Pellet boilers: features, advantages and disadvantages

Various alternative energy sources have become more popular today than ever before. In general, this is a logical explanation. And the main thing is that classic types of fuel, such as gas, constantly rise in price. For this and other reasons, it is necessary to look for new, more efficient and more affordable types of heating.

Let's talk about such a device for heating, like a pellet boiler. This article will focus on his device, how it works, what types it happens, what is its power and fuel consumption. In addition, we consider different models from different manufacturers, as well as how to select them and how to install them.

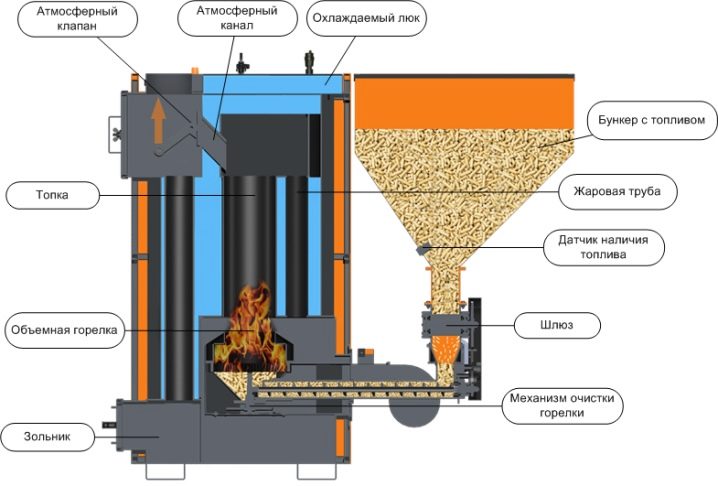

Device

So, the pellet boiler is one of the categories of the solid fuel type boiler for heating, where there is an automatic supply of fuel material working on pellets, which are called wood pellets made of wood.

The first element of which such a device consists is a combustion chamber. As a rule, it has small dimensions. This is due to the fact that the boiler with lining does not need at the same time more pellets to provide the room with heat.

As a rule, pellet burners are installed inside such a chamber. They are part of the boiler where the pellets fall and where their combustion process is directly carried out. Pellet burners can have power from 10 to 750 kilowatts and be either retort or flare. That is, they differ in the ways of supplying air and fuel to the combustion area.

Pellet burners manufactured by different manufacturers may have completely different automatics and they may have different designs. But all of them can quite accurately regulate the amount of pellets that are supplied to the combustion chamber, as well as the air. Properly selected, this ratio makes it possible to achieve the most high-quality pellet burnout in order to produce gases with the maximum temperature, which makes it possible to give off heat well. Due to this, the efficiency of such boilers reaches a rate of 93 percent.

The next part will be a heat exchanger, after which the heat is transferred to the heating system, which can be made on the basis of water or antifreeze.

Note that heat exchangers may have a different design. They can be flat, horizontal, tubular, vertical, with a different number of moves, as well as turns equipped with turbulators and so on. The best solution would be vertical type heat exchangers, which have a couple of moves and are equipped with a turbulator. The use of such models allows you to give the gas more heat.

In all modern models of the considered long-burning boilers, heat exchangers and combustion chambers are placed in a special additional heat insulating casing. This makes working with the boiler safer, more comfortable, and also allows you to significantly reduce the loss of the boiler. The next component of such a system will be a special bunker for fuel, in which pellets are usually stored and from where they enter the burner. The capacity of such parts may be different: from a couple of tens of kilograms to several tons.

These parts are different:

- detached;

- airtight;

- built-in;

- untight.

The size of this element will depend on the indicator of how much such a boiler will operate autonomously. It should be said that, as a rule, the average size of the bunker of such a boiler with a capacity of 25 to 40 kilowatts is somewhere around two hundred kilograms. This may be enough for a period of three to seven days of work in uninterrupted mode.

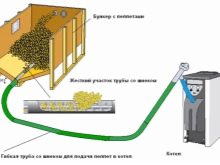

To transport the pellets, almost all the manufacturers of such solutions use an electrically driven screw auger system, which makes it possible to quickly and carefully deliver the required number of pellets. If pellets are to be transported for a considerable distance, then either a pneumatic mechanism or elongated screws of a special design are used.

In addition, pellet solutions can be equipped with various additional technical devices, such as:

- automatic control of the heating system;

- weather-dependent automatics;

- pneumatic or mechanical ash removal system;

- self cleaning mechanism.

In addition, each model has a temperature sensor that will display the temperature inside the device, as well as a special control unit that allows you to monitor the operation of such a boiler.

Principle of operation

As noted above, pellet-type boilers consist of three special mechanisms:

- boiler with a burner;

- conveyor system to feed pellets;

- bunker for fuel.

If we talk about the work of such a boiler, then this is done by the following method:

- pellets are put into the fuel bin;

- their supply to the boiler is done using a screw-type conveyor;

- In the boiler furnace, pellets begin to burn and heat the thermal medium.

In heating solutions of this type, the top-down option of fuel combustion is used. In this case, the combustion will be significantly slower than in a simple firebox, where pellets burn “from the bottom up,” and the heated gas streams circulate and involve all the fuel layers above. This is implemented in this way, if we talk about the design that a burner with a nozzle is located in the furnace, which delivers the heated air directly to the combustion zone.

This makes it possible to control the rate of combustion of fuel, so that the fire region gradually goes down. The supply of heated air can burn fuel much more efficiently.In addition, in this case, ash and soot is formed significantly less, and the efficiency of such boilers increases from 93 to 96 percent.

In addition, the mechanism of the pellet boiler provides an opportunity to work on one tab a little more than 24 hours, which makes this technique an excellent solution to use it in everyday life. In addition, the presence of a fuel bunker makes it possible to make the work of this type of equipment fully automatic.

Kinds

All pellet boilers are solid fuel in nature, since they have all the characteristics of this category of boilers. Steel and cast iron are usually used for their manufacture, and the construction is made of parts that have already been discussed above. But there is a certain distinguishing feature. The burner in this case works not only with electronics, but also with a mechanism that feeds fuel into the furnace. This structural element will have a significant impact on the technical properties of almost any boiler.

According to the above points, boilers are divided into various categories:

- bulk;

- mantel;

- flare.

If we talk about flare models, they are distinguished by durability, compactness and unpretentiousness.In addition, they have a relatively small capacity, which is why such burners are only available in small-capacity domestic boilers. It is better to buy them if you often turn the equipment on and off. This is a good solution for boilers where different categories of fuel are used.

An essential feature of this category of burners will be high sensitivity to the quality of pellets. The best thing here will be to use slightly moist pellets, which retain their own shape before they get into the burner with a small amount of sand, as well as various impurities.

Volumetric burners are the most efficient and most productive of all. They are usually completed with powerful household as well as industrial solutions. As a rule, their weight is greater than that of flare counterparts. In addition, volumetric burners are considered insensitive to how well the fuel quality. Today it is the most popular models of burners.

Fireplace types can be installed only the smallest boilers, which are also called stoves, fireplaces. They are very sensitive to how fuel quality.In addition, they are distinguished by moderate performance, as well as very high reliability due to the simplicity of this device.

It should be noted that pellet boilers are also divided into categories according to their intended purpose for which they will be used. We are talking about boilers for heating and stoves, fireplaces.

The first category is needed to heat the room in which it is installed. Such models are quite compact, work quite quietly and have a nice appearance. The second category is necessary to provide hot water and to heat the room. The power of such models is about 14 kilowatts, and the maximum performance is about two kilowatts.

By the way, if we talk specifically about boilers, we distinguish such boilers:

- with hot water circuit;

- convection, which heat the air;

- combined.

Different boiler models may have different capacities. Today there are a lot of models - 10, 30, 100 and even 200 kW. Each of these models can be used to heat a particular area or building.

Also pellet boilers are divided into groups according to the degree of automation:

- mechanized;

- automatic;

- semi-automatic.

Despite such differences, there will be practically no need for a person to interfere with the operation of the boiler. It only needs to be turned on in the autumn and off in the fall. For the performance of all other functions will be responsible processor. But such an automatic boiler is quite expensive. And we are talking not only about the boiler itself, but also about the cost of its design, as well as its expensive installation. Automatic models will be an excellent solution if the stock of fuel is large. And if you need to constantly load fuel into the bunker, then buying an automatic model makes almost no sense.

If we talk about semi-automatic solutions, then their difference with automatic models is that they will have to clean the ash pits themselves. This procedure is very simple.

The most common category of boilers in our time are mechanized models. They are quite compact, they are distinguished by simple cost, as well as simple construction, which significantly increases their reliability. Since the degree of automation will be significantly less than in cases with other categories, the owner will need to do the cleaning of the heat exchanger, as well as the ash pan with his own hands. But even a person who has no experience can cope with it.

Since the bunker model of the mechanized type has a rather small size, it should be filled about once every two or three days. But then everything will depend on how actively it is used.

It should be said that all boilers using pellets are universal in terms of the types of fuel used.

There are boilers of various categories:

- conditionally combined;

- pellet

- fully combined.

The considered models of boilers can work on wood-type granules. A little more universal are the conventionally combined solutions, which allows the use of different categories of fuel. But any fuel, except pellets, must be used exclusively in special cases and as rarely as possible. The main reason for this is the device of the boiler. The form of the furnace of this device is designed only for the use of granulated fuel. But chips, firewood and coal can cause overheating of the local type, which can be fraught with equipment breakage.

If we talk about combined boilers, they make it possible to apply different categories of fuel all the time.Such an opportunity is made available through the use of a couple of fireboxes. At the same time, despite the universality of such a decision, it will be larger in size and more expensive.

In general, it should be said that pellet-type boilers are rather durable and, if properly handled, can last for twenty or more years. But it will be important to use only high-quality pellets, because some models are designed only for pellets of a certain type and category.

Power and fuel consumption

It should be said that wood pellets have a fairly good calorific value - one kilogram can generate about five kilowatts of thermal energy. For example, to heat a small house with an area of fifty square meters, you will need a kilogram of granulated pellets per hour. To heat such a room, it will be necessary a little less than 25 kilograms of pellets per day.

If we talk about the power of such equipment, then everything is simple. It should be guided by the standard of 1 kilowatt of thermal power per ten square meters of residential. Also, it will not be superfluous to remember that there should be a small stock of about ten to twenty percent.

For example, if the area of the house is from 60 to 200 square meters, then a low-capacity boiler up to 25 kilowatts will be enough.

If the area of the house is 200-300 square meters. meters, you will need a boiler with a capacity of 25 to 35 kilowatts. For houses with an area of 300-600 square meters. meters, you need a device with a power of 35-60 kilowatts. And for very large houses with an area of 600-1200 square meters will be needed especially powerful models with capacity from 60 to 100 kilowatts.

In order to significantly reduce heating costs, you should use these tips:

- It is necessary to get rid of heat loss at home. If there are places in your house that can significantly lose heat, then even the most economical pellet boiler will not help you.

- It is better to purchase fuel immediately. The cost in this case will be significantly lower. Therefore, it is better to immediately buy pellet fuel at once for all time, choosing a supplier who will offer the best price.

- Buy high-quality pellet boilers, where good automation is installed. This will give you the opportunity to significantly save.

Advantages and disadvantages

It should be noted that solid wood pellet boilers will be much more convenient solutions working on wood.

If we talk about the advantages of pellet boilers, then it should be called:

- Easy maintenance.If there is a possibility, the boiler can be serviced independently.

- Environmental friendliness. Such boilers generally do not produce harmful emissions into nature.

- Work automatic type. Such heating solutions with small bunkers require a couple of approaches per day. Where bunkers can no longer approach them for a week or more, which will be very convenient. There are even models that can work on pre-defined characteristics.

- Almost zero formation of ash, as well as soot - pellets burn almost completely, because of its need to clean this boiler less often than if you use wood. In addition, it is quite easy to pick up on sale granules with low ash content, which burn 100 percent.

- Security. Pellet boilers do not run on flammable liquid fuel, gas or electrical energy.

- Fuel is easy to load. Any granule weighs a couple of grams and this fuel belongs to the category of bulk. Usually, pellets are poured into bunker tanks directly from the bags or using a scapula. And boilers generally carry out the collection of such fuel independently.

- High efficiency.These models have an efficiency of up to 94-96 percent, while conventional boilers operating on solid fuels cannot boast performance above eighty-eighty-five percent.

- Inexpensive heat. Pellet type boilers can be an extremely profitable solution. But then everything will depend on operating conditions. If you make a comparison with wood, electric or liquid solutions, they will be quite an economical option.

At the same time, it is impossible not to name a few shortcomings of these boilers. First, pellet boilers require constant ash removal. Of course, this minus is easily leveled, because the ash is considered to be a wonderful fertilizer for indoor plants, plants in the garden plot or garden. Secondly, the pellets can be filled with moisture due to which they will burn badly. They must be stored exclusively in a dry place and in sealed storage bags. Thirdly, such equipment is very expensive. We are talking about models with fuel type automatic type.

In general, it should be noted that compact pellet boilers - this is a good solution for home, as evidenced by reviews of the owners of such devices. A serious disadvantage of the above will be perhaps that price.But such a non-volatile step is worth it.

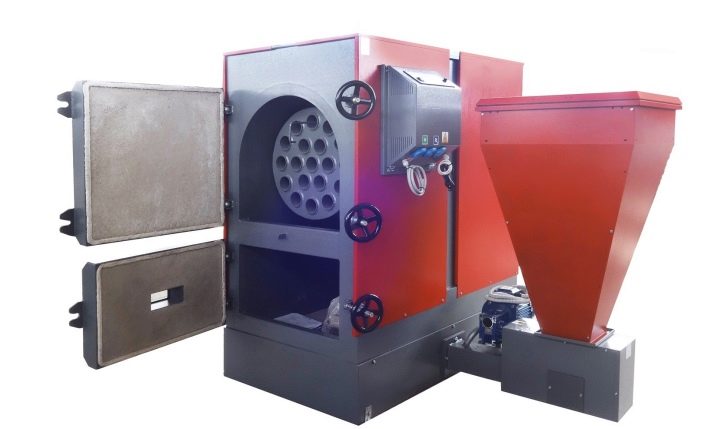

Overview of models and manufacturers

On the market, you can find devices from Russia, as well as from foreign manufacturers. At first we will tell a little about domestic models.

The first category will be models "Orange" from "NCC Biyskenergoproekt". This name they received due to its bright color. Their main features are the excellent ratio of quality and price, as well as high efficiency. In addition, they are easy to use and very reliable. Such models have electronic control, forced ventilation, as well as an automated fuel loading system. The cost of the models of this line is about 150 thousand rubles.

Another line of models that I want to say - "Start". They are assembled in Chelyabinsk, but they include voluminous Polish burners. This makes it possible to achieve high efficiency and complete burnout of fuel cells. This is a line of boilers of the combined type, which have the opportunity to work not only on pellets, but also on wood, as well as small chips. For this purpose, a special cast iron grille is supplied with the model, mounted instead of the burner. The cost of such a model is from 130 to 250 thousand.

Another option is Zota Pellet from Krasnoyarsk. It consumes different categories of fuel. Its distinctive feature will be the ability to control the heating process via SMS. In the line there are five models with a capacity of from 15 to 100 kilowatts, which are used in closed heating systems. If we talk about the reviews, they are as good as the Finnish Auterm Biomatic, but about half the price.

Also quite interesting boilers "Kupper"produced by the Novosibirsk company "Teplodar". Power output devices ranges from ten to forty kilowatts. They are solid fuel boilers with a pellet burner. The price of this model is about 80 thousand rubles. In addition, in the reviews, it is noted that it is not easy to set up such a device, it is necessary to select high-quality pellets and so on. It should also be noted that this is an incomplete series of models of domestic production, presented on the market. Quite interesting solutions in this segment will be products of Pelletron and Obschemash companies.

Now let's talk about the products of foreign manufacturers. One of the most popular brands of foreign pellet boilers is the South Korean Kiturami. They are used both for heating the fluid and for heating.In addition, in the models of this manufacturer there are mechanisms for automatic cleaning of the burner, heat exchanger and its grate. There is a crane automatic fire safety mechanism. The price of such devices from this manufacturer is somewhere up to 200 thousand. Boilers "Kiturami" are among the most reliable. The reviews about them are good, although users note a rather serious consumption of pellets.

Also noteworthy is the brand's products. Faci. Users note that these boilers have an economical fuel consumption, safety from an environmental point of view, nice design, simple operation, and setting. It is also noted that the boilers of this brand require constant maintenance.

Another foreign brand that deserves attention is a Polish company. "Kostreva". Models of this company differ in the use of the latest technical solutions. But, it is laid in the cost of these devices. Users also write that pellet consumption here is higher than indicated in the technical documentation. In addition to boilers, this brand also produces high-quality pellet burners.

The pellet boilers produced by the Latvian company also deserve attention. "Grandeg". It produces four series of boilers, each of which has its own characteristics with a different power from 5 to 100 kilowatts. All models submitted by the manufacturer can be installed in the system where there is a water natural circulation. Owners of devices from this brand note the simplicity in managing such models, as well as high-quality work with pellets of different quality.

Of course, the products of foreign brands are significantly more represented on the market. Also noteworthy are various models from brands such as Roteks and Termal.

In general, it should be noted that today a large number of products are presented on the market, both domestic and foreign brands, which allows the buyer to choose the most suitable solution for himself that will satisfy his needs as much as possible.

Criterias of choice

If we talk about which pellet boiler is better to choose, then we should start from the individual characteristics of this or that device. After all, there are a number of technical aspects that have a direct impact on the efficiency of such equipment.

This is about:

- burner categories;

- varieties of auger;

- degree of automation;

- device heat exchanger.

If we talk about burners that have such heating devices, then there are two categories:

- stoker;

- retort.

The latter do not need cleaning and can easily work with granules of average quality. And the first ones need constant maintenance, and they can work only with high-quality pellets, where the percentage of ash content is minimal.

If we talk about the degree of automation, then various devices of the pellet type for a private house have various means of automation. One of the most interesting functions will be to inform people about what is happening in the heating system via SMS. And the most interesting thing is that you can not only receive information from the device via SMS, but also manage it in this way. There are also models with automatic type loading and regular ones. This will also affect the usability of such a device.

The next important criterion is the heat exchanger device. Here it should be said that there are different versions of the heat exchanger. They can be vertical or horizontal, flat or tubular, with different turns and turns, as well as with and without a device for turbulence of gases.

According to popular opinion, the best option would be a vertical type heat exchanger, in which there are 2-3 strokes, as well as a swirler. This design makes it possible to significantly reduce the temperature of the flue gases, which allows most of the heat not to disappear, but to carry out heating of the room. In addition, the vertical device does not allow ash to accumulate inside the equipment.

The last important criterion for selecting a pellet boiler will be the presence of a flexible or rigid type auger. The hard version is very simple in terms of design and its cost is low. But he has flaws. It can not have a length of more than two meters and in this case it is impossible to change the position of the auger. The reason - a strong binding to the burner. That is, in essence, the surrounding space around this part cannot be rationally applied. This problem can be solved with another 1 auger on an electric motor.

And if we talk about a flexible auger, then it can be mounted at a distance of up to twelve meters. Also, the feed line can be almost any geometric shape.The best devices usually have this type of auger. His only drawback is that he has a rather complicated fixture.

In general, if you rely on these criteria, then you can make for yourself some kind of rating of models and if you do not clearly define what you need, then at least reduce the list of applicants.

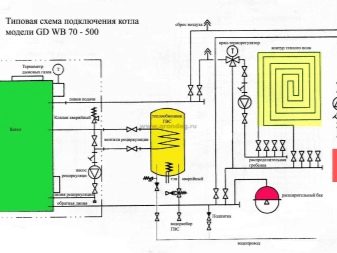

Installation rules

It should be said that if you are interested in installing the pellet boiler with your own hands, then this process should be carried out with the understanding of what you are doing. First, you need a diagram of what exactly you will do and which stage will follow the next one. First you need to make a choice of equipment and necessary parts. It is best to purchase quality products from reputable manufacturers.

You will definitely need:

- circulation pump;

- expansion tank;

- air valves;

- collector;

- sump;

- shooter;

- radiators.

After this, the so-called pellet boiler strapping should be carried out. If you have experience in arranging a heating circuit, you can do it yourself.

First you need to install the boiler, attaching such parts:

- automatic control panel;

- screw connection;

- burner connection;

- installation of fuel tank.

But first you need to choose a place where the unit will be located. It should be noted that for this you need to familiarize yourself with the instructions that come with the correct model of the device. It is necessary to connect the burner of the desired type. Now we put the fuel tank in the form of a bunker, which is sold with the heating apparatus. The size of the room will depend on the size of the room, which will need to be allocated to the boiler room. Now we connect the screw which represents the device for giving pellet. At the last stage, it remains only to connect the automatic control panel to ensure automatic uninterrupted operation of the device.

In general, the process of tying a similar boiler consists of several stages. First we select the place where the collector will be located. Now we attach it to the batteries using sanitary fittings with a diameter of one inch. All unclosed devices are blocked with plugs. By the way, it would be best if all the parts are from non-combustible materials,to eliminate the possibility of fire.

Now you should perform the following sequence of actions:

- lay the pipe from the device with a diameter of just under one and a half inches;

- mount the distribution pipe on the incoming line;

- Embed into the circuit or mount a circulation pump behind the distributor valve.

After that is installed in the horizontal axis. It is advisable to carry out the installation of a strainer in order to protect the device from debris. You can start the installation of the expansion tank, sensors, and safety valve type. You should take care at this stage to start making the chimney.

Now you should go to the strapping of the heating system. All work should be carried out carefully and as accurately as possible in accordance with the instructions. After heating, the volume that is occupied by the coolant increases, and therefore it is necessary to make sure that there is enough space in it and there is no explosion.

For this, an expansion tank is required so that all the water surplus falls into it. Moreover, this element makes it possible to maintain a stable level of pressure in the heating mechanism of the building.To choose a good expansion tank, you should calculate how much water will be used in the mechanism and add to this number about ten to twelve percent. After its connection in it it is required to create a certain level of pressure.

Now it is necessary to resolve the issue with the safety valve. The main purpose of the installation of this element will be to protect the entire system from sudden pressure drops. This will significantly extend its life. After this valve reacts, part of the coolant simply flows out of the heating system, which will make it possible to reduce the pressure. The choice of valves is best done based on the performance of the boiler, as well as the highest temperature of the water that will be pumped.

It will be best to acquire models that are starting to be activated.if the pressure began to exceed the working in the system by twenty to thirty percent. The important point is that the diameter of the inlet valve type should be equal to the tube size or larger. There are various types of protective fittings. The most versatile will be a valve-type protective overflow mechanism.In addition, today it is possible to find pellet-type boilers that have a built-in safety category or do not have it. In the first version, it will be significantly easier to install the mechanism - there is no need to install a valve, an air vent for the heating line and a pressure gauge.

When purchasing a pellet boiler, it should be remembered that it does not have the ability to control the heat supply. That is, to stop the combustion of pellets is not possible. If the electricity is turned off, the circulation pump will stop, and the movement of the coolant will stop throughout the system.

That is why, in order for the operation of this type of boiler to be completely safe, the following points should be ensured:

- use only the fuel specified in the manufacturer’s manual;

- make another emergency circuit;

- supplying the necessary amount of cold water to the mechanism;

- when the system is in operation, it is necessary to close the doors, branch pipes, and inspection hatches of the heating system.

If we take into account these and a number of other nuances, then the repair of such a system will not take long, and it will work perfectly and will depend minimally on the person.

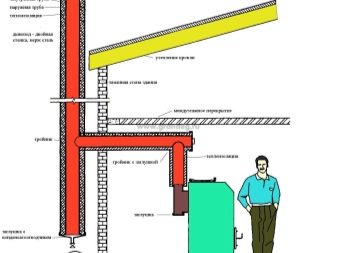

The next stage of installation of the system is the installation of the chimney. The effectiveness of such equipment depends largely on the availability of good traction. If the chimney is made in accordance with the instructions, then it will become a good air vent for any wind force and temperature. The moment that will be crucial is the diameter of the chimney. It must be the same as that of the outlet. In addition, you should install the element that will remove excess water. It should be remembered and the cap. If it is installed as needed, it will not create barriers and will not overlap the pipe in any way.

In the vast majority of situations, pipes made of metal are used to create this part. That is why they should be well insulated, as well as equipped with cleaning hatches. It is best if there is a revision door in each knee, through which it will be easy to clean soot and other products of combustion. It should be remembered that the equipment, the central element of which will be the pellet boiler likes exactly the average draft, for which reason it is important to monitor this parameter during operation.

When the binding was completed and the installation of the boiler was carried out, it must be connected and configured. First, the equipment is connected to the plumbing and heating system. If there is a need, electricity should be supplied. If after starting the device began to quit or fade, then the regulation was carried out incorrectly. To make the correct adjustment, you should consider the power of the equipment, chimney draft, the state of the pellets. Incorrect settings can cause a variety of problems. That is why it is better to entrust the system setup to a specialist.

But in general, as can be seen, pellet boilers are an excellent heating solution for a private house or any other room.

The principle of operation of the pellet boiler, see the following video.