Rinnai boilers: types of structures and causes of breakdowns

Japanese Rinnai heaters have long received high marks from consumers all over the world due to their cost-effectiveness, which is achieved by introducing original technical solutions. These heating units are noticeably different from their counterparts with increased efficiency and a minimum amount of emissions of harmful substances into the environment.

Special features

Rinnai is one of the most famous Japanese corporations that produce high-end equipment at affordable prices. She appeared back in 1920. In the process of manufacturing their products, the concern's specialists apply the most interesting author's ideas and the latest technologies, which allows you to create the most productive and economical devices for heating systems.

Characteristic features of the devices from the famous Japanese brand:

- heat exchangers are made of high quality copper;

- high environmental parameters;

- the ability to control the unit remotely from a mobile phone;

- convenient control panels;

- compact size;

- effective performance even at reduced gas pressure levels;

- regulation of the combustion process;

- increased efficiency;

- work silence and lack of vibration.

It should be noted that the price of gas units from Rinnai will be available to any average man in the street, which favorably distinguishes these devices from their counterparts manufactured by other well-known companies.

Any product from the brand Rinnai will stand out with excellent functionality, 100% reliability, simplified management. If a power failure suddenly occurs or the fuel pressure level drops, a warning will immediately be sent to the device's sensor, and the device will automatically be switched to economy mode to avoid subsequent problems. Products from Rinnai can easily operate on any type of gas - no matter if it is natural or liquefied.Heat will be generated by burning gas through a burner that has a special technical design, and their operation will produce a small amount of nitric oxide.

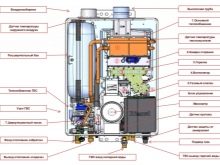

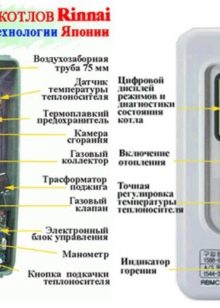

At the same time, consumers should know that despite the fact that the Japanese units have the most outstanding characteristics, their design and operation are quite simple. The body of products is made of durable steel, which is covered with a special paint powder. The main elements of the device are protected from various effects by filling out the foam. All popular models of the manufacturer have a system of automatic flame adjustment.

All processes occurring in the device are controlled by electronic sensors. In these devices, you will never see carbon black due to the fact that the fuel in them will burn without residue. The new vent-type burner itself will regulate the necessary proportions of air and gas, which will significantly increase the efficiency of a particular device even with a small level of fuel pressure.

Types and series

Today, the manufacturer offers a choice of consumers 4 series of devices under the abbreviations "RMF" and "EMF", "GMF" and "SMF".Each of these series is intended for use in strictly defined conditions.

Products of the RMF series will be able to warm the space having an area from 180 to 420 m2.

Their main features include:

- the ability to program the launch of the desired temperature for heating the home for 7 days in advance;

- before the start of work, the coolant present in the product will be preheated, which, in turn, will accelerate the rate of heating of the room;

- availability of remote control device.

The RMF series has in a set one of 2 types (option Standart and option DeLuxe) control panels. Using the standard remote, you can program the unit to work for 12 hours in advance, which is extremely convenient. With the help of the DeLuxe option, it will be possible to add as many as 5 modes to the memory of the console (with the expectation of working 24 hours ahead).

Rinnai also produces a very specific series of EMF units with two circuits. All of them are suitable for heating spaces with dimensions ranging from 110 to 410 m2, which will allow them to be used for heating sufficiently large and even multi-storey buildings. This series of devices is supplemented with a special type of burner, with which it is possible to minimize the emissions of toxic components during the combustion process of the fuel in the system.In addition, Rinnai EMF is completely safe for daily use. They have built-in auto-shutdown systems for fuel and electricity. There is also a voltage stabilizing device.

GMF devices are endowed with the most interesting performance features. They can heat large areas - from 100 to 400 m2, which is quite suitable for private houses.

The “GMF” series has such features as:

- frost protection (that is why even because of a sufficiently low temperature the boiler will not be damaged and will continue to work);

- electric spark ignition system;

- self-diagnosis - with its help, the user will be able to quickly find the breakdown and easily eliminate its cause;

- certain models are complemented by a circulation pump.

Boilers are installed where the pressure level of the coolant is not very significant. For the reason, they are most often purchased for use in rural areas and in holiday villages. It should be noted that to repair if necessary all models of the manufacturer is quite easy. Spare parts for the product “Rinnai RB-GMF” and others like it are easily found in specialized stores, and the consumer himself will be able to eliminate the damage to the boiler without recourse to specialists.

The main advantage of this series is ecological cleanliness due to the minimum emission of toxic waste into the atmosphere. The automation unit here has 3 levels, the regulation of the flame and the heating level of the coolant can be determined depending on the seasonality and climatic features. Diagnostics of all possible errors is displayed on the screen in text and (or) in the form of a digital code. Adjustment of the fan will protect against lack of oxygen for purging. Power of this kind of unit will be 12-42 kW. The most popular models in this series are the RB-166, as well as the 206 and 256, 306 and 366.

The SMF series has many interesting features. The most important of them can be considered the possibility of switching from natural gas to liquefied fuel, just by replacing the injectors in the device. The amount of CO2 produced during combustion of the fuel is not more than 5.72%. Units of this series are available for space heating from 100 m2. Thanks to autoregulation, the products will be operated even at a low level of fuel pressure.

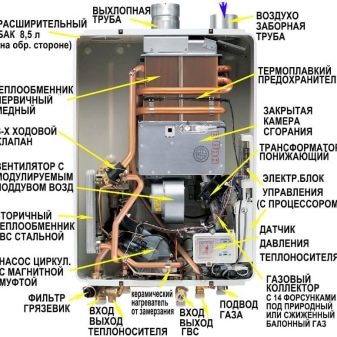

The boilers of the series have 2 heat exchangers, one of them is copper, the other is steel and quite efficient, it guarantees heating of the coolant to 14 liters per minute.In the combustion chamber is the adjustment of the fuel and air mixture, which is proportional to the volume of fuel used. This can be achieved through a turbocharger burner. The functionality of the products will not depend on climate. Emission of harmful substances is minimal, so you will not see any soot or scale deposits.

Using innovations in the production of its units, the concern Rinnai produces and sells also condensation products. Aggregates of this series have increased environmental safety in terms of the number of emissions of carbon monoxide into the environment. This is one of the features of the fuel supply to the burner. Homogeneous mixing of fuel and oxygen is carried out, then they go together to the burner. Carbon monoxide will necessarily pass through the special holes in the heat exchanger, so in this case carbon monoxide will also give up its heat to the system.

Most popular models

RB-167EMF

The convection device has a power of about 18.6 kW. It is compact in terms of parameters, includes in its structure a chamber for combustion of closed fuel. With the help of a special burner, the fluid in the coolant is heated to 85 degrees, and in the DHW circuit - to 60 degrees. The efficiency of the 2nd circuit - up to 10-12 liters per minute.You can easily connect the “warm floor” system to the product. In addition to the device includes a room thermostat.

Positive aspects of using the product:

- the combustion system will extend the life and reduce the number of harmful emissions;

- Regulation of the circuit according to the parameters of the air temperature in the room;

- increased efficiency - 93-94%;

- excellent work even with significant fluctuations in the level of fuel pressure in the main networks;

- a pump is provided for circulation, an 8 liter tank, a mud filter

Rinnai RB-327CMF

This unit is also condensing. Its main advantage can be called high efficiency. The heat output of the device reaches 35.5 kW, the largest heating area is 372 m2. The product is in a strictly designed case, where you will not find the control panel - all the controls will be on the thermostat. You can also connect external control modules that carry out work on the GSM channel to control work at a distance.

RB-167RMF

The original unit is complemented by a control unit with a color screen. The device has a scheme with a closed combustion chamber that takes oxygen from the outside and from the room.

Characteristics of this model:

- remote control using a mobile phone;

- DHW temperature control program;

- weather-dependent automatic system;

- the possibility of regulating the circuit for heating according to the temperature in all rooms.

- self test;

- connection of the thermostat with voice control.

Rinnai engineers added a combustion system to the boiler, which is characterized by 100% fuel combustion with a significant decrease in the amount of toxic substances emitted into the atmosphere. The first heat exchanger is made of copper, the second - steel. On board the unit there is a binding necessary for the operation of the system - from the tank to the security system.

User's manual

For your own home or a regular apartment, Rinnai products can be considered just the ideal option, therefore, domestic consumers increasingly choose them. Almost all settings are made in auto mode. On the control unit there is a screen on which you can find all the necessary indicators: pressure level in the tank, heating temperature, mode of operation of a specific device.

At a reduced level of fuel pressure, a special signal also goes to the display, and the operation of the unit automatically switches to economy mode.

You can remotely control the product using a portable controllerwhich is usually installed in any of the premises of the dwelling, or else the control takes place with the help of a remote control. A series of sensors that measure room temperature is connected to the controller.

Gas valve control may be necessary from time to time. This will help reduce the cost of bottled gas or main fuel.

After a power outage associated with a power outage, all settings are saved in the processor’s memory, and are restored automatically after troubleshooting.

Repairs

Intellectual control of Japanese boilers allows you to display information about the failure of the operation or malfunction of the product on the display in the form of a specific code.

The Rinnai boiler may go out immediately after starting operation due to errors "11" - This is a product signal that no fuel passes into the system. It is possible that the sensor controlling the flame level has failed, the solenoid valve is not working, on which the performance of the gas valve depends, or the board has simply burned out.This can also be attributed sticking gear pressure level and the lack of fuel needed to start the system.

Code "12" appears on the display when the flame is attenuated more than 15-20 times. This happens due to the low level of fuel pressure in the system or due to the presence of debris on the burner itself.

Code "14" indicates that there are certain failures in the power supply network of the boiler operation management, which can be solved independently.

Code "15" indicates that the flow of the coolant has been disturbed. The circulation pump of the product is in it in a single copy. If in the mode of hot water supply or heating this pump does not drive water through the heat exchanger, then this will be the main cause of failure. It is necessary to open the cork of the pump itself and see if the rotor is working or not. To adjust it, you can gently push a screwdriver so that he began to move. You can also clean the fluid filter sump.

Error "18" - This is the transition circuit to earth. Most often occurs when the displacement of a particular voltage (more than 5 V) in the line of the electric module. To eliminate this error, it is necessary to check the voltage level between the 3rd pin of the electric module CN3 and the line when grounding. You will need to be sure of the quality of the cable cover

Error "43" - a critically reduced level of coolant temperature and a decrease in pressure to almost 0. You can try to power the product through a water faucet to obtain the required pressure level and try again to turn on the boiler.

Error "16" - no coolant. To eliminate this problem, check the presence of water in the system.

Error "99" - the impossibility of removal of produced gases. This most often occurs due to the exhaust fan failure. To resolve this problem, it is best to immediately contact the service. There, specialists will clean the fan itself, as well as the entire heat exchanger.

Gas units of the brand Rinnai - the highest quality equipment with excellent performance for residential and industrial buildings. When replacing the injectors, you can use liquefied gas, which is very popular with many owners of country houses, next to which there is no main gas. The original control system will allow you to adjust the necessary modes and set the necessary programs in seconds. Reviews of owners of boilers are completely positive.Repair and maintenance of products is best done only in service centers, spare parts can be ordered there without any problems.

See the video below for the features and characteristics of the Rinnai boilers.