Radiator keys: types and features of manufacturing

Despite the seeming complexity, the repair and modification of a heating radiator with proper dexterity and a suitable tool do not pose a problem for an experienced “home” master, especially if a sufficiently modern heating system is installed in the apartment. The most important tool in such works are radiator keys. In this review, the types of such keys are considered, as well as the features of the manufacture of their self-made variants.

Types of work with radiators

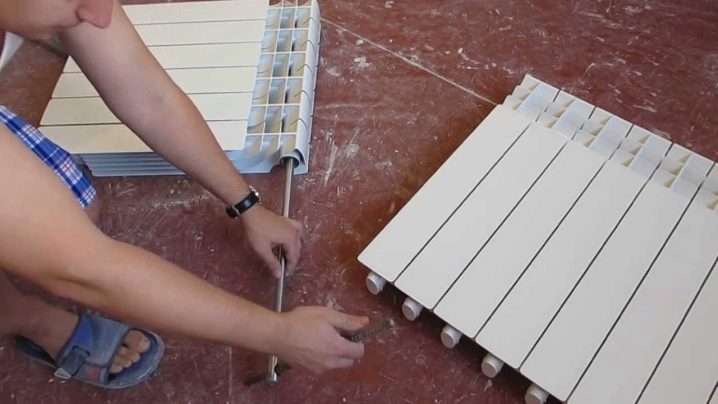

Currently, many apartments have modern bimetallic or aluminum radiators. Such units can be monolithic and sectional. The difference lies in the fact that in sectional models it is possible to install and disassemble individual standard sections.

Such devices are specially designed to be handled as easily as possible. Therefore, adding / removing individual sections can be carried out not only for the purpose of repairing and replacing damaged elements, but also for adjusting the thermal balance of the room. Adding sections will increase the average temperature in the room, and their removal will reduce.

Almost all models of old cast iron radiators, installed in Soviet times, theoretically provide for the possibility of free removal or the addition of individual modules. In practice, over the long years of operation of such products, fastener parts under the influence of multiple heating / cooling cycles and as a result of reactions with coolant “stick” to the radiator and to each other, therefore, it is advisable to remove sections of cast iron radiators only for the purpose of their replacement or complete dismantling.

Tool features

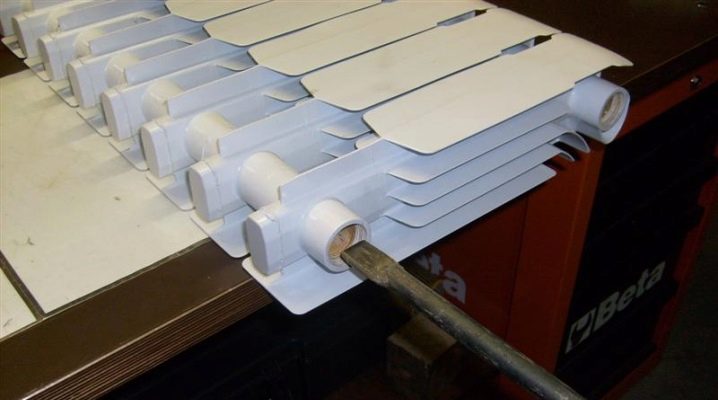

Despite the variety of models of heating devices, they are all arranged according to a similar principle. Separate sections of radiators are attached to each other with special nipple-nuts with counter thread. In this case, the fastener is located deep inside the section, and unscrewing the nuts requires considerable physical effort.Therefore, for assembling and disassembling sections of radiators of heating, a special tool is used, which in general is a fairly long and durable piece of metal of cylindrical section with a “blade” of the correct dimensions at the working end.

Classification

According to the method of manufacture, the keys for radiators of heating can be divided into self-made and manufactured in an industrial way. Industrial tools often have notches on them that correspond to the standard length of the section and allow easy installation work.

In form distinguish between straight and T-shaped keys. To the non-working end of the T-shaped tool is attached a piece of metal rod, which is used as a handle when the key is rotated. Direct keys on the non-working end have a "loop" used to insert a metal rod, allowing you to create a lever.

According to the type of radiators for which the key can be used, they are divided into:

- used for modern radiators;

- used only for old cast iron models;

- combined (for mounting nipples of all existing sizes).

Differences in size of the working part

The main difference between the keys for different types of radiators is the size of the working part. The “spatula” of keys used for modern heating devices is designed for nipples with an inner diameter of 25 mm and a thread size of 1 inch, therefore its length should be at least 30 mm, width - 23 mm, and thickness - 6 mm.

The paddle for the key used for cast iron batteries is designed for 5/4 inch threaded nipples, so it must be 30 mm long, 25 mm wide and 8 mm thick. Combination keys are usually set in a "ratchet". They have a stepped working part with several standard sizes, for example, 3/8, 1/2, 3/4, 1 and 5/4 inches, arranged in the form of a Christmas tree. Such keys are made only in an industrial way and cost from 1000 rubles (individual models) or from 4000 rubles (for sale complete with a “ratchet”).

How to make yourself?

To make a radiator key with your own hands, you first need to find a suitable segment of metal fittings. The size of the segment should be chosen so that the length of the finished key is at least half the length of the radiator, with which it is supposed to work, plus 30 cm (for dismantling 7-section aluminum / bimetallic radiators, a 69 cm long key is sufficient).

For the manufacture of tools needed autogen, hammer and anvil. The estimated working end of the workpiece must be heated to white heat. After that, a scapula is hammered on the anvil with a hammer. The operation should be repeated several times to form the working part of the desired size. Lapping can be done using grinders or grinders.

It is useful in fine-tuning to have an example of a nipple used in the radiator, “trying on” a manufactured tool to it.

To make a T-shaped key, it is enough to weld a bar with a length of 20 cm perpendicular to the opposite end of the working end. To make a key with a “eyelet” by yourself, you need to take a slightly longer billet and, by heating with autogen, bend it with ticks. Do not forget to weld the curved edge.

Application tips

Note that the dismantling of sections of modern radiators requires less effort than working with their cast-iron counterparts. If the fixings of the cast-iron radiators become too strong, they should be warmed up with a blowtorch before dismantling. Also remember that the key that has already been made can always be brought “in place” with the help of a grinder.

To learn how to make a key for the battery yourself, see the next video.