Vaillant boilers: types and subtleties of installation

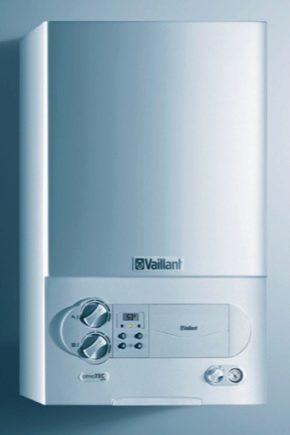

The German manufacturer Vaillant is known for its gas boilers in many countries. And this is not surprising, since the heating equipment of this company is primarily of high quality. Among the Vaillant boilers you can find a variety of options. And they all have a stylish and modern design, automated and easy to use.

The units of this company are equally suitable for both apartments and private houses.

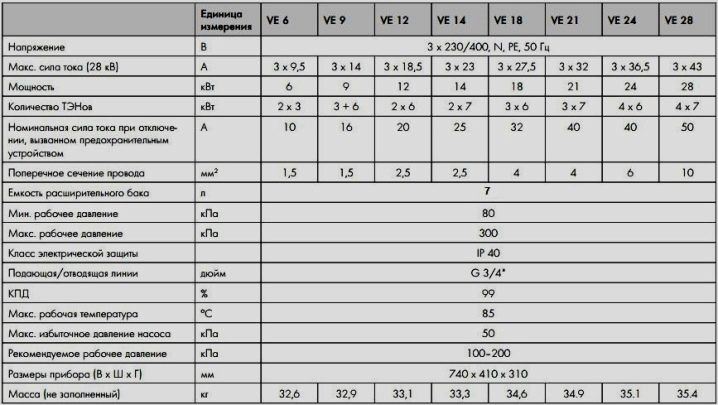

Specifications

The first Vaillant boiler was produced in 1984. Over time, gas heating equipment has become an important invention, having made a real breakthrough. Of course, at first such devices had significant dimensions and weighed a lot due to the massive body. However, over time, more compact wall-mounted, and then floor boilers.

Currently, Vaillant is one of the leaders in the market of gas equipment and other heating devices. Some models from the manufacturer are capable of heating well even rather big houses, and at the same time they are economical. At the expense of devices of various capacities, you can easily pick up the unit for a modest country house, and for a large production facility.

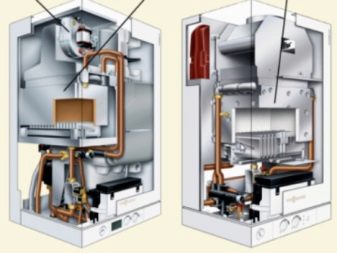

In order to better understand what the Vaillant boiler is, you should consider its structure and familiarize yourself with the characteristics. In all two-circuit units there are two heat exchangers, one of which heats the coolant, and the second heats the running water.

The first heat exchanger, also called the main heat exchanger, is made of copper and has a large number of fins. It is their number and the absence of a special composition as a coating that allows the heat exchanger to become less clogged. As for the second heat exchanger, it is made of stainless steel.

In general, the boiler consists of:

- expansion tank with a volume of about 10 liters;

- connections for the chimney;

- circulation pump;

- hydraulic unit;

- electrical unit;

- emergency electrode;

- ignition electrode;

- burners;

- heat exchanger;

- fan.

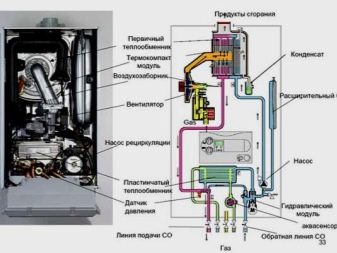

The burner has the ability to modulate the flame in the range of 30-100 percent of the total power. It should be noted a significant difference between the Vaillant boilers - this is part of the device, which is made of high-quality copper, and much better than analogs of other materials. Another advantage of these units is the presence of a gas valve, which makes the flow of the coolant stable.

The hydraulic unit of the boiler includes:

- gas valve;

- another heat exchanger (heating water);

- air outlet;

- valve fuse;

- pump;

- bypass valve;

- pressure gauge;

- pressure meter.

For Vaillant boilers, electronic boards are manufactured in Germany, and by themselves they represent a chip that is able to protect against power surges. But despite its presence, it is better to use an additional voltage stabilizer.

When choosing a boiler, the important point is the area to be heated. As a rule, the following calculations are used for heating - per 10 square meters 1 kW plus a margin of 20 percent. The volume of running hot water is also important. However, this parameter is quite individual.

Practice has shown that for a small family enough figure of 10-12 liters per minute.

The characteristics of Vaillant boilers are on average as follows:

- hot water capacity (with temperature changes within 30 ° C) is from 9.5 to 17.2 liters per minute;

- permissible pressure limit is from 0.15 to 10 atmospheres;

- hot water temperature varies from +35 to +65 degrees;

- The minimum allowable flow rate of heated water is 1.5 liters per minute.

If we talk about the advantages of the boilers of this company, then there are quite a lot of them. The main one is the reliability of heating devices. Manufacturers even give a warranty period of 15 years. At the same time, boilers are also distinguished by a well-thought-out design, which provides efficiency up to 94 percent.

As well as the Vaillant boiler is easy to use, and it does not require constant monitoring due to the built-in automatic systems. The desired temperature can be maintained continuously for any time.

If there are interruptions in gas pressure, then a pressure regulator comes to the rescue, which will improve the performance of the burner. When there is no thrust, the thrust sensor will automatically shut off the boiler, eliminating unnecessary problems. The gas supply valve will be shut off if the flame on the burner has gone out. Thus, the burner can be ignited only if there is a normal concentration of gas in the chamber.This prevents even the possibility of an explosion.

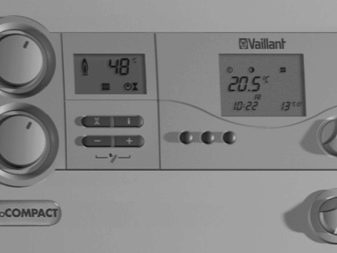

It is worth noting another feature: when any malfunction happens, the testing program will immediately work. The display shows the trouble code and can be quickly resolved. This is very convenient, since you do not have to spend time figuring out exactly what happened to the boiler.

But also it is impossible not to notice the efficiency of the boilers in terms of gas consumption and heat consumption. Moreover, the power of the device can be significant even with its small size. With all this, Vaillant boilers are also environmentally friendly. Emitted products generated in the combustion process cause minimum harm to both the person and the environment.

The boiler has not a lot of minuses, but there are still some. For example, the boiler during operation may make noise. And also among the shortcomings, many users call a very substantial price. However, given the high quality of equipment and its service life, it becomes obvious that the cost is quite normal.

Among the serious shortcomings can be noted the inability of the equipment in the absence of electricity.

Kinds

Types of boilers from the manufacturer Vaillant today offered a lot.

Depending on how the unit will be installed, there are two types.

- Wall-mounted, which are more compact and do not need a separate room. It is worth noting that they are in high demand. Especially such boilers are in demand among apartment owners so that the heating season can be started earlier and completed later.

- Floor, the dimensions of which are larger, and it is desirable to allocate a separate room. Often these models are used to heat large areas. In Vaillant boilers of this type have a large range of power and component components. The main material for these units is cast iron.

And also boilers are divided into:

- devices with a single heat exchanger (single-circuit);

- devices (dual-circuit), which have two heat exchangers.

In addition, Vaillant boilers, depending on the principle of operation, are of several types.

Noncondensation

There are wall and floor.

Among them are:

- atmospheric (AtmoTEC series);

- turbocharged (TurboTEC series).

Single circuit

Devices in this series are denoted by the letters VU, and dual-circuit devices are designated as three letters VUW.

Condensation

Also can be wall and floor. This series is presented with options with one and two heat exchangers.

Electric boilers

Presented by compact devices mounted on the wall.

According to the power model of the boiler can be 12, 24, 28 and 36 kW. Air can be supplied and vented both naturally and with a fan.

Among the Vaillant boilers, the following single-loop series are in greatest demand.

- AtmoTEC plus are models with a power of 24 kW and a power of 28 kW. However, they are equipped with a modulating burner and chimney. Despite the fact that there is only one heat exchanger in their structure, these devices are easy to connect to the water heater.

- TurboTEC plus can only heat the room. However, the power of this series is quite diverse. The great advantage of these devices is that they can work in rooms where there is a lot of dust.

- EcoTEC plus is notable for its increased power from 80 to 120 kW. However, it is condensing. Among the advantages, it is worth mentioning the possibility of collecting up to 6 boilers of this series in cascade and gas savings of up to 40 percent.

Special attention is also paid to the dual-circuit devices of the series.

- AtmoTEC plus has models with power from 20 to 28 kW. It is equipped with a natural outlet for combustion products. Can not be used to form a cascade. Among the advantages, it is worth noting the impossibility of scaling due to the plate and flow heat exchanger.

- AtmoTEC pro is represented by models whose power has only one value of 24 kW. There is an automatic switch only for water heating.

- TurboTEC plus differs in models in a large power range. It has a compulsory exhaust gas disposal system.

- TurboTEC pro, despite its low power of 24 kW, is able to simultaneously provide warm home and hot water.

- EcoTEC plus has an efficiency of 104 percent, and this is at the power of the boilers of this series from 24 to 34 kW. Burner modulation has a range of 28 to 100 percent. And also carried out electronic control over the process of ignition and combustion.

Among the numerous Vaillant units, you should also pay attention to floor boilers.

- EcoCOMPACT VSC - this condensing boiler is equipped with an integrated boiler for layer-by-layer heating of water. Its power ranges from 4 to 32 kW.The main difference between the device and its small size, allowing to place on a small area.

Despite the abundance and high quality of its boilers, Vaillant does not cease to improve the heating process. For example, the company has created a variety of automation, which allows you to even better control the heating, making living conditions more comfortable.

Installation

The service life of Vaillant units depends quite a lot on how they were installed. For proper installation of the boiler must comply with all requirements and regulations. However, before you install, it is important to familiarize yourself with the instructions that come with the device.

The ideal option would be to entrust the installation of the boiler to a specialist with the appropriate experience and license. If there is a desire to try to install heating equipment by yourself, then it is best to use the installation scheme, which is in the instructions.

Installation of the unit begins with its unpacking and removal of the protective film. Next, it is important to check whether all the components are included.

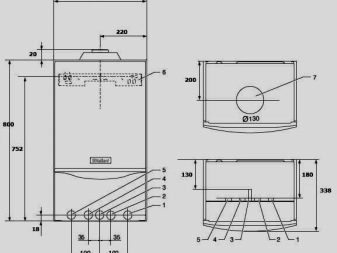

When installing it is important to observe the minimum distances from the device to something:

- above - 40 centimeters;

- on the sides - 1 centimeter;

- bottom - 25 centimeters.

The manufacturer notes that Vaillant units do not need an extra distance to flammable elements.

When all distances are measured, you should use the mounting template, which will help prepare the place for mounting the boiler. It is important to check in advance that the wall can withstand the weight of the unit, and the fasteners in the kit exactly fit. If the wall is not able to bear the weight of the boiler, then additional racks or brickwork should be used. The product is hung on the wall strictly according to the instructions.

Then it is necessary to dismantle and mount the front facing and the lid of the combustion chamber according to the process described in the documentation for the boiler.

Now you can go to the main installation work.

- From the kit take the crimp threaded connection and install it on the pipeline.

- Check in the heating system the volume of the expansion tank. In the event that it is insufficient, then an additional tank should be installed. At the same time it is necessary to install a check valve at its outlet.

- Rinse feed lines.

- Install a stop valve and check valve in the cold water pipe.

- Check that the gas meter is designed for the specified gas flow rate.

- Next is the installation of the pipeline to the gas fitting. To do this, it is best to use a stopcock, without exerting too much physical effort. Then the presence of air in the pipeline is checked, and if necessary it is removed. Then the heating supply line and the heating return line are mounted. To complete this stage it is necessary to check the tightness of the entire pipeline.

- Connect cold, hot water and hot water storage according to the instructions.

- Attach a drain pipe to the safety valve of the boiler.

- Next is the installation of the chimney system, depending on its type.

- As for wiring, it is better to entrust it uniquely to qualified specialists.

- Finally, you can connect additional components or a sensor.

The installation of a floor-standing boiler on gas with two heat exchangers is carried out somewhat in accordance with another, more complex scheme, and in this case they are installed in series:

- Temperature regulator;

- security group;

- remote radiator;

- heating boiler;

- expansion tank;

- pump;

- recharge tap;

- small circuit pump;

- check valve;

- remote temperature sensor mixing unit.

User's manual

Maintenance of Vaillant boilers is an important part of its long and high-quality work.

Every year, some checks and inspections should be carried out to ensure that the unit is in proper condition:

- check chimneys and air ducts for tightness, cleanliness and reliability of their fixings;

- check the general condition of the boiler, if necessary, remove contamination;

- inspect the heat exchanger for damage or corrosion;

- at the maximum value of the heat load, check the inlet gas pressure;

- check electrical connections and connections;

- check the burner for serviceability;

- at the cold water inlet, check the condition of the filter; if necessary, it must be cleaned or replaced;

- make a trial start of the boiler, if necessary, make the system air-free;

- regularly check the pipeline for leakage, if it is violated, eliminate the causes;

- check the flue gas sensor and replace it if necessary.

By performing such simple actions, it is possible to significantly extend the operating time of the heating equipment and save on its repair.

Another important and pleasant moment in Vaillant devices is management. It is easily implemented using the menu and various test programs. For example, there is a test program "Bleed" or programs that allow you to use the device with a minimum or maximum thermal load. Assistance in the management of substantially provide status codes, which can be found in the instruction manual.

It should be noted that the management of boilers from the German manufacturer may even be remotely using the Internet. For this, it suffices to additionally install a thermal sensor.

Owner reviews

According to the owners, Vaillant boilers perfectly maintain the set temperature. At the same time, these units have a pleasant appearance and small size. An excellent solution, users consider the automatic ignition system, which saves even in the event of problems in the pipeline.

Of course, sometimes there are problems with the launch of the system, and you have to contact the specialists. But it can also fail the quality of the water, due to which the heat exchanger is covered with scale. However, this problem is easily solved by installing cleaning filters.

Boilers of their owners delight us with their long service life, quiet operation, easy switching on and simple operation. By most accounts, Vaillant devices can be hung on the wall and “forgotten”. Moreover, even the high cost is pleasant to many, since in this case it is, indeed, an indicator of high quality.

Many over the years of the boilers from this manufacturer do not have any complaints.

Especially in demand are double-circuit boilers, which provide not only heat, but also hot water throughout the year. Wall options take up a minimum of space, and they can be installed in a pleasant corner of the kitchen, even the bathroom.

Sometimes there are complaints that the exhaust gases are not completely vented to the atmosphere. To eliminate this defect, it is enough to install a pump. But there are also, but rather rarely, problems with the NTC sensor.

Thus, we can safely conclude that the German Vaillant boilers rarely fail, fully confirming their reliability and quality.

For information on the advantages of the Vaillant TecPro boiler model, see the following video.