The details of installing a solid fuel boiler in a private house

Any heating equipment has its own characteristics. And they concern not only operation and compatibility with one or another heating systems. It is very important to consider how the installation of one or another heat source should take place.

Special features

In a modern private house, many people try to use gas or even electric boilers. This is understandable: such equipment is automated and quite easy to use. But the classic design - a solid fuel boiler - is also not so easy to give up.

Moreover, now this method of heating is gradually gaining popularity. Gas can not be pulled everywhere, like electricity, connecting to the corresponding networks is expensive,and the stability of their work, even in the most developed areas, can be disrupted by bad weather, technical malfunction, the actions of intruders.

Solid fuel boilers are made of cast iron or steel, it is impossible to say in advance which of the two materials will be better in a particular case. The fragility of the cast iron does not prevent it from serving to keep the developed heat for a very long and long time.

However, the relatively short-lived steel has its own arguments: it is an increased strength and a faster warming of housing.

It does not matter if the boiler is placed in a wooden, brick or other house, the number of circuits becomes the main requirement when choosing it.

Returning to the material of the heat exchanger, it is worth emphasizing that steel endures temperature jerks better, and cast iron is more resistant to corrosion. Steel products are lighter than cast iron, but the joint is made using welding, and it has long been known that each welded joint is a weak point in the structure in which it was made. The skill of welders and careful adherence to technology reduces losses, but cannot prevent them altogether.

It does not make much sense to supplement the single-circuit boiler with a water tank. The more correct step is the purchase of a full unit with two circuits. In the end, installing additional tanks costs money and takes extra time. If you want to purchase a boiler of increased capacity, you need to choose a pyrolysis model. It will also be preferable for those who want to use fuel with maximum benefit. But there is a significant disadvantage - a very high cost.

Installation rules

Foundation

No matter what type of solid fuel boiler is chosen, it is necessary to create a foundation at enterprises of whatever country, because the installation is characterized by a significant mass and size. Because a simple installation without support will entail simply the destruction, forcing the main floor. None of the strongest grade boards can withstand the emerging load. Construction of the foundation begins ... no, not with the delivery of materials, and not even with the calculation of the required thickness.

The first step is to determine where the boiler will be placed. Already taking into account the specifics of this site is determined and the approach to the arrangement of the base.It should be noted that there are still no strict and systematic acts that would determine the entire course of installation of solid fuel boilers. The SNiP section devoted to boiler plants, regulates only the use of generators more powerful than 0.36 MW.

It should also not be guided by the instructions of the norms relating to household gas boilers.

The generalization of the everyday practice of heating with solid fuel shows that all its forms lead to dusting of the surrounding space and the emergence of smoke, albeit in small amounts. This means that the boiler must be placed outside the living space. If you do not select a separate compartment for it at home, you can use the kitchen, corridor.

Ideal locations (in descending order of priority):

- autonomous boiler room on the street;

- technical unit in the house;

- basement;

- garage;

- corridor with decent natural ventilation.

It is recommended to put the boilers on solid fuel closer to the outer walls. In this case: the greater the distance, the longer the required horizontal piece of the chimney. We need to think about how exactly the boiler heat exchanger will be cleaned.Normally, it must remain at least 1 m in front of it, on three other sides, 60 cm each. It is strictly impossible to connect the gas passage of a wood or coal boiler to brick ventilation ducts laid inside the walls. It is important to take into account the placement of other large appliances, furniture, room design and ease of use.

It is required in advance, except for the preparation of the foundation of concrete:

- punch holes in the walls for the discharge of smoke and ventilation;

- cover the fire-prone structures with fireproof materials;

- connect the room to the power grid, providing lighting at night, the work of circulation pumps and automation.

Boilers lighter than 200 kg can, without doubt, be put on a cement screed. The implementation of this element according to the technology eliminates the slightest problem. If the solid fuel device is equipped with a heat exchanger made of cast iron, it is necessary to use a reinforcement concrete screed with a layer of 100–120 mm. For boilers whose mass exceeds 300 kg, a separate stove is required. We must not forget that the pellet boilers create a vibration, which also affects the foundation, which for this reason must be carried out according to a special scheme.

Although small solid fuel boilers and can be put just on the floor, it is necessary to strengthen the right place in advance.

It is reinforced by additional logs, for which a timber not thinner than 10x5 cm is used. When installing several heavy-weight units, there is no need to cast a separate foundation for everyone, but it’s better to create a so-called industrial floor - this is a 120 mm layer of concrete steel rods.

Ventilation

The role of ventilation in the room, where the boiler is mounted on solid fuel, triple:

- ejection of combustion gases so that they do not accumulate;

- maintaining a normal burning fuel;

- replacement of consumed oxygen with identical inflows in volume.

Approximately 4.6 cubic meters is consumed to fully burn 1 kg of wood. m. of air. If the boiler uses coal, it is necessary to provide twice as much intensive inflow. But this is not enough, because the exact same amount of flue gases generated will need to be quickly brought out onto the street. Therefore, it is impossible to do without the exact calculation of the parameters of the necessary ventilation circuit.On the one hand, the air will enter the boiler room almost at the level of the floor, and it is better to organize the exit at the ceiling, in the immediate vicinity of the boiler.

If done otherwise, it will be very little to enter the air, which will not allow achieving effective combustion. In this case, the smoke, in order to leave the premises, will have to travel a considerable distance, often along a complex trajectory. The correct (near the boiler) location of the output allows you to quickly free up the space from insignificant smoke. But: installing a hood near a heat source equipped with a fan will cause it to work in the inlet mode.

Many people prefer to build a boiler room close to the house, so that you can get there without getting out in the rain or frost. However, if there is an entrance door leading into the dwelling, it is recommended to place the inflow grille on it below. The flow of previously heated air increases the efficiency of the boiler.

Important: the hood must be done less than the flow channel. Its cross section is estimated by increasing the heat output of the boiler by 8 times - the result of multiplication will show the required number of square meters. cm.

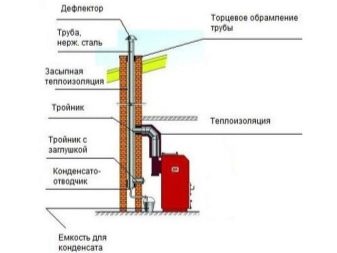

Chimney

Ventilation dumps only excess smoke leaked into the room. The normal functioning of the boiler, the care of combustible gases and the supply of fresh air are provided by a structure such as a chimney. Because its design and creation need to pay maximum attention. There is no need to carefully adjust the axis of the nozzle and the wall opening. All the same, they will have to combine, turning the knee in one way or another.

To eliminate the occurrence of operational problems (primarily condensate), it is required to use insulated pipes. They can be replaced by ordinary tubular structures, which are sheathed with fibrous basalt. The easiest chimney - let out outside auxiliary way. This pipe is vertically attached to the wall. A bunch of chimney with her produced through the so-called tee. Improving the safety of smoke passage through external walls or ceilings is especially important in wooden houses.

In the desired partition an opening is cut in the form of a square. Important: in all directions, the size of the free space should be 0.38 m larger than the stretched pipe.

The unit with which the output is provided is formed from steel with a zinc coating. By pushing the pipe, the voids are saturated with basalt wool. The final step is to attach the outer cover of the box.

If you have to pull a chimney through a brick wall or through blocks of foam concrete, steel sleeves and sealing materials are used. It is not allowed to create 4 or more turns, as well as the use of chimneys, whose total height (counting from the grate) is less than 5 m.

Docking is done so that the condensate flows along the inner surface of the pipe, and rain or melting snow - on the outside of it. Horizontal fragments are installed with a slight slope to the boiler. At the bottom, be sure to equip the hatch for the audit and condensate storage. Invasion of the roof eaves can be avoided by avoiding a pipe from a pair of elbows connected at a 30 degree angle.

The brackets that are installed on the inside of the chimney should be away from the borders of its sections. The head of the smoke channel is equipped with a cap. Depending on personal preferences, the cap is made in the format of a weather vane or fixed cone.The height of the head is determined by how far the channel is derived from the ridge. At the same time, it is unacceptable to place an ogolovka in the area of the wind pressure of both your own house and neighboring buildings.

Strapping schemes

Having finished with the installation of the diverting channels of combustible gases, you need to do the strapping of a solid fuel boiler, and there are not less subtleties in it. Very often such heat generators are equipped with a water tank, which is used in various connection diagrams. The role of the device is to quench the stresses that may occur during maximum load on the boiler.

The choice of heat accumulator depends on the personal tastes of the owner. Moreover, when buying, you should pay attention to the need to maintain a certain load for a specific time by the heat accumulator.

It is necessary to pay attention to the dimensions, since the device will be massive and it will not fit everywhere.

Usually they are guided by the amount of heat energy storage in 30–50 l per 1 kW of maximum power of the boiler. If the peak heat consumption is much higher than the average daily level in terms of 1 hour, and especially if this consumption lasts a long time, you need to install a more capacious tank.

It should be designed for pressure greater than the planned working maximum.Regardless of the chosen connection scheme, it is required to install safety valves and a tank for expansion. It is necessary to carefully carry out all the calculations, and ideally contact the professionals and for them, and for the installation itself.

The correct binding always contains a so-called security group, which must be placed directly on the output of the supply nozzle.

This is a set of systems that automatically relieve pressure if it exceeds the established indicators. This kind of manipulation is carried out by a safety valve, which is complemented by a pressure gauge and a device that just takes the air out. From safety kit to the boiler itself, it is unacceptable to use any kind of locking fittings. When the fuel starts to heat up, the circulation pump is running, and the valve located at the inlet to the heating circuit is closed.

In this case, the movement of fluid occurs in a reduced circle. As soon as the return pipe warms up to 50 or 55 degrees, the thermal head, at the command of the sensor, begins to open the closed loop. This is done smoothly so that the mixing of cold water with hot water contained in the bypass occurs evenly.As a result of the heating of the radiators, the temperature rises, and there comes a moment when the valve closes the bypass to the end. In this case, 100% of the coolant is directed through the heat exchanger of the boiler.

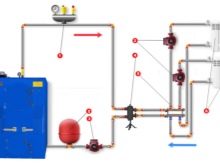

This configuration is the easiest and can be done by hand. Polypropylene pipes are used quite calmly, but you only need to check their official origin and compliance with the required characteristics. It is recommended to use exclusively metal for the gap between the boiler and the security group.

The thick walls of the polypropylene pipe are characterized by weak thermal conductivity, due to which external sensors give incorrect readings, and the three-way valve is late in response to changes in conditions.

Important: from the pump to the copper flask should also be put a metal pipe, the addition of heating elements will allow you to withstand the temperature in the room more clearly.

Connection to the heating system

Rational and correct installation of a solid fuel boiler is not all that is required of it. Be sure to make all the rules and the connection of subsequent elements. After the security group, they usually put a tee leading to the bypass.The switching temperature when adjusting the sensor on the return pipe is 55 degrees. This value eliminates the occurrence of condensate and maintain stable operation of the device.

Useful recommendations

Even a well-designed and well-built flue gas discharge channel can only work effectively with regular cleaning. It is categorically unacceptable to use wood, plastic materials and foam plastic, any wallpaper and textile materials in the finishing of the boiler room. Emergency cooling valves that are independent of the electrical network can be of great benefit. If the coolant warms up to 95 degrees, a part of it is redirected to the sewage system, while the same amount of cold liquid flows inside. Without such devices it is undesirable to operate boilers of increased power.

If it is decided to install a heat accumulator, then gravitational circulation should be ensured between it and the boiler. Even in a big city, not to mention remote areas, you need to install uninterruptible power systems. They will help support the movement of the coolant even when the power is turned off.As soon as the supply is restored, the energy storage device will start charging. The required power of the backup device is 150% of the cumulative peak consumption of all protected electronic components.

Tips for choosing a solid fuel boiler - in the next video.