Viessmann boilers: models and causes of their breakdowns

German-made Viessmann heating equipment has been produced since 1917. For all the time of existence, boilers have proven to be leaders in the market of heating equipment. Viessmann boilers incorporate the latest technological solutions, which allows them to operate with increased efficiency and minimal emissions of hazardous gases into the atmosphere.

Special features

Viessmann boilers have such distinctive features as:

- the device case is made of high-alloy steel of the Rostfrei brand;

- The material used to manufacture heat exchangers is a chromium-nickel alloy that prevents corrosion damage and ensures reliable operation of the equipment for a long time;

- intelligent control of gas combustion, which allows the use of various types of fuel;

- control unit that automatically selects the optimal mode of operation.

Heated and in contact with the environment areas of the heating equipment are covered with a protective layer. The quality indicator of Viessmann boilers is their heat output.

The higher this parameter, the more space the boiler will heat. Equally important is the number of circuits in the system. Heating devices are made with one or two circuits.

Viessmann boiler units are designed to provide heat and hot water to apartment buildings, private cottages with a total area of not more than 250 m². They are installed in any room space, saving space in small houses.

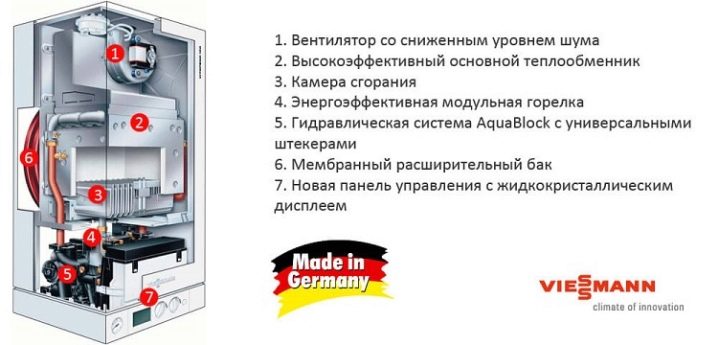

The heating equipment is equipped with the following elements:

- burner with automatic flame modulation;

- accumulative boiler;

- valve for switching to the hot water circuit;

- heating unit;

- single-stage circulation pump;

- sensor control to stabilize the temperature in the circuit;

- self-diagnostics system of the device, thanks to which its maintenance is simplified.

Advantages and disadvantages

Heating boilers Viessmann have such advantages as:

- universality - they use both natural and liquefied gas as fuel;

- automatic control system allows you to easily change the parameters of the equipment;

- profitability;

- comfort;

- environmental Safety;

- small sizes;

- silent work thanks to noise-insulating material from which the case of the fan is made;

- high efficiency;

- ease of installation;

- assembly of high quality parts;

- energy efficiency is ensured by automation, which minimizes the consumption of energy raw materials.

Among the minuses of Viessmann boiler units, the following should be highlighted:

- small parts of the boilers are not designed for high loads, as a result of which they quickly fail under the influence of poor quality water;

- Despite a two-year warranty on the equipment, it is very difficult to find experienced specialists in the installation and repair of Viessmann boilers in case of breakdown.

According to the reviews of the owners of the Viessmann heating equipment, the following have been identified:

- boilers are really reliable, maintainable, stable functioning;

- in industry, they are highly secure;

- the latest models have detectors that help detect leaks, regulate the parameters of air, temperature and pressure;

- The possibility of complete control over the operation of the boiler is an undoubted advantage.

Buyers have identified and disadvantages of this equipment, such as:

- too high price - boilers designed for operation in the industrial segment are 2 times more expensive than domestic boilers;

- premature wear of equipment components during intensive operation;

- poor range of design solutions for the implementation of buildings in comparison with manufacturers of other boilers.

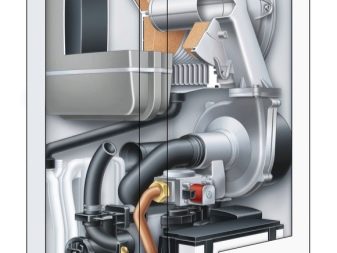

Kinds

Viessmann boilers are made in wall and floor variations, and there are single and dual circuit devices. The heating capacity of boilers can reach up to 85 kW and more. It is worth considering in more detail the main models of Viessmann boilers.

Vitopend 100 WH1D262

This is a traditional double-circuit gas boiler mounted on a wall with a heating capacity of 24 kW. The heat exchanger used is double bithermic.The water heater has a closed type combustion chamber with an electronic circuit board. The second circuit is more powerful, since it heats up about 11 liters in one minute to +57 degrees at 10 atmospheres. At the same time the consumption of gaseous fuel is only 2.83 m³ per hour. The fuel in these boilers can be natural or liquefied gas. The boiler is mounted on the wall with a coaxial type connection to the chimney. For ease of maintenance it is recommended to install a thermostat. The boiler is equipped with circulation pumping equipment and an expansion tank with a capacity of 6 liters.

The main negative quality of this model is the presence of a combined bithermic heat exchanger, since separate heat exchangers are the most reliable.

Vitogas 100-F GS1D870

This is a floor-standing version of the heating device, designed for operation in low-temperature heating systems. The heat output of the model is 29 kW. It is represented by an open type, the number of contours - one. This means that for hot water it is necessary to provide an additional water heater.At the maximum heat output of the device, fuel consumption is about 3.9 m³ per hour. The main element of this boiler is a dimensional heat exchanger made of cast iron, thanks to which the boiler has increased reliability, although its weight is 142 kg.

The heating is electronically controlled, and there is also automatic flame modulation and a room thermostat for automating the control of thermal mode.

Vitodens 100-W B1KC032

This is a gaseous fuel-operated condensing unit with two circuits that uses heat to heat the thermal carrier during condensation of liquid vapors. Since during combustion the gas forms carbon dioxide and water vapor in conventional boilers, the products exit through the chimney, taking with them some of the heat.

And condensation devices using additional heat exchangers do not allow the heat to be removed, and the condensate is then sent to the drain device. This model is available with power ranging from 4.7 to 26 kW, with a closed combustion chamber. Separate heat exchangers are made of stainless steel.

About 3.2 m³ are consumed per hour of fuel, about 14 liters of water are heated per minute.

Boilers Vitodens 100-W B1KC032 have the following features:

- self-diagnosis equipment;

- existing security group;

- automatic flame modulation;

- fuel - natural gas;

- coefficient of performance - 108%, which is more than that of conventional convection-type units.

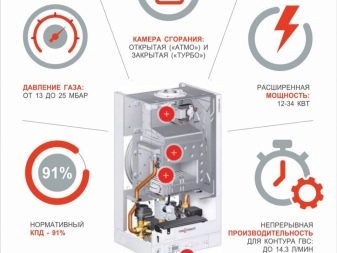

Vitopend 100-W A1JB011

This is a water heater with two circuits, with a heating capacity of 30 kW, efficiency up to 91% and a weight of 39 kg. The equipment is made for mounting on a wall with a consumption of gaseous fuel of 3.47 m³ per hour. The heating device is fully functional in automatic mode. Its main advantage is the ability to function when the voltage and pressure drops. Water is heated per minute in a volume of 14 liters to +57 degrees.

Vitoplex 200

This is a compact boiler in the floor version with medium and high values of heat output - from 90 to 200 kW. The fuel can be gas or diesel.

The efficiency of this model is only 88%.

Possible faults

It is worthwhile to examine in more detail the error codes of the Viessmann heating boilers and how to eliminate them.

- A0 error - burner blocking.Reason: decrease in fuel pressure in the system. Remedy: check the operation of the pressure regulator.

- Error E0 - burner blocking. Reason: A signal was received from the tilting control device. Remedy: check chimney. If this regulator has signaled more than 10 times per day, the burner unit will go into a faulty mode.

- F2 error - failure of the burner. Reason: the temperature limiter has tripped. Remedy: check the level of the liquid in the heater, as well as the condition of the pump unit, bleed air from the system through the chimney. Check the serviceability of the connecting cables, to unlock, turn the relay knob to the right and to its original position.

- F3 error - Burner failure. Reason: the flame signal is already displayed when the burner is triggered. Remedy: check the condition of the electrode and connecting cables. Perform a reset using the power switch.

- F4 error - breakdown of the burner. Reason: no burning signal. Remedy: check the condition of the ignition electrodes and connecting cables, check for pressure and the valves for adjustment.

- F5 error - breakdown of the burner.Reason: Signal from the tilting control device. Remedy: check the health of this device.

- F30 Error - burner blocking. Reason: temperature controller short circuit occurred. Remedy: check the temperature regulator.

- F38 error - burner blocking. Reason: the thermo mode regulator has broken. Remedy: check the thermo mode regulator.

- F50 error - water does not heat up. Reason: Thermal mode sensor of the expansion tank is closed. Remedy: check the health of the sensor.

- F51 error - water does not heat up. Reason: Outlet temperature controller closed. Remedy: check the serviceability of the regulator.

- F58 Error - water does not heat up. Reason: the expansion tank temperature regulator has broken. Remedy: check the serviceability of the regulator.

- F59 error - water does not heat up. Reason: the temperature sensor for hot water at the outlet stopped. Remedy: check the health of the sensor.

- B8 error - burner lock. Reason: the tipping device stopped.Remedy: check the health of the device and perform maintenance.

- B0 error - burner lock. Reason: the tilting control relay is closed. Remedy: Inspect the tilting control relay.

If it is cold in a heated room, the following malfunctions are possible:

- illiterately set temperature sensor - it is necessary to reconfigure the temperature mode;

- heating system shutdown - it is necessary to turn on the power switch and check the safety of the safety device;

- incorrectly configured controller - you need to configure a higher temperature for the thermal media;

- the presence of air in the heating circuit - you need to bleed the air out of the heating device;

- no gas - it is necessary to open the valves for gas supply;

- malfunction of the pump unit - you need to call the service;

- the display shows a fault: the characters U and, for example, b0 - it is necessary to eliminate the problem in accordance with the instructions;

- faults in the supply air circuit - call for service.

If the heated room is hot, the following malfunctions are possible:

- wrong temperature sensor - you need to reconfigure the temperature;

- incorrectly configured controller - it is necessary to lower the temperature of the thermal medium.

Subtleties of repair

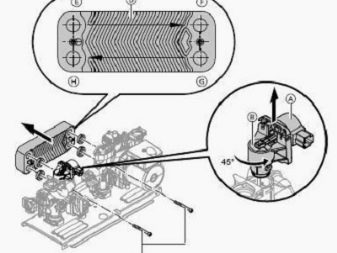

Replacing the built-in heat exchanger

It is necessary to close the heating equipment on the side of the heating system and on the side of the water intake point, to empty it. Check the water intake circuit for sediment, and the heating circuit for dirt. To clean, dismantle the heat exchange unit.

Replacing the heat exchanger is carried out as follows:

- move the stepper motor A to the top;

- turn stepper motors A and B by 1/8 turn;

- loosen screws C and remove the heat exchanger with seals;

- assemble another heat exchanger in the opposite order with other seals;

- when installing, follow the location of fasteners and proper installation of seals;

- observe the marking when installing the heat exchanger;

- reassemble the water heater;

- fill equipment with liquid, bleed air and test for tightness.

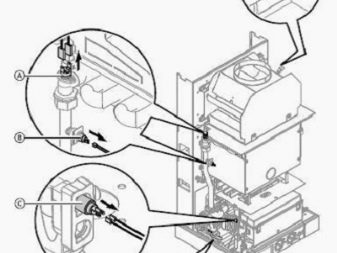

Removing the limiter and thermal sensor

To remove the thermal limiter, you need to check whether the gas appliance will not unlock during an emergency shutdown. Then disconnect the connecting cables from the relay, remove the limiter, mount the new one and unlock it by turning the sensor handle to failure and back. To remove the water regulator, you need to disconnect the cables, measure the resistance and compare with the optimal one.

With high resistance, the regulator must be replaced. Before removing, it is necessary to empty the water heater.

To remove the temperature controller at the outlet and the device for controlling the overturning of thrust it is necessary to remove the connecting cables, measure the resistance and compare with the optimal one. If resistance is high, replace the regulator or device.

Replacing the temperature regulator of the expansion tank is as follows:

- the plug is disconnected from the cable harness;

- resistance is checked;

- if the resistance is too high, the regulator is replaced.

In the next video you will find a review of the wall-mounted gas boiler Viessmann Vitopend 100.