Waste oil heating boilers: device and installation tips

A variety of substances can be used as fuel for domestic boilers, but not all of them are equivalent. Along with the traditional solutions, the search for alternatives is increasingly being pursued. One of them is waste oil.

Special features

Waste oil boiler is attractive because such fuel is considered one of the cheapest compared to others. In practice, it can be used as an artificial and natural oil.

It does not matter how it was used:

in cars;

in the rolling stock of the railway;

in culinary and construction equipment.

The burning of such waste oils invariably produces a large amount of heat. In addition, the oil boiler can be assembled by hand.It is especially attractive for heating of outbuildings, such as garages and utility blocks. But it should be borne in mind that such systems have common to all liquid (as well as specific) positive, negative sides. Need to make out this point in more detail.

Advantages and disadvantages

Since the oil heaters themselves are inexpensive and use cheap fuel, they pay off rapidly. Self-assembly is even more profitable (of course, with strict consideration of all technological requirements and proper maintenance, but this will be discussed in the following sections). With proper assembly and sensible setting, oil burns completely, it does not form toxic products. Oil boilers contain a very small amount of parts, which not only simplifies assembly, but also reduces the likelihood of breakage. Importantly, the rate of warming up of both the equipment itself and the room where it is installed is very large.

But it is worth considering the probable problems. So, oil boilers quickly burn out oxygen. Therefore it is necessary to put a lot of effort into creating good ventilation.The use of waste oil leads to frequent clogging of boilers, and they will have to be serviced and simply cleaned more often than other samples. Boilers of this kind allow the use of not only certain types of natural or synthetic oils, but also their combination.

But the use of various raw materials causes a high risk of the presence of specific impurities. Therefore it is necessary to supply the area supplying fuel into the boiler with a special filter. Due to the rapid clogging of the cleaning system, it needs to be replaced regularly. Thus, the obvious weaknesses and strengths of the oil boiler are due to the specificity of the fuel used. You can more accurately characterize the system, if you understand the features of its device.

Kinds

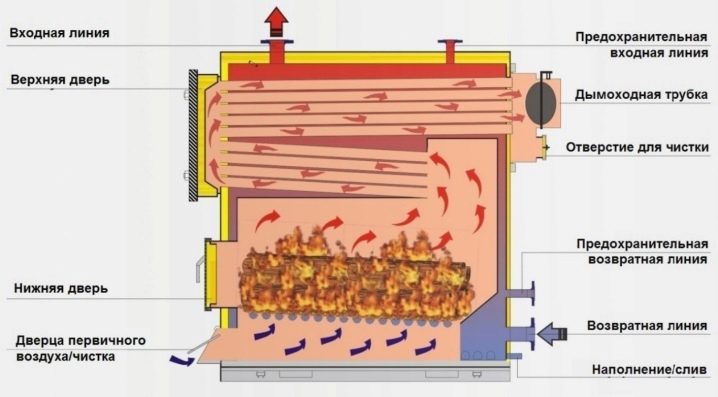

Boilers for working out can heat the air directly. Such systems are notable for their impressive performance and can warm up the air for a long time even in large houses. The peculiarity is manifested in the fact that the tank with fuel is most often placed on the floor, and the heating unit is fixed to the wall or even to the ceiling. In addition to this version, there are oil boilers with a water circuit or even with a pair of such circuits.The single-circuit apparatus is able to supply hot water only to the heating system, if not to use boilers, distribution equipment.

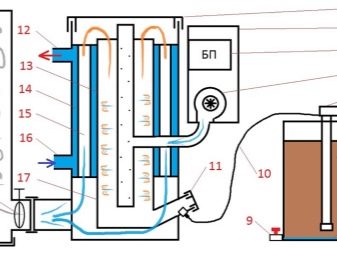

Industrial models of oil boilers are often equipped with automatic control units.

All such modifications are not air, but water ones, and various tasks fall on the automation:

air temperature monitoring;

heat carrier heating check;

pressure check in the heating circuit;

error reporting

Principle of operation

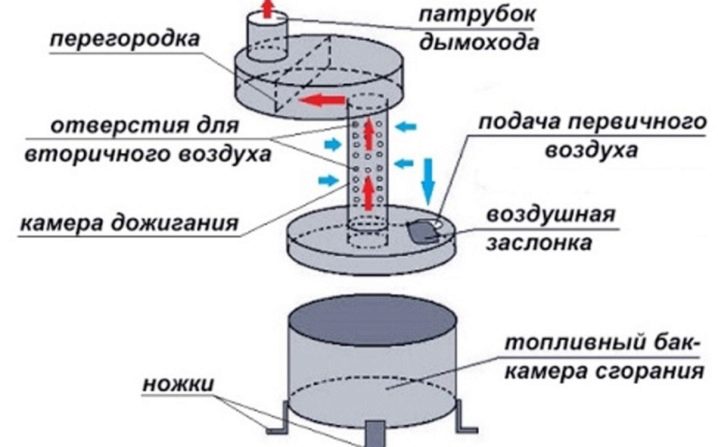

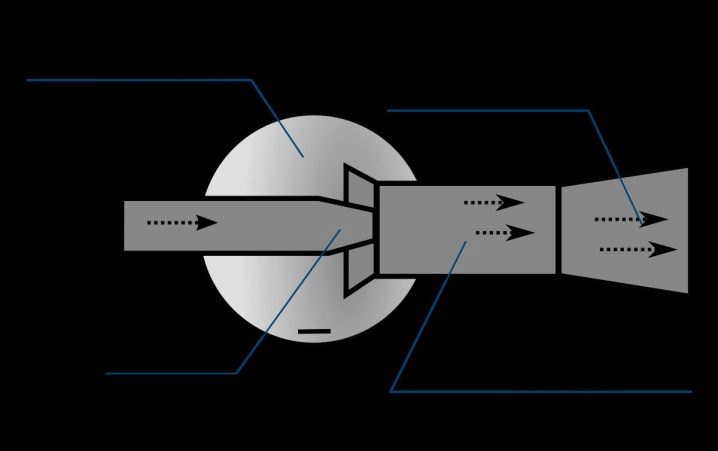

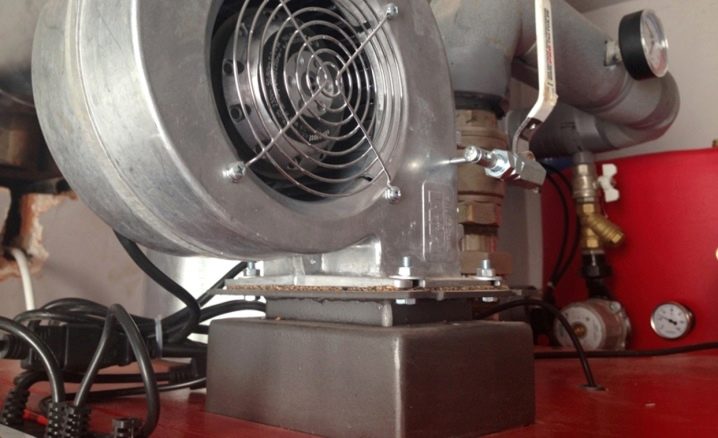

Oil-fired boilers are equipped with two compartments: the first prepares the oil for operation, evaporating it, and the second burns it. Fuel poured into the tank is pumped to the evaporator using a pump, inside which a rather high temperature is maintained. The pipe gets steam to the combustion chamber. Another tube is introduced into this chamber, through which the fan forces air mixed with the oil vapor.

The result is a combination of substances that burns almost without the formation of foreign components.

If you do not preheat the fluid, the system will not work.

It is important to consider that the waste lubricating oils contain a lot of impurities.

Before burning, they are split into simple hydrocarbons, resulting from the oxidation of which:

carbon dioxide;

water;

gaseous nitrogen.

All of these substances (with the exception of CO2, and even in certain conditions) do not pose a danger to humans and other living beings. But in order to ensure the actual safety of the exhaust gases of oil heating, it is necessary to strictly observe the temperature limits. As established by chemists, hydrocarbons can oxidize at 100% only at 600 degrees. If you deviate from this figure by 150 degrees at least in a smaller or in a big direction, the result of burning will be the release of a number of substances, contact with which without a gas mask is not recommended. This places high demands on the accuracy of the design of burners and nozzles of water-heating, atmospheric boilers for waste oil.

You can calculate fuel consumption by dividing the area of the heated space by 10. Note: this only gives an estimate of the maximum performance mode. In some cases, installation of several boilers in the form of a cascade is the most practical.The level of performance (and, of course, oil consumption) is directly related to the quality of the installed burner. Observing these principles makes it easy to achieve a good result.

Learn more about how the boiler works on waste oil, you will learn from the video below.

How to do it yourself?

Find drawings and diagrams of homemade oil boilers is not a problem now. The main thing is to properly evaluate their properties and their capabilities. In many cases, mistakes in designing and building a boiler are extremely expensive. In order to evaporate the oil as efficiently as possible, many recommend placing bowls of thick metal, heated to high temperatures. In these bowls mining is served in very small portions, literally drops. It is worth a drop to touch the steel surface, as it instantly evaporates and is carried away through the duct into the combustion chamber.

The mouth of the air tube is equipped with an impeller that forms a whirlwind. Only under this condition the mixture of oil and air is retained within the working compartment for a long time.

Everything seems to be simple, logical and without extreme complications. But one problem arises: how to warm the bowl so that it evaporates the liquid that has got on it immediately. The simplest option is to place it inside the wick, which is soaked in a randomly selected combustible liquid.

When the wick is laid, the bottom of the bowl is covered with gasoline or diesel fuel, which is set on fire. Having achieved the warm-up of the metal, start pumping oils. The relative simplicity of this technique turns into an increased danger. The next important nuance: let there be a bowl that is already heated in one way or another, but you need to organize an oil approach to it. The materials circulating in open sources mainly describe the jetting of flammable liquid.

Judging by experience, such systems work, but their danger increases sharply. The jet can not burn completely, inevitably released a lot of toxic substances that can get into the room.

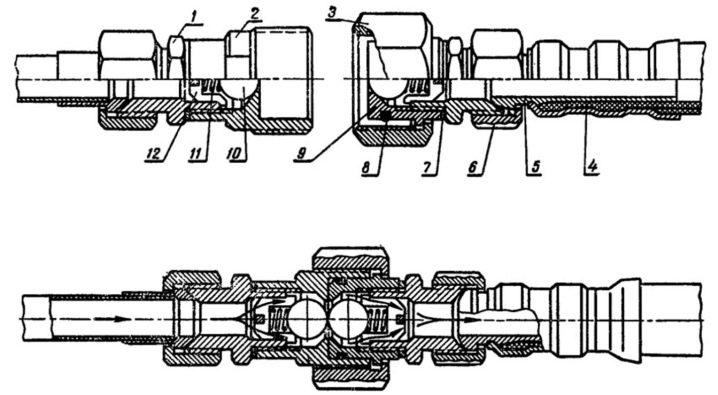

To feed the oil with drops, you will need:

a set of tees;

nipple;

a piece from a hospital dropper.

Choose a hose on which the function of the oil line will fall. One end of this hose is equipped with a filter that lowers the concentration of harmful substances in the fluid.Will be suitable for the solution of such a problem a typical full-cycle car cleaner. All devices that are designed for partial cleaning, obviously unsuitable.

The cleaning unit should be changed about once a month, and in case of intensive use with insufficient quality fuel, even more often.

Automotive filters are equipped with thread manufacturing.optimized for fixing in cars, which can cause some difficulties. It is required to use a piece of oil-resistant hose of the required diameter, and put it on top of the filter. Such a makeshift unit communicates with the oil pipe through the fitting. Check in advance if there is excess oil in the transfer hose. If it is created, the drip passage of fluid will not work.

Waste fuel boilers can also be made by pyrolysis. Afterburning increases the burning time of a single portion of oils. An alternative is only the use of a pump of strictly specified power, capable of producing a well-measured mass of oil. But the complexity of this solution does not allow to implement it in artisanal conditions.Moreover, even in factories, a simplified version is mainly used, when the dosage of fuel is produced by a choke, tees, and a nipple.

It is very important to ensure that the temperature of the used oil is between 10 and 20 degrees so that it flows well. Otherwise, the house will be filled with children and it will not be possible to achieve stability of burning. Once and for all set some optimal mode will not work. It is only necessary to change the composition of the waste oil, submit it with a different temperature, and you have to choose drip pumping settings from scratch. The supply of fuel directly from the dropper to the firebox is impossible.

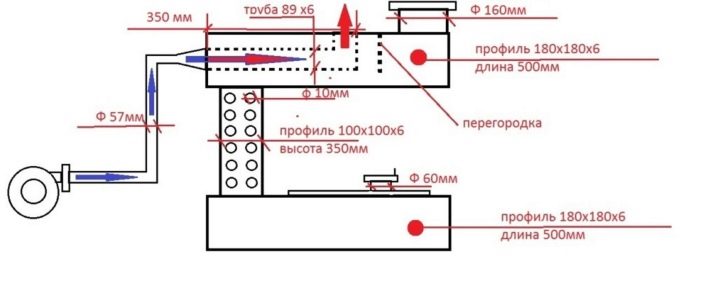

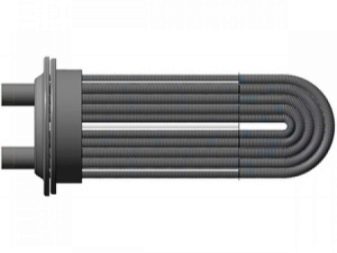

Initially, the oil is fed into the funnel, which is connected to the pipe, through which it goes into the bowl. If the boiler is connected to water pipes, it should be equipped with a pump so that the coolant circulates more efficiently. Sometimes a built-in heat exchanger is created, similar to the letter U. It is placed in the upper part of the furnace and is connected to an external tank for hot water. There is also a scheme with the location of the heat exchanger on chimneys.

When self-fabricating an oil boiler, sheets of steel with a thickness of 0.4 cm are used.It is also recommended to use valves with an internal diameter of 1 or 0.8 cm, pipes, sgony, tees.

In addition to these parts, the work will require:

steel adapters;

pumps;

compressors;

expansion tanks;

high resistance sealants;

welders;

asbestos cloth;

LBM.

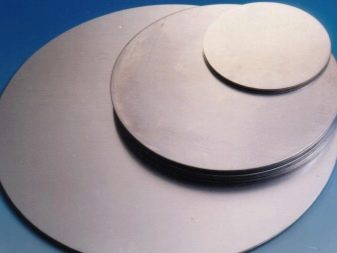

Instead of sheet metal, you can use large sections of pipes with thickened walls. To warm the garage, it is enough to use two pieces of pipe: with a cross section of 50 and 20 cm, respectively. Additionally, apply a pair of round plates with a thickness of not less than 0.3 cm.

For your information: if more powerful heating means are required, use parts of increased dimensions. The workpiece under the body of the coarse pipe is cut to a height of about 1 m, and a smaller billet - to a height of about 0.2 m.

One of the plates will become the bottom of the case, and the other - its cover. Accordingly, they cut a hole in the chimney and a small pipe. It is desirable to strengthen the bottom by welding another plate to minimize the risk of destruction. The bottom of the case is complemented by legs formed from reinforcing rods. At the bottom is the tank, and the side - the door.

Installation

A key requirement for the installation of boilers running on waste oil is compliance with fire safety standards. It is forbidden to use them without an equipped chimney. To protect the ceiling from overheating use special covers. It is necessary to provide a special damper, with the help of which it is possible to block the thrust and to avoid excessive penetration of cold in the event of a boiler shutdown. Both factory and home-made constructions consume oxygen abundantly, therefore care should be taken to ventilate the boiler room.

It is recommended to install boilers on a stone backing or on top of heat-resistant tiles. Forbidding with wooden and plastic elements is prohibited, only coloring with heat-resistant coatings is permissible. Since the waste oil will have to be continuously refilled, it is worthwhile to prepare in advance the ways of access to the boiler. Given the strong heating of the equipment, it is undesirable to place it where there are easily lit or damaged objects. Of course, the heating device should not create any obstacles to the movement of people.

Sometimes under the boiler create a platform of concrete, which is equipped with a small rim.This is an element of passive safety in the event of a spill. Fill the concrete mass must be strictly on the level to eliminate errors. The best location for the automatic control unit is on the wall. But on top of the lid of the boiler itself it is impossible to install it, otherwise the microcircuits will overheat and fail.

The hoses through which the oil is pumped, as well as the electrical wires must be removed from the surface of the boilers. What happens even if they are briefly touched is easy to guess. The installation of a thermal sensor is performed inside the tube located to the side of the boiler. The tank, where the waste oil is poured, is placed no closer than 70 and no farther than 150 cm from the heater. The oil pump adapts to the neck of the drums used.

The diameters of the chimney are equal to the output from the boiler, although sometimes they can be more. Do not make chimneys above 5 m, it almost inevitably causes instability during combustion. It will not be possible to provide the full power of burning fuel. It is recommended to nail steel sheet before burning. A sandbox in the room where the boiler is placed does not hurt either.

The minimum diameter of the chimney is 11 cm, constrictions are unacceptable. It is recommended to make horizontal fragments only in the case when it is impossible to do otherwise. When the smoke channel is led through the wall, it should be pierced strictly at an angle of 45 degrees. The remaining fire and explosion safety requirements are the same as for the coal or wood-burning stove. If you can reduce the number of welds, you should do so.

User's manual

Using an oil boiler for heating a private house can be a very compelling affair. But only in the event that does not violate the basic principles of operation. In the case of penetration of water into the fuel mass, it begins to burn rapidly. You can avoid fire if you immediately apply a carbon dioxide fire extinguisher. Of course, it should be placed directly in the boiler room.

Cleaning of the combustion chambers is performed at least once in 24 hours. To do this, use a special scraper, which comes with factory-made products. Cleaning is performed after stopping the boiler and the fuel is completely afterburning to the dry ash phase.Essence: the boiler is switched to the ignition mode (if there is no special shutdown mode). After the extinction of the fire, it is necessary, after waiting 5 minutes, to open the ashpit and clean it.

Next, the boiler is ignited in the usual way, automation is started. Chimney should not be cleaned. It is quite rare to clean the tube through which the oil is supplied, and only when using low-quality fuel. Inspect this part as soon as signs of poor oil supply are detected. The cover of the boiler is removed, turn it over and inspect the item.

For cleaning use:

steel reinforcement;

thick drills;

wire;

brush made of metal.

Automatic need to blow from the dust. Regularly required to assess its condition. Having found the accumulated dusty mass, it is necessary to immediately eliminate it, even when the deadline has not come formally. Premises with high humidity are equipped with automatics in such a way that it appears behind the wall. The wiring is led out through this wall, if there is the slightest opportunity to do so.

Important: all modifications made in the factories of boilers can not be changed arbitrarily. In the event of any changes in their characteristics, design parameters, arbitrary change of fuel, all responsibility lies with the consumer.It is forbidden to allow children, the elderly, persons with disabilities and pets to the boiler. You can not also leave them in a room with a boiler unattended.

Ignition begins with the opening of the faucet, after which the bottom of the combustion chamber should be covered with a layer of oil from 0.5 to 1 cm. If it is smaller or larger, the boiler cannot be started. If necessary, quick ignition there add 50-100 g of kerosene, a special liquid or diesel fuel. Usually, ignition is carried out using a wick of paper or made from rags. This wick is set on fire and lowered through the ashpit or through the upper hatch to the very bottom of the working compartment.

Further, when the liquid lights up:

start the fan, providing boost;

make sure that the oil does not burn without a boost;

close the lid on the ash pan;

wait from 120 to 300 seconds to boil the oil and the boiler went into operation.

It is possible to reduce the negative effects of using mining, if you defend bought or used oil.

Do not lower the fuel supply pump to the bottom of the tank. If done so, a precipitate may enter the boiler. It is advisable to withstand a gap of 0.1 m.Experts believe that it is worth at least once a month to clean the tank from the blockages that accumulate there.

To turn off the boiler, turn off the tap and wait for the fuel to burn out. It is possible to disconnect the blowing fan at least 5 minutes after the final burnout of the fuel. If the purge of the chamber is insufficient, a lot of smoke and soot is formed. Once in the control unit, they disable it.

It is categorically unacceptable to kindle an oil boiler with acetone, automobile or aviation gasoline, solvents for building paints, essential oils and other volatile liquids.

Periodically, the bottom of the combustion chambers is cleaned of gradually combustible non-combustible substances. The worse the fuel, the more often such cleaning is necessary for consumers. It is possible to reduce the amount of slag, if you refuse synthetic or transmission oil. In the event of the occurrence of an unusually large amount of soot and soot, immediately stop the boiler and call in specialists. Also, the reason for the urgent repair is unusual noise and unnecessarily frequent extinction.

It is unacceptable to connect a waste oil boiler to a heating system that has less power than itself.With insufficient heat consumption by radiators, the system wears out extremely quickly. It is forbidden to add diesel fuel to the heated chamber. Also extremely dangerous practice is the use of mixtures of oils with high-octane fuel. This can provoke an explosion or simply accelerate wear and tear many times.