x93 cm.

User's manual

Owners' reviews about diesel boilers Kiturami are generally favorable. But even with such a perfect, debugged technique, there may be failures. If the burner simply does not start, you must first check, or the power of their sockets is connected, whether there is voltage in the house.

Sometimes problems can be associated with the following details:

- wire from the meter to the outlet;

- contacts of the outlet itself;

- fork;

- cable of the boiler itself, input into it;

- internal wire;

- electronics and fuse.

If power is present, but it does not get warmer, you need to check the effect of the boiler itself. Do not urgently figure out where to buy spare parts branded production. Often the cause of the problem is too low temperature bar, set during adjustment. If this is not the case, you should immediately check, or the boiler works normally.Errors 03, 01, 02 - when all three indicators blink at once, it is possible to assume a failure in the light sensor of the flame, which either does not allow the fire to be lit or immediately extinguishes it after switching on.

The problem is solved by simply removing contamination from the detector. If this does not help, you need to find out whether the stabilizer maintains normal voltage. The maximum deviation from it can be only 5%. The next check is for the presence of fuel and its pumping into the boiler. Another step you can take is to reboot the system.

When the signal 04 flashes, there is either a malfunction of the water temperature meter, or an electronics failure. Failure can also be removed by rebooting. When a notice 08 appears, there is too much distance from the room thermostat to the boiler. It is advisable not only to shorten this wire or eliminate the short circuit, but also to shift the distribution circuit. Error 95 indicates a shortage of water inside the boiler.

To delay boiler wear as much as possible and reduce the likelihood of partial failures, it is enough to follow the simplest requirements. So, it is very important to control the presence of fuel in the tank.Before adding the next portion of the boiler stop and close the supply valve. It is strictly unacceptable to be in the fuel tank of debris, dust or even just water. When there is a long (at least several days) pause in the heating of the house, the electricity supply is cut off.

Before the start of the heating period and after the final onset of heat, the boiler must be maintained, inspected and cleaned.

The use of fuel of dubious origin is not allowed. It must be remembered that a diesel boiler is an equipment of increased danger, because it uses an easily igniting liquid. A few minutes a week spent on inspection and searching for leaks help to prevent serious trouble.

The very first start is always carried out under the supervision of specialists. Given the technical complexity and subtlety of many nodes, you need to abandon the idea to make yourself even a minor repair. Before servicing the boilers should be fully instructed.

It is forbidden to allow children and persons with mental disabilities to the heating system.The main tank for diesel fuel is equipped at a certain distance from the dwelling, ideally underground.

The boiler room must be equipped with uninterrupted powerful ventilation. All tanks and pipes should be taken only very durable, at the slightest violation they must be replaced immediately. A very important parameter for any equipment used is resistance to aggressive substances and temperature fluctuations.

It is unacceptable to use diesel boilers so that the coolant is cooled below the dew point. In such a situation, the formation of condensate and acid can destroy the most reliable structures in 2 years.

More information about the work of Korean boilers - in this video.