Installation of heating boilers

Heating boilers can be very different, but the result of their work depends not only on the type, but also on their quality installation. It is necessary to carefully study all the technical nuances and subtleties, as well as carefully prepare the places for the installation of equipment. But first things first.

Requirements for furnace

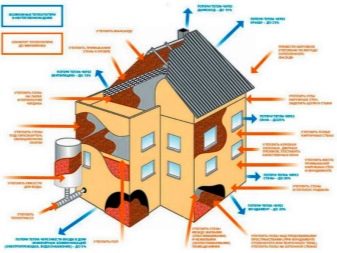

It should be started not from the boiler itself, but from the place where it is installed, that is, from the furnace room (it can be called differently - and the boiler room, and even the boiler room, but the essence does not change). Since all types of heating, including electric, are fire hazardous, heating devices must be surrounded by complete protection systems.If you want to get a new boiler in a private house or planning to build from scratch, you need to be guided by the norms of SNiP 42-01-2002. The references to the 1987 standards found in earlier sources should not be seriously considered.

Knowledge of basic norms is important when arranging in a two-story and one-story house, in a wooden and brick, aerated concrete and frame house. It is useful to get acquainted with the regulations even for those who order the project and the subsequent installation in a specialized organization.

There is the following gradation in power:

- systems emitting up to 60 kW of heat can be mounted in kitchens;

- when generating more than 60, but less than 150 kW, a separate room is required on any floor (for gas boilers, installation in basements and basements is allowed);

- equipment with a power of 150-350 kW is supposed to be installed in autonomous structures on the basement or the first tier, which can be either extensions or completely separate buildings.

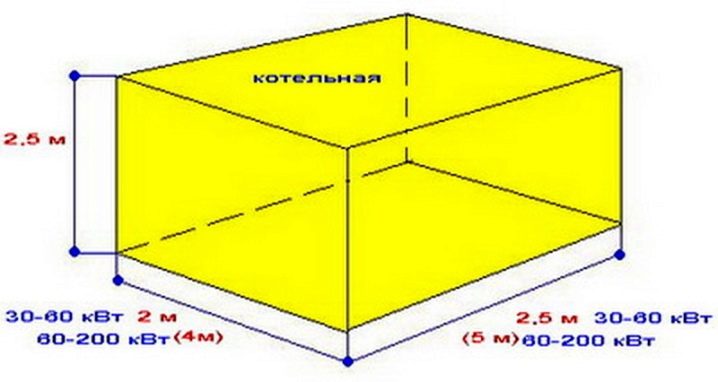

You should not understand these instructions so that only very powerful boilers should be carried out in a separate room. It is allowed to install there and very weak heating installations, if there is not enough space in the main part of the house or it was necessary to assemble the heating infrastructure together.In addition to the degree of isolation, the norms also regulate the minimum allowable amount of space. So, if the boiler produces no more than 30 kW of energy, a room of 7.5 cubic meters should be allocated for it. m by volume. Increasing the power within 60 kW, get the minimum rate of 13.5 cu. m., and up to 200 - 15 cu. m

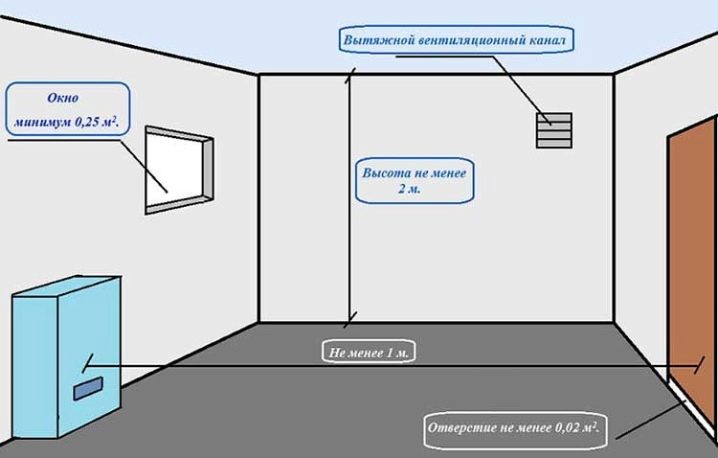

Wherever the boiler room is located in a private house, it is supposed to have good natural lighting. Required by the standard rate starts from 0.03 sq. Km. m glazing (only glass itself is taken into account, without frames, frame elements and the like). Not every window of the required area will suit, but exclusively of a swing type, with a transom or a window leaf, allowing emergency airing of the room during a leak. It is also impossible to do without a ventilation system and a smoke channel through which the combustion products will be carried away. Regardless of the type of boiler, it is necessary to supply water and sewage systems to it.

All systems that produce from 60 kW of heat necessarily imply installation in the complex of monitoring gas pollution in the room. The calculation is carried out by summing the capacities of boilers and boilers.Separate boilers are supposed to be separated from other rooms with fireproof walls, which are able to withstand an open flame for at least 45 minutes.

Based on this requirement, it is recommended to make walls of:

- cinder blocks;

- ceramic and silicate bricks;

- lightweight concrete;

- heavy grades of concrete.

If an extension is being constructed to install the boiler, it must be adjoined to an inseparable wall section, which is at least 1 m away from all windows and doors. The material requirements and degree of fire resistance are the same as for completely separate structures. A bunch of an extension with the main building is not allowed. Even if this bundle is limited only by the foundation, touching them at certain points, problems are inevitable anyway. Sometimes it is allowed with a slight mismatch of the ceiling height to the established norms to increase the size of the glazing as compensation, but this should be carefully calculated in the project.

You can not install gas boilers in the basement of wooden houses. The exception is connected with the arrangement of specially equipped separate premises. Do not use the living quarters, even if they meet other requirements. It is recommended to use fire extinguishing agents.You also need to take care of the presence of smoke detectors and signaling devices.

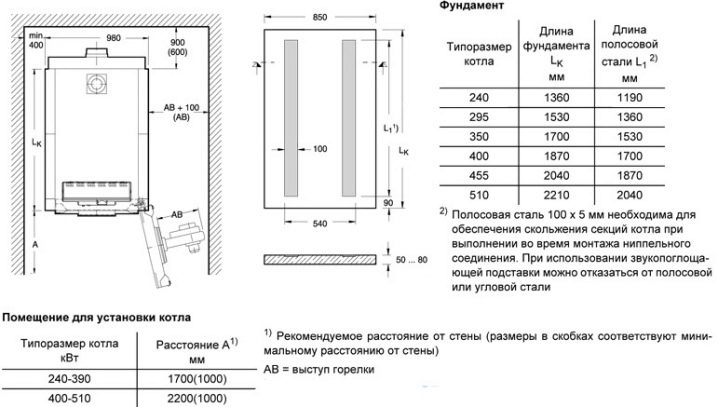

The recommended ceiling height of the boiler room is from 250 cm. Be sure to install a door with a width of 800 mm. The exchange of air with the external environment should occur at least 3 times per hour, that is, every 20 minutes all air should be updated. A backup door is allowed through which you can enter the house, but this door is made only from fireproof materials. The roof in the boiler room must be made of materials that do not support fire.

Often there are questions about whether it is possible to put the boilers in the kitchens. Usually, the strongest ventilation is created there by default, water and gas are supplied. But even these considerations do not mean that in the kitchen space there is a place for any boiler. There you need to put only a device with a closed combustion chamber. The open type of its too much harmful gases throws out.

If a model with an outdoor boiler is chosen, it is necessary to carefully check whether there is enough free space for it. Sometimes there is another question - about the installation of boilers in the bathrooms of city apartments.Theoretically, this is quite possible, but practically everything depends on the compliance of the premises with the established standards. It is not recommended to use gas heating systems in bathrooms. Due to the lack of space, the device dimensions are of particular importance.

Fundamental rules

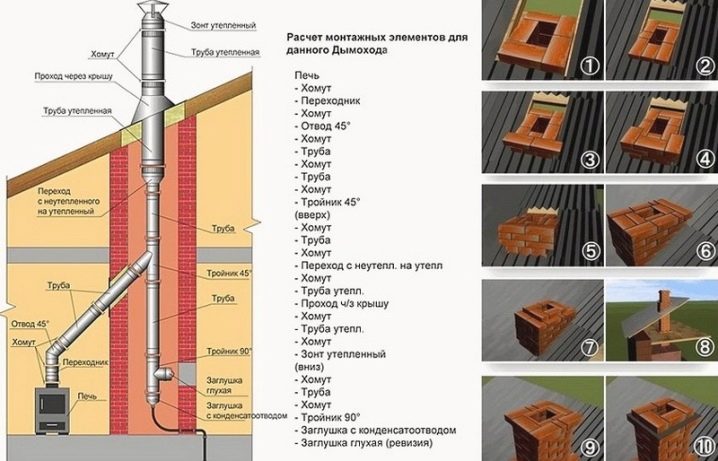

The choice of space and its preparation does not end. Installation of the boiler has its own specific rules that must be strictly followed. If gas heating is selected, the initial length of the chimney at the outlet should not be longer than 0.2 m. And along the whole other outflow line one should not put more than three main turns at an angle of 90 degrees. Failure to comply with this rule may cause delayed evacuation of combustion products.

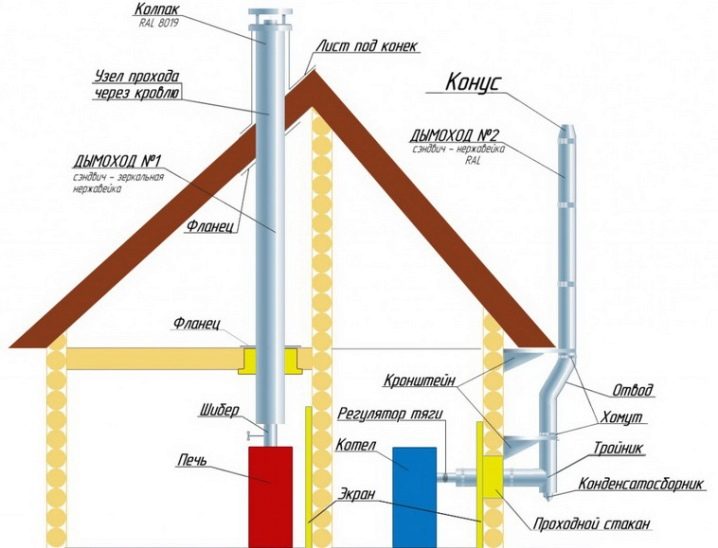

The installation of a cylindrical smoke channel made of stainless steel is preferred. Removing the chimney on the roof, you need to tighten it at least 0.25 m above the ridge. If the exit occurs through a wall or a window, it is planned to remove the end of the pipe by 0.4 m. Already during the installation process, it is carefully checked that the flue passage section is not less than the ejection opening of the boiler.The list of requirements for the installation of electric boilers is smaller, but it is imperative to find out whether the wiring was performed correctly, whether its capacity meets the established standards.

The slightest defects in the electrical network should be immediately eliminated. If the room is equipped with extremely old wiring, it is recommended to completely replace it with a new line. It is advisable to choose for the electric boiler the most dry point of the room, as far as possible from water sources and from windows. When wall equipment is chosen, check in advance whether it is strong, whether there is infection with a fungus. Connect the electric boiler (or automatic gas boiler) relies through a separate outlet, while the supply line is insured with a special RCD.

What you need to know about the chimney?

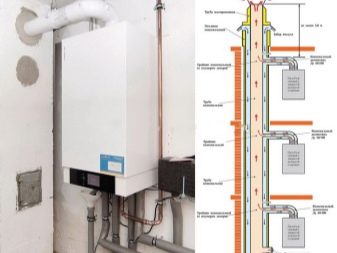

The general information about the chimney above is not enough to clearly understand its structure.

There are three main options:

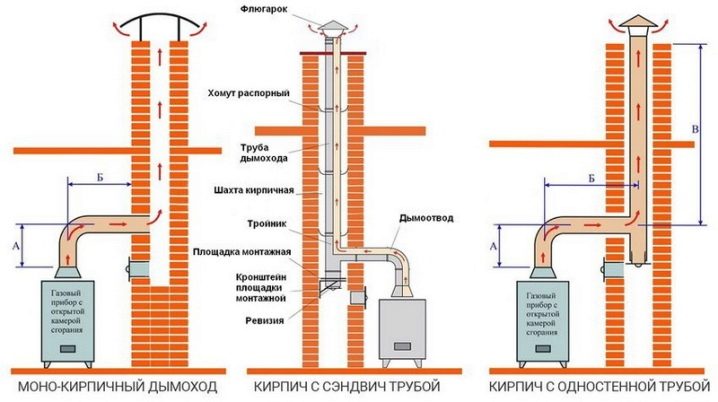

- classic brick construction;

- steel products;

- ceramic discharge units.

Brick construction allows you to drastically reduce costs compared to more modern solutions.In addition, the ceramic brick without any difficulties is experiencing a strong warming with hot gases. Even the ignition of accumulated soot is not dangerous for him. But we must remember that the brick smoke passage is heavier than other solutions. It will have to be placed on a previously prepared foundation or overlap from strong reinforced concrete.

The complexity of the brickwork does not allow to achieve an optimal result with their own hands. Be sure to invite professional masons and stoves. Inside brick communication, ventilation passages are laid in some cases. Allowed the formation of a segment of the pipe above the roof of the front brick or clinker. The minimum allowed wall thickness is 12 cm or ½ bricks.

The size of both the flue and air-pumping channels is selected to be a multiple of the brick blocks. In this case, we must not forget about the correction for vertical seams. This solution allows, if necessary, to select and insert steel or ceramic-made inserts of a round shape. To prevent excessive cooling of the discharged gases, it is necessary to introduce a smoke passage into the brickwork of the wall or place it close to it.For thermal protection of fragments going outside the house or through its unheated parts, it is allowed to use only mineral wool.

Since the main trend in the creation of modern heating boilers has been a decrease in the temperature of the discharged gas, problems may arise when using brick channels. The solution is an inserted ceramic or stainless steel contour. Full-fledged ceramic devices are suitable for boilers of any type.

If you install solid fuel heating equipment, you can not put pipes that are not designed for heating up to 600-700 degrees. Critical values for gas and liquid installations are temperatures of 400-450 degrees.

Since ceramics and heat protection wound on it absorb water, it is impossible to do without external ventilation. In most cases, pipes lead inside vertical channels formed from hollow building blocks or bricks. Ceramic drainage channels are protected from heat loss with mineral wool. From the outer shell of concrete to thermal protection should be allocated an air gap.It helps ensure proper ventilation of the protective material.

Unit selection

It has already been mentioned above that not all heating boilers are equally valuable or equally compatible with certain types of chimneys. But to take into account only these requirements is not enough, it is necessary to clarify the practical features of this or that system. There are thousands of manufacturers on the market, offering tens of thousands of models of heating boilers, so it remains to focus only on technical issues. The choice is recommended to begin with the definition of a suitable energy source, while paying attention to the economic feasibility of each solution. The required power of heating systems is about 100 watts per square meter. m

But this is only a figure for orientation, because energy consumption can vary depending on the humidity of the air and the strength of the winds, on the quality of thermal insulation and the perfection of the systems used. Even the nuances of the distribution of heating and types of structural materials at home, their thermal conductivity is very important. In Russia and other CIS countries, solid-fuel heating systems are traditionally in demand, in few places else they are so popular.But we must not forget that each boiler can absorb only such solid fuel, which the designers have provided for it. Violation of these restrictions can damage equipment and at the very least do not receive the necessary heat.

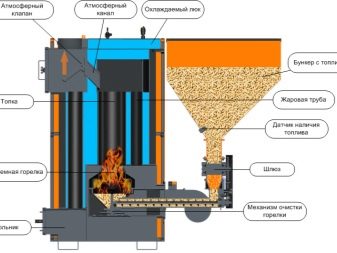

Pellet boilers should be chosen if you need a wood-burning heater, but without the need to add new portions of fuel every few hours. Usually reserves in the tank lasts for several days. But the cost-effectiveness, environmental friendliness and relative practicality of the device are largely negated by a complex structural scheme. Equipment is critical to the quality of the fuel used, which must necessarily fit a certain category. In addition, cheap pellet boilers do not yet exist.

A certain part of consumers make their choice in favor of systems on liquid fuel, which are considered very simple and reliable, able to work for decades. It is possible to mount such a boiler wherever gas equipment is allowed to use, but at the same time it is not required to register or draw up sophisticated technical documentation.The efficiency is quite high, but in cold weather it is necessary to heat the channel through which the fuel flows.

Additionally, it is possible to detect such problems:

- the complexity of the arrangement of fuel storage;

- continuously noisy burner;

- the need to order vehicles for the transportation of petroleum products from time to time;

- bad odors;

- high price at operation.

One out of every four boilers sold on the Russian market is powered by electricity. The devices, spending from 5 to 10 kW, are capable of heating the air in the big house up to 6 degrees, when there is a twenty-degree frost outside the windows. But at the slightest opportunity it is worth refusing an electric boiler and prefer systems on other principles. In general, apart from the special restrictions and availability of "blue fuel", gas boilers are the best choice. They show themselves especially well when receiving fuel from trunk pipelines.

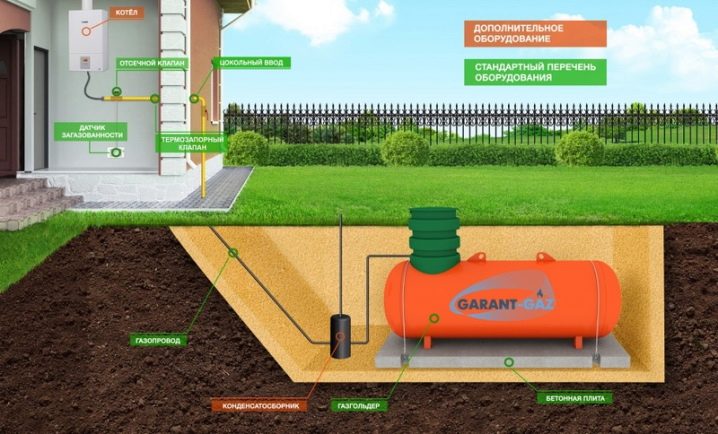

Heating through a gas tank or using cylinders is less profitable. In addition, in these cases there is a need to replenish periodically gas reserves. You will definitely have to install automatic devices that stop the passage of fuel through the pipeline in case of a leak, fire, or if ventilation fails.But the problem does not end with the choice of fuel and the assessment of the required power.

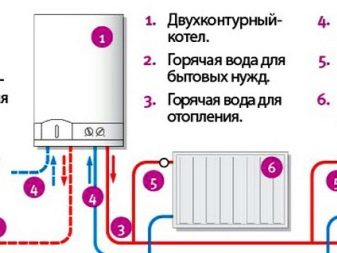

Next, you need to decide how many contours you need - one or two. Heating boilers with a single circuit are cheaper and easier to install. But by themselves they are not able to accumulate hot water, or to supply it, if necessary, to the water supply system. These difficulties are eliminated with the help of boilers or additional columns, but each such device takes up space and spends extra money. Therefore, in most private homes that are not connected to a hot water supply system, dual circuit devices are preferred by default. It makes sense to mount wall-mounted devices only where the walls are very strong.

How to install?

Wall

Despite the known difficulties, many people prefer to connect wall-mounted gas boilers. Often, such equipment is called miniature boilers. It is possible to connect a wall heat source to one system or to a combination of two circuits, depending on how it is designed. If the system is equipped with an open firebox, it will take air from the room itself. If a chimney was previously installed and used,It must be checked in advance.

Often there is a situation when the dirt falls off and closes the passage of hot gases. It is possible to connect the boiler to an existing chimney only through a metal pipe. It is necessary to find out how resistant it will be to mechanical destructive influences, to contact with heated gases and combustion products. Before turning, when the flue pipe is removed from the heater, it is required to stretch a vertical segment, the length of which will be 200% or more greater than the diameter.

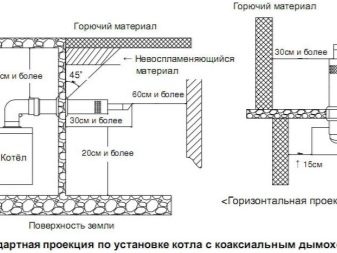

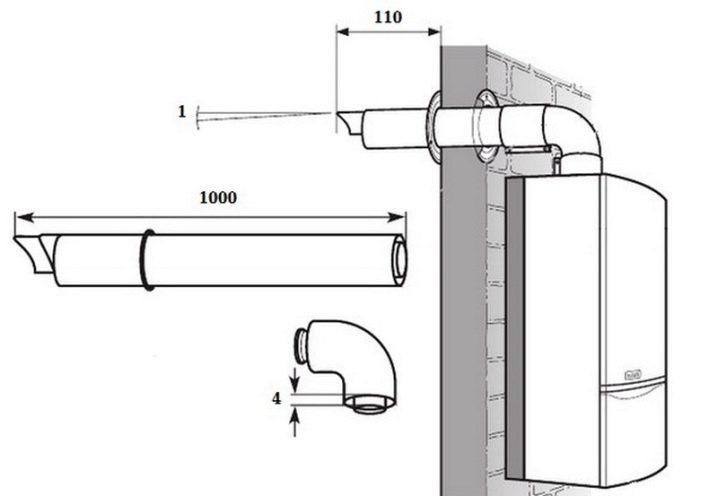

The next zone needs to be installed with an ascent, while the slope rushes towards the boiler. A closed combustion chamber involves the use of a fan. It drives the air from the street, and there is no need to connect to an individual smoke path. It is possible to draw a conclusion into the aggregate smoke channel or through a coaxial tunnel embedded in an external wall. But it is necessary to control, so that various kinds of pollution do not fall on the fan itself, and it is necessary to check this for the first time even during installation.

The recommended scheme of installation of wall heating devices on natural or liquefied gasimplies raising pipes for taking fresh air at 2.2 m from the ground with at least 1.8 cm out of the wall. The pipes with which smoke is removed are required to be tilted downwards, then they will be able to discharge condensate and not clog them. The gap from the walls to the pipe is thoroughly sealed so that dirt and rainwater do not penetrate the dwelling. It is very important that there are no obstacles in front of the outer tube for the emission of gases at a distance of 150 mm at a minimum. All structures that rise above this pipe are placed at a height of 0.25 m in order not to disturb the movement of the smoke stream.

The fact that the gas boiler is installed should be notified to the relevant supervisory service. Regardless of its type, it is required after receipt of the goods to verify the complete set with the description in the accompanying documents and in advertising booklets. Immediately need to contact sellers or suppliers, even when there is only one missing item. Before the installation of the heating unit, it will be correct to flush its pipes and internal water channels, and also to flush the pipes of the main heating circuit, if it has already been installed before.Boilers, on whatever fuel they work and whatever power they have, should be placed on level bases of solid refractory materials.

Dependent on the electrical network equipment is connected via a separate wiring circuit. In any case, this circuit is equipped with a knife switch and a voltage stabilizer. You can put any boiler with your own hands, with the exception of gas; this is the prerogative of admitted professionals.

Connection of heating equipment to the water supply system and water heating networks should be made only after the device has firmly taken its place. Most wall-mounted models are connected to the additional equipment through the end, for this purpose use the filters and fittings included in the delivery set.

Floor

In most cases, a powerful hot water boiler is too heavy to be hung on a wall. And when using relatively light structures, the floor layout is most reliable.

Both wall-mounted and floor-standing gas boilers can be installed exclusively in accordance with the requirements of the industry gas and construction SNiP.The support block, which is placed under the floor heating device and intended to protect against ignition, should not be made of asbestos cement. The fact is that this material too soon loses its strength and is harmful to health.

Prior to installation of the boiler, the following works should be completed at 100%:

- the formation of heating routes;

- installation or replacement of radiators;

- distribution of water supply at home;

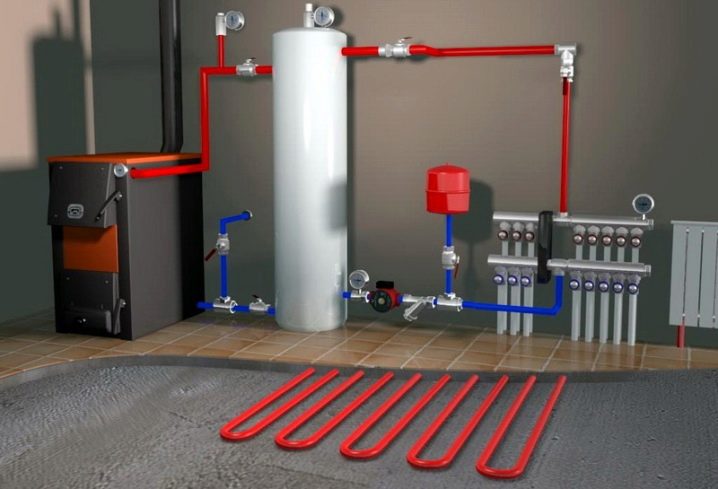

- organization of warm floors;

- installation of electrical infrastructure;

- sewage preparation.

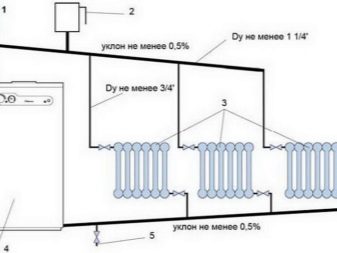

This should not be considered as a simple repetition of the requirements for the boiler room. It is impossible to postpone such construction measures to “sometime later,” they should be completed as soon as possible. The slope of all pipes during installation must comply with the technical documentation. Brackets or robust clamps are used to fasten pipes to walls.

A very important point, no less significant than the correct placement of the boiler, is the pipes that are used in the heating system. If there is a significant amount of money and the ability to solder, you can install copper heating pipes.The reliability of such lines is very high, which largely justifies their high cost. Making a harness from polypropylene or metal-plastic is much easier and cheaper, so most people choose these options. If there is a forced circulation of water in the heating system, there is enough pipes with a section of ½ inch, they will miss all the necessary fluid flow. But when it is planned to use the scheme without additional pressure, through which the coolant circulates due to the gravitational effect, larger channels are required - 1.25 or just 1.5 inches.

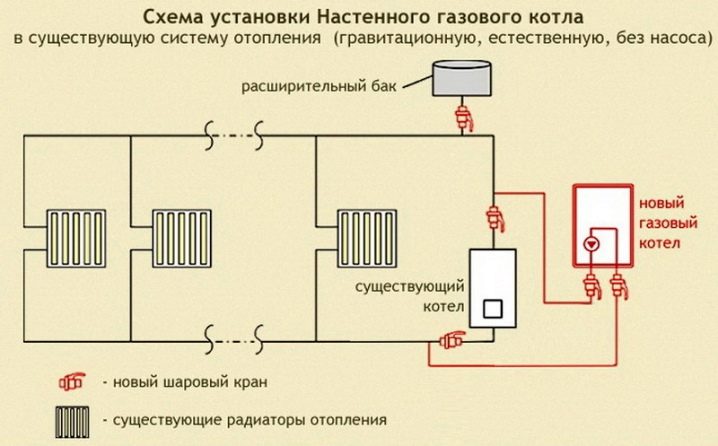

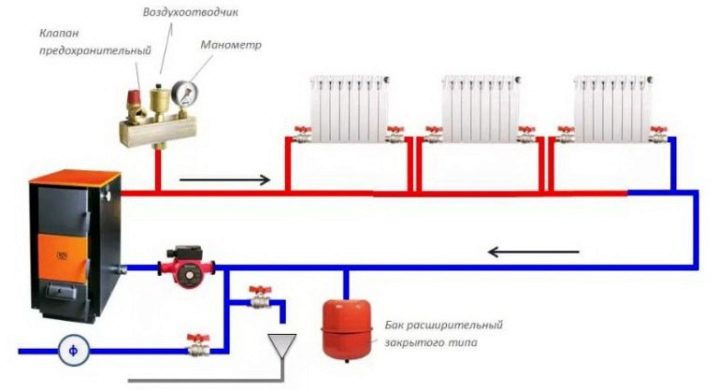

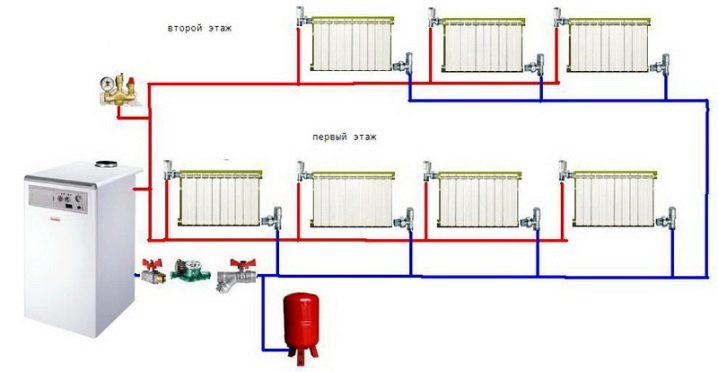

In the absence of significant experience you should not try to create a collector heating system in the house. The simplest one-pipe version implies that the heated flow from the heat exchanger rushes to the first battery, then to the second radiator, and so on to the last point. From the final battery to the boiler, the shortest section of pipe is pulled, which replaces the return stroke. It is in this segment that it is customary to mount pumps.

It seems to be simple, but it should be noted that the single-pipe water routes do not allow controlling the heat output fromindividual radiators. Adjusting the intensity of heating is possible only through the boiler itself, that is, for all rooms at once. In buildings of less than 50 square meters. m is not too significant, and because there such lines are mounted almost always. The two-pipe design is described in much the same way as a single-pipe version, but everything changes when it comes to a special circuit placed parallel to the pressure branch. Complicated design requires the use of more than in the previous case, pipes and fittings, other equipment.

The increase in complexity is justified in a very short time. It is possible to control the emission of heat into the room from a separate battery if a shut-off valve is inserted into the corresponding branch. Problems can be associated only with the fact that it is extremely difficult to deploy a system without a pump. But when it is, the quality of work is much more than the one-tube version. Assembly of the distribution pipes is made only after all the batteries are attached, without exception.

The installation of parapet boilers that do not have a chimney has its own nuances.

Such gas heaters can be mounted in the places not intended for this purpose:

- garages;

- houses in the cottages;

- apartments in high-rise buildings.

Even if there is an opportunity to organize a full-fledged chimney or use an existing one, the parapet constructions are still attractive because of their small size. They, by definition, can not be mounted in a living room or office. Fastening is allowed only on external walls, as far as possible from flammable parts. If there are lighting parts in the wall, the minimum allowable gap to them is 0.2 m.

It is forbidden to output a gas outlet pipe:

- in the glazed balconies;

- under canopies;

- in the internal and external arches;

- on balconies;

- in the entrances of apartment buildings.

Parapet boilers placed on the ground floor should have a chimney raised 0.5 m above the soil level. If in this place people or animals are supposed to pass, the pipe is lifted at least by 220 cm. The coaxial stroke is pulled where it will be convenient to control its condition. It is not allowed to have furniture, electrical appliances and inflammable products within a radius of 0.3 m from the gas boiler. Thinking through the future installation, you need to read the original instructions.When you have to pierce the stone walls, there is no better tool than a puncher with a diamond crown, which is identical in section to an air pipe.

During the work it is necessary to use special glasses and a mask to protect your health. It would be nice to buy gloves with vibration protection, as well as knee pads. It should be taken into account where the material to be extracted when drilling or breaking through the wall may fall. Sometimes it is a danger to passersby or other people's property.

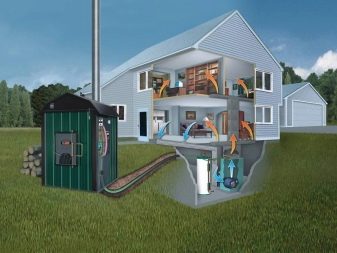

Another important topic is the installation of a turbocharged boiler. Such models are mounted on brackets. The marking of the holes for the coaxial pipe is made using the chimney bend. For drilling it is required to use diamond crowns with a diameter of 12.5 cm. This type of boilers also allows you to do without a chimney, while ensuring a stable burner operation. But there is an even more radical solution to this problem - the external placement of the boiler itself.

Such devices are necessarily equipped with a housing with thermal protection, they are able to heat up to 1000 square meters. m. To control the external boiler is mounted inside the building remote control, the connection of which with the heating equipment is provided by a specialcable.

Additional means for an external gas boiler are:

- special smoke passage;

- fire notification unit;

- radio station, sending signals about failures;

- security alarm.

Installation of external boilers is allowed even at a distance of 50 m from the main wall of the heated structure. Be sure to have to connect an automated faucet with three strokes, blocking the occurrence of condensate and tar deposits in the furnace. Another prerequisite is the installation of the circulation apparatus of a strictly specified power. When installing a street boiler on the roof, it is placed so that the bottom is 10 cm raised above the average annual snow level. Part of the systems for the most complete work is equipped with a heating unit.

Special attention should be paid to the cascade execution of the heating system. This means that a set of boilers is installed immediately (at least two), and each of them supplies heat to its branch. But the coordination of work takes place centrally. Typically, this solution is practiced to warm up the area from 500 square meters. m. However, this is an optional requirement, because the final decision is taken by the owners of the house.

It is important to understand that cascade performance is more complex than more traditional circuits. Only professionals will be able to evaluate all the risks and make the right decision. In large houses with two or more floors, you will definitely have to install hydraulic arrows. Then the loaded circuit is equipped with an additional pump, characterized by increased performance.

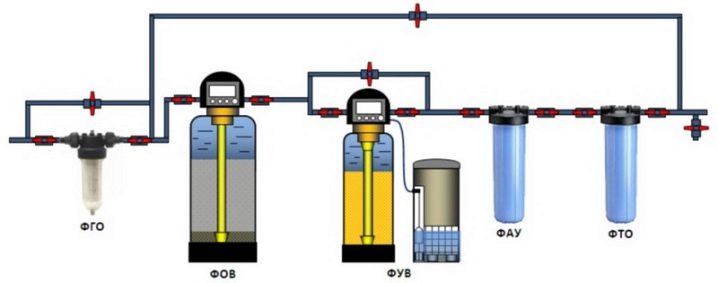

Whichever scheme is chosen, it is very important competent water treatment. Its quality depends on the stable operation of any boiler, the power and type of fuel used do not matter. First of all, impurities that do not dissolve should be eliminated - rust, grains of sand and clay inclusions. The next “adversary” for which filters must be calculated is hardness ions. Mechanical filtration is usually organized on the return pipe, but there are much more ways to arrange softening equipment. The use of polyphosphate type filters is not recommended because they do not create the safest substances.

Cleaning with ion exchange resins is much safer; moreover, the filter can be regenerated and reused. Membrane devices make it possible to obtain practically distilled water, but the cost of using them is excessively high. As practice shows, the use of ion exchange filters will be the most advantageous option. They allow you not to spend too much money and still provide decent protection. It is advisable to order the cleaning elements at the same time as the other heating infrastructure so that there is no mismatch between them.

Tips and tricks

Solid fuel boilers are mounted slightly differently than gas or electric units. The minimum justified floor space for them is 7 square meters. m, but you need to add more space for the accumulation of fuel. Installation of a boiler in a room with combustible walls is possible, only it will be necessary to use 25-30 mm of plaster or to attach asbestos with a layer of 8 mm, additionally covered with sheet iron. It is possible to put solid fuel boilers over a wooden floor only when it is covered with either 30-40 mm layer of first-grade steel or 50 mm of cement. On the sides of the firebox, an area of increased security with a radius of 0.4 m is formed.

How to install a heating boiler with your own hands, see the next video.