NTC sensor in the boiler: what is it and how to install?

Before many Russian residents, sooner or later, there is a need to purchase a heater. Today, in the shops of household appliances you can find a huge number of different types and models from various manufacturers - both domestic and foreign. Gas heaters can be single-circuit or double-circuit, with an open combustion chamber or with a closed, mounted or outdoor.

You can find a suitable boiler in accordance with any requirements and preferences. But one thing unites them - the gas on which this equipment operates. Breakdown can not only seriously disrupt the heater, but also entail a risk to human life. After all, gas is always dangerous. To reduce the likelihood of a malfunction will help the temperature sensor.The devices of this accessory perform several important and useful functions, which we will discuss in this article.

What is needed?

Most modern models of gas heaters have a simple and affordable system settings. But no matter how easy it is to manage, it requires constant attention to adjustment. It is much more comfortable to automate the entire system and not worry about it. Fortunately, almost all modern boilers are equipped with this feature. However, the auto regulator is able to work correctly only by receiving complete and reliable information about the surrounding conditions. This function is taken by special sensors. Fortunately, many models of heaters have the ability to connect additional equipment.

According to their purpose and functions, the sensors are divided into several types.

- A traction sensor monitors the exit of combustion products and reduces the risk of filling the room with carbon monoxide. As a rule, attached to the smoke absorber.

- The flame sensor responds to the absence of fire on the burner. The equipment is obliged to inform the system of this fact as soon as possible so that it blocks the flow of gas, thereby preventing its leakage.

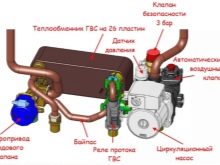

- A pressure sensor is also known as a pressure switch. Reduces the risk of boiler overheating.It responds to a decrease in gas or water pressure. If the drops are too large - sends a signal to the system to turn off the heater.

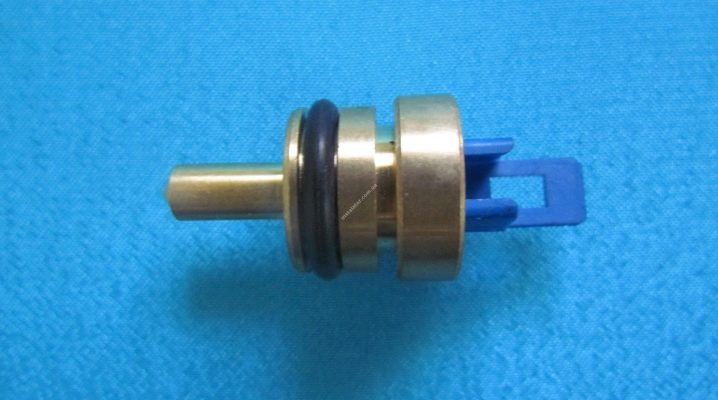

- Overheating sensor protects the unit from boiling. Also has the name "heat fuse". Refers to NTC sensors. Turns off the heater when its temperature reaches critical values.

- Temperature sensors inform the boiler system on the environmental conditions and their changes.

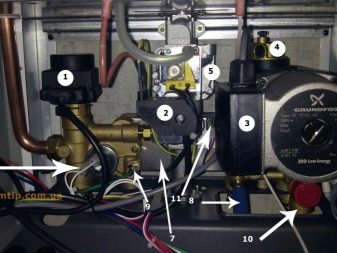

This time we will talk about the last two types of device. Sensors collect and transmit information about the temperature inside and outside the boiler to the automated system. Having a full amount of data, the system is able to control the degree of heating of the circuits in the boiler. Many manufacturers of heaters themselves develop and produce additional equipment. Therefore, when choosing a sensor, it is better to give preference to the same brands to which your boiler belongs. In this case, do not have to deal with the problem of incompatibility.

Principle of operation

The abbreviation NTC stands for "positive temperature coefficient." It must be observed not only inside the boiler itself, but also outside it, so that the unit does not work in vain or does not heat too weakly.If we are talking about an internal overheating sensor, then it is placed in a heater in order to transmit information about temperature conditions to the system from there. Overheating of the boiler is always dangerous not only for himself, but also for those around him. It can simply fail, and maybe explode.

There are many reasons for this, here are the most common ones.

- Air has accumulated in the heating circuit, it should be lowered.

- The duct is clogged with scale. When this happens, claps are heard inside the heater. Scale is removed with chemicals.

- In the room where the boiler is located, high humidity or low air temperature.

- Clogged filters. This leads to impaired circulation in the heating circuit. Filters need to be cleaned or in a particularly neglected case, replace with new ones.

- During a long period of inactivity, the pump became clogged, causing circulation to break down. The pump should be disassembled and rinsed.

You can fix some of these problems yourself, but it is better to resort to the help of professionals. The fuse instructs the electronics to turn off the burner. It also prevents the boiler from starting to cool down completely.At the same time, such a sensor is restored on its own and returns to the previous mode of operation after the temperature has been reduced to an acceptable level.

We now turn to the devices that determine the external temperature. The basis of their work, as a rule, are active substances, which are narrowed and expanded under the influence of the environment. Or this function is performed by sensitive semiconductors. Determining the air temperature, the sensor sends information to the thermostat board, which gives commands to the heater.

Kinds

We have already decided that thermal sensors can serve both to determine the temperature of the boiler itself and to determine the temperature of the air around it. The first of them, in most cases, are located inside the unit together with the coolant and are not very different from each other. A device for determining the air temperature can be divided into subspecies, depending on the selected criteria.

Let's start with the way they are placed.

- Room As you might guess, are located in the premises. Their goal is to determine the temperature regime in buildings that are heated by a boiler.

- Outdoor Installed on the street to determine the external climatic conditions. The sensor responds to cooling and warming, notifying the control panel. Due to this, the boiler is turned on only when necessary, depending on the settings selected by the user. Allows you to significantly reduce the cost of gas.

- Overhead. Also located on the premises. Such models are attached to the pipes that are part of the heating system. For these purposes holders are used, which often come bundled with the sensor itself.

- Submersible. Placed in water, in a designated place inside the heater. They are used exclusively for boilers, so they are of no interest to us.

Also, the heating temperature sensor according to the method of transferring heating may be as follows.

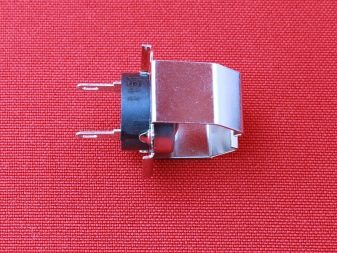

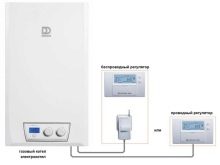

- Wired. It is connected to the electronic panel of the boiler using a wire. According to experts, this method of transmission is more stable and accurate.

- Wireless. The transmission of information through radio waves. Such sensors, in addition to the detection unit, have an additional unit that sends signals to the boiler.

Also, the sensors are divided according to their internal characteristics.For example, the simplest models support the temperature range in the region of 10-40 ° С. Such indicators can be limited only in some cases. The best option for the house are sensors, whose temperature sensitivity varies from -10 to 70 ° C. The dimensions of the room devices are quite small. Approximately 3 centimeters in length and 2 centimeters in width. Dimensions of remote sensors may be slightly larger, but not by much. The manufacturer equips such devices with increased protection, increasing their durability and resistance to wear, moisture and other natural factors. Wireless thermal sensors exceed their size, because, as mentioned above, they have additional units for radio communication.

Installation

Immediately it should be noted that working with gas equipment is a responsible and difficult matter. This business should be trusted only to specialists. Many residents of our country believe that they can save money on the services of a master by doing their own hands. However, the smallest mistake can disrupt the entire system, which would entail even greater costs.

First, let's define the main components of the device. These include the sensor itself, the cable box, several terminals for clamping the cable and the plastic case inside which all this is located. Before installation, you must select the correct location. This is especially important when it comes to street sensor. To work correctly, many external conditions should not act on it.

First, the device should not be exposed to direct sunlight. This also applies to room sensors, but in the room the influence of this factor is much lower. Experts recommend that, where possible, thermal sensors be placed on the north or northeast walls of a building. Secondly, the level of humidity in this place should be the norm. In no case can not install the device on walls covered with mold. Thirdly, the sensor is designed to measure the exact air temperature. So, next to it should not be elements, artificially raising it. These include ventilation, chimney, or even a door. Fourth, consider the height of the house. For example, on buildings with a height of four floors or more, a sensor is installed between the second and third floors.

So, let's say you chose the most appropriate place, go directly to the installation. To attach the device to the wall, you have to remove the cover. Mark points for mounting holes. It is recommended to fasten the sensor to the surface with anchor bolts. Next, it is necessary to connect the wires. Unscrew the special nut used to seal the cable. Connect the two wires and tighten the nut back. Done, you can close the case with a plastic cover.

The installation of thermal switches is not so often required, since most of the modern models are already equipped with them. But it also happens that the sensor fails, after which you need to look for a replacement for it. When buying, pay attention to the characteristics of the device. In this case, we are only interested in the temperature level, since the voltage for the boiler is unimportant. Many gas heaters have space specifically reserved for the sensor. Usually somewhere on the nipple. Before installation, this fragment of the boiler should be cleaned and thermal paste applied to it.

Connection

This item is relevant for wired device types. After all, setting up the connection of wireless sensors is not difficult.Unless, of course, the thermostat is equipped with a radio channel. But with the wiring you can always screw up. First of all, turn off the boiler completely. Use a 30-meter cable to connect the heater to the outdoor sensor. Or shorter, if the distance between the connected equipment is not too large.

A 5 meter wire will be sufficient to connect the boiler to the room sensor. Cable thickness should be approximately 2x0.5 millimeters. How to connect the wires to the sensor, we described in the previous paragraph. Now we also connect the other end of the cable to the terminal block of the boiler. It is not necessary to observe the polarity.

To insulate the cable, it is recommended to use a sealed coupling.

Adjustment

The control and adjustment take place with the help of a temperature controller, which can be installed, for example, in one of the rooms. They can be simple and programmable. The first is clear, they are designed to set and maintain a certain temperature in the room. Programmable controllers have advanced functionality. The most common possibility of such devices - setting the humidity level in the house.

You can also manually raise / lower the temperature in the room or the temperature of the boiler itself, set a specific mode of operation using programming, use the comfort mode or reset all the specified settings. In conclusion, it is worth noting that for the most stable and safe operation of a gas boiler, all types of sensors that we described at the beginning of the article should be used. They will help to fully automate the operation of the heater, reduce the level of gas consumption and increase the service life of the unit itself.

An overview of NTC sensors for boilers, see the video below.