Features of the selection and installation of double-boiler

Today, the heating of a house, household building or apartment is one of the most important aspects that concern their owner. This is not surprising, since in the conditions of a constant increase in utility tariffs, it becomes more and more difficult to maintain comfort in the cold season. For this reason, they are increasingly rejecting centralized heating in favor of the individual. And today we will talk about one of its components - double-circuit boilers.

Device and principle of operation

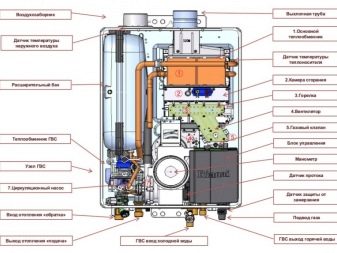

At its core, the type of boiler in question is somewhat reminiscent of a flow-type gas water heater.Their difference lies solely in size. If we look at what is inside such a double-circuit boiler, then we will see equipment for the operation of 2 circuits - hot water supply and heating. To understand how a similar boiler works, you must first look at what is inside it.

So, the components of a double-circuit boiler are:

- primary or, as it is also called, primary heat exchanger;

- secondary heat exchanger;

- burner;

- burning chamber;

- three-way valve;

- circulation pump;

- automation system.

The main heat exchanger is responsible for heating the heat carrier directly in the heating circuit, and the secondary one will be responsible for the supply of hot water. The burner will be a heat source in this boiler. It is interesting that in such models they install powerful burners so that they can immediately serve both circuits, which saves space. The burner is usually located in the combustion compartment, as well as the main heat exchanger. The three-way valve switches between hot water mode and heating mode.The circulation pump moves the heat carrier by the heating mechanism or by a smaller circle of the hot water circuit. Automation will be responsible for the performance of the system as a whole.

Of course, this is not a complete list of all the elements that may be present in the design of a double-circuit boiler. But the above-mentioned parts are the main ones and without them such a boiler will simply not work. Although you can find a number of models on the market where there is no secondary heat exchanger. In this case, the preparation of hot water will be carried out with the help of dual combined heat exchangers.

As already mentioned, the considered variants of boilers can perform work in the heating mode and in the hot water mode. When the boiler starts up, the heating circuit starts working, after which the pump starts to circulate, the burner is activated, and the three-way valve becomes in a special position, which allows the thermal carrier to simply move along the heating mechanism. The burner will be active until the automatic control panel commands it to turn off.In general, its work is managed exclusively by the software part. It can estimate the temperature of the heat carrier, measure the air temperature outside the window and in the house.

To get hot water you just need to open the faucet. Autocontrol will fix the current through the circuit responsible for the supply of hot water, after which the three-way valve turns off the heating mechanism and allows the heat carrier to circulate through the small circle. The heat carrier enters the secondary heat exchanger, where the prepared water will flow. When the valve is in the closed position, the three-way valve will switch to heating mode. At first glance, the device of the boiler seems quite complicated, but the principle of the device is as simple as possible. The boiler double-circuit on solid fuel or on gas receives more and more distribution today.

Such solutions are chosen for small size, convenience and excellent technical characteristics. At the same time, such boilers cannot operate in two modes simultaneously. But you can put up with this shortcoming.

Types

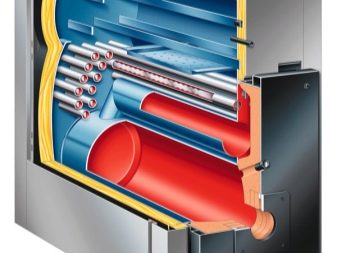

Double-circuit boilers may vary according to different criteria.In our time, the most purchased solution is a gas unit. It is popular because of the availability of blue fuel and ease of installation. Such models can be equipped with various heat exchangers, for example, a separate additional primary exchanger. That is, in this case, the heating will be carried out using a flame. That is, it is a smaller version of the heat exchanger. But this option is inexpensive and the simplest. And repair in case of breakage of one of the heat exchangers will be easier.

Another option is with a bithermic heat exchanger. It is a tube in a tube and also belongs to the category of primary. Heat carrier moves in the outer part of the pipe, and hot water moves in the inner part. This option makes it possible to provide a stable temperature. But the repair of such boilers will be significantly more expensive. The next version of the boiler is represented by a model with a secondary heat exchanger. This option receives heat from the heat carrier that was heated in the primary heat exchanger, and not from direct combustion of the fuel.

The advantage of this design is that with a large number of taps, the difference in temperature will be minimal and its differences will not be so great. The second heat exchanger in a number of models can be combined with hot water supply and circulation. But such options are more expensive.

In addition, boiler types may vary depending on the type of fuel used.

There are such models as:

- pellet

- diesel;

- wood burning;

- coaxial;

- combined.

Of course, these are not all categories of models existing today, but they are the most popular. Now let's talk about them in more detail.

Pellet boilers can operate using so-called pellets. Usually they are created from waste wood and paper industry. This solution is quite effective, has high efficiency and allows you to provide heat to the room for a long time at a low fuel cost. Wood-fired boilers can also be included in this category, although they are slightly different in that wood-burning models always need to be manually and manually heated.In addition, it is more difficult to keep the temperature in some kind of framework, and the fuel reserves will take up a lot of space. And at night, such a long-burning condensing boiler will have to be replenished with fuel, which means that it cannot be automatic.

In addition, such boilers will have to be cleaned quite often. Generally, if we are talking about firewood, then this type of fuel should be spare. That is, a combined boiler of this type would be a good solution for a private house.

Another version of the boiler is liquid fuel. The advantage of this solution is that it does not require any coordination with various regulatory authorities. The main fuel for this type of boiler will be diesel. The advantages of this solution will be autonomy, high efficiency and the ability to save a significant amount of resources.

About gas boilers have been a little said. Today it is the most profitable type of fuel. It is also considered environmentally friendly. And when connected to a centralized gas supply, such a solution would be the most cost-effective. In addition, such boilers can operate not only on gaseous, but also on liquid fuel.But here everything will depend on the burner installed inside the boiler.

You should also go back a little to the topic of solid fuel boilers. If you use coal or peat, these are also possible solutions for use in boilers. But coal emits quite toxic combustion products, which creates a constant need for cleaning the boiler and chimney.

In the case of peat, the situation will be like this and even a bit worse. Coal generates a large amount of heat, which somehow smooths out its shortcomings. But this can not be said about peat.

In addition, boilers can be divided according to other criteria.

By location, they are:

- wall mounted;

- floor standing

The wall version is usually hung on the wall by fixing it on special slats, which are fixed to the wall with bolts, screws, and so on. Such solutions save space in the room if it is too small. Floor solutions are also used, but, as a rule, in cases when there is enough space in the room or when you want to take them out of the room, highlighting for this some small room at the top.

In addition, boilers vary in type of combustion chamber.Usually double-circuit boilers are equipped with an open combustion chamber. But there are models with a closed one. They are called parapet and turbo.

The parapet boiler, unlike those under consideration, can be safely used in an apartment, as it is done with a closed combustion chamber, which implies not only the absence of any combustion products in the room at all, but also reduces the need to use a chimney. And this means that the parapet boiler is the ideal solution for apartment buildings.

The turbocharged boiler is a compact model and also has a closed-type combustion chamber. Such a solution is usually intended for local heating mechanisms, which is characterized by forced circulation. Also, turbo boilers differ from all the above-mentioned models in that they have a special diversion system, where a coaxial exhaust structure is installed. Such a chimney not only allows the removal of combustion products, but also gives air to the burner, since it is carried out using an external pipe. And due to the fact that it is simpler to call such a construction “pipe in pipe”, and this double effect is obtained.As you can see, there are a large number of double-boilers of various types, which allows everyone to find a model that is ideal for heating their homes.

Power

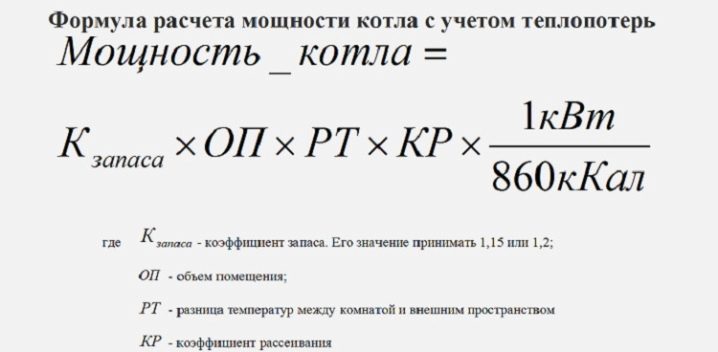

The main criterion that should be taken into account when choosing the type of boiler in question will be power. Before choosing, it is also necessary to calculate how much energy will be needed to heat the room of interest to you.

To do this, consider the following factors:

- the height of the walls in the building;

- the area of the room to be heated;

- what material the walls are made of;

- whether there is insulation and how well it performs its functions;

- how many windows and doors there are in the house;

- the area where the building is of interest to us;

- number of floors;

- the ratio of the glazing area of the room to its size;

- is there a warm attic.

But in the case of the type of boilers in question, one factor must also be taken into account - the performance of the hot water supply circuit. According to the well-established formula, it is known that 1 kW of heat is needed per 10 square meters. That is, if your house has an area of 240 square meters, then you need a boiler with a capacity of 24 kW.If 280 m2 - then 28 kW. Well, if we are talking about a large area of 1000 square meters, then for such rooms you can even find models of boilers with a capacity of 100 kW and above. Therefore, the dimensions of the room matter. In general, it would not be superfluous to take models with a margin of 2-3 kW.

The performance of the DHW circuit is also important. Usually this characteristic is indicated in the passport and depends on the temperature set by the user. For example, models of boilers with a power of 24 kW will have an average performance - it is 11-13 liters per minute if the temperature is raised by 30 degrees. If you raise it by 50 degrees, the performance will change by 6-7 liters. If you need more water, you should select models with more power.

If, for some reason, an exact calculation of the power does not work, then you should take the area of all the rooms in the house and get a pure multiplied by 100 or 150. As a result, the boiler power in watts will be obtained, which is needed to heat the home and get hot water. It should be noted that the insulation of the building and the reduction of heat losses makes it possible to reduce the power required for heating the device and reduce costs during the repair phase and during subsequent use.

Another factor that should be paid attention to, besides power, is the temperature difference of the fluid coming in and out of the boiler, as well as the volume of hot water that it can heat up in a minute. In this case, it is better to compare these characteristics with the level of hot water consumption by your family members. In some cases, just a double-circuit boiler may not be enough corny. And then you have to buy more boiler. With a boiler to solve this problem is not difficult. But it should be understood that the acquisition of too powerful devices is also not an option. After all, as in the case of a weak boiler, you simply lose money, and too serious characteristics are unlikely to give any advantages in a small house located in the private sector.

It is for this reason that it is better to always give preference to a solution that will be as effective as possible in a particular case.

It can be of different types in this case, if it is:

- Flow through option. These boilers have a hot water priority mode. Their essence is that if it is necessary to take a bath or wash the dishes, it is enough to turn on this mode, and the pyrolysis boiler immediately makes the circuit responsible for the supply of hot water active.Such models are the most reliable and will be an excellent solution for apartments and houses with a small area. In addition, such heat exchangers usually have a small capacity.

- Models with built-in storage tank. In this case, the volume of the tank can vary from 150 to 180 liters. Such models can carry out heating of water both in the flowing mode, and in the accumulation mode. But it should be said that in the flowing mode the water will be somewhat colder than in the storage one, which is explained by the possibility of better heating of the water due to the presence of more time for this.

Comparison

Now it should be said that it would be better for a private house. There are not only double-circuit boilers, but also single-circuit boilers. Such solutions can carry out heating of the apartment or house. They are usually connected to the radiator system and they heat the water exclusively in them. This version of the boiler does not allow to heat water for domestic needs. That is, the consumer needs to look for another option.

But there are also double-circuit boilers. Their difference from the single-circuit is that it can not only carry out the heating of the house, but also heat the water for various needs. That is, in essence, the difference lies in the heat exchanger.

If you need to choose a boiler, you should proceed from your needs. But the advantages of a double-circuit boiler over single-circuit ones are unambiguous, which means that such a solution will in most cases be really more profitable than a single-circuit heating boiler.

Rating manufacturers and reviews of professionals

When you have decided on the technical characteristics of the device that you need, you can start searching for a suitable model, as well as a manufacturer. It is rather difficult due to the fact that there are a huge number of brands on the market today, the prices of whose products differ very substantially.

It would be best to divide manufacturers into three segments:

- expensive;

- average price category;

- cheap.

If we talk about the category of expensive, then these can be called boilers of such manufacturers from Italy as Ferroli, Ariston, Baxi, Beretta. In the same category there are products of German companies Valliant, Wolf, Viessmann. This group can include models of boilers of the company Navien from Korea. The boilers of all the companies mentioned are of high quality and work as reliably as possible.True, only in certain conditions.

They should receive a constant and stable power supply so that there are no serious deviations in voltage and frequency. To ensure such parameters, it is necessary to purchase an electronic voltage regulator. Another important condition for their stable operation is a certain gas pressure. As a rule, we are talking about 2 atmospheres.

More affordable will be double-circuit boilers, which were produced by Russian companies. We are talking about Danko, Protherm, Siberia. They are as functional as the above options, but still more adapted to work in domestic conditions and calmly respond not only to deviations in terms of power supply, but also to reduced gas pressure.

Also on the market are products of such companies as Bosch, Junkers and Buderus. All of them are united by the fact that they are directly related to the Bosch brand. The last two companies are its subsidiaries. A feature of this group of products will be that such AOGV can not be called either European or Russian. The fact is that Bosch has a number of enterprises located in Russia, which is why it is possible to purchase both products made in a domestic plant and in a European enterprise.Although according to the users, there were no serious differences between them.

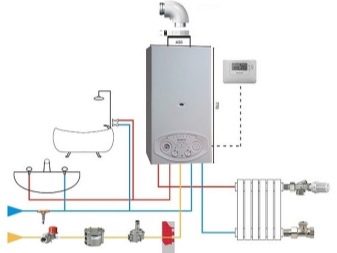

Installation and connection

The connection scheme of a dual-circuit heating boiler will depend not on the type of fuel on which the device operates, but on the category of the heating system. It will be important whether this is a single-circuit system or a two-circuit system, it has natural or forced circulation, and so on. It will also be important to equip the boiler. For example, dual-circuit models for heating with a secondary heat exchanger already have a pump in them, which makes it possible to immediately connect them to the circulating system of both hot water supply and heating. But the liquid-fuel and solid-fuel models do not have them, which means they will have to be bought separately.

The procedure in most cases will be standard. Installation begins with the installation of a special valve on the water supply system, as well as a coarse filter, which will make the system water cleaner. Now it is necessary to connect the branch pipes of the heating system and the hot water pipes for domestic use.

They are also connected using shut-off valves and connecting to the boiler. Then you need to connect the circulation pump.It should be said that if it is in the composition of the boiler, then there is no need to re-buy this element separately.

The final stage of connection is the gas pipeline. It is best to find a place for the boiler that will be as close as possible to the gas pipe. If this is not possible, the connection should be made only with the help of special gas hoses. It’s better not to carry out this moment with your own hands in order to prevent some kind of serious error. It is better to contact specialized companies that are licensed to carry out this kind of work. Now you need to deal with strapping. It is required to install a valve on the gas pipe, as well as a strainer, connecting all this with the help of flanges. After that, you can begin to make the chimney. If the wall is installed in your own home, then a coaxial chimney will be the best solution. To make it, it is necessary to punch a through hole with a diameter corresponding to the diameter of the chimney. After that, the coaxial pipe must be led out of the wall.

The process of installation and connection of the boiler is completed. To configure the device should only a specialist who has the appropriate education and experience in this matter.

Faults and repair

Gas boilers, like any other equipment, can break and fail. There are several categories of problems. The first is very difficult to detect. For example, if the voltage falls below the allowable mark, then most boilers simply do not turn on.

If we talk about the most frequent breakdowns, it should be called:

- Crashes in the program of automation. Usually they are the result of improper settings as well as sensor adjustments.

- Problems with control boards. Specifically, in this case, it is better to simply replace such a board, since its repair may cause damage to other nodes.

- Problems in the nozzle.

Some factors directly affect the normal operation of bypass gas solutions.

These include:

- If the pressure in the air expansion tank rises or falls, the reason for this is a nipple break.

- The deposition of scale in heat exchangers may be due to the rigidity of the thermal carrier or its poor circulation.

- If there is no thrust in the chimney duct, then most likely this is caused by blockage of the chimney duct.

- When,If dust or plugging of the burner or primary heat exchanger is observed, this may be due to the increased humidity or dustiness of the room where the boiler is used. In addition, the cause of this phenomenon may be the lack of the required amount of air, without which burning is impossible.

- If temperature sensors are out of order, the reason for this may be either water or the poor quality of these devices.

- There are also cases when various sensors of the boiler failed due to overvoltage in the gas boiler circuit.

In addition, not all faults can be detected by an ordinary user. Some of them can only be detected by a professional, and then with special diagnostic equipment. As for the repair, not only the diagnostics of various failures, but also the repair should be carried out only by a specialist.

Gas boiler is a large interconnected system in which if one element fails, then the work of all the others is seriously disturbed. And finding a problem can be very, very difficult.If the boiler heats up badly, then there can be a huge amount of reasons for this, since a breakdown could cause a disruption in the operation of other elements of the boiler.

Improper repair can cause very big problems, even a fire or explosion, so it would be dangerous to risk and make repairs to someone who has no experience in this matter. The implementation of self-repair even with minor malfunctions risks turning into the fact that the next time the master simply does not want to repair the boiler when it finds traces of self-repair, and the boiler will simply have to be thrown away, which faces serious costs.

The process of selecting a gas bypass boiler must be carried out at least in consultation with a specialist, as the boiler is a complex system that combines various devices. Each must work accurately and reliably to ensure the quality of the device. And in the event of a malfunction, it is imperative to contact a specialist and in no case do not carry out independent repairs.

In the next video you will find the principle of operation of a double-circuit boiler.