Electric boilers: the types and subtleties of installation

When a private house, whether it is outside the city or within its boundaries, is considered as a place of permanent residence for a family, the question arises of creating an efficient heating system that would be economical and at the same time allow it to maintain a comfortable temperature in the house during the cold season. In the majority of owners of such houses will prefer the heating mechanism with a water circuit, which is generally logical. But if everything is more or less clear with the system, then what type of boiler should be used to heat the heat carrier that will circulate around the circuit. If there is a gas main near the house, it will be better to install the corresponding boiler, because gas is a fairly affordable energy source.

If there is no gas nearby, then there are a large number of different solutions, among them the electric boiler is often used, which for the heating mechanism can be a wonderful solution and make it really economical and efficient.

Special features

Electric boilers appeared in the last century and quickly gained popularity among consumers. The main feature of such a technical heating solution is to provide a heat flow of 1 kilowatt, so much energy should be expended. In such heating devices, there is no loss in the transition of energy from electrical to heat. Of course, some of the heat will still be lost and dissipated, but this percentage will be extremely small. From this another feature also emerges: all losses in the amount of a maximum of a few percent will still dissipate around the house, because they will be created when heating conductors of indirect type, as well as different parts of electronic circuit boards. The efficiency of such a boiler will be 97-99 percent.

In general, any electrical installation that produces heat, works with high efficiency, and the issue of energy saving falls entirely on the shoulders of the home owner.

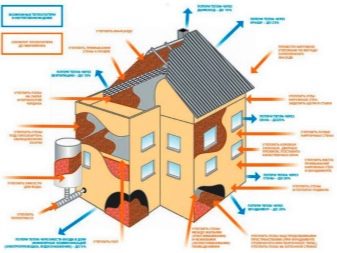

To make the electric boiler as efficient as possible, the following measures should be taken:

- install a two-tariff electricity meter;

- install a heat storage tank so that it is not used during the day;

- to warm the house to minimize heat loss;

- make heating systems with a lower temperature of the thermal carrier - heated floors;

- to automate such a heating system that will reduce heat loss to a minimum.

In addition, there is no need to obtain any permits for electric heating equipment, including the installation. At the same time, a good ventilation system should be made in the room. In addition, electric heating equipment is quite affordable. Its cost ranges from six to seventy seven thousand rubles.

In addition, electricity is fraught with significantly less danger than the same gas and other types of energy sources.

Advantages and disadvantages

If we consider the advantages of electric boilers, then the following should be mentioned:

- the use of such equipment is not associated with burning,as well as open fire; according to fire safety criteria, such boilers are the most reliable, of course, if the electrical wiring is in order, as well as good fuses installed;

- the absence of combustion products - the possibility of poisoning by combustion products or carbon monoxide is completely excluded, so there is no need to equip the system of exhaust combustion products, as well as to do additional ventilation;

- This type of boiler does not need a separate boiler room, it can be mounted in any place due to the fact that the operation of the device does not involve the release of various gases and even unpleasant odors; now these boilers have a pleasant appearance and can be a wonderful piece of furniture in the same utility room, in the kitchen or in the hallway;

- similar boilers are considered environmentally friendly;

- they are very easy to operate and maintain;

- they are very easy to issue documentation;

- the installation procedure of such a boiler is extremely simple and it can be carried out even by a non-specialist;

- considered models have the highest efficiency, which is equal to 98-99 percent;

- when installing such a boiler, there is no need to register it and contact the regulatory authorities;

- small weight and compact dimensions of modern models;

- Such units are an excellent component for the mechanism of "smart home".

At first glance, electric boilers are almost the ideal source for space heating.

They, like any other device, have a number of rather significant drawbacks.

- The high cost of electrical energy. Before purchasing such a boiler, it should be calculated, or its use is profitable from an economic point of view, because the task is to save and not spend even more than before.

- An open heating system cannot be used in this case. The same applies to the variant with the natural circulation of the heat carrier.

- Not all battery types can be used. Some models of batteries in the heating system, where the central element is an electric boiler, will not work. These are heavy cast iron batteries as well as steel radiators. They will simply cause unnecessary losses of electrical energy, and their efficiency will be extremely small. The best solutions are bimetallic models.

- A number of electric boilers are very sensitive to the chemical composition and quality of the heat carrier used.

- Such a heating system is completely dependent on the supply of electrical energy. If there are interruptions in electricity in the city, then such equipment is better not to be installed.

- For quality work requires the installation of a voltage regulator, which entails additional costs.

In general, there are arguments both for and against such a heating boiler. If we consider reviews about the use of such solutions for heating, they are mostly positive. Users note the efficiency and high efficiency of such boilers. To its advantages they include the good, fast warming up of the room. This allows you to create a quality climate inside and significantly increase the comfort of staying in it.

If we talk about the shortcomings, users note the high cost of electrical energy, as well as certain limitations in terms of the impossibility of using various types of radiators. From certain points of view, electric boilers are one of the best solutions on the market today. Properly planned and installed pipe routing,as well as batteries correctly placed in various rooms in combination with an electric boiler allow optimal and uniform transportation of heat to different rooms of the house. This makes it possible to adjust the heating temperature well, which makes it possible to really make the microclimate in the house ideal for all family members, as well as save energy.

Kinds

If we talk about the types of electric boilers, then The following categories should be highlighted:

- classical models that heat the coolant with the help of heating elements;

- induction electric boilers;

- models based on electrodes.

You should consider each category in more detail.

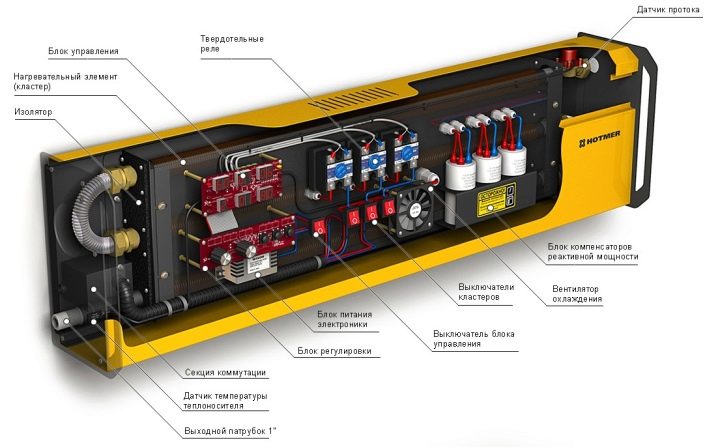

The basis of electric boilers with heating elements is a thermal electric heater, usually made in the form of a tube made of metal, filled with either an insulating material based on ceramics, or quartz sand. Inside such a heater, either a tungsten or nichrome spiral is made, which is welded by the tips to the metal contacts for connecting the wires. Usually such a heater is shaped like a U.Wires are connected to the contacts located on the tips of the device. Although now you can find a model where the heating element is presented in the form of a conventional rod, made of stainless steel.

The working part of such a heating solution is the capacity for thermal media, where there are several heating elements. Their figure depends on the power. Capacity can be located in any position that does not affect the operation of such a device. The main thing is that the heating elements are completely covered with water, otherwise they face overheating and rapid breakdown. Most often, boilers of this type have a control unit that is responsible for controlling the temperature inside as well as the pressure. This information he receives with the help of sensors. And also a plant of this type can sometimes have its own pump for circulation.

If you pay attention to the principle of operation, then when you start and then warm up the mechanism, the controller activates all the heating elements at once. At this point, the device consumes the most energy. When the device reaches the temperature set on the thermostat, the heating stops and just starts maintaining a certain water temperature atAid 1–2 heating elements.

It is best to use purified water for such boilers to prolong their service life.

The boiler has a number of advantages, which consist in low cost and quite good suitability for repair. For these reasons, such a boiler is most often used as a heating solution for your own home or summer house.

Such a heating unit has disadvantages, such as:

- long heating of water is due to the fact that the coil heats the fluid not directly, but with the help of insulating material and pipe walls;

- such a wall-mounted boiler has maximum dimensions among all categories of such equipment;

- The hot wire from tungsten is rather quickly deformed and just burns out, therefore such boilers work no more than ten years;

- if salts are deposited on the walls of the tubes, this slows down the heating process even more, therefore it is required to annually understand the boiler and remove deposits, if, of course, the design of the device allows this;

- the most affordable models are a container covered with thermal insulation, in which there is a minimum number of electronic components; In this case, the tank must be supplemented independently.

The second type of boilers that should be mentioned is the electrode one. The essence of the work of such equipment is based on the conductivity of ordinary water due to the presence in it of various metal salts. A similar method of heating a heat carrier is also used in installations of an electrode character. For this reason, in the heating mechanisms heated by such boilers, in no case should water be used without salt or distilled water. These categories have low conductivity.

In general, a similar boiler consists of a container in the form of a metal pipe, which is covered with a layer of insulation. Inside, there is usually installed an electrode made of steel to which the wire of the phase of the electrical network is connected. The so-called neutral wire is connected to the housing, where it serves as a second electrode. When the device turns on, the water between the electrode and the housing gets very hot. Such a solution makes it possible to determine the small dimensions of the device.

It should be noted that there are models of electric boilers for the house, where there are three electrodes in the case, and not one. They are called three-phase.The liquid goes through the pipe at the side, and goes through the pipe at the top. The rate of heating water depends on its chemical composition. Therefore, manufacturers often write what should be the thermal medium for the most efficient operation of such equipment. Some even provide recommendations that allow you to bring to the desired chemical composition with salt solutions, if the concentration in the source water will be low. For its determination requires a water chemical analysis.

If for some reason one boiler cannot provide the required temperature of the heat carrier, then it is necessary to install two or three heaters and turn them on one by one. In general, you will need to buy a set of automatic equipment to control and maintain the temperature. This is the main disadvantage of this water-heating boiler - its power cannot be controlled, it will be constantly at maximum. To regulate the temperature of the liquid can only turn on and off the installation. If the area that needs to be heated is small, then low-power electric boilers can be used, commuting silent thyristor starters.

If the power is high, the device is activated and switched off using a magnetic starter, which when activated produces a loud click, which is why it is necessary to modify the sound insulation in the furnace room.

In addition to this drawback, there are also disadvantages such as:

- on the electrodes constantly appears scum, which must be removed;

- the binding of a similar boiler will be more difficult, than analog on TENA;

- it is necessary to select and purchase an automatic kit;

- Aqueous chemical composition has an impact on the efficiency of work, over time, the heat carrier begins to lose its characteristics, because salts in hot water fall out as sludge, which is delayed by a filter.

The third type of boiler, which should be said - is induction. Such a heater is positioned by sellers in specialized stores as the most energy-saving. But it only implements a new method of heating a liquid with the help of electricity on the basis of the well-known law of physics. And there is simply no saving in this context. The device uses the principle of induction of the electromagnetic type.A core of metal is introduced into the coil, where there is a certain number of turns, which is heated from the eddy-type currents that occur in it. After that, heat from the core is given to the thermal carrier, which moves around it.

The structure is similar to the electrode version, but the induction boiler body is of a larger diameter, because the coil is soldered to it in height. Power is easy to adjust using thyristor starters, but the automation must be set separately. The induction option, when compared with those described above, requires minimal attention and has the longest service life. You can forget about scale if you use water without salts in the mechanism. The efficiency of such a boiler in practice is 99 percent, although the rate of heating of the whole mechanism is slightly lower than that of the analog based on electrodes. In addition, its dimensions are also small, which allows mounting the boiler on the wall in any room. Induction heating makes it possible to make high power boilers - up to 50–60 kilowatts.

If we talk about the disadvantages of such boilers, then we should mention the highest cost among all categories of the equipment in question, as well as a separate procedure for implementing the strapping scheme.

In addition, electric boilers also differ in the number of circuits.

They may be as follows:

- single circuit;

- dual circuit.

It is worth understanding what the difference is. Single-circuit models are designed exclusively for space heating. At the same time, it is possible to connect an indirect heating boiler to them and make hot water supply. Dual-circuit options, in addition to being part of the heating system, can be a source of hot water for domestic use. In them there is an additional heat exchanger, which can be both accumulative and flow-through - similar to the built-in capacity for heating water.

It should be noted that the double-circuit boiler can not work on two circuits simultaneously. If you open the tap with hot water, then the thermal medium for heating the room will stop heating.

If we talk about the advantages of single-boiler, then the following should be mentioned:

- low cost;

- high power;

- good efficiency;

- small consumption of electrical energy.

Among the shortcomings are the following:

- if you need to heat the water, you will need to buy a boiler;

- If you use a boiler, the design will be quite large and unaesthetic.

The advantages of the dual-circuit model are the following:

- small size;

- simple installation.

They have such disadvantages as:

- high price;

- serious requirements for maintenance and quality of thermal media;

- instability of water temperature and pressure.

It is difficult to say which model is better. If you want to save space and electricity in the apartment as much as possible, then it is better to take a two-circuit variant. At the same time, single-loop solutions are considered more reliable and convenient in operation.

How to calculate the required power?

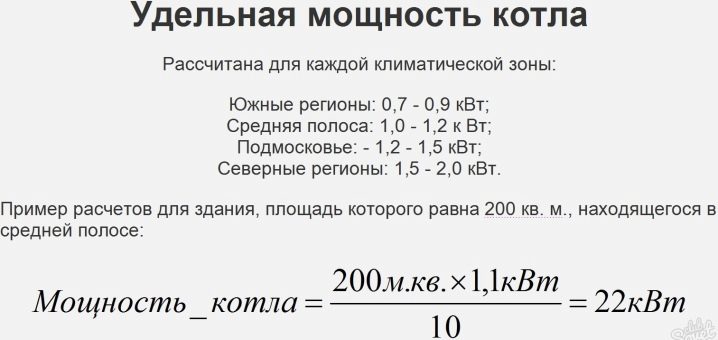

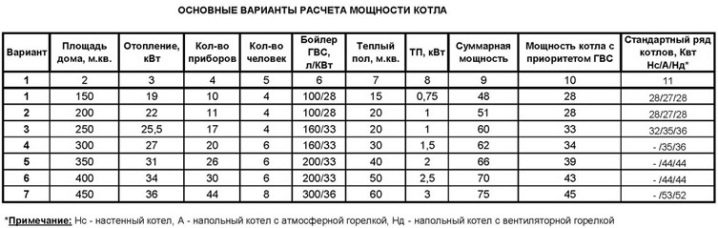

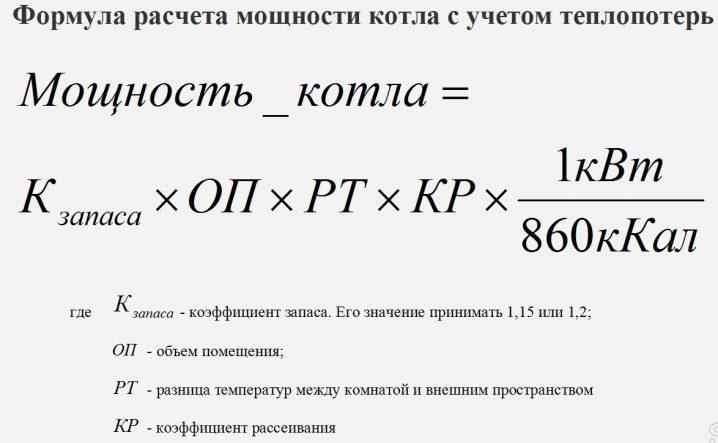

In order for the heating system to be fully balanced and correspond to the room where it is installed, the device must be calculated in advance. At different periods, the temperature outside changes, which is the cause of the change in the temperature conditions in the room. You can only make an approximate calculation based on the heat loss of materials that were used to create the components of the house. To perform the most accurate calculation of power indicators of electric boilers, it is necessary to take into account the thermal carrier, heat loss and the size of the room.The simplest version of the calculation is based on the floor space that will need to be heated. The proportion of one hundred watts per square meter is perfect for an average weather zone, where conditions are milder, for the south you can reduce power, and for the north - lift it. In Soviet times, they took 120 kilowatts.

Nowadays, such a decision can not be called correct. It is better to get a more powerful option than freezing in the winter season. Based on the area, it is necessary to carry out the calculation of electric boilers, using special formulas.

To calculate the need to know the following indicators:

- power figure for a particular part of the country;

- area of interest premises.

For the south, the figure is 0.7, for the north - 2, and the middle band - 1.2. The bottom line is to multiply the area of a room by a regional indicator. The value will be received in watts. To convert it into kilowatts, it is necessary to divide the resulting number by 10. Of course, this technique is not easy to call ideal, because it also takes into account the characteristics of the climate, which will significantly affect the cooling rate of the room. For example, for heating a building with an area of 100 m² located in mid-latitudes, a heater with a capacity of about 10–12 kW is required.If the area is 150 squares, then the power should be 15 kilowatts, and if 200 m² - 20 kW, and if 60 m² - then 6 kW.

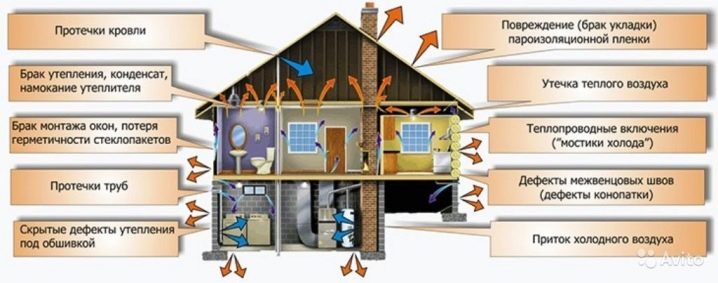

Many owners are faced with the fact that the electric boiler has a high capacity, and the cold is still present in the building. This is due to the fact that such a factor as heat loss has an effect. If the house is not insulated floors and walls, you can find a gap in the various elements, in this case, the street warms more than the house. The device must give no less heat than the loss of the room. For example, if the heat loss at home is about fifteen kilowatts, then the heater must have at least the same power so that the temperature in the building is comfortable. But the heat losses go constantly, which indicates that the device must always be turned on, which is impossible. Otherwise, the failure of the device will be only a matter of time, and during the heating period it is unacceptable.

Before you start making calculations for an electric heating boiler, you should determine the heat loss of the room.

To do this you need to know such moments as

- from which various elements of the house are made;

- thickness and area of these elements;

- area of windows and their number.

This is all necessary to determine the thermal resistance of the house. Any material has its own thermal conductivity. To calculate the thermal resistance of various elements of the house, their thickness should be divided by the thermal conductivity coefficient of the materials from which they are made. The calculation must be made separately for a particular material. After this is done, all numbers should be summed.

When the heat resistance of the house is calculated, you can begin to count the total heat loss. To do this, the construction area should be multiplied by the temperature delta inside and the delta outside the window. The result should be divided by the thermal resistance of materials. If we talk about the temperature delta, then it is taken for the coldest time. The similar option for the electric boiler is the most exact and correct. This method is somewhat more complicated, but it will give the result as accurate as possible.

An important factor influencing the choice of electric boilers of heating is the coolant itself.

Its important characteristics are as follows:

- volume;

- scheme of breeding heating pipes;

- properties of a fluid.

The breeding scheme is an indirect factor, however, such that it has an impact. The most important is the volume of thermal media. If the calculation of the power of the device was done correctly, but the calculation did not include the fact that a heat accumulator was mounted in the circuit. And in this tank can fit a lot of water. Its volume is always considered a separate line, but less than three hundred liters it is usually not done.

And to heat 1 liter of water by one degree, about 0.001 kilowatts is spent per hour.

The device must heat the fluid to a level of, for example, 38 degrees. At the first start, the water temperature will be about twenty degrees. When the thermal medium heats up to the desired degree, the heating will end. You can calculate how much energy will be spent on heating. It should be noted that the calculation of the power of the electric boiler should be carried out with the calculation of heat loss. Various clumsy methods do not show any effectiveness, for which reason this issue should be approached most responsibly and clearly.

How to choose?

Many are wondering how to choose a good electric heating boiler for heating.One of the most important properties for this type of equipment is the performance indicator that has already been mentioned. It depends on the efficiency of such devices and operating costs. But in the case of the equipment in question, this coefficient is not so important due to the fact that all models have an efficiency in the region of 96–98 percent. Therefore, you should pay attention to other characteristics.

The most important is power. It is usually measured in kilowatts. It determines how much heat transferred to the fluid will flow into the heating mechanism. The power of the boilers is usually provided by the operation of electric heating elements, which are located inside the heat exchanger.

The power level should be such as to completely compensate for the heat loss from all rooms and, if necessary, also ensure the efficient operation of the hot water supply mechanism.

For electric boilers, this characteristic ranges from two to sixty kilowatts. In order to carry out the correct selection of the power of the electric boiler, heat engineering calculation should be made for the whole building.Best of all, if it will be done by specialists. This characteristic should be determined at the rate of 1 kilowatt per 10 square meters of floor space. If you still need to heat the water, then the power should be at least a quarter more.

Another important characteristic is the control mechanism. With it, you can significantly reduce the cost of heating and hot water. In various models of heat generators there are different options for reducing energy consumption. Usually, automatic control mechanisms are used, which are responsible for regulating the operation of units. The simplest such device is a thermostat. The essence of his work is extremely simple - you should set the desired temperature of the thermal carrier at the outlet, when it increases to the required value, the thermostat turns off the heating elements.

More opportunities are presented at the boilers, which have control panels with a microprocessor inside, but such models are significantly more expensive, although the costs will pay off pretty quickly due to the savings in electricity.

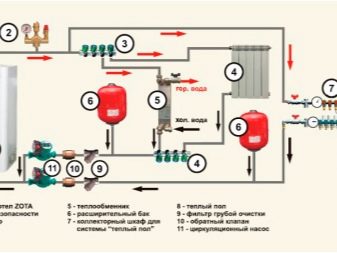

Another important factor to which attention should be paid when selecting an electric boiler is its equipment.This point affects the price of the unit, and efficiency. It was mentioned above that the purchase of models with incomplete bundle entails additional financial costs for the purchase of parts and temporary losses for installation. If we talk about a complete set of electric boilers, then a number of models are miniature boilers. They have a pump for circulation, and an expansion tank, and remote-type temperature sensors, and a filter that is responsible for cleaning the thermal medium, and an antifreeze mechanism and others.

The criterion to which attention should be paid when selecting an electric boiler is the voltage of the electrical network. Although this factor does not apply to the devices themselves, but it can not be ignored. Power boilers require voltage from a 380 volt line. For this reason, before purchasing a boiler, you should find out whether such a line can be drawn to the desired object. If not, then it is better to be content with a single-phase solution of 220 volts. Naturally, not the last moment, in addition to these properties, when selecting an electric boiler is its manufacturer.

It is better to give preference to recognized and well-known manufacturers of such equipment, the quality of which is confirmed by real customer reviews.

Installation

It is worth considering how to install the electric boiler with your own hands. For this purpose, a special scheme, which is used by all specialists. But first it should be noted that electric boilers are divided into floor and wall ones by the method of fastening. In principle, the difference in their installation is not very large. Wall mounted boiler is fixed to the wall, and floor - to the floor. Otherwise, the system is the same.

Before talking about the procedure itself, it should be mentioned which tools should be available at hand, namely:

- punch or drill;

- building level;

- lath for installation;

- profile for fasteners;

- electrical wire;

- elements for fasteners;

- several pipes;

- special key to connect the boiler to the heating mechanism;

- cable of the desired section;

- metal or metalplastic pipes;

- boiler installation plan, thought out in advance.

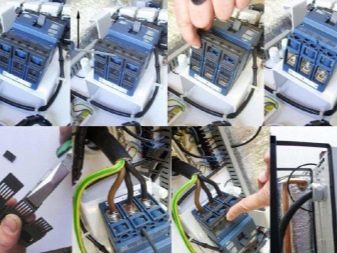

Moving directly to the installation process, it is worth noting that it is performed in several steps.

- It is necessary to mark the place where the boiler will be mounted. To do this, you need to take a pencil and level, draw out the place where it will be located.It is better if the appliance is placed as far as possible from the plumbing.

- Using a perforator or a drill, you should punch the holes you need and make sure that the wall can hold the device.

- After that, fix the profile of the fastener, as well as the mounting bar. The level of the bubble type should make sure that all fixings are even. The device should be attached to the wall as well as possible. For this it is better to use dowels.

- If the installation is carried out on the floor, then a special support made of metal should be attached to it.

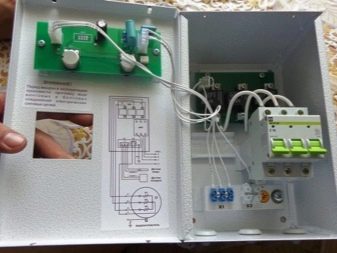

- Now you need to install grounding. A number of models can work without it, but it should be understood that the operation of such devices in the absence of grounding is dangerous for residents and for the building itself. It is better to make a separate power line, because the power does not always make it possible to connect the device to the simplest automatic input type.

- To create a ground connection, you must create a grounding center. So called a few metal pins connected by reinforcement. They are deepened into the ground.

- If the device is connected to a special machine, then the neutral wire is conducted to the pins.Surplus surplus is simply discharged into the ground.

When the device has been mounted, a wire with a cross section of a certain type must be drawn from the machine. If the device has a power of up to six kilowatts, then it can be connected to a single-phase automatic device; if from 6 to 12 kilowatts, then to two-phase; and if more, then only to three-phase. To connect the appropriate device must be purchased and the corresponding automatic security. Now you should install a protective off device nearby. Next, you need to hold the wire off timer, as well as temperature control devices. After that, the installation of the electric pump and the expansion tank. The tank is mounted using an electric drill and fasteners, and the pump is placed near the boiler on a pipe that will supply water, which will provide residents with hot water, will help avoid overheating the device and save some electricity.

After that, the expansion vessel and the electropump are connected using metal or metal-plastic pipes. Then you need to hide all the electrical wires in the cable channels, for which you want to mount a protective casing.The next stage is to connect the device directly to the heating mechanism. To do this, turn off the water using a stopcock. It remains to attach the device to the pipeline by means of flanges and couplings.

Now it remains only to connect the device to the mains. First you need to make sure that there is grounding and everything is done correctly. The distance between the contacts should be 0.03 centimeters. When the boiler started to work, you need to turn on the water and check the operation of the equipment. To test the boiler’s performance in various modes, there is sometimes a need to remove excess air from the system. To do this, you need a pump or compressor that will create the necessary pressure.

Recommendations for use

It is worth paying attention to the following general recommendations for the operation of electric boilers:

- it is better to carry out the installation of the electric boiler during the repair, which will significantly save time on installation;

- if the installation of the boiler is carried out already in the existing heating system, then it must be very thoroughly rinsed using special means;

- electric boilers are also beneficial to use as an additional option for heating the room;

- if there is no experience in installing electrical equipment, then it is better to entrust its installation to specialists;

- when using an open type system, it will not be superfluous to install valves;

- on the back of the heating system it is best to install a filter;

- grounding is best done with a cable made of copper; its cross section should be four millimeters;

- if the boiler is an electrode, then for the most efficient operation it must be equipped with an air vent, a pressure gauge and a check valve;

- be sure to leave on one side a place in order to carry out technical work when it detects any malfunction of the boiler;

- Before installing an electric boiler, it should be clearly defined with its type and functionality, it should be calculated which solution will be best of all; Of course, electric heating is not the most economical, but choosing the right boiler will help you save a lot;

- should be determined before buying the necessary power of the boiler; it makes no sense to overpay for a too powerful model if its potential is not fully utilized anyway;

- There are models that can be connected to the network as 220 volts and 380 volts. But you should still clearly know the allowable power consumption for the house before you buy;

- it is better to immediately buy fully equipped models, so that later you don’t have to spend money on the same elements, but at a higher price;

- it is necessary to install a filter that cleans the heat carrier in the heating system, which will make it possible to significantly extend the system operation time;

- even before installing the boiler, it is necessary to pay maximum attention to the security system, which will protect the device from falling or too much increase in pressure of the heat carrier in the system;

- to save money, you can purchase a boiler, where power is regulated in steps, which makes it possible to use only a part of its resource in spring or autumn; This solution is best implemented in models with automatic programmable control units installed.

The installation of an electric boiler is a very responsible process that must be carried out exclusively by specialists. If we talk about electric boiler as a source of heating, then it is an excellent solution for any private house or room.But the choice of such equipment should be treated very responsibly, so that it does not become the reason for the emergence of a serious item of expenditure in the family budget during the heating period and this type of heating does not prove to be an ineffective solution. There are many factors to consider in order to make the right choice. You should familiarize yourself with the most popular models from well-known manufacturers in order to purchase the best option for an electric boiler.

To learn how to properly install an electric boiler, see the following video.