Navien Deluxe boiler: technical specifications, installation and operation

Each gas boiler is in many respects a unique development, despite the relatively unified structure. After all, every manufacturer is trying to get ahead of its competitors and offer a more technically advanced solution. No exception and products Navien Deluxe.

Special features

The gas double-circuit copper of Navien Deluxe is extremely popular among the Russian consumers recently. The pleasant ratio of price and quality, combined with excellent technical parameters, fully explain this preference. It is not necessary to choose the 24 kW model in the table of the South Korean manufacturer. But at the same time, it is quite suitable to illustrate the features of the devices of this brand.

The company's product range includes wall-mounted gas by-pass gas systems with closed combustion chambers.

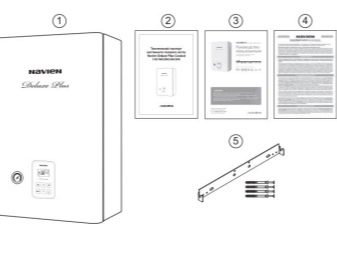

Navien Deluxe is completed with:

a pair of stainless heat exchangers (for heating and plumbing circuits, respectively);

expansion tank;

pump for pumping;

gas valve;

one more valve equipped with three strokes (switching operating modes);

security team;

a number of other parts that support the uninterrupted action of the heating unit.

The boiler monitors not only the temperature in the heating circuit, but also the flow of fluid through it. Expanding tank is made in the form of a flat product. An air vent device is provided; a differentiating relay is always installed. The system has a fan, electrical ignition is organized using a transformer. Separate electrodes provide ionization and ignition.

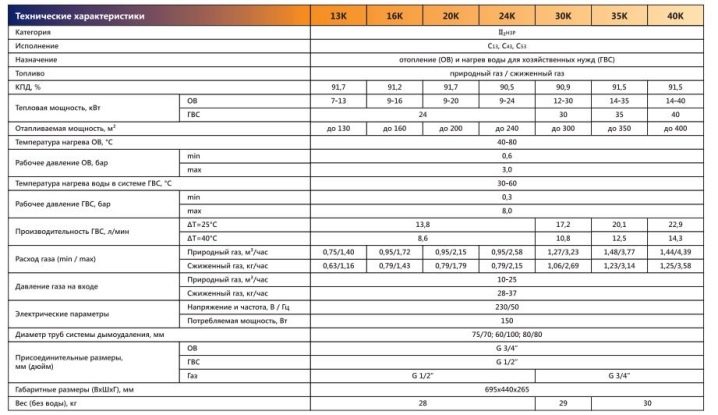

Characteristics of models

Version "Coaxial 24K" differs from "Deluxe 24k" and "Deluxe Plus 24k" because it is made with the expectation of connecting to a horizontal chimney of a coaxial performance. Its diameter (according to the scheme one tube to another) is 6 and 10 cm, respectively.“Deluxe 24 k” in standard and coaxial versions are equipped with a remote control unit, which also has the functions of a thermostat.

The “Plus” option does not have such a unit, but it is equipped with a front coordinating panel. The chimney can be connected through a pair of pipes.

The 13K boiler is distinguished by an automated system that protects against freezing. When the temperature drops to a mark of 9 degrees and below, the system starts up a circulation pump. The choice of the newest Smart Tok line is justified for those who want to use the resources of a modern remote control.

Burners in South Korean boilers are made with modulation, which allows:

make the ignition fire silent;

adjust the temperature smoothly;

reduce the heat load on the nodes located inside.

Voice prompts are provided in any Navien boiler model. Engineers were able to adapt their systems to the conditions of work in real Russian networks. Provides self-diagnosis function. Judging by the reviews, including those left by experts, heating devices from South Korea almost do not break, they are distinguished by high performance.However, they serve for a long time.

"Atmo 24AN" is produced according to the classical scheme with convection, equipped with an open combustion chamber. Due to its power of 24 kW, it successfully warms the house up to 240 m2, burning a maximum of 2.47 m3 of gas per hour. In a minute the boiler is able to warm 13.7 liters of water. Copper is used to create the primary heat exchanger and strong steels for the secondary.

A changeover to the use of liquefied gas is permissible.

Control of the unit becomes more convenient thanks to remote systems with thermostats built into them. Binding all already created inside. If you pay attention to the "Smart Tok", it is easy to find the exceptional perfection of this modification. It can be controlled via the Internet and recognize its own problems. There is a specialized programmer that sets the operating modes, the power adjustment allows to receive from 8 to 24 kW of heat energy per hour.

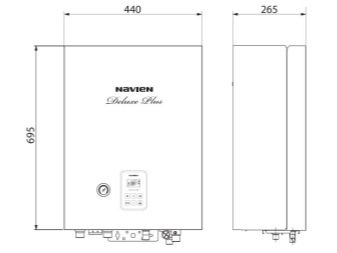

Connect and configure

The connecting size for a heating contour makes ¾, and for a water supply system - ½. Gas is also fed through a ½ inch channel. Before you install the boiler in an already mounted system, you must, of course, turn off the heating and drain all the water from the circuit. The recommended power supply parameters are 230 V and 50 Hz, deviation from them affects the product negatively.

Possible not only interruptions or breakdowns, but also the occurrence of fire.

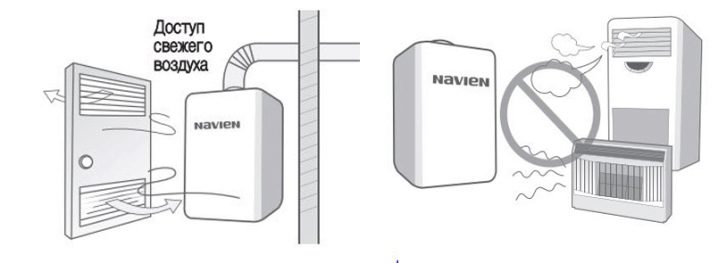

Mounting the system with your own hands, it is prohibited to connect any other electrical appliances in parallel with the boiler. The use of extension wires and adapters is not allowed. Better from the very beginning to design a home power supply circuit with all the necessary requirements. Instructions from the manufacturer indicate the great importance of ventilation of the boiler room. It should be not just powerful, but designed on a professional level.

Before starting, check the water connection and the position of the control valves. You can not think that if the boiler will be stopped for 2 or 3 days, it can be turned off. The lack of electricity can lead to the appearance of ice inside the boiler and in the heating system, which is extremely bad for them.

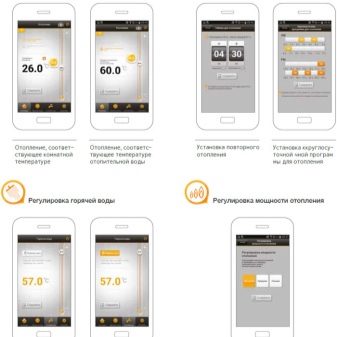

In the modification of the "Smart Tok" switch is provided from winter to summer mode. By selecting the latter, users indicate to the system that it will only be used to generate hot water.

The water temperature is set by the rotation of the special handle. It is impossible to regulate this indicator while using hot water supply.If necessary, you can set a program for the fastest possible heating of water in the water circuit. After turning the knob on the information display comes a new dose of information. For simple radiators, temperatures from 48 to 76 degrees can be set, for floor heating under concrete - from 26 to 60 degrees.

Tips

Even the exceptional craftsmanship of South Korean manufacturers does not allow 100% elimination of violations and problems at work. Bad water heating is mostly due to the filling of the heating system with air traps. The problem is solved by removing the accumulated air or changing the automatic tap. Pollution of the filter in the heating circuit cannot be excluded.

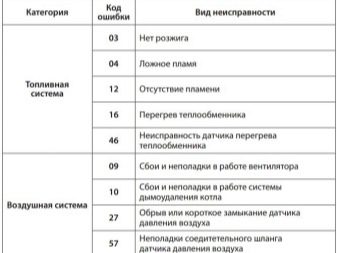

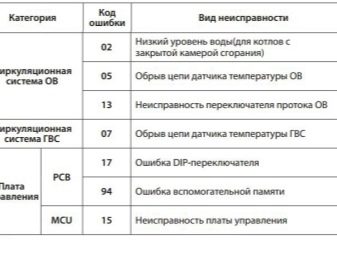

Error number 2 means that the coolant concentration is below normal.

This situation is corrected either by adding water or eliminating leaks. Code 3 indicates that no gas is being supplied to the burner. It is required to check in which position the valve, whether the fuel in the cylinder has run out, and whether there are no incidents on the line. Judging by the reviews of the owners, the South Korean boilers are smaller than many other versions and are distinguished by a quick access to the set temperature.But it is noted that there are no control bodies on the boilers themselves and that the inclusion of two hot water taps on the water supply occasionally reveals an insufficient warm up force.

If the boiler is leaking, in many cases it is flowing water from the drain plug, which is covered too weakly or leaky for some reason. When the cause is more complicated, you will have to remove the problem block, disassemble it and clean it. Turn off the clamping nut, remove the air vent. Using a hexagon, unscrew the cap, then remove the gum (fit a needle or a screwdriver with a thin sting). Take out the piston and spring, and when the float falls out, it is necessary to rinse it and then return it to its place (in the reverse order).

A more detailed overview of the Navien Deluxe boiler can be viewed in the next video.