Features of heat storage for heating boilers

Heat accumulators for heating boilers are a useful invention and are widely used by owners of autonomous heating systems. The device significantly saves thermal energy, has a simple device and can be mounted independently.

Purpose

The role of heat accumulators in the heating system is difficult to overestimate. The device collects and stores the coolant, maintains the necessary temperature in it, and if necessary gives it back to the system. This contributes to maintaining the optimum temperature conditions of the rooms even when the boiler is turned off.In addition to maintaining the specified thermal parameters, the battery protects the boiler from overheating, taking away excess heat from it, and reduces the amount of fuel consumed by 30%. When this occurs, a synchronous increase in the efficiency of the heating device occurs.

One heat accumulator can simultaneously serve several boilers operating on a different type of fuel. In addition, the device plays the role of a water heater in the hot water supply system, and for some time it heats the water when the boiler is turned off.

But the use of heat accumulators is not advisable for all types of boiler equipment. For example, in high-tech automated electric boilers, the installation of heat stores is not economically justified. Such devices themselves control the rationality of resource use and are equipped with thermal sensors that disconnect them from the network in the event of overheating. But for solid fuel and pyrolysis boilers such devices are essential.

This is because the combustion chambers of such units require regular loading of solid fuel, which makes it necessary to constantly monitor the degree of its combustion and constantly toss coal or firewood.At night, doing it is not quite comfortable: you have to get up several times a night and control the operation of the boiler. The solution of the problem can be the installation of the heat accumulator, which will allow to store the heat generated during the day and effectively spend it at night. The owner of the room will be able to sleep peacefully all night, and the installation of the device will significantly reduce fuel consumption and significantly reduce heating costs.

Specifications

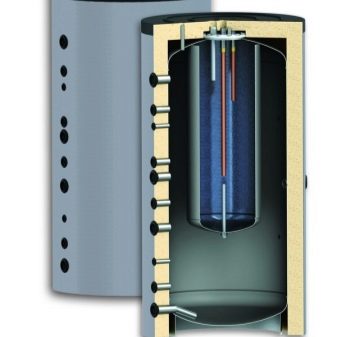

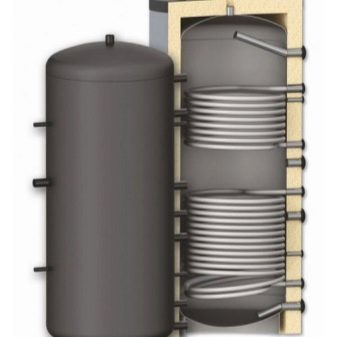

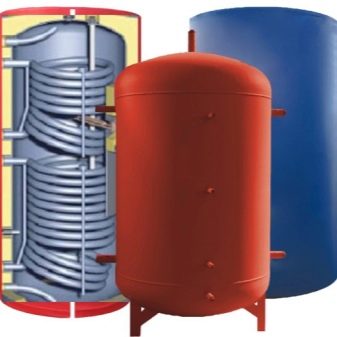

Structurally, the heat accumulator resembles a large thermos. The case of the device is made in the form of a cylindrical tank and is made of stainless steel. On top of the tank has a strapping of insulating material, which contributes to a noticeable increase in the cooling time of the coolant. Insulation thickness on factory-made models is 100 mm. From above, the heat insulator is closed with a tight casing, which is used for the production of leatherette. Heat exchangers are located inside the tank. Their number depends on the volume of the tank and the power of the model, and can vary from one to three - in factory models, and up to five - in self-made ones.

The volume of the tank can also be different: in the most budget options it is only 100 liters, while large industrial installations are equipped with tanks of several cubes and require separate boiler room equipment for their installation. In some models, a smaller boiler is installed inside the main tank, providing hot autonomous water supply. On the battery case there are several threaded connections used to connect the device to the heating boiler, as well as to connect the heating wiring. The rate of heat consumption from the drive depends on the heat loss of the room, the external temperature and the capacity of the storage tank. Heating on the passive mode with the boiler off can be carried out from two hours to two days.

Principle of operation

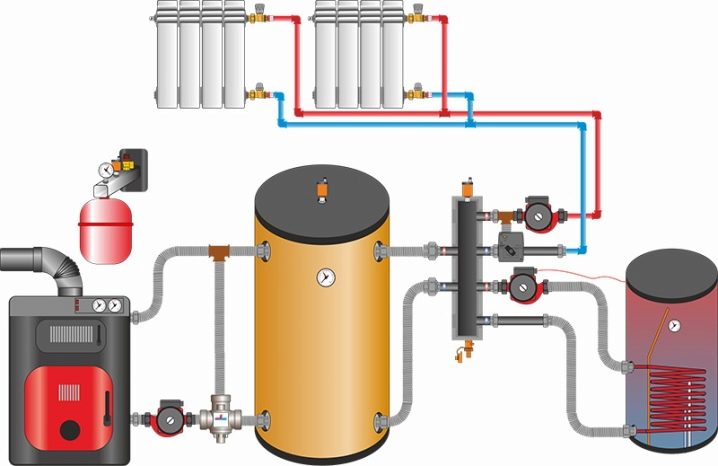

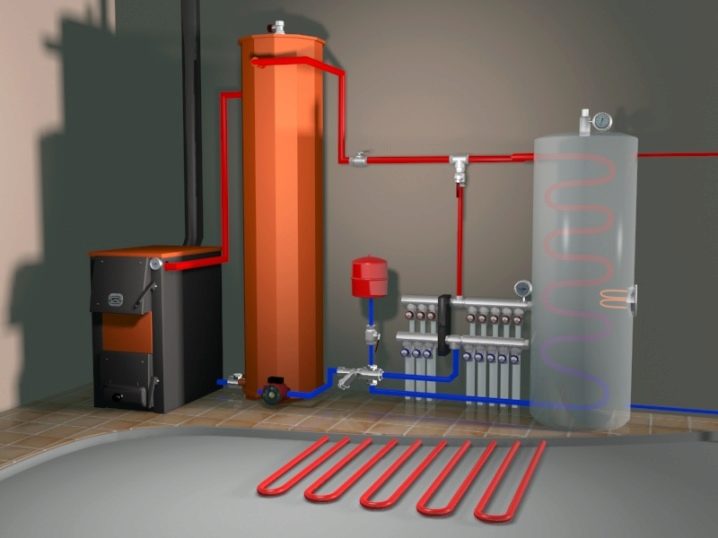

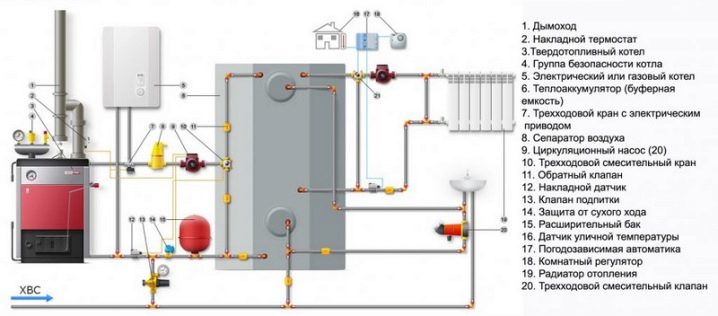

The scheme of the heat accumulator is quite simple. Due to the work of circulation pumps installed between the boiler and the battery, the hot coolant through the top nozzle enters the buffer tank. In this case, the cooled liquid returns to the boiler through the lower pipes. In the area between the heat store and the radiators, another pump is installed that provides the coolant to the radiators.

After the water in the batteries gives up its heat to the room and its temperature reaches the lower permissible mark, the temperature sensors automatically trigger. At their signal, pumps are turned on, which instantly resume the supply of hot coolant to the radiators.

During idleness of the pump, located at the outlet of the battery, there is an accumulation of thermal energy. After a complete burnout of one fuel, the boiler switches to standby mode, and the house is heated by means of a heat accumulator, which transfers the accumulated heat energy to the radiators. If there are no heat accumulators in the system, the hot liquid will heat the room uncontrollably, which will cause it to overheat and make it necessary to open windows to lower the temperature. This will mean that the boiler heats the street, and fuel resources are wasted. Use of the heataccumulator will help to avoid such situations and will provide an economical fuel consumption.

Species

Classification of heat accumulators is carried out in two ways: functionality and the principle of thermal efficiency.

Functionally, the devices are divided into two types.

- Accumulative batteries for heating systems, it is necessary to connect only radiators, and can function both on water and on antifreeze. Such models will be the best option for arranging a budget heating system and can be used for additional connection of “warm floors”.

- Heat accumulators for heating and hot water supply, along with heating, it is necessary to connect plumbing fixtures to hot water. Only water is used as a heat carrier in such models. The use of antifreeze is not recommended due to the risk of mixing fluids in case of emergency situations.

According to the principle of thermal recoil, batteries are also divided into two types. The first type is represented by static models involving the direct heating of the coolant inside the tank, which can be carried out with the help of heating elements. The second type includes dynamic devices that work in conjunction with a heating boiler, and which receive already heated coolant in a storage tank. As a result, the coil located inside the tank is heated by hot water,coming from the boiler. Dynamic models are often equipped with three-way valves, valves and automatic devices. This allows you to adjust the temperature of the water in the batteries and the “warm floor” system through valves that control the water circuit.

Criterias of choice

Before you start purchasing the heat accumulator, you should decide on the complete set and size of the storage tank. The calculation of the required volume should be based on the power of the boiler and the compliance of these indicators with the parameters of the drive. When determining the required volume, it should be borne in mind that according to the owners of heating boilers, each kilowatt of power should account for 50 liters of capacity. Thus, for a 2 kW boiler, the capacity of the heat storage tank tank should be 100 liters.

After the required tank size is determined, you can proceed to the choice of model according to functional features. If the owners are often not at home, it is advisable to purchase the most automated model. Such a device will regulate the heating temperature of the coolant itself and turn off the equipment in the event of a breakdown or accident.When choosing a heat accumulator for operation in high-pressure pressure systems, it is better to dwell on models equipped with torospheric covers.

Manufacture and installation of homemade device

The modern market of boiler equipment offers a huge selection of heat accumulators of both Russian and foreign production. However, in the absence of the possibility of acquiring a factory model, it is possible to make the heat accumulator with your own hands. The simplest version of such a device would be an ordinary barrel, equipped with inlet and outlet nozzles, and wrapped with insulating material. The effectiveness of this design will be small, but for heating a small brick house, it is quite suitable. For the manufacture of the tank will require sheet metal and welding machine. After the tank has been welded, 4 nozzles slam into it: two for supplying water and as much for returning it.

Inlet and outlet connections should be located on opposite sides of the tank. Then, a coupling with a thermal sensor and a safety valve embedded in it is welded into the upper part of the tank.Next, the insulation is settled and the drive is installed in place. In the absence of a welding machine or skills to use it, you can take the capacity of the refractory plastic. In order for the tank not to lose its original forms during operation, it is recommended to place it in a specially made lattice type frame. The role of the factory coil can perform the usual corrugated metal hose.

Installation of the heat accumulator does not require special skills and can be performed independently.

To do this, you must strictly follow the installation rules and perform a series of actions.

- Make a detailed diagram of the heating system, noting on it the features of the layout, the size of the rooms and the number of floors.

- When moving the coolant in a natural way, the placement of the storage tank should be made directly next to the boiler.

- When connecting the boiler and the pipeline, it is necessary to completely seal the joints, using synthetic sealants recommended for these materials.

- The air temperature in the room where the equipment is installed should not fall below 10 degrees.

- The installation of the connecting pipes must be carried out in such a way that in the event of an accident, access to them should be open and not blocked by the device itself or other objects.

- Placement of the buffer tank should be strictly on the same level with the boiler. Higher drive locations are not allowed.

- After installing the pumping equipment, it is necessary to fill the system with water and make a test run. When a leak is detected, it is necessary to drain the water from the system and take steps to eliminate the leakage. Then re-fill the system and restart.

Heat accumulators for solid fuel boilers are an important link in autonomous heating systems. They are able to heat the house and provide the owners with hot water even when the device is turned off, which significantly reduces fuel consumption and significantly saves the family budget.

To learn how to install a heat accumulator for heating boilers, see the following video.