Heating boilers for a private house with wood and electricity: design features and advantages

Heating a private house today is an important issue for any owner of this type of home. In addition, large-scale construction of cottages has led to the development of the segment of heating mechanisms. Increasingly, the owners of suburban buildings are installing modern autonomous-direction heating systems in order not to depend on water heaters on gas or something else. The main reason for this is the high cost of blue fuel or the fact that the house cannot be connected to the centralized gas supply.

It is for these reasons that universal combined boilers for electricity and firewood become in demand. They are quite profitable, because they can act on different types of fuel.It is possible to use such boilers almost everywhere, they do not need any special conditions for stable operation.

You can work with them also for the reason that there is no need to be afraid of pressure drops, power cuts or lack of gas. If problems are observed, simply switch to another fuel source. By the way, such a solution can work on different fuel solutions - on gas, on solid fuel cells, on liquid fuel or electricity.

Device and purpose

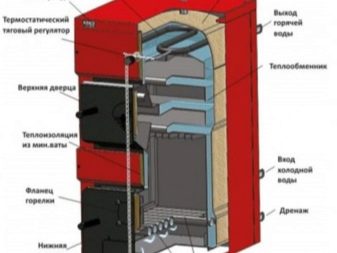

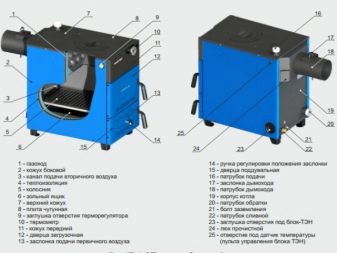

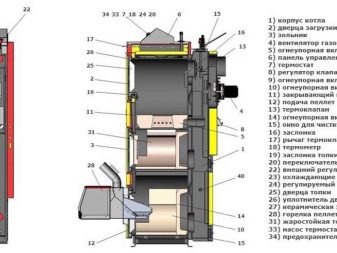

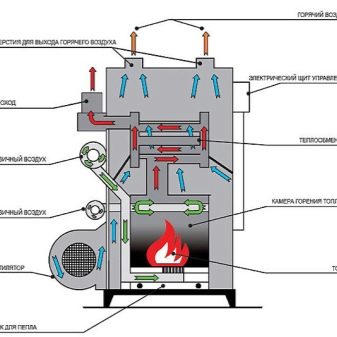

To date, the combined version, operating on wood and electricity, is significantly different from the models that work exclusively on solid fuels. Their main feature is that right in the tank itself, where the heat carrier is located, the heating element is installed.

Usually in the lower compartment of such a device there is a fire-box where firewood is burning. All thermal energy that is released, heats the coolant, which then enters the heating circuit.

In the considered devices, devices are installed, including the heating elements in the automatic mode, so that the thermal carrier is heated to a certain predetermined temperature.But it will be so when there is no power when solid fuel elements are burned through. That is, it turns out that when the wood burns through, the amount of heat decreases, the temperature, respectively, too, and immediately begins heating, and the boiler automatically switches to work from electricity. It should be said that in these moments there is absolutely no need for a person to penetrate, because everything is regulated and switched only with the help of automation. This allows you to be sure that the switch will occur at exactly the right moment, and the efficiency will be maximum.

During the combustion of solid fuel elements, power is released in the region of 25-32 kilowatts. This should be enough to heat the building, whose area is 100-110 m2. And after that, the desired temperature will be maintained by the electric type.

If we talk about the structure of such a boiler, then it usually consists of the following components:

- firebox;

- housing;

- gas outlet;

- chimney;

- grate;

- damper;

- various doors: blower, air, furnace;

- tan;

- regulator.

These are the main elements. In fact, the constituent parts of such a boiler are much larger.It should be said that the heating boiler has a similar design so that the minimum temperature is maintained in the circuit, and then when the wood is placed in the furnace extremely unevenly. Such a solution is designed to protect the device and, in general, the whole mechanism from the fact that it can freeze. You can simply turn off the fully heating boiler and not be afraid that the pipes are frozen. Such a hybrid apparatus can also have a low power consumption in order to simply maintain the lowest temperature in the mechanism.

Principle of operation

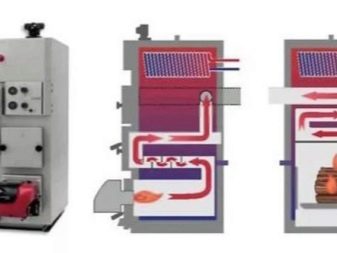

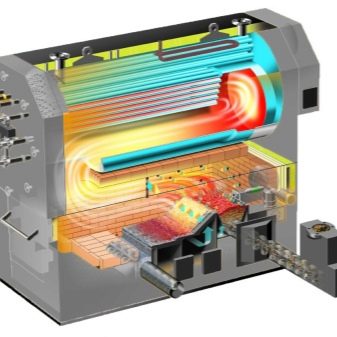

It should be said that a similar boiler works with very simply. A heat generator that runs on electrical power simply triggers an electrical heater. Such heaters in the form of tubes begin to heat the thermal carrier in automatic mode. This scheme of heating water is also presented in the so-called boilers. This process, as a rule, is automatic and is controlled by a special device. Manually, you only need to put solid fuel in the furnace.

While the heating element is heating the water, it is necessary to put firewood in the firebox and set it on fire. The special combustion chamber is usually located at the bottom and transfers heat to the heat exchanger. When the temperature of the thermal carrier rises to a certain point, the heating element simply turns off, and then the heat is generated exclusively by firewood. In some cases, the burning of wood can reach 30 kW, if we talk about power. Although usually the indicator starts from 8 kW. 30 kilowatts to heat the house, should be enough with a vengeance.

After the wood burns out, the heating element starts up again and simply maintains the temperature at the required level. If there is a desire, it is possible to carry out a fire chamber only with the help of firewood, and teng should be used exclusively to insure. When the wood is finished, only with the help of the heating element will the heat be supplied. But here the principle of “two in one system” can also be used. The idea is that wood and electricity are used simultaneously. It will be quite convenient at night, when it is not possible to add firewood to the fire chamber on a permanent basis. A combined variant is usually used - in the evening a person lays in the firewood, and the heating element is activated to maintain heat.To make it so, you should not include it in full.

If a person prefers to use electricity for heating, and wood serves as a backup option, then it becomes even easier to maintain the device. With the help of automation just set the desired temperature and all. It will be supported by the teng and there is no need for a person to interfere in this process at all. If the supply of electricity stops, which is possible, simply put the wood in the furnace and the boiler starts to work on this type of fuel.

When operating the device on solid fuel, it should be ensured that the valve located on the chimney is constantly open. If the boiler works on electric energy, then the position of the valve does not matter and can be kept closed. In general, as you can see, the operation of such a boiler is very simple.

Advantages and disadvantages

It should be said that this category of devices has its own advantages and disadvantages, on which it is necessary to stop your attention.

If we talk about the benefits that such a combined boiler has, then it should be called:

- Long time operation.If a boiler of this type is properly operated, then it will be able to qualitatively perform its functions for at least 20 years.

- Autonomy. It makes no sense to control the operation of such a boiler, since the automation installed in it will perfectly control its operation. Especially when it comes to work from the outlet. Heating with the use of the heating element is limited to the uninterrupted transfer of electrical energy.

- Competent design. Heat is distributed as efficiently and efficiently as possible, and energy losses will be very low, which makes these boilers an excellent and effective solution.

- Efficiency. Electricity today is one of the most affordable types of energy, however, like wood. As a solid fuel alternative, you can use coal or briquettes or pellets. In general, if we talk about efficiency, such a boiler simply has no equal.

- Versatility. Such solutions are universal, because you can use any of the 2 types of fuel at will.

By the way, here it should be said that such boilers will be an effective solution if they operate at partial power.

But with all these advantages, combined solutions also have disadvantages. But they have any equipment for heating, which in general is not surprising.

If we talk about the shortcomings, it should be called:

- Great mass. Boilers that are made of cast iron, have a weight of a couple of hundred kilograms, or even more. To install such a boiler, you must first make a cushion of concrete to strengthen the base of the floor. Due to the fact that the device is heavy, there are no models that can be mounted on the wall. There are only solutions for floor mounting.

- Difficult design. Combined versions are distinguished by a rather complex structure, which leads to higher prices for installation and maintenance.

- Low power component. Usually the power of electric heaters should not be greater than the capacity of the camera, where it is necessary to put firewood. The capacity of the firebox for firewood is usually from 6 to 25 kilowatts.

- Takes a lot of space. As a rule, in order to install such a boiler, it is required to allocate a separate boiler room for this - a boiler room, where fuel reserves should be stored.

Judging by the reviews, most users believethat the acquisition of such boilers is an absolutely justified step, even though the cost of models of such boilers is about a third more expensive than conventional devices that use only solid fuels. And even in this case, it is still more profitable than installing one or another boiler separately, and then changing it to another.

Criterias of choice

As mentioned above, the characteristics of such a device are important when choosing a device, because manufacturers offer a large number of combined models of heating boilers operating on both wood and electricity. Any such electric boiler has a different configuration and performance.

Before buying this option, you should think that it will be better for your home and pay attention to the following characteristics:

- Dimensions and weight of the device. If the boiler is too heavy, it may be necessary to reinforce the surface area with a concrete screed to install such a boiler.

- Power. It all depends on the type of fuel used. It is best to understand in advance what the device will work on.

- The size of the camera with the function of the firebox.The volume of a given compartment depends on how often it will be necessary to put solid fuel in the boiler.

- The number of contours. A number of options has an interesting feature - water will be heated only with the help of the heating element. It is best to purchase models where the coil is built into the furnace chamber.

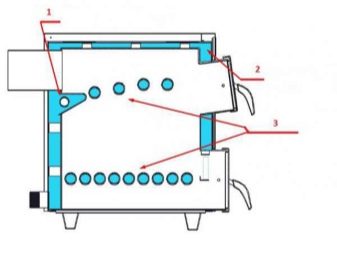

- Material manufacturing heat exchanger. As a rule, there are two options - either steel or cast iron. Steel solutions oxidize quickly and corrosion appears on them. But they are lighter in weight and rather well resist sudden temperature changes. Cast iron is excellent in resisting corrosion, but it also heats up for a long time. Of the disadvantages it should be noted a large mass, as well as the fact that with a large temperature difference can easily become covered with cracks.

- No noise. Installation of special valve ensures quiet operation of the device.

- Grid-irons They are made from different materials. As a rule, from ceramics and cast iron. The latter are more heat-resistant and suitable for the combustion of various solid fuel elements. Apply cellular iron grates coated with ceramics. Such solutions are suitable for bulk options that consume more oxygen when burned.

Quite good are the boilers of the “Cooper” line, and more specifically, this is the Zota Master 20 model.

Acquisition of boiler equipment working on wood and electricity for home - the excellent decision from the point of view of universality and economy of money. In addition, currently these types of fuel and energy are considered the most affordable. Of course, such boilers have a number of certain disadvantages, but they are more than offset by the advantages and high power at low costs. That is why boilers operating on different fuels are by far the most interesting solution when compared with other heating appliances, boilers, heating systems, and so on. Their simple design makes it possible to ensure maximum efficiency when heating a house, while using the minimum amount of energy resources.

For information on how the Traian TR-18 and Ten combined heating boiler (wood + electricity) works, see the video below.