Diesel boiler: device and installation details

Diesel types of boilers are not used for heating private houses. Not the greatest popularity of these units due to the relatively high cost of diesel fuel. However, in areas that are not connected to the main gas, such heating systems are quite popular. Today we will take a closer look at diesel boilers, as well as examine their device and consider the subtleties of their installation.

Special features

When building any dwelling it is extremely important to take seriously the choice of the heating system. Today, there are many different methods of heating residential (and not only) buildings. Of course, the most popular and frequently occurring gas equipment, but not in all situations, homeowners have the opportunity to turn to its installation. In such situations, people acquire alternative units such as electric or diesel.The latter are less common, but this does not mean that they are ineffective.

If you decide to install a similar device in your home, then you should consider that the price of fuel for it may disappoint you a little. That is why such systems are less common, but they are ideal for the private sector.

Nowadays, we can safely say that heating living space with natural gas is most beneficial from an economic point of view. However, users who cannot use such resources have the opportunity to use liquid-fuel heating units. They are distinguished by a rather simple and uncomplicated device. In addition, these devices are considered to be more reliable and practical than electric ones, since they are not volatile (note that this does not apply to all models).

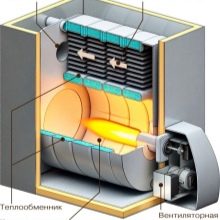

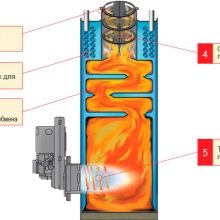

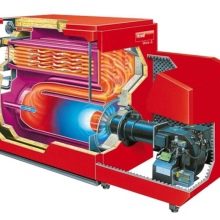

The device of these units consists of components such as a diesel burner, fuel filter, pump, all the necessary sensors and control panel. If we consider briefly, the work of such a heating structure is that the liquid fuel is pumped into the combustion chamber,where it is mixed with air. After that, it is sprayed with a special fan and further ignited. Gases, which are formed at the same time, go straight to the chimney or coaxial pipe.

A feature of such units is that they need to be installed on a separate area. Often, homeowners allocate cellars for these devices that overlook the street. You also need to remember that the installation of a diesel boiler is allowed only in a room with a ceiling of at least 3 meters. Many users are pleased that the installation of diesel boilers does not need to get permission.

Fuel for such devices should be kept in specialized tanks. Their dimensions are directly dependent on the calculation of the volume of consumption. It should be borne in mind that tanks should be located outside the site. The source of diesel fuel, located separately, will be responsible for the fully autonomous operation of the entire installation. Thus, the household will always be provided with heating and hot water.

As a rule, the boiler body is made of cast iron or alloy steel.Such devices, like gas, are wall and floor. It is precisely the outdoor options that are in great demand because they are distinguished by simple maintenance and good performance characteristics.

Advantages and disadvantages

Diesel boilers, like any other heating units, have both positive and negative qualities. Both those and others should be known if you are going to supply your dwelling with such a system.

To get started, let's take a look at the advantages of diesel heating systems, for which they are chosen by modern owners of private houses:

- Diesel is an affordable fuel that is not difficult to get, even if you are in a remote region that is not connected to the gas mains.

- If you turn on the regulation of the heating process, it will occur in automatic mode. In this case, the diesel burner will turn on and off based on the temperature conditions of the thermal carrier that is present in the system.

- To install and run such thermal equipment, it is not necessary to stock up on special approvals. You do not need to collect a lot of documents and get permissions for a long time.relevant authorities.

- At installation of the diesel device there is no need for fixing of an expensive flue and ventilation. For such systems it is allowed to use a simple coaxial chimney, which is discharged through wall ceilings in any convenient place.

- Such devices have an affordable price, especially when compared with induction specimens.

- Diesel boilers are distinguished by a high level of efficiency (95%). They boast excellent heat dissipation. Of course, the effectiveness of units depends largely on their proper design.

- The lion's share of these devices can function not only from diesel, but also other types of fuel.

- To maintain this equipment, it is not necessary to have a special education or a wealth of experience / knowledge.

- These units are installed quite easily and quickly. To cope with this task is possible without seeking the help of experts.

- Diesel boiler models are autonomous. With a significant capacity, the fuel bunker may last for several months of operation.

- Modern consumers face a wide range of different diesel boilers.

Such heating systems are rich not only with pluses, but also with minuses:

- Diesel boilers are notable for noisy work that does not suit many homeowners.

- To install this unit you need to build a separate boiler room.

- On the plot you need additional free space for the placement of the bunker, and it must be large enough so that the boiler can operate for a long time.

- The installation of the chimney for this heating system must be approached as seriously as possible. In this case, no mistakes can be made.

- If you live in a cold region, you will have to additionally build a system for heating liquid fuel. This will lead to additional energy costs.

- During operation, diesel units emit an unpleasant characteristic smell of fuel.

- The diesel boiler will require periodic maintenance from the owners - it will have to be cleaned from time to time so that the soot does not clog up the mechanisms, hindering the normal functioning of the equipment.

- For the operation of the diesel boiler you need to stock up with high-quality and purified liquid fuel.If you use conventional formulations, the efficiency of the unit can significantly decrease. In addition, this often forms blockages of chimneys and heat exchangers.

- Diesel fuel, although not uncommon, is usually quite expensive. Given the high consumption of the operation of these models can not be called cost-effective.

Kinds

Diesel boilers are different. Let's get acquainted with the characteristics of various types of such units.

Single circuit

Single-circuit unit, working on diesel, has a high performance. Such instances are designed for installation in the heating system. However, we must remember that they do not provide for heating water.

If in the future you want to connect hot water to such a unit, then you will need to build a special indirect heating boiler into the heating system itself. The main advantage of units with a single circuit is that they can be used to heat residential buildings of impressive dimensions.

Double circuit

Dual-circuit heating devices are considered more popular and in demand, as they provide heating for the home and provision of hot water.Depending on the manufacturer, in such constructions a bithermic or separate heat exchanger is used.

In modern double-circuit boilers powered by diesel fuel, there are often built-in storage tanks. The main advantage of such units is that they provide the fastest possible water supply to the user when it is necessary (that is, immediately after opening the tap).

Wall and floor

By type of fasteners distinguish wall and floor models on diesel. So, the wall model is a small unit that takes up very little free space in the boiler room. Such devices are supplied with 1 or 2 heat exchangers. Modern consumers choose such boilers for their modest dimensions and discreet but neat design.

Outdoor copies are the most popular and common. Similar options are presented by the units having various power, up to 100 kW and more. Based on very powerful products, the whole productive boiler-houses are organized, which can simultaneously feed several different buildings or generate heat for industrial or business buildings.

Steel and cast iron

Diesel units are made on the basis of a cast iron or steel heat exchanger. So, steel options can boast an affordable price and low weight. Such models are in great demand and are found in many homes. However, these specimens have one serious drawback - they do not last very long. For this reason, cheap steel units are usually equipped with steel elements.

Cast iron heat exchangers are installed in expensive and productive devices. Such models are characterized by massiveness and impressive weight, but at the same time they are not afraid of significant temperature loads. Cast iron is used in the manufacture of not only expensive machines, but also in the production of high-power copies — in this case, such material cannot simply be dispensed with due to the noticeable loads on heat exchangers.

Atmospheric and turbocharged

An atmospheric burner burns fuel with natural waste disposal. In this case, the products of combustion themselves go into the chimney, obeying the burden. It is important to add the indicated apparatus with a high-quality and reliable chimney going to the roof.An open combustion chamber is not designed for the presence of unnecessary parts for the formation of thrust. For this reason, these products are famous for practicality, durability and low cost.

The boilers of the turbocharged type have a closed combustion chamber. They are designed to work together with coaxial chimneys. Such units are equipped with a fan, which forcibly "expels" the waste of combustion, and also regulates the traction in the chamber. Thus, efficient combustion of fuel is carried out, and there is simply no need to organize a full-fledged chimney. Turbocharged models are more expensive because they have a more complex structure.

Universal and with replaceable burners

Heating on a diesel engine in a private house is quite possible to convert into gas. To do this, just need to buy a device equipped with interchangeable burners. Such equipment is called universal. It will act on different types of fuel.

Also, modern manufacturers produce and such options diesel boilers, which can operate on different fuels without changing the burner. These instances can be reconfigured even for gas operation.

Principle of operation

Absolutely any boiler on a diesel engine works on the same principle as its alternative on gas - with a command from the control module, the burner is ignited, after which the heating of the heat carrier starts, which lasts until the burner is turned off.

In units with two circuits, there are additional heat exchangers with special three-code valves. At the same time, during the opening of the taps with water, the circuit responsible for heating is turned off, and the hot heat carrier begins to circulate in the secondary heat exchanger, preparing the heated liquid.

The consumption of the apparatus operating on diesel fuel is about 1/10 of its direct power. So, if the model you purchased has a power of 24 kW, then it will consume approximately 2.4-2.5 l / h. The smallest fuel consumption is standard only for weak devices with low power. As a rule, such equipment is bought for the dacha.

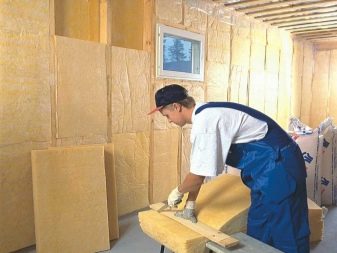

Installation

Installation of a diesel boiler can be done by hand. These works are carried out in several stages. First you need to equip the boiler room.For this, it is recommended to build a separate soundproofed space. It is necessary to arrange this structure so that there is still some free space nearby to place the container under the diesel fuel. If the fuel wire is too long, you will need to purchase a more powerful boiler with an impressive suction power. In addition, the unit will have to be further warmed.

Equipping the boiler room, you will need to install a container for storing and supplying diesel fuel. It should be noted that the tank for diesel fuel placed in the boiler room should not be greater than the capacity of 0.8 m3. Most often for this purpose they buy special polymer containers, which are not afraid of "aggressive" liquids.

In addition, these elements are equipped with such details:

- fuel intake with a hose and float, which is responsible for collecting fuel from the surface, where there is no dirty cage;

- a breather valve required to eliminate fuel vapor;

- a float gauge that shows the remaining fuel as well as its consumption;

- diesel filter.

Tanks for diesel fuel are often buried in the ground, thereby providing heat insulation to this part.In cold areas of tanks and pipes it is important to warm up well.

Having built a fuel tank, it is necessary to proceed to the installation of the chimney. When installing a diesel boiler there is no need to fix complex and expensive options. There are no special requirements for the height of chimneys. Most often, heating units powered by diesel fuel are supplemented with inexpensive coaxial chimneys having a ventilation duct. This detail is passed through the wall of the boiler room. At the same time, it is not necessary to insulate the smoke channels.

Then you can proceed to connect the unit to the heating system. During combustion, diesel fuel emits carbon black, which upon contact with moisture forms an aggressive liquid. Moisture can accumulate in the chamber of the boiler. To avoid these problems, you need to install a jumper between the direct and reverse flow. In other matters, the connection scheme of the diesel device is no different from other options.

The expansion tank, the safety components, the distribution manifold and the pump are usually installed inside the boiler room, although this is not considered a prerequisite.

Service

A boiler operating on a diesel engine requires regular maintenance, which consists of:

- cleaning up once a season (sometimes more often);

- node repair, if necessary;

- regular removal of deposits in order to avoid destructive accumulation of soot (you can do it yourself or contact a specialist, especially if we are talking about cleaning technically complex parts like an ignition system);

- replacement of worn oil seals, gaskets;

- setting up the burner and turbocharger.

Manufacturers

Today, there are many popular and large companies on the market of heating systems, whose diesel boilers collect positive user feedback and are of excellent quality.

The brand "Olympia" from South Korea produces high-quality diesel units equipped with reliable automation. Branded devices of this brand have a low fuel consumption per day.

Italian brand Ferroli boasts a rich assortment of diesel boilers of different capacities. The company offers units that can be used in both domestic and industrial environments. However, it is worth considering that the boilers from this brand have a rather high price.

Kiturami - This is another famous brand from South Korea. In its assortment there are gas, diesel, solid fuel and pellet units, as well as parts for them. Kiturami diesel units are represented by the “Turbo”, “Stso”, “Kso” collections. These series include models of different power with a turbo cyclone burner.

Finnish manufacturer Danvex known for its diesel automatic boilers, equipped with special burners with sensors and other high-tech additions. Brand models from this brand are economical and easy to manage / maintain.

German brand Buderus offers the choice of buyers high-quality diesel boilers with high efficiency. Branded products of this brand are distinguished by quiet operation, ease of operation, as well as the ability to connect to any chimney.

Viessmann vitorondens - This is another well-known manufacturer from Germany, producing diesel boilers with very high efficiency (103%). Branded units manufactured under this brand are manufactured on modern equipment using innovative technologies. Viessmann vitorondens boilers are safe, durable and soundproof.

For information on how to select and run a diesel boiler, see the video below.