Beretta boilers: types and possible causes of breakdowns

Boilers Beretta from the Italian manufacturer are popular with buyers, because they are effective, safe and are assembled from high quality materials. The manufacturer independently develops and introduces innovative technologies that deservedly enjoy good reviews from professionals and regular customers.

Heating boilers Beretta are the best combination of quality and price.

Special features

The brand of heating equipment Beretta is produced by the manufacturer Riello, who initially specialized in the production of diesel burners.

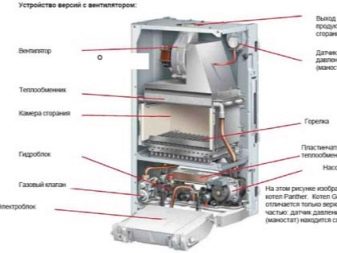

Technical features of boilers:

- fuel - natural or liquefied gas;

- burners are made of stainless steel;

- weather-dependent automatic unit, that is, the equipment independently selects the thermal mode based on the parameters and weather conditions;

- the presence of an automatic air vent in a circulating pump unit;

- availability of safety valve, pressure gauges, membrane expansion tank;

- electric firing in volatile boilers;

- device self-diagnosis: checking thrust, pressure in the system and the presence of fuel;

- there is no risk of thermal carrier freezing;

- working agent temperatures - from +40 degrees to +80 degrees;

- water temperature - +37 - +60 degrees;

- pressure in the heating circuit - up to 3 bar, with built-in boilers - up to 8 bar;

- chimney - atmospheric, coaxial.

In addition to high-quality assembly, thereby eliminating the risk of faults, the boilers of this manufacturer have the following advantages:

- style solution with smoothly flowing lines;

- adaptation to operation in Russian climatic conditions;

- various equipment variations;

- compactness;

- average price range;

- the ability to self-install and troubleshoot minor problems.

Thanks to these advantages, Beretta gas boilers are in great demand.

In the opinion of consumers, it can be concluded that the main disadvantages of Beretta heating equipment are:

- Failure of heat exchangers due to high water hardness. To avoid this problem, soft water should be fed into the system.

- Burnout of the control unit, since imported equipment is equipped with an automation system, which implies their sensitivity to electrical power. Therefore, for optimal boiler operation, it is necessary to install a voltage regulator.

- Faults in expansion tanks as a result of incorrect calculation of the system or a large amount of circulating thermal media. To eliminate the problem, it is necessary to install a larger expansion tank.

Kinds

The Italian manufacturer has tried to meet the needs for every taste, so it produces lines of gas boilers that differ in technical characteristics and purpose. There are models for private houses, city apartments and industrial premises.

All heating equipment Beretta is divided into types of features such as:

- Mounting method. There are wall and floor devices. Wall options differ in small overall dimensions and a possibility of installation in private houses. Floor differ in the high power and bulkiness, are intended for installation in production buildings or cottages of the big area.

- The principle of operation - boilers of condensation and classical types. The first for heating the premises use only thermal energy as a result of gas combustion, and the latter, in addition to this energy, receive the energy of exhaust gases, their efficiency often exceeds 100%.

- Combustion chamber - atmospheric with marking “A”, turbocharged “S”.

- Number of circuits: single-loop "R" and dual-circuit "C" models. Dual-circuit equipment can be equipped with a heat exchanger of bithermic and separate type. Purpose: heating the premises and the organization of hot water. Models with one circuit are designed to provide only heating, but are equipped with a pipe for a built-in boiler.

Main series

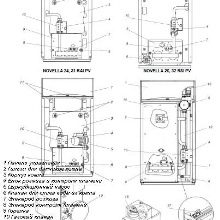

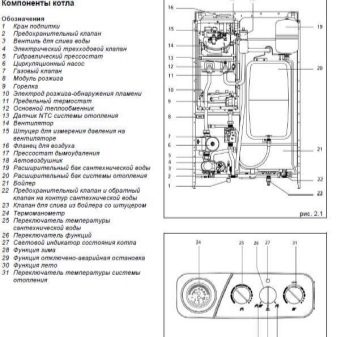

The “City” boilers are available in nine variations with different performance and configuration.Equipped with one or two heating circuits with a maximum power of 24 and 28 kW with combustion chambers, both open and closed. The fuel used is natural and liquefied gas. Turbocharged boilers are also available with a heating capacity of up to 50 kW with one or two circuits. The cost of the boiler depends on the configuration and power.

Technical characteristics of the City 35 CSI model:

- space heating up to 350 m2;

- heat exchanger - separate type; for the heating circuit - copper, for hot water supply - steel;

- combustion chamber - turbocharged type;

- Efficiency - 93%;

- power - 37.6 kW;

- water heating - 20 liters per minute;

- weight - 42 kg.

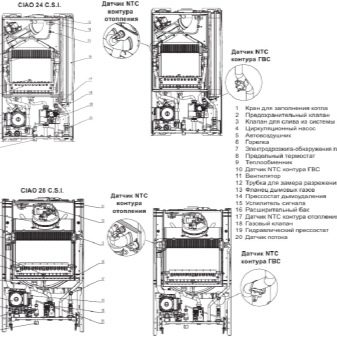

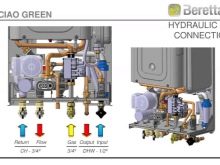

Ciao boilers are available with only two circuits with both open and closed combustion chambers. The equipment is equipped with a heat exchanger of bithermic type. A distinctive feature of this series of boilers is the option to protect the coolant from freezing. In the event that the coolant is cooled to +5 degrees, the automatic heating of the water in the system begins.

Technical characteristics of the model "Ciao 24 CSI N":

- space heating up to 240 m2;

- fuel consumption - 2.78 cubic meters per hour;

- power is 24 kW;

- Efficiency - 92%;

- the combustion chamber is closed;

- ignition - automatic;

- dimensions - 74 x 40 x 34 cm.

Mynute models are available with a condensing and traditional operating principle. Traditional models are equipped with one or two circuits, closed or open combustion chambers, with a capacity of 24, 28 kW and an expansion tank with a capacity of 8 liters. There are options for auto ignition, antifreeze, self-diagnosis.

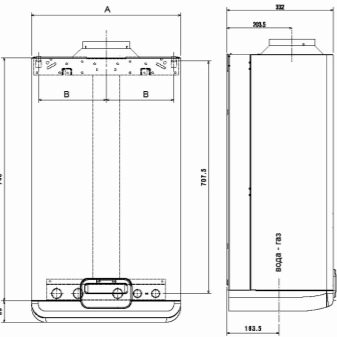

Novella boilers are manufactured with an open combustion chamber, piezo-ignition, non-volatile. Available only in floor version with one circuit. They are equipped with a heat exchanger made of cast iron and a two-stage burner made of stainless steel. The heat output of the equipment is from 90 to 280 kW.

Technical features of the model "Novella 45 RAI":

- the combustion chamber is open;

- performance - 45 kW;

- fuel - natural gas;

- fuel consumption - 5 cubic meters per hour;

- weight - 154 kg.

Boilers "Boiler" with a heating capacity of 28 kW are equipped with closed or open type combustion chambers. A distinctive feature of the boilers of this series is the presence of a built-in 60-liter boiler with a separate type heat exchanger. In the configuration with the boiler is a circulation pump unit.The equipment is equipped with an option to protect the coolant from freezing and a burner device.

Features of the model "Boiler 28 BSI":

- power - 28 kW;

- Efficiency - 91;

- installation method - wall;

- Overall dimensions - 46 x 94 x 60 cm.

“Exclusive” models are installed in closed heating circuits with forced circulation of heat carrier in a system with four modes of operation. Power equipment is in the range of 16 - 35 kW.

Technical features of the model "Exclusive 24 CAI":

- the number of contours - two;

- heating capacity - 26.7 kW;

- Efficiency - 90%;

- the combustion chamber is open;

- dimensions - 33 x 80 x 40 cm.

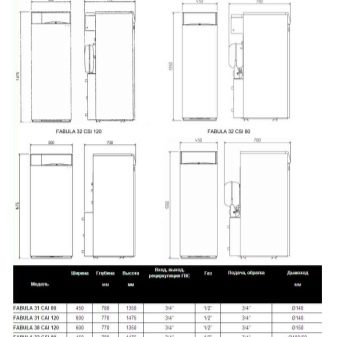

The Fabula series represents a double-circuit boiler with an integrated boiler, which provides a large volume of hot water without interrupting the heating of the room. The boiler can be a capacity of 80, 90 and 120 liters. Maximum performance - 43 kW with modulation of combustion. The heating circuit is equipped with a heat exchanger made of cast iron, while the hot water circuit is made of steel with a magnesium anode, which provides reliable protection against the formation of scale. The advantages of this series include reliability and high quality assembly of parts.

Characteristics of the model "Fabula 31 CAI 80":

- power - 31 kW;

- coefficient of performance - 90%;

- 80 liters boiler;

- weight - 125 kg;

- overall dimensions - 135 x 45 x 79 cm;

- fuel consumption - 3.5 cubic meters per hour.

Faults and their removal

In the opinion of consumers, Beretta boilers practically do not identify faults. In case of breakdowns, the manufacturer has provided independent equipment diagnostics. This function includes control sensors that detect faults in the system, signaling this to the control module. As a result, the boiler stops working, and the LCD screen shows the error code. To eliminate the error you need to fix the damage.

Error "A 01" indicates that there are problems with ignition.

In this case it is necessary:

- make sure that the fuel flows by opening the valves;

- check the condition of the fuel valve;

- examine the terminals;

- diagnose the ignition electrode - in some cases, the electrodes can become clogged, so they need to be cleaned with emery paper;

- change the control unit.

The error “A 02” indicates that the thermostat has broken. To correct the problem, it is necessary to check the functioning of the thermostat.

The error “А 03” indicates that the exhaust gases are not removed through the chimney.

To resolve this problem, you must:

- Check traction by bringing a lit match to the window. If the flame does not deflect, thrust is absent.

- Clean the chimney from the foliage or ice.

- Check the ventilation and clean the fan blades from soot and dust.

The error “А 04” means that the signal from the thermostat is on. To fix the problem, it is necessary to repair and replace parts of the control unit.

The error “A 05” indicates the breakdown of the hot water temperature sensor. To fix the problem, you need to check the contacts and, if necessary, install a new part.

The error “E 40” indicates that the sensor contacts have opened. To correct the error, you need to change the wiring and tighten the contacts.

Error "E 42" signals the sensor closure on the incoming line. To fix the problem, you need to make a diagnosis of connectors and replace the defective part.

Error “Е 46” - the bell flashes, signaling an increase in the temperature of the coolant. To eliminate the error, check the flow rate of the heat agent. The optimum is 2 cubic meters per hour.

Not all malfunctions are indicated by an error code.

If there are other deviations in the system, the following recommendations will help:

- If the heating equipment is functioning normally, but not heating, then the problem may be that the system is under pressure. To do this, remove the air tap Mayevsky. It may also not start the pump, so you need to check its health and switch to a different speed.

- The smell of carbon monoxide and smoke. The problem can be solved by cleaning the chimney from foliage and soot.

User's manual

Before the installation process it is necessary to collect technical documentation: agreement on the supply of fuel for the developer and the installation project. Technical specifications are consistent with the gas service worker.

After a personal check of the object for the correctness of the gas supply, the specialist makes a conclusion that all safety rules are observed. On this basis, it will be possible to open the valves, which is connected to the boiler. The heating system is pressed to a pressure of 1.8 bar.

It is also important to remove air from the heating system.All seams and joints must be sealed; a pressure stabilizer and a source providing constant power are installed on the device. It must be borne in mind that antifreeze should not be added to the heat carrier.

Heating floor equipment is installed on the floor surface from the wall at 10 cm, which is made of non-combustible materials. Otherwise, there is a need for a special protective material. Only if these rules are observed, the gas service will give permission to install the boiler and connect it to the main pipeline.

Beretta boilers are exclusively connected to metal pipes. Flexible hoses are permissible only for connecting additional consumers.

Wall-mounted Beretta boilers are installed in special rooms that meet all safety requirements. In private cottages, a boiler room can be installed on any floor, except living rooms, bathrooms and bathrooms. Depending on the heating output of the heating device and the capacity of the boilers, the area of the boiler room depends.

In the event that the boiler is equipped with a closed combustion chamber, the area of the boiler room can be any, the presence of window openings is not controlled either. However, you need to take care of the influx and removal of oxygen in the required quantities.

You should know that the area of the boiler room should be more than 4 m2 with a ceiling height of more than 2.5 meters. The width of the doorway should not be less than 80 cm. It is also important to organize good ventilation in the room, since the combustion process is supported by the influx of oxygen.

The boiler room must be equipped with a gas analyzer, which will allow you to notice possible gas leaks. The gas analyzer must have an electric valve to be able to shut off the gas supply. In apartment buildings, the installation of a heating device in the basement is strictly prohibited.

Gas coppers of Beretta are rather simple at operation. After studying the manufacturer's instructions, you can understand how to connect the equipment. After installation of the boiler, the temperature regime of the thermal carrier must be adjusted.

After the end of the cold season, boilers with two circuits need to be switched to summer mode, with only a hot water system functioning.

The heat carrier in the system is water without salts and mechanical impurities; otherwise, scum forms on the inner walls of the heat exchanger. Hard water must pass through the filter unit.

In the next video you will find a review of wall gas boilers Beretta "Ciao" and "City".