How to connect an indirect heating boiler to a single-circuit boiler?

Heating equipment is now quite diverse. But to understand all its subtleties is extremely important, because otherwise you can make fatal mistakes. This fully applies to water storage devices that heat it in a mediated manner.

Special features

The main feature of the connection scheme of any indirect heating boiler (the brand and model can be ignored here) is that it is deprived of its own heating unit. Water takes heat from external heating systems.

They can receive thermal energy due to:

- burning mineral or organic fuels;

- electrical resistance effect;

- contact with the central heating system;

- accumulation of sunlight.

Device

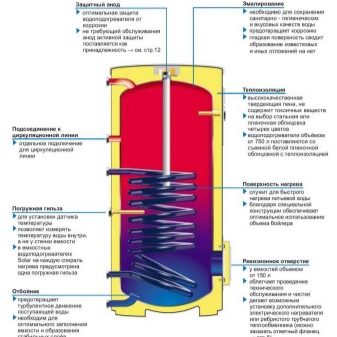

For any kind of external sources of heat energy, the boiler works equally, with rare exceptions. And even the private innovations of individual firms protected by patent law do not change the essence of the long-established pattern. The portion of heat carrier received from any source goes through a coil built into the drive. Circulation is maintained by the pump. When close contact with the tubes or reservoir, where the initially colder water is located, it is heated.

Since even one joule of heat, which is in vain radiated outside, has an extremely negative effect on the operation of the system, it is necessarily equipped with thermal protection. As an impermeable to the outflow of heat material is usually chosen polyurethane or polystyrene. Intake of new doses of cold water naturally occurs from the general water supply system. Each new portion passes through specially designed connections. As soon as the cycle of movement in the coil is completed, the coolant enters the heating system of the house - for this, a very special pipe is provided.

Further, certain differences already begin: Although most boilers are designed to supply cold water at a lower speed, there are also those in which it enters through the top. In this design, the liquid must first completely pass through the system to the lowest point. Variations with the output of the heated coolant are noticeably less, in almost 100% of cases it is output from above. It is difficult to find the reason why you should do otherwise. After all, the top location allows you to supply hot water as long as possible, as long as there is at least a small portion of it in the tank.

To coil occupied the largest possible space within the body, it is usually made in the form of a spiral. When the coolant passes several cycles through this pipe, the temperature becomes equal to the heating of the liquid in the boiler itself. At the command of a special relay, the special circuit that supplies the pump stops. During the subsequent cooling of the coolant to the set value, the relay gives another command - to close the circuit - and the heating is resumed. The advantages of such a device are quite well known. All these points should be taken into account before the start of work.

Installation principle

If it is required to mount a tank with a capacity of up to 200 liters, this can be a wall-mounted product. For its mounting brackets are provided of a special kind, which should be located on flat and sturdy vertical surfaces. Conventional plasterboard partitions for mounting even such a “light” drive are of little use. It is necessary to choose between saving on the arrangement of interroom space and saving on the boiler. Floor-mounted appliances are preferable to meet the needs of large households, sometimes even putting products with a capacity of over a thousand liters and allocating for them a special boiler room.

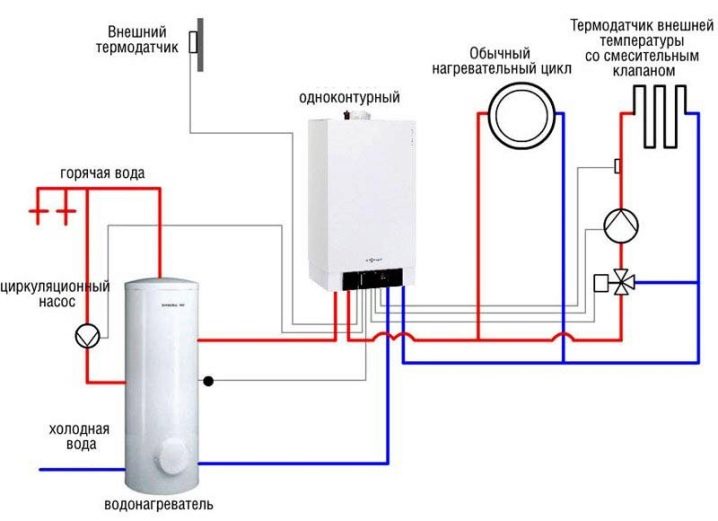

In private homes can be limited to indirect heating boilers, accumulating from 250 to 300 liters of water. The exact choice of capacity should be made taking into account the real and projected needs. When connected to a double-circuit boiler equipped with a built-in pump, the automation of the boiler takes over the coordination of the valve operation according to the signals from the thermostat. This is very important, because a dual-circuit heater, in contrast to a single-circuit, must supply hot fluid both to the heating system and to the plumbing circuit of the hot water supply.

If you mount a three-way valve, the water heater will gain an advantage in the system compared to the heating circuit. This approach is acceptable when a large tank is installed. For your information: a similar connection method is also practiced with the forced use of hard water, which hampers the normal use of the DHW system. Although of course, it would be much better to take care of softening the incoming coolant. But sometimes you have to unwittingly adapt to it.

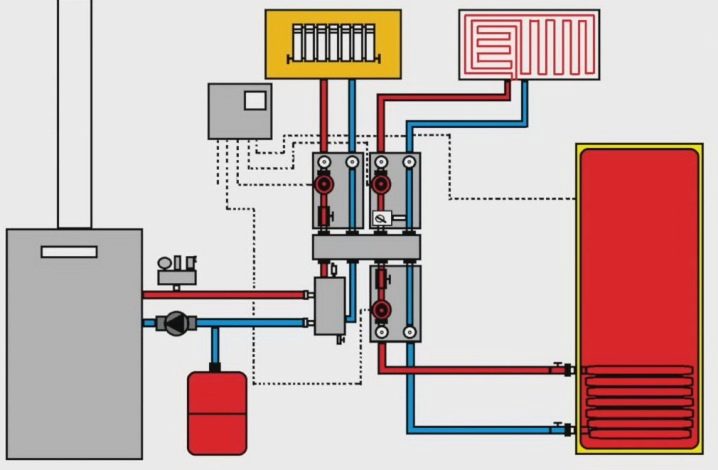

Problems may arise due to the fact that a significant consumption of hot water can complicate the functioning of this scheme. In this case, the method of obtaining heat, including using a pellet boiler or other solid fuel boiler, is not of significant importance. And here comes a boiler to the rescue, which smoothes out oscillations in two contours. Thanks to him, even the intensive flow of coolant has little effect on the daily life of people. Installers must consider which of the functions will have the highest priority.

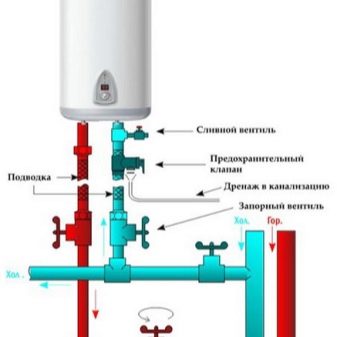

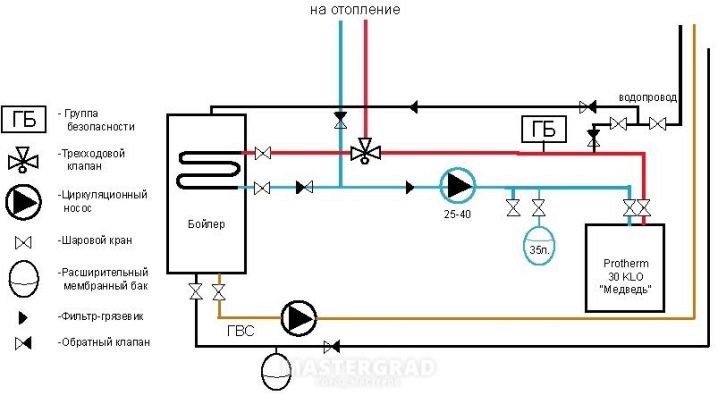

Connection of indirect heating boilers to a single-circuit boiler can be made using a pair of pumps.Then the water flows with their help are distributed through two pipelines. It is usually assumed that in the first place will be a hot water circuit. The algorithm of the boiler operation in conjunction with a single-circuit apparatus is also adjusted accordingly. In order for different liquid flows in heating not to change the basic parameters of each other, a return valve must precede both pumps. Hot water is supplied exclusively from the boiler.

Installation

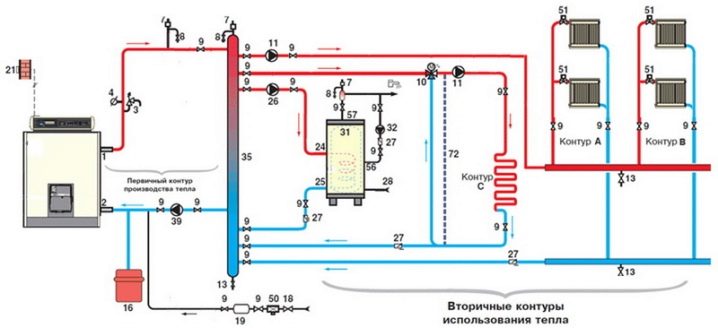

High-quality piping of the boiler connected to a double-circuit boiler implies docking of the water heater with one of the heat exchangers. A ring system is formed when the inlet of the boiler communicates with the initial part of the heat exchanger. Everything is designed in such a way that the water coming from the water supply system passes the heat exchanger of the boiler. It will go straight to the boiler, and from there it will penetrate the DHW route. Connect an electric boiler can be about the same pattern, but the water supply is connected with the first pipe of the second node, exchanging heat, and the second pipe is already attached to the boiler.

It is recommended to install the water heater as close as possible to the energy source in order to simplify their combination with the help of automation. When the device is mounted, it is the turn of docking.Important: a properly mounted and connected water heater is required to take only a certain amount of heat. An excessively large flow can paralyze the heating system. To solve such a problem is most often possible, if you install it yourself or with the help of professionals, a circulation pump with automatic control.

Only in the very last turn mount the thermal unit. It is almost always recommended to assign the assembly of the circuit to specialists. The nuance is that indirectly heated boilers with a control unit must be connected exclusively to heating systems that receive water from unmanaged boilers.

Required only:

- pull up the feeder and taker moves;

- connect the drive with water supply;

- put a comb dispensing hot water on the top outlet;

- fill the tank and immediately start warming up.

The simplest boilers interact primarily with automated heat sources. When installing, you will have to take care of connecting a sensor that measures the force of the warm-up. This sensor is supposed to be associated with a strictly defined input into the boiler.It is allowed to connect boilers, independent of the power grid, to independent boilers, but this at once complicates the work and requires a special scheme. It should be noted that it is possible to heat the water inside the boiler a little weaker than the liquid in the coil is heated.

Therefore, when the boiler is transferred to a low heating mode and can supply coolant heated to 40 degrees, only combined type heaters will be able to raise the temperature. They always include an electric heating element that helps to add heat. If, when setting up a system that controls recirculation, the primacy is given to warming up the hot water in the faucet, the movement of the entire coolant is sent through the storage unit of the storage unit. As a result, the total consumption of time for obtaining a liquid with the required temperature is noticeably reduced.

As practice shows, if designers and installers of a boiler house prefer the option with priority, it is possible to provide comfortable conditions for residents. To warm the entire volume of fluid in the tank, it should spend from 20 to 40 minutes.And if we talk about temperature stabilization against the background of coolant flow, this time is reduced by several times. Even a small dwelling is unlikely to cool down enough for it to be found in it. But much depends on the installed boiler and boiler: their power should be the same, and ideally it is recommended to put the boiler with a reserve of 25% of power.

In order to guarantee the stable operation of the apparatuses connected to combs that distribute hot water, it is necessary to supplement the outlet from the boiler with a special expansion tank. The recommended value - 10% of the main tank, helps to extinguish the effects of thermal expansion. All connected branches are supposed to be equipped with ball-type shut-off valves. With their help, any node can at the right time to disconnect from the line and check or repair.

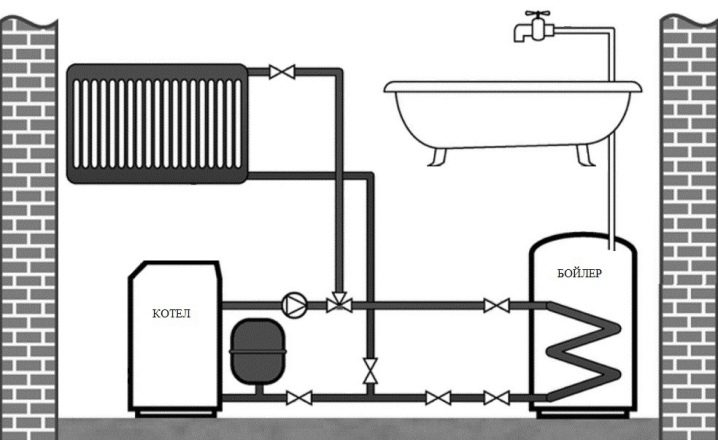

Piping through which fluid is supplied is usually fitted with non-return valves. With their help the opposite course of the heat carrier is prevented, convenience and safety of installation increases. It is sometimes necessary to put a boiler near the boiler, on the supply environment of which a pump is installed that provides circulation.In this embodiment, it is very important to provide a separate circuit through which water will flow into the heater from the boiler. In essence, a parallel connection type is created.

If the pump is both in the boiler and in the boiler, immediately after the circulation pump a three-way valve should be mounted, one channel should be connected to the water heater pipe. This ensures the normal operation of the heating. A tee should be installed on the return pipe to the point of entry into the boiler. And already in this tee connect pipe, pulling liquid from the heat exchanger. Such a simple system easily and elegantly solves the tasks.

As soon as the sensor signals that the temperature of the coolant has dropped below the set mark, the valve transfers the fresh flow to the boiler. At the same time the heating system stops. When the normal value is restored, the same valve reverses the switch. The minimum number of components reduces the risk of breakage. And the simplicity of execution allows you to quickly find the problem, if it still appears.

When a boiler independent of the power grids is used, ensuring the priority of the boiler is not so easily achieved,as in other variants. It is recommended to put the water heater higher in relation to the floor of the room than radiators. It is advisable that the low point of the wall model be raised above the boiler as well. But just to comply with such a requirement is obtained only in individual cases. When it is executed partially, it is still worth raising the drive to as high a height as possible.

Putting the boiler on the floor, immediately reduce the rate of heating of the liquid. Worse, the lower part of the tank is basically unable to warm up normally in this mode. If you connect the boiler on the classical system, then any power outage will deprive access to hot water. The problem can be solved by using a larger pipe for the circuit connected to the water heater than on the heating element. Immediately at the beginning of the heating branch, the thermostat head is positioned and the sensor is superimposed. Energy is given by batteries.

Without continuous recirculation, systems with water-heated towel rails are unable to operate. The advantage of this circuit is that water when you open a hot faucet comes instantly.But the total consumption grows, and the efficiency of the system is a big question. Worse, recycling poses the problem of mixing dissimilar fluid layers. However, since it is decided to use a heated towel rail on water, this is the only possible choice.

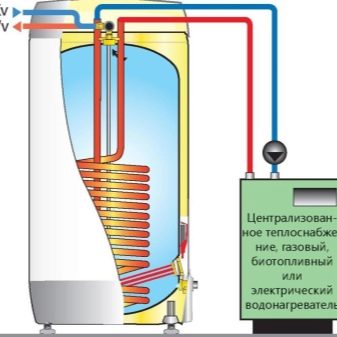

By choosing indirect type Protherm boilers, you can combine them into a single system with gas or single-loop single-loop boilers of the Skat model. The popularity of water heaters associated with a solar collector is also growing. Such a solution allows even in the winter period to provide itself with minimal costs both with heat and hot water. The single-circuit variant involves placing the collector under the tank, and the tank itself communicates hydraulically with the lower manifold manifold and with the upper outlet from it.

Tips and tricks

To assess whether, say, enough of a boiler for indirect heating of 200 liters, it is required to find out:

- how many water points will be used;

- what their separate and general need is;

- how fast the water should be heated in each tap;

- to what temperature should the liquid warm up.

The same 200 liters can cover all the needs of a family for 5 people.In this case, you will need to install a boiler with a minimum power of 33 kW.

Professional calculation should also take into account:

- heat exchanger areas;

- thermal capacity of water;

- coil length and configuration;

- current consumption (if installed heater).

For information on how to properly connect an indirectly heated boiler to a single-circuit boiler, see the following video.