Features of the Kupper boilers

The Kupper brand boilers are products of the Novosibirsk Teplodar manufacturing company. Just recently, this manufacturer produced a solid fuel type of combined boilers. Boiler equipment almost immediately after its appearance received a huge demand. There are reasons for this. The fact is that prior to the appearance of this product on the domestic market, either low-quality Russian boiler installations or high-quality expensive imported analogues were offered. So, what else are the Kupper boilers good for, let's learn from this article.

Advantages and disadvantages

The Kupper boilers are considered to be high-efficiency solid fuel equipment.

The units have a number of positive qualities.

- Impressive power with excellent efficiency.

- The operation of the boiler will not depend on the supply of electricity or the presence of a gas pipeline.

- Attractive appearance.

- For their work, the units use an available type of fuel, such as coal.

- The fuel that is used is universal. In reviews, the real owners of this boiler equipment say that this boiler is fully capable of working even on ordinary wood, stone or brown coal. Here, of course, firewood will give the smallest effect, and yet, when there is no alternative fuel available, firewood does a good job with its direct tasks.

- Self-cleaning The boiler itself is slightly polluted, respectively, cleaning equipment is needed less often, and the cleaning procedure will not cause any difficulties.

- Protection. Development engineers diligently thought out issues related to the safe operation of modern boiler units. Therefore, "Kupper" attributed to the best equipment for reliability.

Studying all existing features of boilers, the conclusion is that there are some flaws.

- This boiler is new. It is difficult to say whether this item is considered a disadvantage.Here are just consumers still could not get the full information in the instructions on this equipment. Therefore, a large number of conclusions comes from the statements of the manufacturer.

- Steel, which the manufacturer uses, in its durability is very different from the cast-iron material.

- The configuration does not provide for the existence of a control unit for the heating element, as well as the thermostat. You have to purchase these parts separately.

- Each model presented has a single circuit.

- In addition, fuel loading has to be done manually.

Kinds

Boiler equipment OK 15, 20, like other models of boilers, has become very popular. Before considering models 15, 20, or 30, you need to figure out what are the modern types of solid fuel boilers from the manufacturer "Teplodar".

- Steel and cast iron model. Pig-iron material is quite brittle and nevertheless will serve much longer than ordinary steel. Steel boilers 15/20 are made by seam welding technology, but the loading of fuel from steel boilers is carried out much more often cast iron. It's all about accelerated heating of the fuel.

- Gas generator or ordinary model. Long burning equipment has its own advantages over traditional models OK 15 / OK 20. At the same time, the price for a unit of long burning is several times higher. For this reason, often the choice falls on the traditional type.

- Model dependent or not dependent on electricity. The boilers that do not have heating elements use air supplied in a natural way, which is why these models have become independent of electrical energy. But boilers equipped with heating elements will require connection to the network, only they use these models if necessary.

Models

Teplodar is a manufacturer that manufactures Kupper boilers. The plant produces 6 different models.

This includes equipment such as:

- HVAC 10;

- OVK 15;

- HVAC 18;

- HVAC 20;

- The Kupper 22 Pro;

- HVAC 30;

- OVK 42;

- The Kupper 36 Pro;

- 42 Pro.

It's pretty easy to figure out the numbers and the value of OK.. For example, OK means a heating boiler. A model that has a HVAC in its name is considered a heating boiler, equipped with cooking hobs in addition.In the meantime, the numbers are a measure of heat output.

Boiler equipment with the presence of the “Pro” in the title indicates a series of equipment production, that is, this long burning boiler.

Chambers with a furnace of these models are more, and this will allow to increase the frequency of the fuel load up to 8 hours.

So what is the best of this presented range? What equipment is used for different situations?

Here you need to understand.

- OVK 10 has the lowest power, while the heating system is perfect for a private house with an area of no more than 100 m².

- OK 15 boiler installations with a corresponding power of 15 kW should be suitable for a building of 120 m².

- OVK 18 / OK 20 - the most productive. The power is sufficient for heating 175 m², while the HVAC 18, in addition to heating the area of the dwelling, will allow to cook food.

- Experts advise to choose OK 36 when the area of the building is more than 200 m².

In fact, to determine the model is easy to make the right purchase. When selecting the boiler, just remember that a power of 1 kW will allow you to heat 10 m².Along with this, you should definitely choose equipment with a power reserve. In this way, boilers will not work at highs, heating the room.

The work of the boiler unit

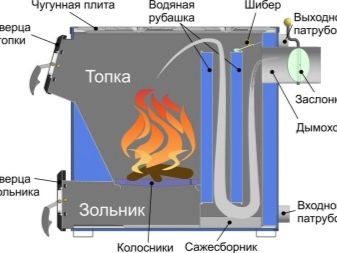

To understand exactly how this device functions, let us familiarize yourself with the principle of operation of the Kupper boiler plants, OK.

- Fuel is put through a special door into the boiler chamber. You can use wood, coal, briquette peat.

- The camera is located at the bottom of the design, exactly here the kindling is carried out.

- When fuel combustion produces heat, it begins to heat the water jacket, that is, the liquid in the heat exchanger.

- The heat carrier of the boiler equipment can circulate naturally or forcibly.

- Exhaust smoke, that is, the gas goes through the chimney pipe. For models of the OK series, starting with a 15, 150-millimeter branch pipe of a boiler chimney in diameter, the less powerful OVK 10, meanwhile, has a diameter of only 120 mm.

- Multi-row types of heat exchangers, like the pipes themselves, are in a chess position, they heat the coolant.

- The design of the liquid stagnates in the heat exchanger does not allow.

- You can use the basalt type of insulation, if you need to increase the efficiency of the Kupper.

Electricity, gas, pellets

In fact, it is unclear exactly how all these concepts were associated with solid fuel boilers. Perhaps, that uses only coal or firewood.

Everything is quite simple here - you just need to carefully read all the features of the Kupper boilers.

- Each unit is equipped with heating elements with a power of 6 kW. And if it is said about models OK 30 and higher, then here the heating element is 9 kW, and this is several times more powerful. If the boiler equipment has heating elements, this allows the unit to work on electricity and solid fuel.

- TEN is not capable of efficiently heating buildings with a square above 100 m². And yet the existence of heating elements will perfectly maintain the required coolant temperature.

- For easy control of heating elements, you can buy a special control panel with specialized sensors that regulate water and air. Thanks to this panel, full control over the operation of the heating element is performed, it will be possible to switch on everything at once or to make partial switching on. Panel can be purchased separately.Unfortunately, it is not included in the kit to the boiler equipment.

- The boilers operate on gas fuel. In addition, heating equipment can work on pellets. To put the equipment in the required mode, you should purchase an automatic type of pellet or gas burner. Details set to where the door from the furnace. The door must be removed, and then cut into the place of the selected burner. By the way, the indicators show: gas consumption is several times higher than the fuel consumption of an ordinary gas boiler.

Buying an ordinary solid fuel boiler, they jointly acquire the same advantages as the Kupper equipment has, since, apart from the usual solid fuel, the unit works quietly on pellets and gas fuel.

Such combined boilers can meet the highest demands of the consumer.

Installation

Effective, and most importantly, safe operation of the boilers is achieved only with proper installation, that is, with proper connection to the heating system and, of course, to the chimney.

Consider the most important requirements that must be observed.

- The boiler room, where the installation will be carried out, must necessarily have an excellent air supply, lighting, both artificial and natural.

- If pellet equipment is used, there must be power supply in the boiler room.

- The floor where the heating boiler unit will be mounted must be smooth and fairly durable. The flooring should not be combustible. If the unit is installed on the floor of wood, then between the boiler and the floor must install a protective screen, for example, a steel sheet.

- Meanwhile, the distance from the boiler wall to the solid fuel boiler should be maintained from the front side at 2 meters and not less, and from the side - not less than 1 meter.

- The room itself is necessarily equipped with a drain to the sewer.

- It is recommended to use special sandwich chimneys together with boiler installations, which, by the way, are also produced at Teplodar. It is necessary to isolate the chimney from the ceiling of wood. In addition, the pipe should have a length of at least 5 meters, while it should rise above the very ridge of the lid at a distance of 50 cm.

About the pros and cons of the boiler model Kupper Pro22, see the following video.