Boilers long burning: the rules of choice and installation

Every owner of a private house is faced with the need to choose a heating system. And for many this question can be transformed into a problem. It is impossible to do without a heating system, but not everyone can take into account all the features of a particular building and be at the same time as efficient as possible.

Special features

It has long been known that a good solution is to create a water heating system located in the house, which works by circulating heat carrier in radiators with the help of an extensive pipe system. In most cases, its central element is the gas boiler. But it is not always possible to put the boiler of this type, for which reason you have to take the electric version.But this option is significantly more expensive, and the probability is high that it can work intermittently, which, in general, negates any advantages of such a design. And in this case, the so-called long-burning cauldron can be a very worthy alternative.

It is designed so that firewood can be loaded into it on average twice a day., and some models can work up to 7 days without additional loading of wood. At the same time, there are models of this type, which make it possible to use coal, pellets, eurowood, peat or, in general, liquid fuel. There are options that work on sawdust, which allows every homeowner to find a solution that best suits his interests.

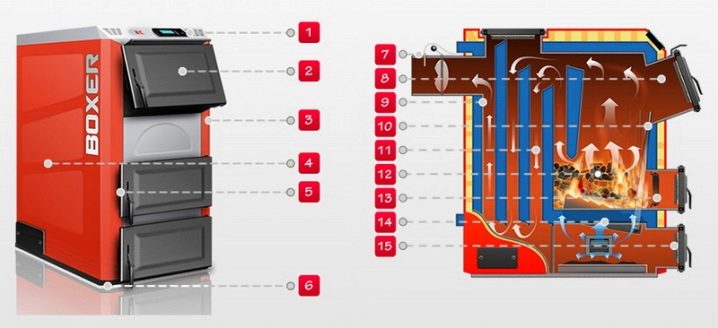

Coppers of long burning have a number of features which rather significantly distinguish them against the background of all other solutions present in the market:

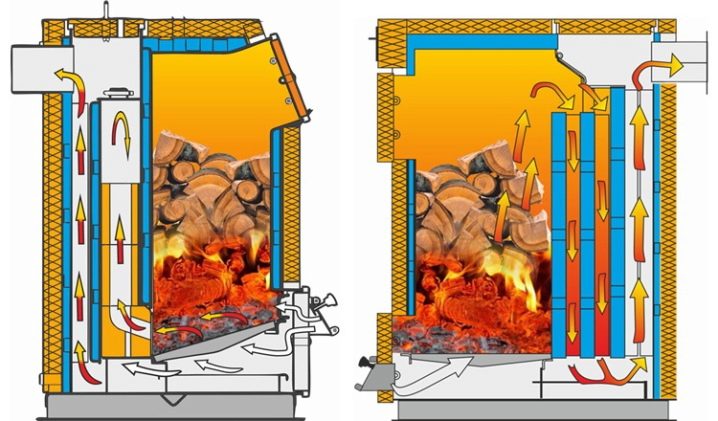

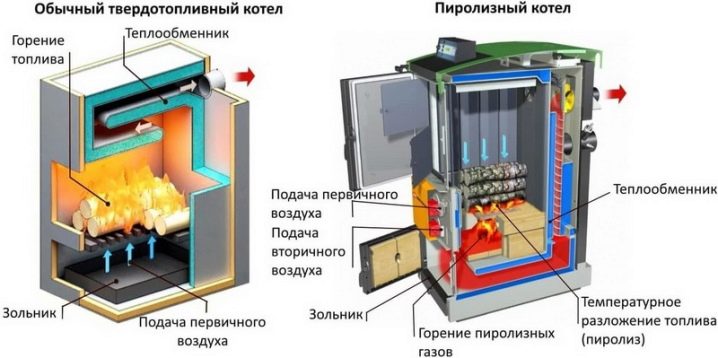

- combustion technology is that the material does not burn from the bottom up, as in most solid fuel boilers, but rather, on the contrary, which allows to increase the time of fuel burning and heat generation;

- the heat exchanger delivers heated air into the chamber in well-defined doses;

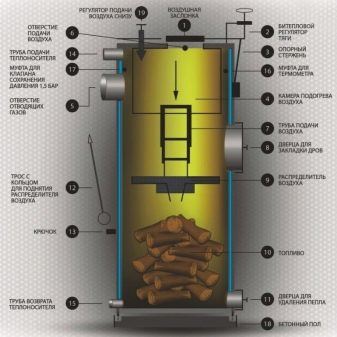

- the telescopic boiler, which is the most efficient, makes it possible to supply heated air to the combustion compartment through a so-called divider;

- such a boiler practically does not depend on how wet solid fuel is; it is heated before serving with the help of heated air and undergoes a drying procedure;

- the chamber for burning fuel in units of this category is completely sealed;

- Thermal mechanics are responsible for regulating the temperature of the heat carrier; therefore, the absence of electricity is not a reason to stop the operation of the boiler;

- Such devices are reliable and as safe as possible in terms of fire hazard.

If we talk about the advantages of this category of boilers, then the following should be mentioned:

- simple and at the same time reliable device design;

- many models do not depend on the supply of electricity;

- the cost of such solutions is not much higher than other types;

- can use one fuel tab up to a week.

It should be called and disadvantages, such as:

- quite impressive dimensions;

- the boiler needs to be cleaned regularly due to the fact that during smoldering it emits quite a lot of soot and burning.

Principle of operation

Solid fuel boilers appeared quite a long time, but had one drawback - the fuel had to be constantly added as it burned. It was not very economical, so the effectiveness of such a device was in question. It was only in 2000 that a solution was found that allowed, in essence, the creation of long-burning boilers anew. The principle of their work is to some extent similar to the work of pyrolysis models. The bulk of the heat does not depend on whether coal or wood is burned. Its efficiency is affected by the gasification of the hardest fuel.

Since the burning process is carried out in a completely closed space, the so-called wood gas is released through a special telescopic tube. It goes to the heating pad, where it mixes with secondary air. Wood gas is pumped into the device using a special fan. And this happens until the moment when solid fuel does not burn completely. The combustion temperature in this case can reach more than one thousand two hundred degrees Celsius. The effectiveness of this technique lies in the slow consumption of fuel, which maximizes the efficiency and efficiency of such a heating device.

Coppers of long burning have very high efficiencyaccounting for about 95 percent. The burning is not immediately the whole bookmark of wood, but only its upper layer. This is possible due to the fact that the supply of air masses is from above and not at the bottom. When the top layer is completely burned through, the air supply is activated, and the air gets exactly as much as necessary to burn the top layer, which makes it possible to significantly increase the burning time and control this process as much as possible. It should be noted that similar heating devices should be used exclusively as elements of the heating mechanism. If you need to make a system for heating water for domestic purposes, then this option is definitely not suitable, but it is the ideal solution for heating a large house.

Security measures

So that the long burning boiler will serve as long as possible and work stably without causing injury to someone from the house residents, several operational rules should be followed.

- Do not allow the system to overheat. One of the characteristics of such a boiler is that it cools down very slowly, due to the high characteristics of heat inertia.For this reason, it is important to ensure that the temperature is not above a certain level. It should be very careful if the pipes are made of plastic or metal-plastic. When the output temperature is from +105 to +120 degrees, serious problems may appear in the form of pipe melting. For this reason, at the installation stage of the heating system, it is necessary to install switching valves and heat exchangers for cooling.

- It is forbidden to install a shut-off valve in the pipeline between the boiler and the expansion tank.

- Indoors it is worthwhile to install a good ventilation system to continuously ensure the flow of air.

- Do not start the boiler in the absence of water in the expansion tank.

- It is forbidden to put on the device of various kinds of objects that are quite easily ignite.

Observing such precautions, you can be sure that the operation of the long-burning boiler will be safe and long-lasting.

Manufacturers and reviews

Today, a large number of different manufacturers of long burning boilers are represented on the market. Their characteristics are quite similar, for which reason it is very difficult to make a choice.

Liepsnele

The model range of the Lithuanian manufacturer Liepsnele is represented by equipment whose power ranges from 10 to 40 kilowatts.

Coppers of long burning work at such types of fuel as:

- coal;

- shavings;

- sawdust;

- firewood;

- briquettes;

- fuel pellets.

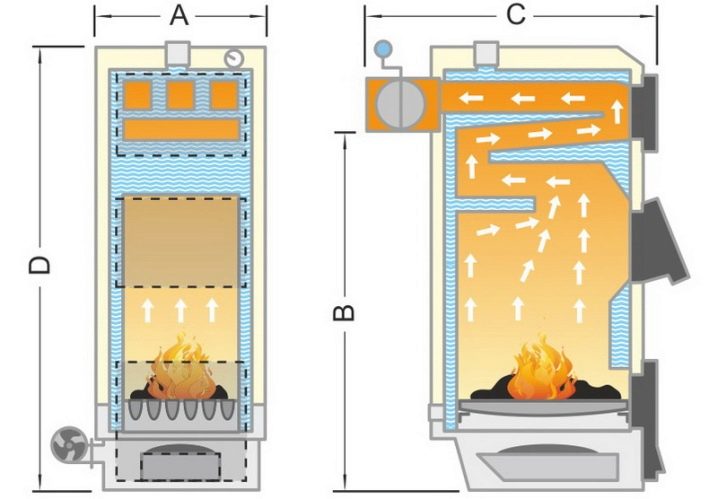

The design features of these boilers can be called classic. They can be attributed to the category of the so-called mine models with upper combustion. This line of long-burning boilers is energy independent, has a high efficiency - more than 90 percent, and in any mode of operation and when using any kind of fuel. Such a mine boiler is an excellent solution for the owner of any private house.

SWaG

The Ukrainian company SWaG manufactures universal boilers of long burning of a mine structure, which have an electronic control system, which makes it possible to most accurately regulate the combustion regimes. All models of this manufacturer have a capacity of 10 to 50 kilowatts. Their distinguishing feature is the presence of a turbine that supplies air to the combustion compartment, which significantly increases the efficiency of the device during ignition in the heating mode of the system.

It should be noted that all boilers of the Ukrainian manufacturer have safety devices that include the following elements:

- thermometer;

- air vent;

- pressure reducing valve.

SWaG models are suitable for heating houses with an area from 120 to 550 square meters. They can continuously work from 12 to 36 hours on wood and from three to six days if coal is used as a fuel. At one time you can download from 70 to 400 kilograms of fuel. By the way, the models from SWaG are quite unpretentious in the matter of fuel. You can use wood chips, straw, sawdust and even waste, if you mix them with coal or wood. But coal, prone to coking, it is better not to use.

Stropuva

The Bulgarian company Stropuva carries out the production of long-burning coal-type boilers that can be used for heating both industrial and residential buildings. All models of the Bulgarian company are equipped with a draft regulator, which makes it possible not to connect the model to the power grid, thereby ensuring its non-volatility. Stropuva models have power from eight to forty kilowatts. They can be used for heating buildings ranging from 30 to 400 square meters. They can work on wood for up to 32 hours, and up to five days on coal.At one time, you can load inside from thirty to eighty kilograms of wood or from 70 to 180 kilograms of coal. Such solutions are characterized by high safety and resistance to hydraulic shocks, since the deformation will be directed inward.

"Week"

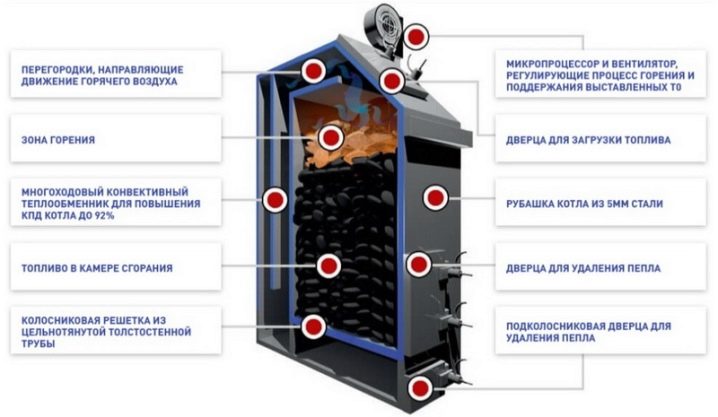

Boilers from the domestic company "Week" can work up to a week on one coal load. They have a high rate of efficiency, which is 92 percent. And the presence of automation makes it possible to carry out precise control of water temperature and microclimate in various rooms. It is very easy to recognize this boiler - it has the shape of a rectangle with a door for loading fuel located in the upper plane. The type of combustion in the models of this manufacturer is the top, and smoke circulation is also provided.

The heat exchanger at such a boiler has several moves, which allows heat to be removed from the most heated places. The furnace is equipped with a grate type grate, as well as two doors for cleaning. Through the first door that is in the fuel chamber, the combustion products are removed from the furnace, and through the second - from the ash pan. As well as this boiler has received a special control unit, based on a special microprocessor that allows you to control a supercharged fan.It allows adjustment of the air supply to the chamber and the mode of combustion of the fuel.

If the boiler shuts down, it fades, but as soon as the power supply is resumed, it can warm up again without human help. In the boilers of this manufacturer can burn almost everything: wood, coal, pellets, wood chips, and even construction waste. It should be said that the model of this manufacturer does not expose any special requirements to the quality of coal due to the presence of an effective boost. Such boilers can be used to heat private houses ranging from 100 to 600 square meters. The price of boilers is up to 220 thousand rubles.

It is worth considering the rating of models that cause confidence among users.

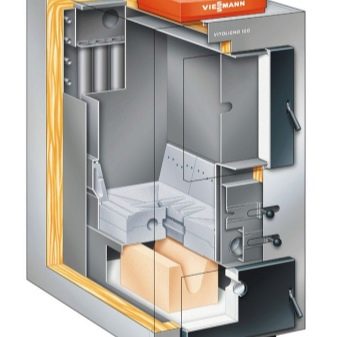

- German boilers are the most reliable. Against the background of all German manufacturers, Viessmann and Buderus products stand out. All manufacturers data models are fully automated and have an economical fuel consumption.

- Austrian boilers occupy the second position in the ranking of users, as the quality is almost identical to the units from Germany. Among the advantages of Austrian heating devices can be called the presence of a security system consisting of many levels, as well as full automation of boilers.The most interesting products will be brands Wirbel and Froling.

- The third position of the rating went to models from the Czech Republic. The most popular manufacturers of boilers are Atmos and Opop. These manufacturers specialize in creating entire stations of a universal type that can operate on various types of fuel. Interestingly, the best-selling Czech boilers are those that have a cast-iron exchanger.

- In the next position - boilers from Latvia, which are represented by products of the Stropuva brand. Their main positive feature is a long time working from one fuel bookmark. In offline mode, such a boiler can operate for more than two days. Models of this brand have how simple the design that you can even assemble it yourself according to the scheme.

- Russian boilers occupy the penultimate position of the user rating, since the first models of long-burning boilers from Russia were, frankly, unsuccessful. But now all the errors have been corrected, and the popularity of domestic heating equipment of this type has increased significantly. At the moment, the products of Bourgeois-K, Traian, Teplodar and others are popular.The model of a domestic boiler called “Tundra”, produced in Novosibirsk, is very popular.

- The last place in the ranking is Polish boilers. Equipment from SAS, Wichlacz or Defro is a great solution for any private home. All models from these manufacturers are analogues of products from Austria and Germany, but their cost is significantly lower. The only problem that caused the last position of the boilers from Poland in the rating is that there are difficulties with the supply of spare parts to the boilers.

Not included in the rating of products from a country like Slovakia. It is worth telling about it separately due to the fact that the model called “Bear” is considered to be one of the most popular among owners of domestic private houses.

How to choose?

Today, high-quality boilers for long heating are offered by both domestic and foreign manufacturers. But their designs, as well as technical and thermal characteristics are very different from each other.

When choosing such a boiler, attention should be paid to such characteristics as:

- construction features;

- manufacturer;

- country of manufacture.

If the country of manufacture was said a little higher, then the first two factors should be discussed in more detail. It should start with the calculation of performance. If the boiler of this type is chosen correctly, then it can easily heat a private house of 400–500 square meters. When selecting such a device, it is necessary to take into account the performance of the heat generator.

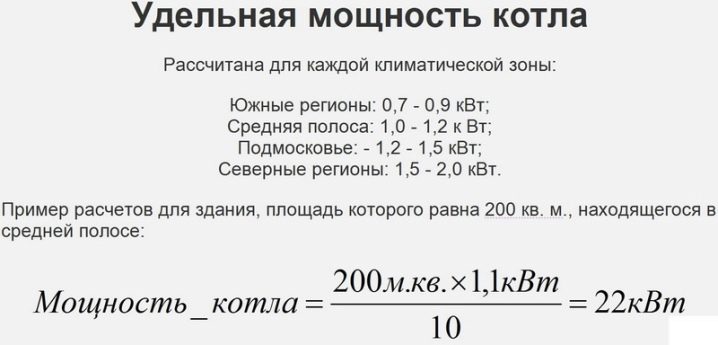

If it is necessary to calculate the power, then this is done as follows:

- the total area of the building is calculated;

- the required boiler power is calculated, which can be done using a formula where one kilowatt is equal to ten square meters;

- if in the boiler structure there is a DHW circuit, then 15-20 percent is added to the resulting figure, which turned out higher.

Important. The obtained calculations will be suitable for buildings that have average thermal insulation characteristics and are located in middle latitudes, and the height of the ceilings will be no more than two meters seventy centimeters. If the room has serious deviations from these parameters - its configuration is more complicated or the number of openings of windows and doors is too large, then it is better to perform calculations using calculators available online.

It is worth more to dwell on the second criterion, which influences the choice of device - these are design features and characteristics. There are several categories of boilers of this type currently available.

They usually differ in several characteristics.

- The number of contours. For example, solutions with a single water circuit for heating on long-burning firewood are not equipped with a built-in hot water coil. In this case, ordinary water is heated by connecting an indirect type of heater. Of course, these are additional costs for the purchase of the tank and its installation. And if the boiler is two-circuit, then it can easily be heated immediately and water for domestic needs, and thermal media.

- Automation. As a rule, the operation of such boilers is regulated with the help of a damper - manual or based on mechanics. If the boiler version is automatic, then there must be a mechanism for forced air injection, as well as removal of combustion products. As a rule, the auto controller is connected to the room heat regulators. In this case, the error in heating the heat carrier will be no more than 1–2 percent.But we should not forget about universal boilers with built-in boiler storage. In such models there is only one cumulative circuit, but they are intended for heating both hot water and thermal media.

- The design of the furnace compartment. Today there are two solutions: vertical and horizontal. Vertical heating is a good option for boilers of this type, where raw wood is used. The solution will be the principle of lower fuel burning. Raw wood from above will be dried during the burning of the lower layer. This solution is used in the German models "Visman", in the domestic boiler "Kholmov" and in other analogues.

There is another algorithm for selecting such a device.

The choice must be made on several points.

- Type of fuel. From the category of fuel depends on the effectiveness of the considered devices for heating. Not every fuel can be used precisely for long burning. For example, wood is most effective at the start of combustion. And peat briquettes can just give off heat for quite a long time, thereby maintaining a certain temperature.But the best solution is a universal model in which you can download several different fuel options.

- The material of the boiler. Usually it depends on the type of fuel. For example, if you use coal, then the best choice would be a steel boiler, and if you use firewood, you should prefer the option of cast iron. The mass of the whole structure also depends on the material used. For example, a cast iron apparatus will be about twenty percent heavier than a steel solution.

- Power. This parameter depends as much as possible on the physical dimensions of the loading chamber. The longer it is, the longer the time the boiler can work on a single load.

- The price of the product. This parameter is conditional due to the fact that it is not necessary to save too much, because the boiler is the main source of heating, the performance of the device directly affects the creation of a comfortable environment in the building. Be sure to check out the device’s data sheet to review the technical specifications.

Wiring diagram

Before buying the type of boilers in question, it should be determined where it will be installed.For this, the house is usually made flue. But most often there is not enough space in it, since there are usually already elements of gas or other heating in this place. Therefore, the installation of a solid fuel solution in a private building can be done in an extension behind the furnace wall. It is necessary to install a frame made of metal structures. Usually it is sheathed with sandwich panels or with professional sheets with insulation. This option will be a good solution for those who plan to heat the house with coal.

Options for low power is better to put directly on the rough floor screed. They are lightweight and do not vibrate the base, as they lack a fan or another screw-type conveyor that delivers pallets. Before installation, it will not be superfluous to measure the dimensions of the boiler and, in general, to see whether it will look normal in the place where it is planned to install it. It should be understood that it should stand in such a way that it can be easily approached and conveniently serviced in the event of any breakage. If the unit has a capacity of more than 50 kilowatts, then it requires a foundation of concrete. The basis should be a good land, including the addition of rubble.Such a foundation is also necessary for long-burning boilers, where there is a mechanism for raising and lowering something heavy.

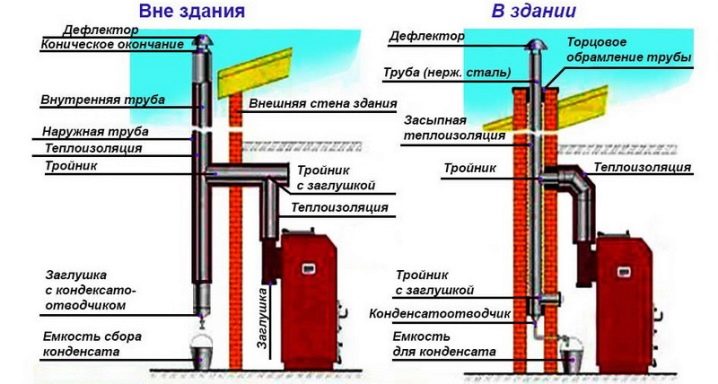

It so happens that project drawings for private buildings provide for the construction of a chimney shaft in the thick wall with a pipe coming out of the roof. If there is no mine or it is occupied, then you will have to separately install the chimney for such a solution, working on solid fuel. It is better in such a situation to apply double-walled solutions with insulation. They are fairly simple to assemble, just mounted on the wall, and also presented a great variety.

Installation

Installation of a boiler of long burning consists of several stages. First you need to determine where the boiler will be located and prepare the room. If previously there was no other model where it will stand, then it is necessary to think about the mechanism for the discharge of gases in the building and its location. The room where it will be located should be uninhabited. Before installing the boiler, its location should be covered with a metal shield, while the dimensions should be more than a quarter larger than the dimensions of the device itself. For high-power models, a foundation should be made from a concrete-based screed.Its height should be no more than 10–15 centimeters.

Before installing the boiler, check the sloping level of the foundation, which should be level. After that you can begin the installation of the boiler. First you need to note the location of its location. You should know that according to SNiP, the boiler must stand at a certain distance from the walls, and the distance from the firebox door to the wall should be one meter and a quarter. On the sides and back, the distance between the boiler and the walls should be at least 70 centimeters. The wall that is in front of the boiler must be protected by an additional layer of plaster thickness of two and a half millimeters. And also it would not be superfluous to install a sheet of metal at a level just above the boiler - 20-30 centimeters.

Now the unit is being mounted on the prepared foundation. It is necessary to check with the help of the level, how exactly it is set. The pipe from which the gases come out should be positioned with the chimney pipe at about the same level. If the line is uneven, this may cause a violation of thrust during operation. Now you need to install spare parts that come with the device.

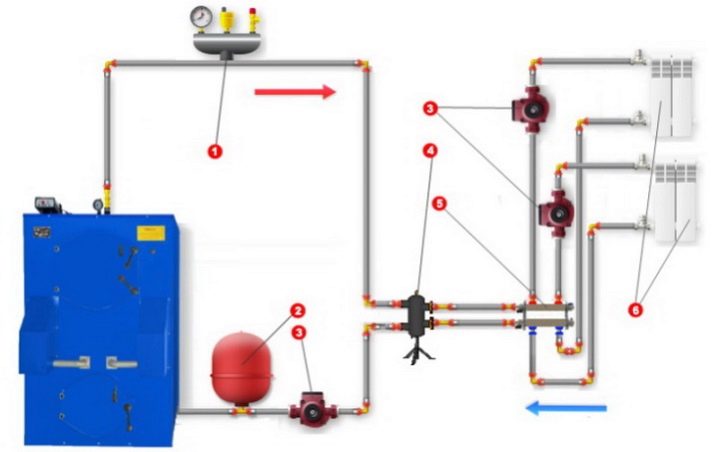

The next stage is the harness, which is considered the hardest part. There is a harness with natural and forced circulation. The heating system can be either open or closed. In the case of the natural option, the water goes through pipes under its own pressure. If we consider the option of forced circulation, it is necessary to install a pump that will create pressure.

Selection of the connection mechanism depends on the following factors:

- device location;

- number of floors and rooms;

- area of the house.

For example, a scheme with natural circulation is suitable for single-storey buildings, since it is inefficient for multi-storey buildings. Depending on which system will be selected, and the installation of certain elements will be made, so this point should be omitted.

In the next step, it is necessary to connect the structure to the chimney. All boilers must be connected to a pipe that allows smoke to be removed. If the house already has a brick pipe, then it is enough to connect a boiler to it to it. Otherwise, it is necessary to understand how it will carry out the conclusion - through the wall or through the roof.To do everything correctly, you should know that the channel between the chimney and the boiler must have a distance of at least one meter. This is very important for high performance of the device, as well as for the safety of residents. It is best of all if there are as few bends in the chimney as possible, because an additional twist is another obstacle to the natural thrust of gases, which can reduce the boiler performance.

If we talk about joining the chimney in more detail, then it should be said about the inclination of the horizontal section of the pipe that leads from the boiler. Its slope should be 45 degrees. If this cannot be done, then the ideal solution is a range from fifteen to thirty degrees. You can not make this area even, because the normal thrust will be impossible. To connect the boiler to the chimney, be sure to treat the joints of the joints of all parts of the chimney with a sealant, which will avoid the leakage of smoke. First you need to connect the first part of the pipe to the nozzle located on the boiler. The diameter of this pipe should not be less than the diameter of the nozzle of the boiler itself. If this feature is omitted, the throughput of the pipe will be significantly reduced.

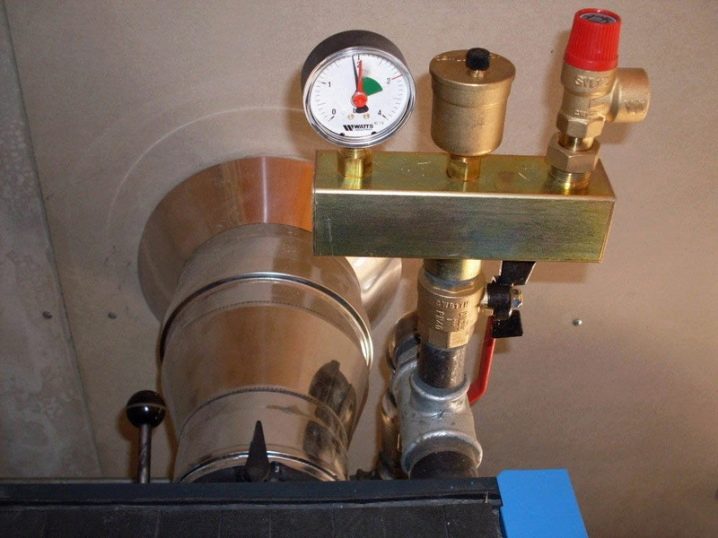

Now you need to install a security group. Its main task is to relieve pressure in the network if it has reached a critical level. It is installed directly at the outlet of the supply pipe. If we talk about normal pressure, then the ideal indicator is three bars. If this value is exceeded, the safety valve should trip. As well as the components of the security system usually include a pressure control device, air vent and pressure gauge.

The last stage remains - the connection of the whole structure to the heating system. Before starting the operation of the boiler, it is necessary to carry out a pressure test for hydraulics under pressure a day. It is necessary to open the valves of the locking type and all the taps, to make the water connection Next, you should increase the pressure to 1.3 atmospheres to ensure that there are no leaks in the system. Then you need to start the boiler and close the door tightly. When the fire becomes steady, you can open them and load firewood. When you first start you can feel the characteristic chemical smell - it will burn out the remnants of factory oil. After a while, the smell will disappear. If in the process of testing any problems or malfunctions were identified, the boiler should be turned off, let it cool down, and then fix the problems.

In general, the process of choosing a long-burning boiler is very responsible and should be carried out in compliance with all the rules and subtleties. In addition, the installation of such a device must be carried out exclusively in compliance with all norms of SNiP. If you decide to install such a device yourself, before that it would not be superfluous to consult with a specialist who will tell you how and what should be done.

To learn how to properly connect a long-burning boiler, see the following video.