Induction heating boilers: types of structures and subtleties of the installation process

It is important to equip any dwelling with a reliable and efficient heating system. Fortunately, today there are many options for heating private buildings. One of the most popular and sought-after is an induction boiler, which is the best solution if the house is located in a non-gasified area. Today we will take a detailed look at what features such systems possess, what they are and how they should be installed correctly.

Special features

Currently, many homeowners face problems with heating.This is especially true of buildings that are located too far from the gas supply lines. Of course, in such a situation, you can get by buying gas cylinders, but this may cause interruptions in their supply. In this case, the best option would be an induction heating boiler, which is powered by electricity.

Such units in many ways superior to traditional devices operating with the help of heating elements. Electric heating itself is an artificial process of raising the temperature by conducting energy from the outside. There are several different types of these units. Today, they are produced by many manufacturers, so modern buyers have a rather wide choice of induction boilers for any wallet.

The main feature of such devices is that for their installation in the house does not need coordination with the relevant organizations. In addition, the homeowner does not have to contact the experts for the drafting of the project, as well as its confirmation that it is often quite expensive. When conducting gas heating to do without these stages will not succeed.

Modern induction boilers are distinguished by the efficiency of their work. That is why they are chosen by many consumers. With such a unit, the house always maintains a comfortable temperature and cozy atmosphere, which is noted by many owners of private houses. However, it should be noted that such heating systems, despite their effectiveness, cannot be called “cheap pleasure”.

For this reason, some people decide to make them themselves. This task is quite doable, but for this you need to possess certain knowledge and at least minimal skill.

Application

Modern induction boilers are used in the following cases:

- for heating residential areas;

- for heating administrative and industrial buildings;

- for heating of those or other structures having special regulations on ecology / safety;

- when booking a source of thermal supply;

- used in hot water systems;

- used to connect to the combined heating systems;

- suitable for use in heating systems with remote control.

Types

As mentioned earlier, there are several types of induction boilers on the market today. Each of them has its own individual characteristics and features that are important to consider when choosing a suitable unit for your home.

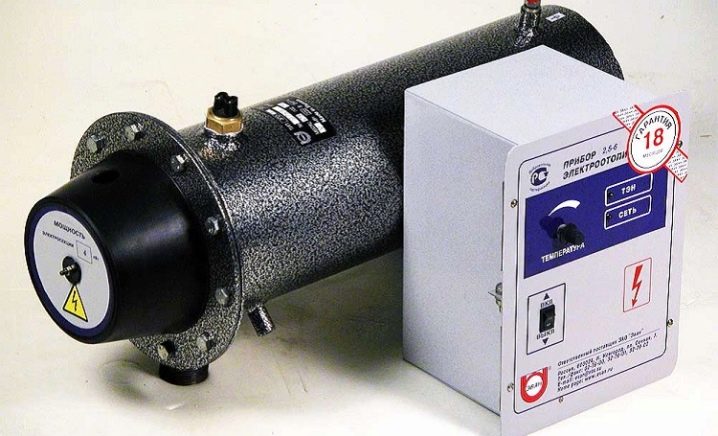

SAV

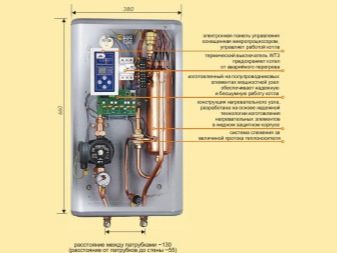

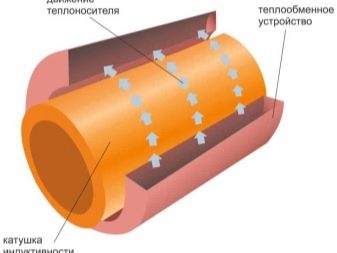

Today, induction boilers SAV are quite common, in which a current with a frequency of 50 Hz is applied to the initial winding. As for the secondary winding, a closed pipe system with heat carrier is used here. This detail also acts as a heat exchanger in the form of a kind of labyrinth consisting of pipes. The heat exchanger in SAV boilers heats up very quickly due to the induction current. This component makes it possible to significantly increase the performance of the heating unit.

These types of induction heating systems with a power of 2.5 kW are capable of delivering heat up to 2100 kcal / hour. Such an apparatus can heat an area of 25-30 square meters. m

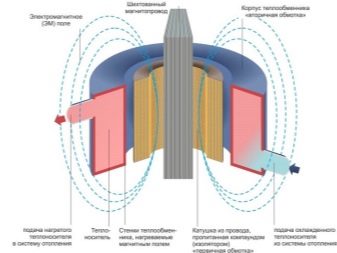

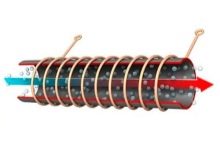

Whirling

A feature of the vortex boiler (VIN) is that the current supplied to the primary winding, first changes in the converter, that is, turns into a high frequency one.Because of this distinctive feature, the intensity of the electromagnetic field as a whole increases, and this, in turn, reinforces the resulting Foucault currents. Such units are economical and reliable, so they are chosen by many homeowners. In addition, vortex boilers are usually small. They are made of metal.

Also induction devices for heating are:

- single phase;

- three phase.

Design

Induction boilers are quite “tricky” structure.

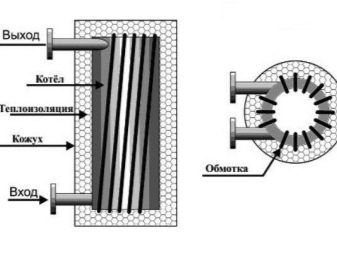

Their design is a mechanism assembled from several layers:

- The outer shell acts as the first layer of such units.

- The next layer is insulating. It consists of heat and electrical insulation.

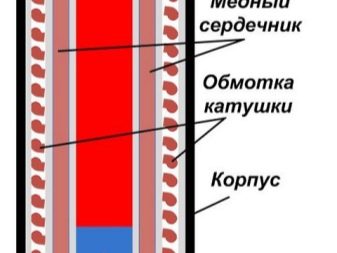

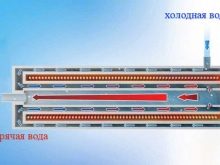

- The third important component in the design is the core, which consists of 2 walls. This part is a ferrimagnetic pipe of steel in the amount of 2 pieces. The thickness of their walls is 10 mm. Tubes can have a different diameter and fit into each other. The tube inside is framed by a winding. It is this part that performs the function of the core, and the outer tube acts as a heating element.

Principle of operation

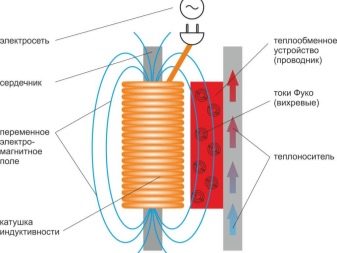

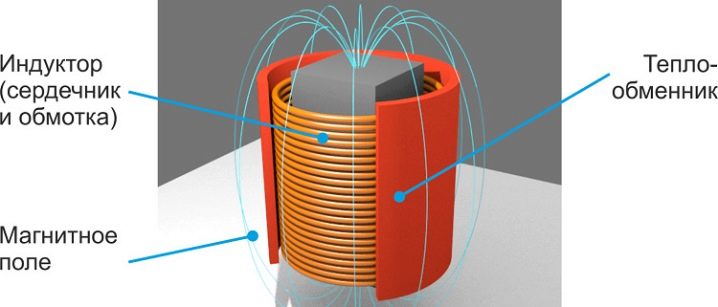

Let us examine in detail how the induction heating equipment works. In these devices, the heating occurs due to the energy of the alternating magnetic field. It is consumed by an object that warms up in the unit. Subsequently, this item converts energy into heat. From this it follows that the heating of the equipment occurs from conductive elements.

To convert electrical energy into thermal energy, the following components must be present in the apparatus:

- alternating current (conventional mains 220 V, 50 Hz);

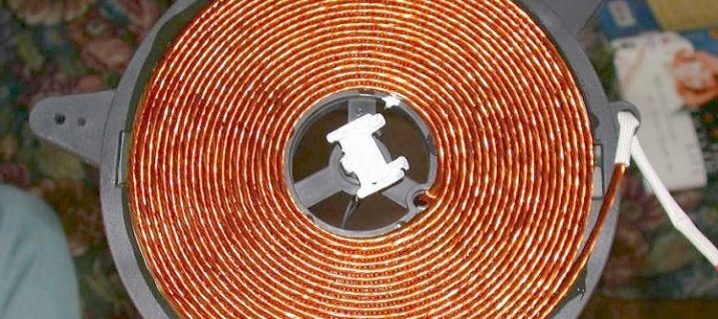

- inductor, which is a cylindrical coil with several turns (as a rule, they are made of copper);

- a core made of a ferromagnet (a magnet is attracted to this material).

Let us analyze step by step the principle of operation of induction heating:

- alternating current crosses the inductor and forms a magnetic field around the coil;

- after this, the magnetic field on the core creates the so-called Foucault eddy currents — it is they who heat the billet under the influence of Joule heat;

- the heat from the heated core then passes to the heat carrier due to the thermal conductivity of the materials used.

Simply put, it is a kind of step-down transformer installed in a pipe. So electricity is supplied exclusively to the core (contacts are not used). The heated core is still in contact with the thermal carrier. You should be aware that various particles may settle on the surface of the core, which can adversely affect the heat transfer properties.

Advantages and disadvantages

Such heating devices as induction boilers, like other similar units, have their pros and cons. Both positive and negative sides should be reviewed in detail if you are going to install such equipment in your home. To begin, consider the good induction varieties of heating boilers.

The main advantage of such units is their reliability. If such products have automatic equipment, then they can operate offline, and the owners will not have to constantly monitor them. In this case, only the absence of heat carrier can lead to device breakdown - then the core body in the system can overheat too much and melt as a result.

In such units can be installed any type of coolant. Induction current does not matter what to warm up, as long as it uses liquid.

Induction boilers are distinguished by high efficiency (over 90%). Of course, the specific value mainly depends on the design of the heat exchanger in the unit and other structural features of a particular model. The advantages of such units can be attributed to the fact that over the years their efficiency does not fall, so even after a long time you will not notice that your heating system has become less efficient.

Induction heating equipment is not subject to breakdowns - it does not require frequent and expensive repairs. To install such a unit does not need to build additional ventilation or chimney, which often costs users a tidy sum.

Serves such equipment for quite some time. If these types of heating boilers are used correctly, they can last for more than 30 years, because there is nothing to burn in them, because the inductor is sealed in a housing and reliably insulated from contact with a thermal carrier.In addition, the coils are not twisted tightly and they are filled with a special protective composition. For this reason, the possibility of damage to the coils is minimized.

The fluid in such systems is heated to high temperatures. The minimum value is 35 degrees Celsius. Such units are installed quite simply. Household models are a segment of pipe of small size, which is sealed on both sides. At the same time, there are 2 fittings on the case, which are necessary for connecting the coolant supply and return flow. There is also a cord to connect the automation. Connecting such systems is not difficult - to cope with this simple work is possible without the involvement of specialists.

If you pay attention to the reviews of the owners of such units, then we can conclude that they are practical and undemanding in matters of service. Most models of such boilers work silently.

Induction heating systems are characterized by high efficiency. They are distinguished by a small inertness, so the heating of the heat carrier begins very quickly (immediately after the launch of the system). Just as quickly, such boilers are turned off.In such an apparatus, the spent coolant does not need to be changed too often. It is quite enough to do it once every 10 years.

These types of heaters, as a rule, do not leak, because they have no detachable internal connections. These units are able to operate at constant current, and with a small voltage in the network. According to experts, harmful scale does not accumulate on the heating element in such devices. This is due to the vibration of the core (because of this, extra particles cannot be deposited on it). In addition, the scale is not collected due to the temperature of the coolant (not higher than 90 degrees Celsius) and the closure of the system, which may contain a limited number of carriers.

Also, many people use special formulations that do not emit harmful deposits. Using such a heating unit, you do not have to think through the removal of combustion products, as well as to carry out activities for the maintenance of equipment.

Now it's time to get acquainted with their minuses:

- First of all, one of the drawbacks of such devices is their high price.They are several times more expensive than devices with Teng. However, the high cost is due to the presence of automation.

- Usually these devices have an impressive weight. For example, a boiler with a diameter of 12 cm and with a height of 45 cm will weigh as much as 23 kg.

- These boilers are suitable exclusively for closed heating systems.

- Such units can create wave interference at a short distance. For this reason, experts advise to install them as far as possible from any household appliances.

- If you are going to install an induction boiler in a large house with 2-3 floors, then you will have to additionally install a high-capacity circulating pump - this is necessary so that the device works stably.

- Induction units are volatile. If electricity is turned off in your home, then the heating will also stop working. Of course, this problem is solved - you can buy diesel generators, but it will be an additional waste.

The disadvantages of such systems are not many, but they are significant. In addition, it should be borne in mind that the efficiency and efficiency of the units depends largely on the quality of automation.For this reason, it is impossible to save on the purchase of an induction device - in cheap products there may be unreliable automation, which will negate many advantages of the equipment.

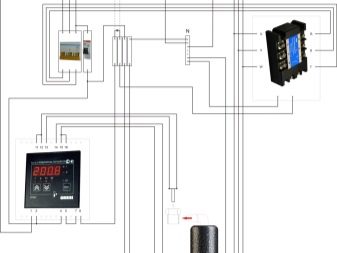

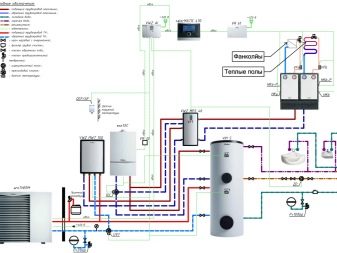

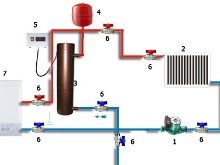

Wiring diagram

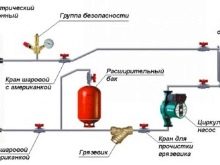

Composing a detailed drawing of the induction heating system, you can see that it is in many ways similar to the connection scheme of classic equipment. First draw the preliminary drawings of the future nodes. At the outlet of the tank, the system responsible for safety is fixed — it starts up in situations where the critical pressure in the heating system rises. In addition, an expansion tank is always installed - an excess amount of heat carrier enters it in case of expansion.

Radiators are installed in all the rooms of a private house. Special taps are installed at their entrance / exit. The number of sections should be selected based on the dimensions of the premises and the temperature of the batteries themselves. At the entrance to the device it is necessary to put a coarse filter.

Fabrication and installation

You can make and install the induction unit yourself. Let us consider in more detail how to do this.

First you need to stock up:

- all the tools you need to work;

- rolled wire or steel wire having a diameter of up to 7 mm;

- copper wire;

- plastic pipe with thick walls;

- metal mesh;

- welding machine (inverter).

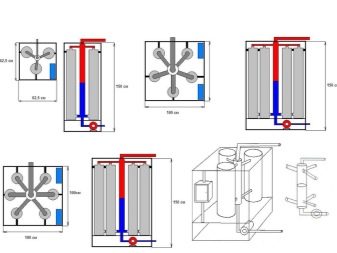

To make the body part for the unit, you need to buy a plastic tube with dense walls and an internal diameter of 5 mm. A similar detail will act as the base of the induction coil, and as a part of the heat conductor. It is necessary to rely on the scheme of the heating system. Place it in front of your eyes to make it easier to assemble the unit.

In the electromagnetic field should be heated pieces of steel wire. They should be cut to a length of 5-7 cm. As for their diameter, it should not be more than 7 mm. In addition, you will need special adapters - they will serve as the connection of the boiler with pipes. On the one hand, there will be a cold thermal carrier inside, and on the other hand, it will be removed warm due to induction. Cut wire elements must be placed in the inside of the pipe. Next, the device is very important to properly fix from 2 sides.

To make the induction coil yourself, which will be the main part of the heater, you need to prepare an enameled copper wire. About 100 turns should be wound on the plastic case. Keep in mind that it is necessary to leave an equal distance between different sections. After the inductor is assembled, you can proceed to its direct connection to the system itself. It is permissible to install such a boiler on any part of the pipeline passage.

The coil must be connected to a high frequency inverter. It is very important to remember that it is forbidden to launch such equipment if there is not enough coolant inside, since the plastic casing may melt under the action of high temperature values.

After all the above work, we can assume that the heating boiler is almost ready. Now it is very important to make its operation safe. To this end, all uncovered elements of copper wire should be closed with a special material characterized by high thermal and electrical conductivity.

Consider the basic rules for the installation of such heating devices:

- The system must be installed at a distance of 30 cm from the walls and 80 cm from the floor / ceiling.Adhere to this rule is important to ensure the safe operation of the boiler.

- It is allowed to install such systems only in a closed heating network. In such conditions, the thermal carrier will be forced to circulate.

- Experts advise to fix the pressure gauge, the blast valve, as well as the automatic device for the air vent behind the water connection.

- Self-made induction apparatus is permissible to install in systems with distributing of plastic / polypropylene pipes.

Operation Tips

When using such a boiler is important to eliminate the formation of scale. For this, many homeowners use special liquids. If you do not take into account this feature, then the formed deposits will negatively affect the heat transfer of the unit. So, scale in half a millimeter reduces heat output by about 10%. The thicker the sediment layer, the less heat transfer will be.

If you are making a similar heating apparatus on your own, then you will need to attach the first adapter by welding, and simply attach the second with a thread.

Note that such systems for heating are allowed to be installed in buildings that are not regularly installed by people.

If you decide to buy a finished machine, and not to do it yourself, then you need to find out the thickness of its steel core. The thicker the walls, the longer this component will not be exposed to rust. In a high-quality induction apparatus, not only water can act as a heat carrier, but also antifreeze, oil, and other petroleum-based compounds.

Take into account that high-frequency current can be supplied to such a boiler only after turning on the circulation pump and full filling of the unit with thermal carrier. If you want to get the maximum effect from the induction boiler (both self-made and purchased), then you should connect them with a group and operate them in turn or simultaneously.

Selecting a specific boiler capacity, you need to calculate it in this way: for 1 square. m square will require 60 watts. If people do not live permanently in the dwelling where you are going to install the unit, then this indicator can be reduced.

Thanks to its compact dimensions, the induction boiler can be installed, for example, in the kitchen.To hide the equipment, you should use a regular box or a hinged locker with pre-cut openings for pipes. Induction apparatus can be installed in the garage. If the building has a small area, then it is permissible to form a small trim. For heating such rooms one radiator will be enough. Entirely the entire heating structure may take less than a square meter.

Independently assembling and installing an induction boiler, do not forget about its grounding.

In the next video you will find making your own hands-on efficient and economical induction heater.