Boilers of long burning on wood for home: rules of selection and recommendations for installation

For centuries, wood served as the right source of energy for heating homes. But traditional stoves have long been outdated and for the most part prove to be impractical structures. It is much more appropriate to use now the boiler plants, providing a long-burning fuel.

Special features

Coppers of long burning on fire wood perfectly warm houses of various form and the area. They are fully compatible with water heating circuits, although they can also be used for direct heating of air.Unlike a simple solid fuel boiler, which completely burns the pledged fuel in 2-3 hours, these structures can sometimes work for several days in a row.

Important clarification: advertising figures of long work refer to the modes of maintaining the minimum temperature. If you have to warm up the house to more comfortable values, the actual duration of the session is reduced to 12-24 hours on average.

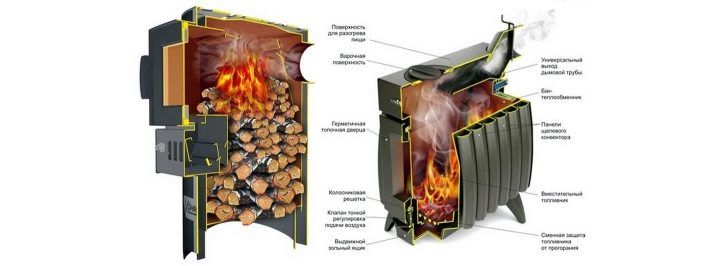

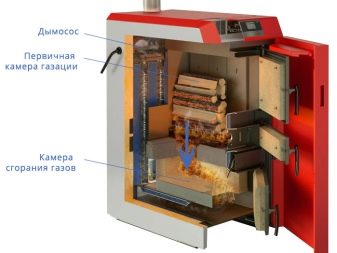

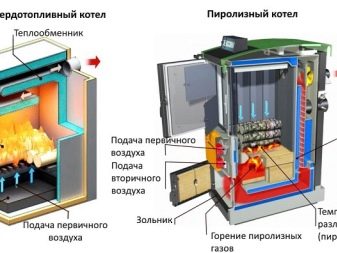

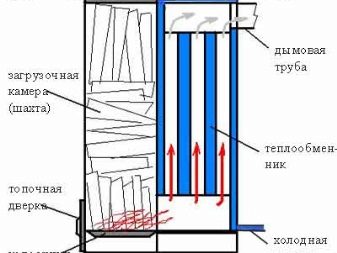

The increase in the duration of combustion is achieved due to the initial oxidation of the wood mass with an insufficient amount of oxygen. Charred fuel emits a lot of carbon dioxide and special flue gas. He is redirected to another cell and burned out. Since the combustion of gases occurs at very high temperatures, almost always the second compartment is fired with fireclay bricks. Exceptions are when other heat resistant materials are used.

In addition, to increase the duration of fuel combustion, as well as increase the intervals between loads helps increase the working chamber capacity. Removal of gaseous products of combustion is made through a chimney broken form.Power and size, color and shape can be very different, the choice here is subjective. As with conventional solid fuel boilers, performance is of great importance. With the same heat generation, it is possible to spend less fuel, because the system has a higher efficiency.

Rules and regulations

A long-running heating boiler can be a real find only with proper operation. Pyrolysis plants work well mainly for heating. Somewhat worse they cope with obtaining hot water for domestic purposes. The standard requirement for a long-burning boiler is the minimum emission of carbon dioxide into the atmosphere.

The fuel can be used a variety of organic substances:

- firewood;

- pellets;

- brown coal;

- coal (anthracite);

- coking coals;

- peat briquettes;

- various waste of woodworking production (they are also granulated or briquetted).

An indispensable requirement for any fuel that is put into the boiler for continuous burning is the minimum humidity. This is especially important when using wood.Yes, some manufacturers indicate that their equipment allows you to burn and wet fuel.

But high efficiency and speed of heating in this way is not achieved. Instead of normal pyrolysis, wood will be dried almost all the time, and its total consumption will increase rapidly.

Kinds

Traditionally, the wood hearth (even classic ovens) was made of cast iron. But the quality of such products turned out to be too low; under the effect of sudden temperature jerks, they could suddenly become covered with cracks or even fall apart. In the twentieth century, boilers began to be made from difficult-to-melting steel grades, and another achievement of technology was the creation of an intricate internal structure.

As a result:

- increased efficiency;

- increased several times the period of guaranteed work;

- reduced requirements for operation;

- the capriciousness and the likelihood of a sudden failure repeatedly fell.

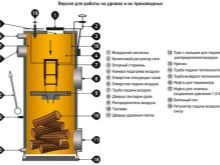

Even the most advanced designs are rarely equipped with automation. If it is, it is only to the extent that it guarantees total security for consumers. Differences often relate to heat exchanger performance.Models with a water circuit provide the fastest possible heating and drastically reduce unnecessary heat consumption. However, such a product in the event of a breakdown is repaired heavily.

In other designs, the heat exchanger is made of a whole complex of pipes. Their location is not accidental, but corresponds to those areas where heat transfer occurs most effectively. In the event of a defect, the entire “shirt” or its separate part is much easier to remove and replace with serviceable equipment. As for automation, the simplest version of them involves the presence of a thermostat and damper. This bundle controls the flow of air into the working section and, accordingly, the intensity of solid fuel burning.

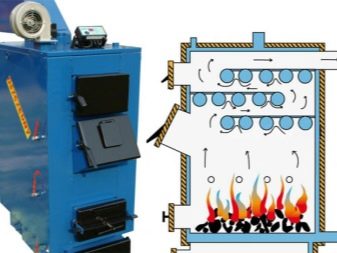

More sophisticated designs contain a fan forcing intake air. It regulates the burning process more smoothly and intermittently. Importantly, the safety and efficiency of the system increases. Coppers of long burning can give heat and to batteries of steam heating. Schematically, the organization of such a contour is close to the water variant, but it is calculated at significantly higher pressures and temperatures.

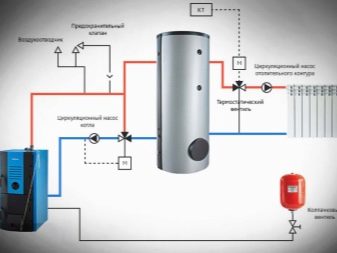

An open steam circuit usually requires a significant concentration of dry saturated steam. The lack of it turns into difficulties for condensate drainage and cold air in the lower part of the heating equipment. Sealed systems are distinguished by the fact that water immediately flows to the heat exchanger.

In many houses, open circuits are used, where the coolant is first fed into the storage tank, and then goes to the boiler itself. If the condensate fills the pipes not 100%, but only partially, it turns out to be much better.

The steam system is created on the basis of a simple furnace much easier than water. The rate of warming up the house will be higher. There is no situation where all the water would collect in the storage tank or inside the heat exchanger, and the pipes and batteries would be empty. The freezing of heating devices is also excluded, it is possible to reduce the size of the heating apparatus.

The weaknesses of steam heating are:

- the unsuitability of PVC pipes;

- increased risk of burns;

- significant noise;

- complicated adjustment.

Furnace systems and boilers operating exclusively on wood are not considered to be very convenient.Most of the designs are now combined, that is, they allow the use of coal, and sometimes some other types of fuel. Under normal conditions, a tree is loaded inside, and when severe frosts set in, the use of coal fuel is justified. Such systems work well in conjunction with hot water circuits. Their complexity is quite high.

They use:

- branch pipes;

- air outlets;

- ash pits;

- pipelines;

- heat exchangers;

- separating parts;

- connecting blocks and many other parts.

Increasingly, steel alloys of the last generation are being used to create wood boilers. Soil does not form on steel, it conducts heat much better than cast iron, in terms of strength it is not inferior to it and at the same time it is less fragile. Correction of damage, if they occur, will be as simple and easy as possible. But the steel boiler suffers quite a lot from corrosion. According to this indicator, cast iron is much better, but unfortunately, it is easily covered with carbon, which can even prevent the replacement of deformed parts.

To a large extent, this deficiency is compensated by the fact that damage to cast iron in a residential building is extremely rare. As for the power of the equipment, in most cases it varies from 5 to 30 kW. The length of the loaded firewood is important, generally, it is from 40 to 50 cm, but the more such a parameter, the higher the amount of heat received from one bookmark. In 60 minutes, from 4 to 6 kg of firewood can burn, depending on the design of the boiler and its operation modes. But this classification is conditional, since many nuances affect the exact fuel consumption.

Until relatively recently, the connecting diameter of the chimney was of great importance. The situation has changed due to the fact that almost all heating systems are designed on the basis of a size of 15 cm. If there is a boiler in the boiler, it provides stable heating of water in the process of burning fuel. The use of tanks allows to solve the same problem, but it turns out to be more expensive and adversely affects the reliability. The capacity of the boiler for the house ranges from 20 to 200 liters, a smaller volume is not justified, and a larger one is redundant, even in a large cottage.

Both automatic and ordinary wood boiler can be top loaded. The basic principle of operation is the same as that of more traditional devices, in which fuel is placed on the side.But do not assume that such systems differ only in the location of the door, as if the washing machine.

The difference is evident even in the fact that the grate of grates is freed from contamination as quickly and easily as possible. Some models even provide special external mechanisms.

Most of the heat generators gaseous products of combustion raise to the top. In structures with a vertical fuel injection, the smoke channel has several convective passages. The mining mode, in which combustion takes place from below, and at the top of the fuel only dries, provides impressive work efficiency. The load itself is done quickly and without excessive effort. Maintenance costs are reduced.

But vertical loading has its weaknesses:

- it is necessary to lay out logs very carefully and carefully;

- increased susceptibility to changes in thrust;

- significant resin accumulation in the working chamber.

If you throw firewood inside as you need, the efficiency of burning them will drop significantly. And in the most difficult situations, the burning process can stop altogether.Because only the most accurate people manage to properly maintain such boilers. It is extremely important to thoroughly prepare the exhaust ducts. It will not succeed if you do not make meticulous engineering calculations for the length of the highway, the number of turns and so on.

The walls of the combustion chamber should be systematically cleaned using raw wood. But if you dry them properly before loading, it is quite possible to eliminate this problem. Experts believe that wood-fired top-loaded boilers are optimal for heating private houses of a small area not supplied with gas mains.

If it exceeds a certain value, the effectiveness of the work will rapidly decrease. Judging by the feedback from consumers, such installations are an ideal option as a backup heat generator.

How to choose?

But even such a worthy and proven device should be chosen as carefully as possible. Only under this condition, you can count on the optimal result when heating a private house or bath. Russian and foreign wood boilers operate at approximately the same technical level,so it is necessary to focus more on the properties of a particular model, and not on the brand. Of course, in this case, the general fame of the manufacturer is quite important. You should also pay attention to the heat output, which should not be excessive (and many companies are trying to supply the most powerful equipment).

The selection of the boiler for the sauna or sauna room is further complicated. It is very important fast and intense warming up. In some cases, you even have to look for models that can warm the air to more than 100 degrees. And it automatically cuts off all designs equipped with a water jacket. Maximum - a tank in which water is heated, and that is not always.

To increase the intensity of heating helps the placement of special ribs placed on the outer part of the body. If you need a "heater", choose a furnace with a special capacity, usually fixed above the hull. Sometimes there are options with a grid surrounding the furnace around the perimeter. It is for this mesh that the stones will have to fall asleep. The right choice of construction material is very important. The best results come from boilers made from special bricks or natural stone.

The durability of such devices justifies the most demanding requirements, and the aesthetic parameters will be optimal. The availability of ready-made kits simplifies installation, but their total cost is very significant.

Quality designs are often made from cast iron with chromium, which allows you to endure sharp temperature jerks without cracking. The total service life as a result is up to 25 years. The only limitation preventing the widespread use of cast iron wood boilers is their considerable price. You can save money by choosing a product made of heat-resistant steel, but it is not very durable, as the welds are under tremendous stress.

However, the lack of a water jacket negatively affects the stability of the material. The fire burning inside heats the structure up to 1000 degrees. And soon there is a scale, with the fall of which may eventually appear a kind of "sieve."

Even cast iron is not an absolute guarantee of quality. If the design contains thin parts, there is a high risk of their quick breakage.It is recommended to inspect the working parts of the combustion chambers and cast elements. They should not be the slightest cracks, broken off areas, surface sinks. The less curved and intricate the path of smoke through the internal chimney, the better the boiler cope with the heating of the bath; This requirement is especially important for steel products.

Wood boilers are sometimes used to heat water in swimming pools. It is no secret that weather conditions often do not give pleasure to people, but even on the hottest day, the water in the pools often turns out to be extremely cold and unsuitable for swimming. If there are children jumping there or just people with poor health, the risk of hypothermia is great, and it’s just unpleasant.

In order for the boiler to fulfill its function, a circulating pump must always be installed in the system. Also, do not forget about compliance with fire protection regulations.

Choosing a wood-burning cauldron for long-term burning to give, you should focus on the number of rooms. Water heating manifests itself well in large houses, especially if the whole heating season or the main part of it will live there.If the cottage will be used only during the vegetative period of plants, it is advisable to choose designs that directly heat the air. They will give heat as quickly as possible and eliminate the effects of cold weather in early spring or late autumn. But it happens that the air flow encounters a barrier and can not heat the entire room; then the choice should be made in favor of the water scheme.

Single-loop systems are most often more powerful than dual-circuit counterparts, and with identical fuel consumption can heat a large room. But double-circuit devices can also get hot water, which is very valuable for country farms. The principles of choice between forced and natural circulation are about the same as in other cases. Heated summer cottages should be heated with plain water, which is undesirable to drain even in summer. When they live in the summer cottage and occasionally attend it in the winter, it is worth choosing antifreeze; but it is much more active than water flows from any hole, which increases the demands on the installation of circuits.

Installation

The high price of long-burning boilers manufactured at enterprises makes it necessary to look for an answer to the question of how to make such an apparatus with your own hands.There is nothing extremely difficult in the presence of skills and a certain set of tools in this. Moreover, there are various variations of homemade boilers, taking into account certain nuances of their application. As in the factory products, it is necessary to form two chambers - one for simple combustion, the other for pyrolysis. The primary preform can be a simple metal barrel, the recommended capacity of which is 200 liters.

The lid must be trimmed, the board is welded instead. They take a massive billet or something else heavy, and make a round piston. The main requirement is that its diameter be slightly lower than the internal section of the barrel. A hole is then cut into the lid, into which a duct pipe with a diameter of 10 cm will be placed. The minimum excess of this pipe above the barrel is 200 mm.

The chimney structure, which is set up on the side, is prepared from metal-roll section of 10 cm. The air duct is supposed to be welded to the piston. The upper end of the pipe is equipped with a damper, with which you will need to dispense the flow of air. Bottom to the piston boil ribs that help tamp the mass of fuel.

To achieve complete success, you will need:

- detailed diagrams;

- pipes of different lengths and diameters;

- sheets of steel with a thickness of at least 0.4 cm;

- metal rolling for receiving legs;

- heat-resistant mixture designed for laying stoves and fireplaces;

- welding machine;

- welding electrodes (they are selected by brand and size, in most cases there is enough electrodes with a cross section of 0.3-0.4 cm);

- LBM.

First, a segment is cut from a pipe with thick walls that is equal in length to the height of the future firebox. A bolt is welded at the bottom, and a circle of at least the same section as the pipe is cut from a sheet of steel. Having punched a hole in the circle with a drill through which the bolt can enter, connect the circle to the air duct using a nut. The free movement of the round part allows you to easily and gracefully close the lower portion of the airway pipe. But this work is not yet completed.

Next, take the "grinder", and using the disk on the metal, form vertical slots, the thickness of which is about 1 cm. The body is made on the basis of a cylinder with an airtight bottom. The usual diameter is 40 cm with a length of 100 cm; the exact dimensions may differ if the spaces are smaller or larger, but they must allow the laying of all the necessary firewood.

Instead of using a fully finished barrel, welding of the bottom to a thick-walled cylindrical part is allowed.

For your information: if you make a heating boiler from a gas cylinder, the period of normal service will increase. The top of the case serves to form openings through which gases are discharged. The length of the chimney is selected individually. The air duct must be connected so that the blower turns out to be out of the bottom. Important: the pipe through which fresh air is supplied must end in 5-7 cm before the chimney starts.

An important role in the normal operation of a homemade pyrolysis boiler is played by a heat dissipating disk. For its manufacture take a round sheet of metal with a thickness of 1 cm, and the diameter is chosen so that it is slightly inferior to the size of the body. The handle should be welded to the disk (it is made on the basis of reinforcement or wire). Boilers without a disk, as practice shows, work less efficiently. Next comes the turn of work on the convection housing.

This is a cylinder or pipe section 2-3 cm wider in diameter than the outer contour of the housing. The casing must be connected to the firebox. For the bond between them, metal jumpers are mounted.But if the gap is not too large, you can not make such jumpers, but simply weld the casing to the outer shell of the furnace throughout. Since all parts fitted with handles will heat up (including the cover), it is advisable to mount a protective coating with low thermal conductivity.

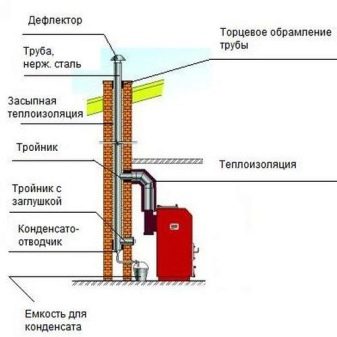

Coppers of long burning are surely equipped with legs. With their help, the device rises above the floor or the ground by at least 0.25 m. The legs are made of channels or corners. When all these manipulations are completed, it remains only to download a portion of firewood and ignite them. Soon a wave of pleasant warmth will spread throughout the house. But there are a few subtleties that need to be taken into account when designing and constructing a solid fuel boiler. The best chimney is straight, round in shape. This provides a very strong draft, since the hot air will spiral.

Note: it is recommended to slightly narrow the output compared with the rest. Bend for smoke necessarily raise to 5 m at a minimum.

The smallest permissible thickness of stainless steel in the chimney is 0.5 mm. Use in it black (rusting) metal is unacceptable.The exact diameter is always chosen not less than the size of the boiler pipe. If you still have to make turns or bend the highway for smoke, such places should be from 1 to 3, and the radius of each is at least equal to the diameter of the pipe. When choosing a brick chimney, it is divided into several moves, and a chamber that collects soot is placed at the bottom of each move.

All cameras should be equipped with doors that help clean the compartments as soon as the thrust is reduced. Straight as an arrow pipes should be mounted in two-story houses to increase the heat in the upper tier. The output of the chimney through the wall has other advantages - inside the house it will be freer and safer. Even in violation of the integrity of the structure, carbon monoxide poisoning is almost completely eliminated. But such a chimney is not recommended for areas with a harsh climate, where its rapid cooling turns into a serious problem.

When a brick chimney is being formed, the pipe being installed is put into the dressing method according to a premeditated order drawing. Approaching this part of the ceiling should be no more than 5-7 lines of bricks.The exact distance is estimated by the height of the walls, taking into account the nuances of the design of the heating device. Then a fuzz is done, that is, the area where the outer part of the pipe expands and the inner part does not. Especially important is the fluff in houses with hardwood floors; it leads up to the attic or to the second floor at least 1 or 2 lines of masonry.

The main part on the upper tier (if only the house is not one-storey, ending with a roof immediately) is called a riser. Near the rafters, the riser becomes wider by ½ bricks. Another extension (otter) is made of 8-9 masonry lines. The role of the otter is not limited to thermal protection of the rafters and roof structures. It prevents precipitation from seeping into the gaps separating the roof from the pipe walls. After the otter, a cement pitched finish is made.

It smoothly merges with the neck of the pipe (the perimeter of which is equal to the perimeter of the riser). The neck is laid out of 6 or 7 rows of bricks, over which the tip is placed (another 2-3 lines). Steel umbrellas or hubcaps provide additional protection from external contamination and moisture. When using high-quality bricks, you can not be afraid that the safety margin of the structure will be exhausted by a solid fuel boiler.

But still, steel elements are considered the best, because the inevitable pores of a brick will absorb soot and soot. Subsequently, this layer will grow with frightening speed. A compromise solution is often exhibiting a steel pipe inside a brick road. A more modern option - laying the polymer channel of the special raw materials. Such an innovative design, as its manufacturers claim, can last for several decades.

A very important question is where exactly to put the wood-burning boiler for a long burning in the house. Placing it in the kitchen is quite possible, if only it is spacious enough. In addition to the space under the boiler itself, it is necessary to provide for a site for placing the tank with water. If the system is designed to burn not only wood, but also coal, consider the likelihood of a coal dust explosion and take appropriate measures.

Closest approach to the wall - 0.1 m; when the walls are made of easily combustible materials, they are coated with asbestos, which the steel sheet must hold from 0.3 cm thick.

In front of the boiler, another sheet is laid out without fail, the length of which is at least 0.6 m,and the width is equal to the width of the heater itself (it is possible even with a small margin). It will be even better when the same sheet is laid out on the floor under the boiler. In all other areas, the floor must be made of concrete. If this rule is not followed, you will have to put a layer of fireproof tile.

Other plans to decorate the space in the kitchen will have to be abandoned for the sake of security. Installed in the room where the boiler will stand, the window should have an area of 8 cm2 per 1 kW of heat output. It is impossible to use such equipment if it is impossible to install it while limiting the total length of horizontal chimney segments to 120 cm. It is very useful when there is water supply and sewage near. The minimum allowable kitchen area for a solid fuel boiler is from 8 square meters. m, even if it seems that a particular sample requires less space.

Manufacturers Overview

The complexity of self-made wood boiler should not be exaggerated. But still, in general, the samples collected at the plants under the guidance of experienced engineers are more reliable and more stable. It is impossible, of course, to disassemble all the models that appear in the ratings of the best heating equipment.But to read the reviews about the relatively cheap and most popular versions of boilers is extremely important.

NMC "Siberia-Gefest KVO 20 TE" It is designed to supply hot water only to the heating circuit and is capable of generating 20 kW of thermal energy per hour. The equipment of this model is completely independent of electricity, because it is controlled by a mechanical system. With the help of an open combustion chamber with an efficiency of 80%, it is possible to heat up to 200 m2. In addition to the wood-burning firebox, a 4000 watt heater is provided.

In addition to firewood, the use of coal is allowed. As a result of the boiler operation, the coolant warms up to 60-85 degrees, depending on the mode. The device provides pressure up to 2 bar, is equipped with a thermometer and is designed for the most mass type of chimneys with a section of 15 cm.

Another very attractive version is Kiturami KF-35A double-circuit boiler. Such a device is also equipped with an open firebox and provides power up to 24 kW. Its efficiency is higher than that of Siberia, by 5%. The connecting dimension of the chimney is the same. Korean manufacturer gives an official warranty of 24 months. The load can contain up to 40 kg of wood, the burning time reaches 5-6 hours.Allowed to lay the wood length to 0.85 m.

Operation Tips

Like a simple stove, a wood-fired boiler should be operated according to strictly defined rules. Although some manufacturers allow the loading of raw wood, a thoroughly dried mass is still preferable. It increases not only the efficiency of the device, but also its overall service life. In the process of use, it is necessary to carefully monitor the state of even seemingly minor structural parts. Very small firewood is laid at the very beginning.

Under the firewood lay out paper, shavings, dried to the limit of moss or bark, then small twigs. It is impossible to lay firewood very tightly, because if there are no gaps between them, the device’s mode of operation will be disturbed. When there are neither branches, nor chips or paper, it is allowed to kindle a wood boiler with coniferous paws. It is strictly prohibited to ignite it with any kind of liquid of natural or industrial origin, with gas. The pyrolysis chamber is freed from the products of combustion before any kindling.

The noise in the chimney, accompanied by the appearance of white fire in the firebox, shows excessive intensity of thrust.But red tongues appear, if the oxygen supply is unjustifiably small. The best and most stable mode is when the wood burns yellow.

When you start any solid fuel boiler will create condensate, it is a law of nature. Stopping the flow of condensate only after the entire volume of the furnace warms up. Ignition of firewood is carried out necessarily at the flap open to the limit.

In the next video you will find a review of the boiler 12-hour long burning on the wood.