Condensation boiler: the details of installation and operation

Heating of a house or other building is far from its ancient prototype. It has long been no longer necessary to throw firewood or coal into the "insatiable" firebox. But to fully realize the benefits of modern equipment, you need to know this very equipment.

What it is?

A condensing boiler, including one working on gas fuel, is designed to solve the problem of feeding a heated floor. The low (relatively) temperature of the circulating fluid makes it possible to cope with this task effectively. And also, according to the suppliers, it is possible to reduce the expenditure on the purchase of energy carriers for a long period of time.If you refer to the information materials of manufacturers, you can stumble on the mention of efficiency at the level of 108-100%. This seems to be contrary to the laws of thermodynamics, especially since the best boilers of other types have an efficiency of 90-95%.

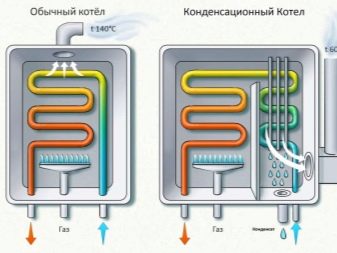

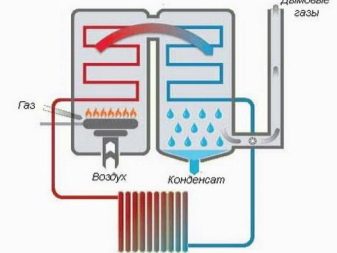

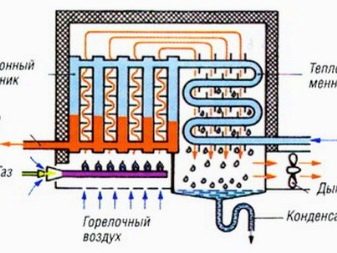

The reason for this difference is that ordinary gas-fired boilers do not involve the evaporation and condensation stages in their work. Hot gases passing through a heat exchanger in a condensing boiler do not fly off into the chimney, carrying off useless few percent of thermal energy. The solution to the problem is found in lowering the temperature of the flowing gases to 55 degrees This temperature is equal to the dew point under normal conditions, water vapor condenses when it reaches this point and release thermal energy. So, the main feature of the condensing boiler is the use of energy released during phase transitions.

Advantages and disadvantages

Modern-style condensing boilers do not forget about environmental issues. Using latent heat energy avoids condensation. The feature of these systems is the minimum amount of noise and comfort during use.But it is important to understand that the condensing boiler is more expensive than comparable power analogues. A single solid amount allows you to pay back the investments sometime in the future, but initially you should post it in full.

In Western European countries, wall and floor condensing boilers are used very actively.because long-term consequences are calculated there. In addition to efficiency, the equipment operating on this principle is distinguished by increased safety. This parameter is supported by the embedded electronic system. Digital panels have neither handles, nor levers - but they work quite effectively. Some models are equipped with monitors showing the technical parameters, which makes it possible not to rush to and fro, constantly checking the operation of the system.

Important: the condensing boiler normally works only with uninterrupted supply of gas or other fuel. It is not provided in all places in Russia, and the residents of such territories, unfortunately, will have to give up their decision.

Boilers consume about 70% less fuel than alternative designs. The wall type of the boiler is more popular than the floor format.But the latter is characterized by an increased diversity of the range and can warm up the increased territory.

Condensing boiler is different from conventional convection apparatus, not only high efficiency and energy efficiency. The low temperature of the exhaust gases causes such a difference as the possibility of building a plastic chimney. When using fuel, a minimum of harmful substances is emitted into the atmosphere. Of course, the optimal parameters are achieved only with proper installation and quality service. Here, much depends on the people themselves.

Principle of operation

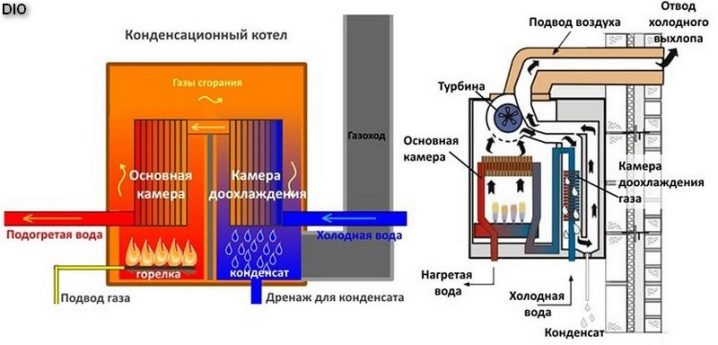

The condensing boiler works in such a way that the first heat exchanger is heated when the fuel is burned, and the second takes heat from the burned gases. The walls of the secondary apparatus concentrate steam. But so that the condensate process does not cause corrosion, manufacturers use excellent alloys. They are selected on the basis of chemical resistance.

To the secondary heating circuit collected maximum heat, use solutions such as:

- attaching additional spirals;

- use of internal parts of various sections;

- installation of a condensing heat exchanger on the return path of the heating system.

It should be noted that the best results when using condensing boilers can be obtained only with the use of the latest burners. In them, the mixing of air and feed gas is carried out strictly in the optimal proportion.

Gas condensing boilers with a boiler can solve the problem of hot water even when using heating systems that have a single-circuit profile.

There are three main options:

- embedding the boiler in the boiler itself;

- adding external tanks;

- the use of boilers operating under the scheme of indirect heating.

According to statistics, a built-in boiler with a capacity of 50 liters can cover the needs of a family of 3 or 4 people in hot water supply 100% without any difficulty. It should be borne in mind that the presence of a tank narrows the choice of the consumer; it is impossible to hang on the wall, even the strongest, constructions with a volume of more than 100 liters. It so happens that the boiler was not originally equipped with a boiler - or even equipped, but its operation is not sufficiently effective. The solution is the installation of remote tanks.Compatibility with them is ensured in almost all wall mounted gas appliances.

The pipes and pumps that provide circulation in such a system should be designed separately for heating and for hot water supply. The total capacity of the tank is selected according to the power of the boilers. If it is not large enough, the heating of the fluid will take a very long time or will not reach the required value at all. The standard approach in the factory setting automation boilers implies the primacy of the heating vector. As soon as the coolant cools excessively, the sensor detects this and starts the heating block.

To keep hot water all the time at the same temperature level, boilers with a boiler are equipped with internal heating elements. The controller depends on the electrical supply and is sent by the automation of the boiler itself. Quite an interesting question - will it be possible to use boilers for heating?

Theoretically, this is possible, but there are a number of pitfalls.

- Most drives are equipped with heaters of only 1500 watts. This is enough for heating 10 square meters. m, but only with a solid warming and not too strong winds, frost.

- TEN, working constantly, will significantly increase the total electricity consumption.

- It is possible to push water through the system using standard strapping, but it is not able to compensate for the weakness of the central link.

It should be noted that condensing boilers are not only gas, but also diesel; similar designs are produced even by many eminent manufacturers. The promised efficiency is slightly lower than that of gas-powered apparatuses, however, 98% is an extremely good indicator. Viessmann Vitorondens 222-F and 200-T are vivid examples of such systems. The heat exchanger is made of stainless steel grades. The systems use a universal type burner capable of applying any kind of liquid fuel.

Low emission of harmful substances due to the preparation of a mixture of fuel and air in ideal proportions. The developers were able to equip these devices with a comfortable control unit and sensor equipment. Heat sources can even be built into a completely streamlined heating system. Modern condensing boilers are almost always equipped with special housings, which additionally reduce noise.Thanks to this, they can be used even in the immediate vicinity of the living space.

Device of the main nodes

Even a general acquaintance with condensing heating equipment shows that it is rather complicated.

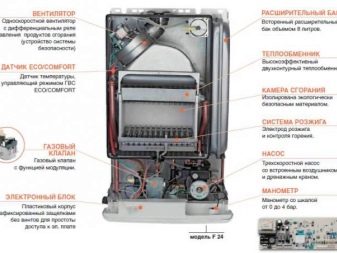

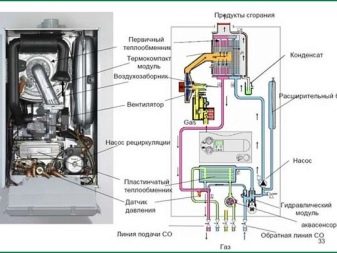

The main components of it are:

- fuel combustion compartment;

- an apparatus that supplies this fuel;

- fan that improves the discharge of the mixture;

- source heat exchanger;

- cooling chamber, where the mixture of vapor and gases cools to a temperature of 56-57 degrees;

- condensing circuit heat exchanger;

- condensate collector;

- chimney through which cooled gases move;

- pump that pumps water through the heating system.

The initial heat exchanger mates tightly with the compartment where the fuel burns. In this exchanger, the resulting gases cool slightly, but are still heated up more than the dew point. At this phase there are no particular differences from the classical condensation scheme. Then the smoke mixture artificially moves to heat exchanger No. 2, which cools the gas mass to less than 56 degrees. Condensate, sharing its heat with the heated system, goes through the drainage pipe to the sewage system.

But it is important to understand that not pure water condenses inside the boiler, it is saturated with inorganic acids. Since the temperature of the liquid is above room temperature, the aggressiveness of even a weak solution rises considerably. Therefore, designers are trying to use resistant substances - stainless steels or an alloy of silicon with aluminum.

To reduce the damaging effects of acids, it is recommended to put cast heat exchangers. The weld, even made very high quality, is the entrance gate for caustic substances.

Chimneys are also made from acid-insensitive steels or plastics. Horizontal fragments of the gas stroke should be directed at an inclination. This solution allows you to redirect the water that appears during the condensation of water vapor back to the boiler. As the gases leaving the condensation circuit lose their temperature, the moisture that did not condense before will inevitably settle on the walls of the chimney. It is known that heating boilers are required to produce a different amount of heat depending on the time of day and weather conditions.

Adjustment is made using a burner; modulated type allows you to make this setup very easily. There are options with fixed power levels, and then the boiler automation just less often gives the command to turn on. In most of the most modern devices, modulated systems are put in place, which are considered to be more adequate and flexible designs. The amount of fuel consumption is determined primarily by the total power of the heating equipment and the load it carries. Condensation boilers are designed in such a way that they do not work well in high-temperature circuits and require too high air quality.

Selection features

The advantages of condensing boilers fully compensate for their individual weaknesses. But to realize all their advantages, it is necessary to take into account many subtleties when choosing. The latent heat released during condensation varies depending on the fuel used. If you use methane (in other words, natural gas), the heat released allows you to increase the energy output by 11% compared to simple combustion. Liquefied gas adds 9%, and diesel fuel increases heat generation by 6%.

Other types of fuel - not only liquid, but also solid, make a much smaller additive of energy. The above types of fuel are considered the most promising for use in condensing boilers. Condensation of water released during the combustion of solid fuels gives too little effect, since it is provided in a very complicated way. Even among pellet apparatuses such an approach is rare. By enhancing the cooling of the flue gases, you can increase the selection of energy.

But the paradox is that with the loss of heat by these gases, it will actually be more difficult to extract heat. The equipment is becoming more complex, the actual addition of energy does not meet expectations. In addition, boilers are able to work at different air temperatures, in different modes. And while you should avoid the appearance of condensate in the chimney or boiler.

It is very important to choose devices with a minimum number of such phenomena.

Considering that convection boilers can be regulated only due to the operation of the burner, it is desirable to choose options with the most complex burners and the units controlling them. Bitermic heat exchangers cost less, they are simpler technically. But such devices are much more demanding than the usual quality of water flowing through them.If it is not large enough, the pipes will be filled with a layer of scale very soon. Inevitably, the efficiency of the system will fall.

This danger is less characteristic of separate heat exchangers, but they require the addition of:

- secondary heat exchanger;

- crane with three turns;

- systems operating this crane.

The higher the required power of the boiler, the less should be auxiliary parts. Predicting their impact on the practical operation of the system is extremely difficult. First of all, as energy production increases, it is necessary to remove the built-in expansion tanks and pumps with their surroundings. The strongest boilers do not even have control systems. You can correct the situation by purchasing specially selected additional systems and units.

The latest novelty is pumps that allow you to adjust the shaft torsion rate. Such a device immediately increases the cost of the entire system and complicates it. We'll have to put a more advanced than usual controller. Rarely, such equipment is installed in the boiler itself, almost always it has to be bought separately. And therefore it is necessary to pay both for installation, and for more careful setup.

Nevertheless, experts believe that these pumps own the future. According to their estimates, by 2020 almost all new boiler models will be equipped with such systems. Chimneys in condensing boilers already now initially differ from conventional models. In addition to the use of acid-resistant materials, characterized by the use of a coaxial circuit. Most often, the two pipes in such circuits are made of plastic.

Important: coaxial chimneys can not be longer than 5 m, which must be considered when choosing, as is the preferred choice in the wall.

Sometimes several condensing boilers are used at once in the form of a cascade. Such installations are included all together only in very cold weather. The reliability of operation also increases, when one device fails, you can completely stop it and distribute the dropped load. For the greatest savings, it is worthwhile to use boilers with weather-dependent automation.

Installation

The connection scheme of the condensing boiler should be thought out as clearly as possible. The slightest mistake in it can lead to serious problems during operation, devaluing all investments.It should be borne in mind that condensing boilers should not be installed in living rooms, maximum - in kitchens. The ideal solution is the choice to install a separate insulated space, where the ceilings are raised at least 220 cm. The walls should be covered with plaster, and even better - tiled.

The ideal floor is the one that is as flat as possible and covered with a non-combustible layer. It is necessary to prepare a passage with a width of at least 0.8 m; boiler room, whatever it was, is equipped with glazing of at least 0.3 square meters. m 10 cubic meters. m internal volume. This volume itself is calculated in accordance with the power generated by the heater. The use of boilers that are not equipped with sewage is prohibited. The cascade group of condensing boilers means a separate shut-off valve for each unit.

The boiler room is connected with the general extract from the house; the air flow is organized either with the help of ventilation grilles in the doors, or directly from the street.

It is strictly forbidden to mount the condensing boiler at an inclination, even a very small one. Particular attention should be paid to plastic chimneys and protection from condensate.

It is categorically unacceptable to use all materials designed for resistance to significant heat. Do not put the pipe joints so that they interfere with the necessary movement of condensed water.

Recommendations and feedback from owners

It is better to install a fan before the burner in order to increase the efficiency of fuel combustion. Judging by consumer reviews, the larger the heated area, the higher the efficiency of the use of the condensing boiler. The chimney must be equipped with forced ventilation means, as well as be as tight as possible throughout. Fastening of all suspended parts of the infrastructure is made by dowels.

The required capacity of the condensate tank should be carefully calculated.

How the condensing boiler works, see the following video.