Protherm boilers: causes of breakdowns and subtleties of repair

Slovakian brand Protherm quickly won the domestic market, and all this thanks to the introduction of the most modern developments applied to the manufactured units. Each worker at the assembly is personally responsible for his work front and is personally responsible for the quality of the assembled device.

Special features

Any equipment for heating will not be able to operate, for a long time without the high-quality service maintenance by experienced specialists. It is necessary from time to time to clean the device from accumulated there scale and burning, as well as to conduct diagnostics aimed at finding problems that may be associated with automation and other parts of this system. In the segment of wall-mounted installations, Protherm is one of the most popular devices in our country.

This brand has great demand due to:

- low price;

- ease of management;

- excellent quality;

- maintainability;

- a huge number of services.

Protherm produces a whole range of devices for both heating and water supply to homes of any area. The brand is known for the manufacture of quality control blocks and automation components for comfortable control of devices, as well as their economical operation. But even devices that have the highest quality standards sometimes get into situations when suddenly you need to repair the Proterm boilers.

Admit to these devices can only those masters that have all the necessary skills of repair work and a huge store of knowledge about the characteristic features of the units of this brand.

Models

The most interesting models of the brand are:

"Cheetah"

This model of dual-type gas unit can be attributed to products with an affordable price. On the market, you can easily find 2 popular modifications of the model - one with the removal of combustion products of conventional fuel (MOV) and the second - with a forced discharge (MTV).Here there is a control of the product by an internal thermal sensor or a special temperature sensor placed outside. The design includes an LCD screen, the management of which monitors the operation of the device. It does not need to be connected to the chimney, since the product has a coaxial type smoke exhaust system, where the chimney is not needed at all. The heat exchanger is made of steel, a separate sensor will monitor the pressure level in the entire system. Installation method - on the wall. Installation is made for heating residential buildings and heating water. Depending on the size of the building, you can choose one of 2 devices - 24 kW or 28 kW.

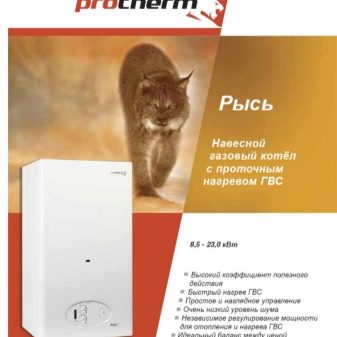

"Lynx"

The low price and increased efficiency of 94% distinguish this model, while the consumption of combustible material will be quite small. It has 2 modes of operation: "economy" and "comfort." Built-in electronics will provide auto-ignition. The unit is equipped with a 3-stage circulation pump, there is protection against freezing when the temperature drops by more than 5 degrees.

"Skat"

A wide range will allow you to choose a device from 6 kW to 18 kW. The electric boiler has a special power control system, it functions quite quietly and is suitable for heating oversized premises.The installation is single-circuit, ideal for heating residential areas, efficiency up to 98%, must be connected to the network of 220 V. Because of this impressive number of functions, the device has the ability to control the system from a distance.

Bear 40 KLOM

This is one of the most popular models in a series of cast iron units, as well as KLOM 20, 30, 40 and 50 products. Such a device is often used together with a device that runs on solid fuel as a secondary heating device. Efficiency approximately 92%. The “Bear” modification has a separate line of 40 KLZ, this device has a large boiler of 90 liters, in addition, it is possible to replace individual sections in order to significantly reduce the costs that may be associated with repair work.

"Panther"

It is used for heating office premises, residential buildings and providing them with heated water. There are models with a combustion chamber of hermetic type or open type. Heating water - 13-15 liters per minute, the largest heated space - 260 m2. The product can function with a low level of pressure, it has high-quality protection against freezing and an increased degree of safety.With the help of the screen you can monitor the entire operation of the device. The design includes 2 heat exchangers, the first - to create heat, the second - for heating water. Here there is a special mode "comfortable", when it is connected, heated water flows from the tap in just a couple of seconds. Built-in self-diagnosis system.

"Jaguar"

The model belongs to the most affordable gas boilers for heating small city apartments or country houses. You can choose one of two options with a capacity of 11 kW or 24 kW, the device heats 10 liters of water in one minute. There is a flame self-modulation, autonomous operation of 2 circuits is possible.

"Leopard"

According to the building, the “Leopard” unit, a double-circuit with a bithermic copper heat exchanger, is placed on the wall. Two circuits allow this device not only to heat the rooms, but also to heat water for domestic needs. This will help the owners of the equipment to significantly save on the purchase and installation of boilers, because in this unit there is already an excellent heat exchanger. Leopard products can be produced with both closed and open combustion chambers.

Power installations "Leopard" varies from 9 kW to 23 kW. These units can be with traditional chimney or turbocharged. Since these products are quite compact, extremely affordable and completely safe, they are actively used in private households.

This is an excellent solution for heating country cottages, ordinary houses and apartments, as well as oversized storage facilities and other buildings.

Errors

All the latest modifications of devices from the Protherm brand have special stylishly designed panels for digital control, which allow you to instantly recognize any possible error that has occurred in the system.

The most common trouble codes are:

- F00 - the temperature sensor installed on the flow opened;

- F01 - thermal sensor installed on the return line, opened;

- F1 - lack of flame, blocking of the entire ignition system and lack of fuel supply to a special valve (or a low level of fuel pressure);

- F2 - thermal sensor in the circuit does not work;

- F4 - hot water sensor is not functioning;

- F5 - external type temperature sensor is broken;

- F6 - exhaust gas sensor failure;

- F7 - disconnection;

- F10 - probable closure in flow-oriented meters;

- F11 - a possible short circuit occurring in the meters installed on the return;

- F20 - overheating of the contour of the device;

- F22 - low pressure level in the circuit of the device;

- F23 - temperature difference exceeded the permissible parameters;

- F24 - circulation is bad in the circuit;

- F25 - problems with the thermostat in the circuit;

- F26 - EVR engine is broken or shut down;

- F27 - no flame;

- F28 - no fuel or just a low level of its pressure;

- F29 - the flame during operation of the device goes out for no reason;

- F33 - oxygen is poorly supplied;

- F36 - diagnosing thrust (if it is a model with chimney removal of fuel combustion products);

- F49 - incorrect voltage on a particular terminal;

- F61 - no signal to control the gas valve;

- F62 - wrong signal to close the gas valve;

- F63 - the board memory for system management is faulty;

- F67 - wrong signal to control the device;

- F75 - failure of the pressure level sensor;

- F83 - no coolant, or the temperature during the operation of the burner does not increase, there is no hot water;

- A6 - low temperature in the room where the unit is located;

- F05 - little air to operate the boiler.

If you have installed and connected a new boiler, but for some reason the batteries are slightly warm, and the product does not heat the room, then it is quite possible that you simply didn’t pick up the boiler correctly or adjust its operating temperature incorrectly.

How to eliminate?

What should you do if your installation broke down, and A certain code appears on its panel and how to fix this problem:

- F1 - you need to find the "restart" button, double-check whether the gas valve and the plug in the outlet are turned.

- F2 - it is worth checking the temperature sensor of the heating circuit and, if necessary, replace it with a new one.

- F4 - the hot water sensor needs to be replaced, in case of oxidation of the contacts it is necessary to clean them.

- F5 - replacement of an external temperature sensor.

- F6 - it is worth checking the wires going between the sensors and the board that could break, also it is worth checking the ignition system.

- F7 - check all the wires, they may break.

- F10 - in this situation it is necessary to completely replace the NTC device.

- F20 - you need to check the temperature sensor for operation.

- F22 - most likely, you will have to replace the sensor, designed to measure the level of fluid pressure. Most likely, it will be necessary to add water to the system. It is worth double-checking whether the system is airtight, since the pressure level may well be lowered due to leakage. If it is present - eliminate it immediately.

- F24 - you need to check whether all existing taps in the heating system are open.

- F25 - thermostat may be faulty (due to a break, for example).

- F26 - need to restart. The electronic board may need to be replaced.

- F29 - you need to double-check the quality of the device grounding (phase, zero). Pay attention to the appearance of the burner, if necessary - clean it.

- F33 - recheck the resistance (for the possibility of a circuit or a break).

- F62 - you need to try to restart the system using the "restart" button. Carefully inspect the special fittings and all existing connections, checking their tightness.

- F75 - it is worth checking whether the pressure level sensor is operational, whether the pump is working. It is possible that airing has occurred in the pipes of the heating circuit.

- F83 - it is worth filling the system with a certain amount of water.Recheck your expansion tank for leaks, if necessary - repair it or replace it as soon as possible. You will also need to review the system to determine if there is no leakage. If it is found - quickly eliminate it.

- А6 - it is necessary to raise the temperature with the help of a small radiator placed in the boiler room.

- F05 - it is necessary to check whether the chimney channel is clogged, whether there is a necessary draft in it, for this purpose simply open the window in the room where your boiler is located.

What to do if the main burner does not start in the Protherm Bear 30 TLO boiler, see the video below.