Pyrolysis boilers: technical characteristics, types and methods of installation

Choosing a boiler is a very complex and controversial task. In search of an optimal solution, many people pay attention to pyrolysis structures. But they cannot be considered as some kind of universal, suitable for all cases solution. It is necessary to carefully deal with their features with specific examples.

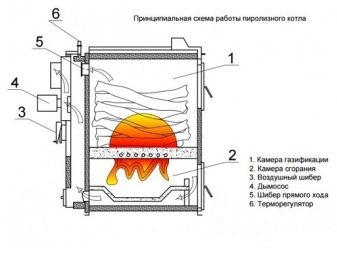

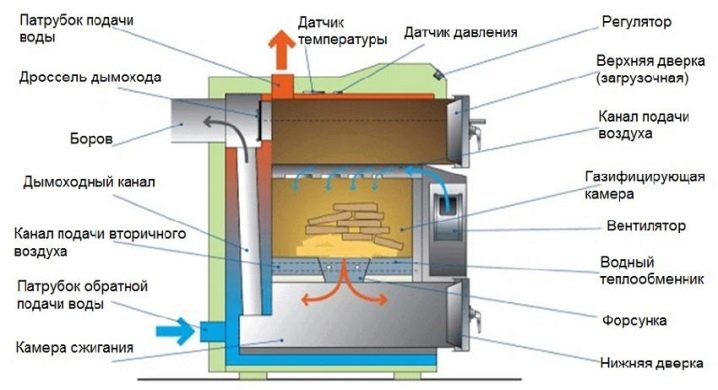

Device and purpose

Pyrolysis boiler for heating a private house works by burning fuel at very high temperatures and with limited access of air. Instead of solid fuel, a new special gas is actually created.It is additionally burnt in a special chamber, which is usually located below the designated solid material. Accordingly, the air is pumped first to the upper part, and from there it enters the lower chamber. Since this is contrary to the laws of physics, it is necessary to overcome them artificially, using fans or pumps.

The lack of oxygen in the air used helps to make burning more stretched than in ordinary boilers or furnaces. It is possible to extend the heat release time from a single portion of firewood, for example, up to 20 hours. Miracles, of course, do not happen: they give off thermal energy in small portions. But for the greenhouse, this solution turns out to be even a plus, because it allows maintaining a stable temperature without overheating and undercooling.

Since only automatics can set the modes and switch them in time, the most advanced designs cannot be cheap; however, their capabilities are worth it.

Separate conversation deserves the use of a pyrolysis boiler for a bath. It is more practical and gas, and electric heaters.In terms of efficiency and convenience, it is ahead of many furnaces, especially when compared with homemade designs. Any pyrolysis boiler has a horizontal segment (the so-called "hog"), which is designed to connect the structure with the chimney. The wall thickness at this point is 4.5 mm, and the usual length reaches 50 cm.

The characteristics of the pyrolysis boiler make it possible to consider the increased (in comparison with simple solid fuel alternatives) cost quite appropriate in most cases. The time of using one fuel load is difficult to predict in advance; it depends on a large number of factors. The technical documentation and popular descriptions are usually the minimum and maximum possible numbers.

They are affected by:

- humidity of the fuel used;

- temperature in the house and on the street;

- quality of insulation;

- features of the heating system.

Dry distillation is regulated using a nozzle, which dispenses the flow of atmospheric air. Importantly, boilers operating on the principle of pyrolysis, are able to dry stored firewood or coal stored in the same room.Features of the operating mode exclude the ingress of not only carbon monoxide or carbon dioxide into the living spaces, but also safer water vapor. Most designs work best with very well dried wood.

It is for it that the design parameters of the ultimate power and the combustion period are calculated.

Principle of operation

Pyrolysis boilers favorably differ from simpler solid-fuel apparatuses with increased efficiency. As well as ensuring long burning, this effect is caused by features of the working process. Pyrolysis begins with the ignition of wood, which must be well enveloped in fire. This is achieved by maximizing the opening of the throttle and bleed. The firebox is filled to a certain level with firewood, they are supplemented with a small splinter.

As soon as a steady flame appeared, the boiler is ready for operation in full mode. To do this, the throttle valve and the ash valve overlap and start the automatic.

It doesn’t matter if the system is operating at some moment on a natural charge or if the fan is working. It does not change the essence of physical and chemical processes.As soon as the access of oxygen is limited, instead of a strong fire, ember remains. But not for long: automatic systems almost immediately give the command to start the fan.

He does not blow the fire, but moves the gaseous pyrolysis products to another chamber; that's where the flame burns.

The only difference is that the management of all these actions can take as simple mechanical devices, and electronics. Inside the main furnace, the temperature can reach "only" 500 degrees. But in the pyrolysis compartment, this figure rises to 1100 and even to 1200 degrees. The closer to the top of the torch, the higher will be the temperature. It is curious that the exhaust gases in such a boiler, on the contrary, are colder than usual.

It is important to consider that the fuel loading mode has its own characteristics. The direct motion flap is unlocked, but for some time the traction in the chimney still remains. With a fan, the system will not stop its operation. This means that the pyrolysis will continue even at this very moment.

Since there is a rapid movement of hot gases in the working chamber, only the strongest materials are used.

Advantages and disadvantages

To study the reviews of owners and specialists on specific models, it is not enough to get acquainted with the ratings of the best modificationsIt is also necessary to answer the most important question: how do the advantages and disadvantages of pyrolysis boilers correlate, do they really justify the investment. And here there can be no universal answer, because a lot depends on priorities and on the features of equipment use.

When the wood ends, the ash pan and gas passages are barely covered with soot.

Any pyrolysis boiler already has built-in automation due to its design features. Working for hours at a gas station frees up a lot of time and effort. As a fuel, you can use almost any waste processing and harvesting of wood, and sometimes not only them.

The flip side of these benefits are:

- attachment to the power grid;

- mandatory installation of uninterruptible power supplies;

- unsuitability of raw wood;

- the inability to supply water to the heating circuit is colder than 60 degrees (it forces corrosion);

- the inability to automate the very loading of fuel (flow from the bunker only makes manual work less often, but does not exclude it at all);

- the need for lining with fireclay bricks;

- increased cost compared to simple solid fuel machines.

Fuel types

Talking about pyrolysis boilers “generally” is useful, but it is equally important to understand what kind of fuel they can use. They can be stoked by almost all types of fuel that are available in private households. Wood-fired boilers do not use all kinds of logs, of course, but only those whose length does not exceed 0.4 m. Heat transfer is of decisive importance in choosing a suitable tree species.

Birch burns quite hot, but with a lack of air can produce a certain amount of tar.

Coniferous wood manifests itself in much the same way. Oak firewood is the most "energetic", but the cost of their use is excessively high. Aspen and alder firewood provide the least soot, so they are used mainly for cleaning chimneys. Most experts recommend the use of hardwood, best of all those that contain little resin. Instead of the usual logs, the tree can be represented in the format of pellets.

To obtain them are used by-products of the agricultural and forestry industries, as well as peat.Processing at high pressure perfectly replaces bonding, so there is no point in fear of increased toxicity of pellets. Another modern modification of the old version is the so-called Eurodrove. They are made from the same raw materials as pellets, but under the press are briquettes in the form of a cylinder.

The length of the briquettes is slightly increased - up to 45 cm.

Coal boilers represent a weighty alternative to wood. Mineral fuel, like forest fuel, is used in two stages: initially, it emits volatile gases, and then solid coke mass burns in the afterburning chamber. Brown coal, on average, burns in 8 hours; when using anthracite, the time between refills increases already to 10 hours. The sawdust boilers, which are inexpensive and do not pose any environmental threat, are fairly widespread. The supply of sawdust is now arranged in a convenient compact package, from which nothing should not get enough sleep.

But in addition to these advantages, they have a disadvantage - a small amount of heat and rapid combustion compared with other solids. Some boilers run on waste oil, which allows an efficiency of up to 94%.1 l of mining gives up to 11 kW of thermal energy. After refining to the level of heating oil, the recoil increases by about 25%. More accurate data can not be called without analyzing the type of boiler, mode of operation and the nuances of the chemical composition of waste oil.

In addition to the purely technical characteristics of the fuel, it is necessary to take into account their practical properties. So, coal burns hotter than many other types of fuel and emits a minimum of harmful substances. With it, it is easy to extend the pyrolysis process - and without that longer than the classical burning. Pine wood is not suitable for the firing of solid fuel boilers. When used, its working chambers become very dirty.

To use sawdust and shavings, not subjected to pressing, it is impossible. They contradict the very essence of a solid fuel boiler. At market value, undisputed leaders are pellets and special granules. But we must not forget that pellet and coal boilers operate with less power than wood or combined type.

No need to lay inside the chips shorter than 70-100 mm (the exact limit depends on the model).

Overview of models and manufacturers

Pyrolysis boilers in Russia are being made, and quite successfully.A striking example of this are the designs of Popov. Experts believe that such a scheme is one of the most economical at the moment. On the territory of our country, Popov’s boilers are also good because they do not depend on electricity, control is done by mechanics. At the same time, even in the most remote areas or with unstable power supply, it is possible to regulate the temperature with an accuracy of 0.5 degrees.

Importantly, to stop the system is obtained at any convenient time, and the removal of ash is possible even during operation.

Popov boilers are used in:

- greenhouses;

- warehouses of agricultural products;

- country and country houses;

- baths and saunas;

- emergency heating systems.

The use of damp wood of low quality is allowed (which attracts the attention of sawmills and woodworking enterprises). However, the thermal efficiency of this fuel is 50% less. It is possible to increase power only after the final evaporation of water contained in the wood. The temperature of the emitted gases is limited to 140 degrees. Important: the critical humidity for fuel used in Popov boilers will be 65%.

Significant positions in various ratings invariably occupy Tokarev boilers. The power of such equipment varies from 15 to 100 kW. It is equipped with automatic systems that allow you to maintain a strictly specified heating as long as possible. You can lay any kind of wood, even waste from the production of furniture or peat briquettes.

The Tokarev system successfully copes with the heating of residential and industrial premises for 8-12 hours per tab, has an efficiency of 90%.

"Bourgeois-K" allows you to use for heating not only water but also antifreeze. The company has developed three main versions: with manual adjustment, with automatic adjustment, with automatic adjustment and hot plumbing. The efficiency of any version is 85%, the mass of the structure ranges from 180 to 900 kg, the heating of the fluid is up to 90 degrees. Outgoing gases are heated to 150 degrees. Installation of pipes from 7 to 13 m is required, chimneys with an internal cross section of 0.15-0.25 m communicate with them.

Boilers "Bourgeois-K" are equipped with an elaborate thermal protection, which uses mineral wool. Any units of the apparatus are made of a special kind of steel, carefully tested for resistance to heat and corrosion.Specially developed powder coating reliably stops moisture, salt and acid. Of course, it does not suffer from significant temperature and is resistant to mechanical abrasive effects. Mechanical adjustment allows you to almost eliminate the risk of excessive heat.

The manufacturer declares that it is impossible to put chimneys having horizontal sections to its boilers.

The Traian company also supplies relatively good boilers. Model TR-50-1KT allows you to heat the premises with a total size of 520 square meters. m. Traction control is performed by an automatic device, can additionally be connected to the heater. Pipes for supplying hot water to the system should have a typical diameter of 1 ½ inches. The figure "50" in the model index indicates thermal power, and the efficiency is 92%.

The TB-10-2KT is a dual-circuit apparatus. It can be connected to it additionally. Power of the attached electric heater makes 3 kW. The boiler itself produces 10 kW and provides an efficiency of 85%. The mass of the device is 190 kg, it can work with chimneys with a cross section of 150 mm and a height of 7 m; preferred two-pipe heating scheme.

Traian Company provides a full factory warranty for 30 months from the date of purchase. The chimney should have a diameter of 0.2 m. It is recommended to use the boiler in a two-pipe heating system. The choice of water or antifreeze as a coolant is left to the owners.

But for normal work with antifreeze artificial circulation is required.

Excellent results are shown by products of Buderus. The pyrolysis boiler S121-2-21 will be able to heat up to 180 m2, it is possible to connect the heating tank to the water circuit. The total heat output reaches 21 kW, and the size of the loading chamber makes it possible to inject logs up to 0.58 m long. The housing is made of steel, the system is designed for both gravity and pump circulation. The ash compartment is formed of fireclay.

The designers took care of safety: if the door is opened, the smoke will be completely stopped by a special smoke exhauster that is started automatically. Warranty service is available 2 years after the adoption of the boilers in operation. Atmos equipment is produced in the Czech Republic, and this brand has become one of the leaders in the European market of solid fuel systems.4 out of 5 boilers of the Czech manufacturer go abroad, including to industrialized countries with severe technical control. Gas generators on wood give up to 100 kW of heat, combined (allowing the use of more coal) are limited to 50 kW.

If the record power is not required, you should pay attention to Atmos AC, consuming only coal and issuing from 20 to 26 kW. The Russian competitor, Divo, supplies boilers capable of heating from 120 to 750 square meters. m. "Divo-10" provides thermal power of 8-12 kW, consuming no more than 2.1 cubic meters. m tree per month. The maximum length of a log is 49 cm, the boiler itself “pulls” 130 kg. "Divo-12U" more economical with the same capacity, consumes up to 1.5 cubic meters. m of wood, it is possible to connect the ten.

The manufacturer claims that double afterburning of pyrolysis gas increases the efficiency up to 92%, and that the boiler will pay off by the end of the third heating season.

Use is allowed:

- wood waste;

- briquettes;

- brown coal;

- anthracite of various sizes;

- peat

German products have been confirming their quality for the past 150 years. The high authority of the national industry is also maintained by the Viessmann brand. Pyrolysis boiler "Vitoligno 100 S" is equipped with a controller "Vitotronic". Automation coordinates not only the power of heating and ventilation of the furnace; it helps to find out what problems have arisen and whether it is necessary to load additional fuel. The series includes five different modifications, the power of which ranges from 25 to 80 kW. The combustion chamber can hold 100-350 l, the maximum length of logs in any case is limited to 0.5 m.

If the used wood is dry enough and the boiler is set up correctly, you can count on an efficiency of 87%. It is recommended to use fuel with a maximum moisture content of 20%. Under the brand "Geyser" are sold household, industrial and semi-industrial pyrolysis type boilers. In the household segment, the company represents apparatuses with a capacity from 10 to 30 kW. The PC system Economy-10, thanks to a carefully designed water jacket, will be able to transfer pressure up to 10 atm, this guarantees the safety of using the boiler.

In standard rooms (with a ceiling height of up to 3 m), it will provide 100 square meters of heat. m. In a month it takes a little more than 2 cu. m quality wood.The option of accession of TEN is provided. Grate bars and gate valves are supplied with the boiler. Accommodation in an isolated space is not required.

The design of the PC-100 will help heat up to 1000 square meters. m, the water tank holds 100 liters of fluid. The recommended chimney diameter is 25 cm. Within a month, a powerful machine will burn up to 10.8 cu. m dry wood. Single capacity of the firebox - 0.65 cu. m

The manufacturer guarantees the comfort, simplicity and safety of use of the device.

Ukrainian company "Motor Sich" specializes in the production of aircraft engines, but also to the pyrolysis boilers it fits quite professionally. For engineers who are focused on such a complex production, they do not pose the slightest problem. Attention should be paid primarily to such modifications as the "MS-16" and "MS-25." They are able to take a fresh cut down of wood, even at a humidity of 50%. To warm the house size of 100 square meters. m, you need to spend about 30 kg of wood for 24 hours.

Sophisticated design is very stable and allows installation even under street canopies. The time from one load to another is 8-15 hours, that is, continuous supervision of the boiler is not required.The outer walls are from 0.6 to 1 cm in thickness, they are immune to the harmful effects of the resin, almost do not burn through. Such attractive qualities are achieved through the use of refractory ceramic concrete.

The air-tightening mechanism and controller are made in the EU, fully meet the latest requirements of the standards.

Criterias of choice

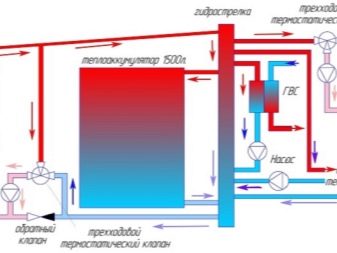

Choosing a model is not all that is required to make the right decision. The heating boiler with a water circuit is good because it reliably heats even large houses and minimizes effort. Water heating is smoother than using air convection, the distribution of energy becomes more even. Increased thermal capacity of water in comparison with the air also turns out to be a plus. Yes, it warms up worse, but it keeps better the heat already received and allows a little less attention to be paid to new fuel budgets.

Air boilers will be better in the event that it is impossible to provide constant monitoring of them. They are also preferable for periodic heating, when the heating circuits cool from time to time.Non-volatile boilers help not to fear a sudden power outage or to heat houses where it is not there and it is not clear when it will appear. The elimination of the pump makes the system less noisy; but there is no full confidence in the stability of the heating under any conditions. Natural circulation forces to buy pipes of increased section, which cost more, are heavier and take up a lot of space.

It is also worth remembering that without forced circulation it is impossible to heat houses with a height of more than one floor. At the slightest violation of the thrust efficiency of combustion is sharply reduced. As for the mine-type boilers, they are almost always combined and can even be called universal, as they are able to absorb very different fuels. Bookmark it is spent more economically than in other schemes.

It is possible to clear the space under the furnace from ash directly during operation without stopping the heating.

We must not forget that for the mining boiler the correct binding is crucial. Violations when performing it are immediately recalled by loss of performance and loss of valuable characteristics.In addition, the simplicity of the device does not mean that it will be easy to manufacture such equipment in artisanal conditions. Yes, such a task is in principle feasible. Only with the greatest care and careful calculation.

Coppers with a pig-iron fire chamber differ in the increased thermal inertia and are badly regulated. It will take a long time to warm up or cool the system, and even an automatic regulator will not allow to correct the situation. Moreover, the heating will react to changes in the environment slowly, and therefore additional inconveniences will be created. It is strictly prohibited to load cold firewood or fill the tank with cold water.

Insure can be using knot podmesa.

Separate conversation deserves the power of the pyrolysis boiler. It is impossible to understand exactly whether 20 kW is enough, or this indicator is excessive, if you only focus on the area of the house. The best source of information is a project prepared by experienced architects who will indicate all the necessary parameters.

Consideration should be given to:

- the height of the structure;

- the presence of heated or unheated attics, basements, adjacent extensions;

- the number of windows and their sizes;

- the number of cameras in each glazing;

- thermal insulation excellence;

- average annual and maximum possible wind speed;

- insolation;

- air humidity in a particular area.

How to do it yourself?

It is quite possible to make a pyrolysis boiler with your own hands, only you need to make detailed drawings of an improvised apparatus, carry out a comprehensive calculation and prepare a connection diagram. Combustion chambers divide the grate, solid fuel and its residues are burned at the bottom, and gases obtained during pyrolysis are burned at the top. In industrial conditions, other designs are also used, but for amateur craftsmen it is better to choose the simplest solution. Ready-made branded products cost at least 36 thousand rubles, while they can only heat up to 100 square meters. m

Doing your own hands work will be cheaper by about 25-30%.

For this you will need:

- welding machine with 3 or 4 packs of electrodes;

- Small size angle grinders;

- electric drill;

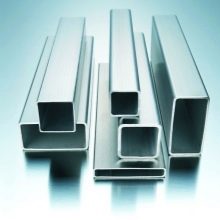

- pipes with a diameter of 5.7 cm with a wall thickness of 0.35 cm;

- pipes with a diameter of 15.9 cm, thickness - 0.45 cm.

- tubular profile 3x6 cm, wall 0.2 cm;

- tubular profile 4x8 cm, wall 0.2 cm;

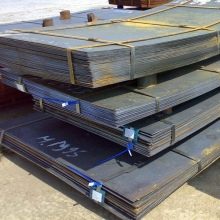

- steel strips;

- iron sheets;

- chamotte

Whenever possible, it is worth creating a 3D sketch of the internal equipment, then the presentation will become clearer, the work will be simplified. Important: cutting metal grinder can not give a fairly smooth cut. The fee for cutting it with a guillotine, including when building a boiler from a cylinder, is absolutely necessary and justified. After assembling the chambers, duct and walls are welded to them from behind. It is convenient to make a smoke channel from a channel bar, but no one forbids the use of a profile pipe; you only need to prepare holes for ventilation in it.

The next step is the formation of a hole under the air tube and the welding of the nozzle. To connect this pipe with the boiler, use a 2x2 cm profile of a tubular section. The heat exchanger is formed from a profile of 5.7 cm - it must be cut into homogeneous fragments, put on a plate and attached around the perimeter by welding. Then the heat exchanger itself is welded to the boiler and the throttle is prepared. It is time to weld the front wall, but it should already have openings for air intake and ejection.

Assembly continues by welding the lid and the hog, only after that the inside of the boiler is assembled.For your information: at this stage it is already possible to align welding spots with a grinder, a file or a metal brush. The fastening of the casing with the corners is achieved with the help of small holes that are welded. Next comes the turn of the test for tightness, in the course of his boiler for the first time filled with water. The lid, placed on top, must be insulated; air damper control is provided with threaded rods.

When the boiler is completely closed, the hinges and the door are mounted (preferably cast iron); lining is recommended from bricks. Important: the downstream chamber should also be lined, for this purpose refractory material is used. It is cut and grinded to keep the camera as tight as possible. Attention should be paid to the exact fit of the valve’s dimensions to the requirements of the project.

The air duct from the profile pipe is complemented by a blower fan.

Turbine devices that create vortices help to increase the efficiency of the boiler. They not only make the transfer of heat better, but also contribute to the cleaning of pipes from various blockages. Before the device is finally put into operation, you should make sure once again that the joints are tight.Now the water is supplied under pressure of 3 or 4 bar. Create it will help a special device - opressovshchik.

In order for the boiler to work normally, it must be equipped with a safety group - at least with a pressure gauge, a device for pressure relief and air exhaust. The system is set to self-discharge when a pressure of 3 bar is exceeded. Attention: it is impossible to arrange any tests for empty boilers, especially in the absence of a thermometer. Verification involves laying out paper and 2 or 3 logs.

Ignite the paper should be with the chamber closed tightly and with the throttle door open.

As soon as the whole tree is engulfed in flames, the flap is shut off in order to start the much needed pyrolysis. Bottom watching when there will be a torch. Immediately after that, the time until the coolant boils is counted. When it happens, turn off the fan and thereby extinguish the torch. Only the perfect passage of all stages of such a test allows you to use a homemade boiler for heating.

Experts believe that it is best to use iron grate for the pyrolysis boiler. Instead of a cylinder, an unnecessary steel safe can serve as a good blank.There just steel is quite strong and reliably protected from destruction at high temperature. To increase the heat exchange area will help add the contour of the pipes. A refractory brick is placed at the bottom to improve air penetration in the corners.

Installation

Quite a few people do not have sufficient knowledge and do not have special tools and skills to handle them. But even the lack of a welding machine and the ability to use it is not terrible. Step-by-step instructions for mounting and tying the finished pyrolysis boiler will help to fix the matter. Knowing it is useful, of course, when using self-made equipment. Immediately it should be clarified that decisive importance in choosing a connection scheme has the priority of simplicity or functionality.

Thus, the most advanced options allow the use of heat-accumulating tanks, which help to maintain a stable temperature for up to 48 hours even when the boiler is not working.

Before installation, you should purchase specially selected:

- fitting;

- pipes;

- elbows;

- filters;

- check valves and other accessories.

Experts believe that the best circulation pumps - German production.They may be a bit more expensive than models from other countries, but durability and increased performance justify the difference. But you can choose the manufacturer of other components at your discretion. Since inside the pyrolysis boiler there are contours with a very strong heating, as in metallurgy, it is necessary to scrupulously observe the fire regulations. The boiler room should be placed in a separate room.

Normal ventilation will be achieved only through an opening of 100 square meters. see. Putting the boiler is required exclusively on concrete or brickwork. The space in front of the chambers is covered with a steel sheet 1x1 m in size and at least 0.2 cm thick. It is unacceptable to mount the boiler where the wood is stored. The height of the chimney above the roof should be at least 0.4 m, and it is forbidden to install leaking structures to remove smoke.

The minimum approximation to walls, even made of non-combustible materials, is 0.7 m. It is advisable to level the boiler, as the slightest inclination to the side will have a bad effect on its characteristics. Experts and experts recommend to insulate the chimney from the inside.This helps to avoid condensation and the associated negative phenomena. All these tips can be realized without recourse to specialists, that is, with minimal costs.

The chimney pipe must reach a height that supports the desired traction. The minimum value is 50 cm above the ridge of the tallest building located within a radius of 10 m. Installation of chimneys whose diameter differs from the diameter of the gates or gas flow throttles is not allowed. After these gates should be mounted straight vertical length of 2 m, only in the next section can rotate 45 degrees, and strictly up to 100 cm.

Insulation is mandatory for all sections of the chimney, which are raised above the throttle, regardless of their placement in the room or outside the house.

For modular chimneys, condensate assembly is practiced when the upper knees are inserted into the lower segments. It is impossible that the chimneys at least slightly pressed on the gates. From the top of the head line to the top of the pipe leave a gap of at least 15 cm. Thermometers are placed strictly on the return lines of the heating systems, at least 1 m from the boiler.It is advisable to use a thermometer with scale markings up to 120 degrees.

The initial section (1 m outlet for the coolant) and the same segment at the beginning of the return stroke is better to form from metal. The first turns are made in the format of semi-branches. You cannot use right angle corners instead. In general, it is recommended to reduce the number of turns. There must be at least 2 m of free space between the front part of the boiler and fences or walls.

Service

The tightness of the boiler itself, pipes and chimney should be checked regularly, at least before the start of each heating season and after it ends. For ignition it is required to apply only dry wood, the bookmark is made with paper up to the opening for primary ventilation. Service works are reduced to the removal of ash and ash from the working chambers. Also, the heat exchanger should occasionally be freed from solid combustion products.

The frequency of cleaning it is determined by:

- the type (energy value) of the fuel;

- its moisture level;

- concentration of resinous substances.

Remove soot and soot should be carefully, for this are special blades.Even if they are not included, the manufacturer indicates in the technical documentation the recommended devices. It is important to control the tightness of the loading and pyrolysis chambers. When the gasket seals sit down, the doors tighten more tightly or change the seal itself. Replacing the lining itself is carried out only if it is allowed according to the instructions and only on recommended materials.

In the absence of clear instructions, it is advisable to consult with the manufacturer’s specialists. It is not allowed to heat pyrolysis boilers in direct combustion mode for more than 12 hours in a row and during the day; all manufacturers, without exception, refuse to replace the burnt partitions. The primary mode is designed strictly for initiating the pyrolysis process. Do not extinguish firewood or coal with water; only sand is used. But this is an extreme case, it is recommended to be limited to turning the gates (chokes) with the doors closed.

Do not heat the boilers with the doors open, with the exception of igniting small pieces of wood. The frontal technical window should not open when the pyrolysis unit is operating.If you want to visually check the possible pollution, use the window in the back of the gas passage. If necessary, the repair of the boiler should be invited mechanics with welding equipment and the necessary skills.

Experienced experts will choose the welding mode without additional instructions.

You can find out how to make a pyrolysis boiler with your own hands from the video below.